ASTM D2889-95(2010)

(Test Method)Standard Test Method for Calculation of True Vapor Pressures of Petroleum Distillate Fuels

Standard Test Method for Calculation of True Vapor Pressures of Petroleum Distillate Fuels

SIGNIFICANCE AND USE

The true vapor pressure of a distillate fuel is a relative measurement, both of the tendency of the most volatile portion of the fuel to gasify, and of the restraining pressure required to prevent gasification of the most volatile portion. Thus the measurement is of importance when a fuel is to be utilized in applications where no gasification may be tolerated, and temperature-pressure conditions are expected to be near the true vapor pressure of the fuel.

SCOPE

1.1 This test method describes the calculation of true vapor pressures of petroleum distillate fuels for which distillation data may be obtained in accordance with Test Method D86 without reaching a decomposition point prior to obtaining 90 volume % distilled.

1.2 The test method may be used to calculate vapor pressures at temperatures between the 0 % equilibrium flash temperature and the critical temperature of the fuel. Provision is included for obtaining a calculated critical temperature for fuels for which it is not known.

1.3 Critical pressure-temperature data are usually not available for petroleum fuels. However, if both the critical pressure and critical temperature are known, the values shall be used as the coordinates in Fig. 1 to establish a critical point to be used instead of the focal point established as described in 6.5.4; and the calculations described in 6.5 through 6.5.4 are not required. If either a determined true boiling point or determined equilibrium flash vaporization temperature at 0 % distilled at atmospheric pressure is known, the determined value shall be used to establish the lower limit of the bubble-point line referred to in 6.4.

1.4 The method is not reliable for distillate fuels having a boiling range of less than 100°F (38°C) between the Test Method D86 10 and 90 volume % distilled temperatures.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2889 − 95(Reapproved 2010)

Standard Test Method for

Calculation of True Vapor Pressures of Petroleum Distillate

Fuels

This standard is issued under the fixed designation D2889; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes the calculation of true vapor 2.1 ASTM Standards:

pressures of petroleum distillate fuels for which distillation D86Test Method for Distillation of Petroleum Products at

data may be obtained in accordance with Test Method D86 Atmospheric Pressure

without reaching a decomposition point prior to obtaining 90 D287Test Method forAPI Gravity of Crude Petroleum and

volume% distilled. Petroleum Products (Hydrometer Method)

2.2 ASTM Adjuncts:

1.2 The test method may be used to calculate vapor pres-

sures at temperatures between the 0% equilibrium flash Temperature Pressure Conversion Chart (16 by 20–in.

drawings)

temperature and the critical temperature of the fuel. Provision

is included for obtaining a calculated critical temperature for

3. Summary of Test Method

fuels for which it is not known.

1.3 Critical pressure-temperature data are usually not avail- 3.1 Equilibrium flash vaporization (EFV) temperatures are

calculatedfromdistillationdata(TestMethodD86)determined

able for petroleum fuels. However, if both the critical pressure

and critical temperature are known, the values shall be used as on the sample. The distillation data, calculated EFV data, and

APIgravityofthesampleareusedwithagraphicalcorrelation

the coordinates in Fig. 1 to establish a critical point to be used

instead of the focal point established as described in 6.5.4; and procedure to obtain two pairs of temperature-pressure coordi-

natesthroughwhichthebubble-pointlineofthephasediagram

thecalculationsdescribedin6.5through6.5.4arenotrequired.

If either a determined true boiling point or determined equi- for the sample may be drawn. The calculated true vapor

pressure at a specified temperature is obtained by reading the

librium flash vaporization temperature at 0% distilled at

atmospheric pressure is known, the determined value shall be pressure at the intersection of the bubble-point line and

used to establish the lower limit of the bubble-point line specified temperature.

referred to in 6.4.

NOTE1—Detailsoftheprocedureanddatasubstantiatingitsvalidityfor

establishing equilibrium flash vaporization temperatures have been pub-

1.4 The method is not reliable for distillate fuels having a

lished.

boiling range of less than 100°F (38°C) between the Test

Method D86 10 and 90 volume% distilled temperatures.

4. Significance and Use

1.5 The values stated in inch-pound units are to be regarded

4.1 The true vapor pressure of a distillate fuel is a relative

as standard. The values given in parentheses are mathematical

measurement,bothofthetendencyofthemostvolatileportion

conversions to SI units that are provided for information only

of the fuel to gasify, and of the restraining pressure required to

and are not considered standard.

prevent gasification of the most volatile portion. Thus the

1.6 This standard does not purport to address all of the

measurement is of importance when a fuel is to be utilized in

safety concerns, if any, associated with its use. It is the

applications where no gasification may be tolerated, and

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under jurisdiction ofASTM Committee D02 on Petroleum the ASTM website.

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom- Available from ASTM International Headquarters. Order Adjunct No.

mittee D02.04.0K on Correlative Methods. ADJD2889. Original adjunct produced in 1987.

Current edition approved Oct. 1, 2010. Published November 2010. Originally Edmister, W. C., and Okamoto, K. K., “Applied Hydrocarbon

ε1

approved in 1970. Last previous edition approved in 2005 as D2889–95(2005) . Thermodynamics, Part 12: Equilibrium Flash Vaporization Correlations for Petro-

DOI: 10.1520/D2889-95R10. leum Fractions,” Petroleum Refiner, PEREA, Vol 38, No. 8, 1959, p. 117.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2889 − 95 (2010)

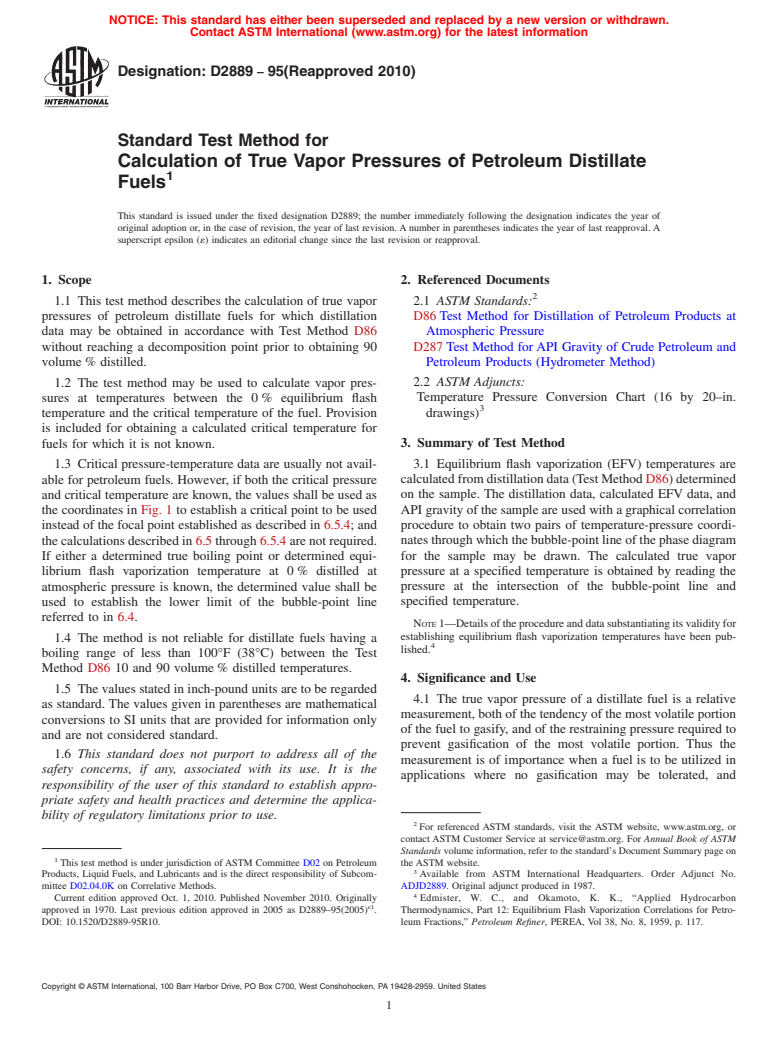

FIG. 1 Test Method D86 Distillation Temperature and Equalization Flash Vaporization Temperature Pressure Conversion Chart

temperature-pressure conditions are expected to be near the 6.3 Calculate the EFV zero volume percent temperature by

true vapor pressure of the fuel. subtracting the sum of the three differences obtained from Fig.

3, from the EFV 50 volume% temperature calculated in

5. Data Requirements

accordance with 6.1.

5.1 Distillation temperatures at the initial boiling point

3,5

6.4 PlotapointonFig.1 atthecoordinates,14.7psiaand

(IBP)and10,30,50,70,and90volume%distilledobtainedin

thecalculatedEFV0%temperature.Thispointestablishesthe

accordance with Test Method D86.

lower end of the phase boundary line commonly referred to as

5.2 APIgravitydeterminedinaccordancewithTestMethod

the bubble-point line. If the EFV 0% temperature at atmo-

D287, or a method of equivalent accuracy.

spheric pressure has been measured, use the measured value

instead of the calculated value.

6. Procedure

6.5 Use the following procedure and the curves on the right

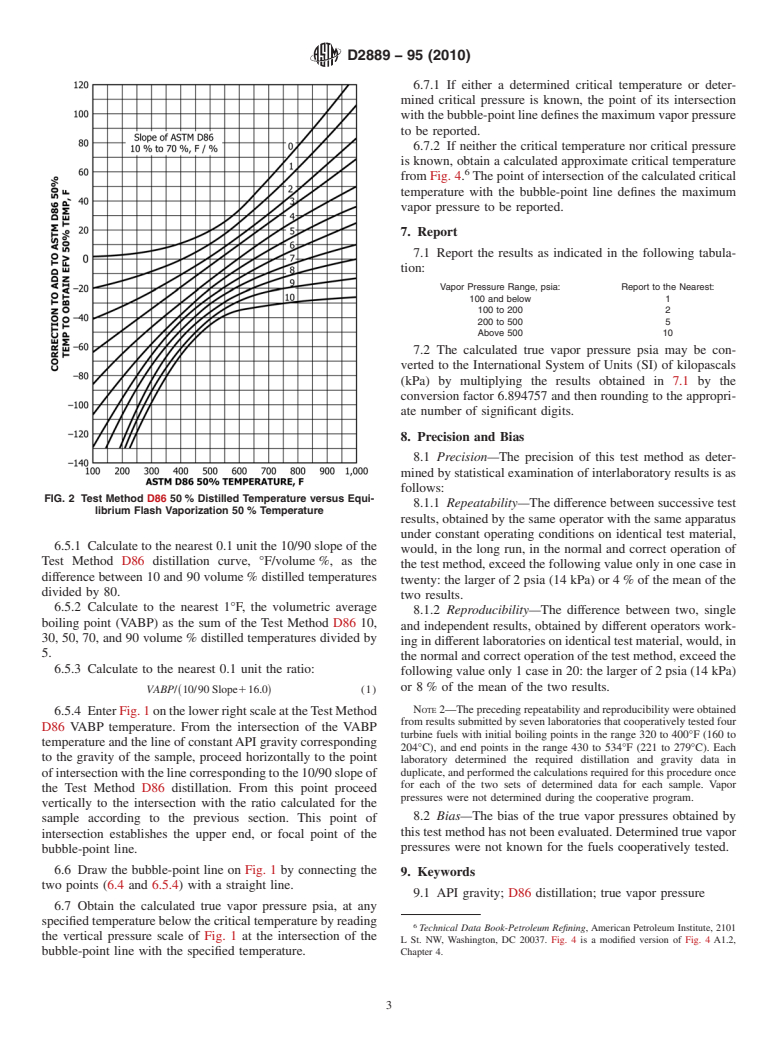

6.1 Calculatethe10/70slope,°F/%,oftheTestMethodD86

portion of Fig. 1 to obtain coordinates for the upper end, or

distillationusingthe10and70volume%distilledtemperature.

focal point, of the bubble-point line. If both the critical

Using this slope and the Test Method D86 50 volume%

distilled temperature, obtain to the nearest 61°F a temperature temperature and critical pressure of the fuel are known, the

difference, °F, from Fig. 2. Add °F to the Method D86 50 calculations described in 6.5.1 through 6.5.4 are not carried

volume% temperature to obtain the equilibrium flash vapor-

out. The critical temperature and critical pressure are used as

ization (EFV) 50 volume% temperature.

the coordinates in Fig. 1 to define a critical point to be used

instead of the focal point.

6.2 Calculate the differences between the Test Method D86

IBPand10volume%,the10and30volume%,andthe30and

50 volume % temperatures. Using these differences, obtain to

the nearest 1°F, the temperature differences between corre- 1

Precision of the test method as given in Section 6 was obtained using 8 ⁄2 by

sponding EFV percentages from Fig. 3. 11–in. charts and should be improved using the 16 by 20–in. charts.

D2889 − 95 (2010)

6.7.1 If either a determined critical temperature or deter-

mined critical pressure is known, the point of its intersection

withthebubble-pointlinedefinesthemaximumvaporpressure

to be reported.

6.7.2 If neither the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.