ASTM D93-20

(Test Method)Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

SIGNIFICANCE AND USE

5.1 The flash point temperature is one measure of the tendency of the test specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties which must be considered in assessing the overall flammability hazard of a material.

5.2 Flash point is used in shipping and safety regulations to define flammable and combustible materials. One should consult the particular regulation involved for precise definitions of these classifications.

5.3 These test methods should be used to measure and describe the properties of materials, products, or assemblies in response to heat and an ignition source under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of these test methods may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

5.4 These test methods provide the only closed cup flash point test procedures for temperatures up to 370 °C (698 °F).

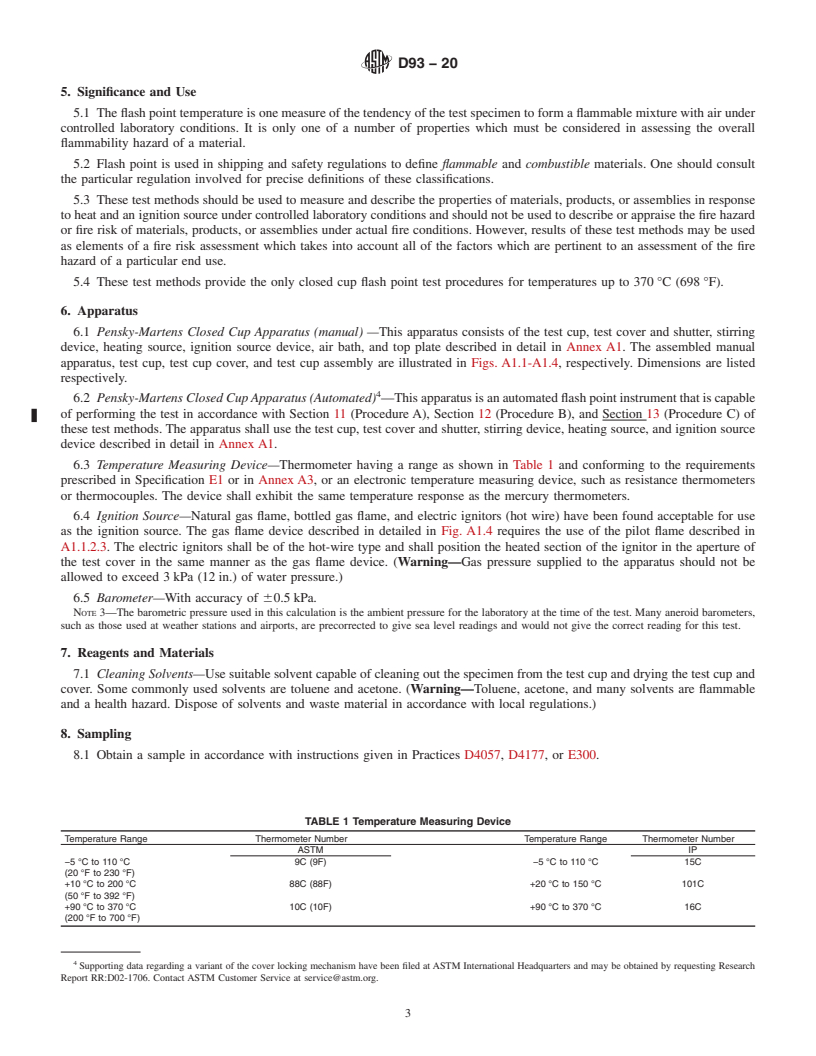

SCOPE

1.1 These test methods cover the determination of the flash point of petroleum products in the temperature range from 40 °C to 370 °C by a manual Pensky-Martens closed-cup apparatus or an automated Pensky-Martens closed-cup apparatus, and the determination of the flash point of biodiesel in the temperature range of 60 °C to 190 °C by an automated Pensky-Martens closed cup apparatus.

Note 1: Flash point determinations above 250 °C can be performed, however, the precision has not been determined above this temperature. For residual fuels, precision has not been determined for flash points above 100 °C. The precision of in-use lubricating oils has not been determined. Some specifications state a D93 minimum flash point below 40 °C, however, the precision has not been determined below this temperature.

1.2 Procedure A is applicable to distillate fuels (diesel, biodiesel blends, kerosine, heating oil, turbine fuels), new and in-use lubricating oils, and other homogeneous petroleum liquids not included in the scope of Procedure B or Procedure C.

1.3 Procedure B is applicable to residual fuel oils, cutback residua, used lubricating oils, mixtures of petroleum liquids with solids, petroleum liquids that tend to form a surface film under test conditions, or are petroleum liquids of such kinematic viscosity that they are not uniformly heated under the stirring and heating conditions of Procedure A.

1.4 Procedure C is applicable to biodiesel (B100). Since a flash point of residual alcohol in biodiesel is difficult to observe by manual flash point techniques, automated apparatus with electronic flash point detection have been found suitable.

1.5 These test methods are applicable for the detection of contamination of relatively nonvolatile or nonflammable materials with volatile or flammable materials.

1.6 The values stated in SI units are to be regarded as the standard.

1.6.1 Exception—The values given in parentheses are for information only.

Note 2: It has been common practice in flash point standards for many decades to alternately use a C-scale or an F-scale thermometer for temperature measurement. Although the scales are close in increments, they are not equivalent. Because the F-scale thermometer used in this procedure is graduated in 5 °F increments, it is not possible to read it to the 2 °C equivalent increment of 3.6 °F. Therefore, for the purposes of application of the procedure of the test method for the separate temperature scale thermometers, different increments must be used. In this test method, the following protocol has been adopted: When a temperature is intended to be a converted equivalent, it will appear in parentheses following the SI unit, for example 370 °C (698 °F). When a temperature is inte...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D93 − 20

Designation: 34/99

Standard Test Methods for

1

Flash Point by Pensky-Martens Closed Cup Tester

ThisstandardisissuedunderthefixeddesignationD93;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

This flash point test method is a dynamic test method which depends on specified rates of heating

to be able to meet the precision of the test method. The rate of heating may not in all cases give the

precision quoted in the test method because of the low thermal conductivity of some materials. There

are flash point test methods with slower heating rates available, such as Test Method D3941 (for

paints, resins, and related products, and high viscosity products in the range of 0 °C to 110 °C), where

the test conditions are closer to equilibrium.

Flash point values are a function of the apparatus design, the condition of the apparatus used, and

the operational procedure carried out. Flash point can therefore only be defined in terms of a standard

test method, and no general valid correlation can be guaranteed between results obtained by different

test methods, or with test apparatus different from that specified.

1. Scope* 1.3 Procedure B is applicable to residual fuel oils, cutback

residua, used lubricating oils, mixtures of petroleum liquids

1.1 These test methods cover the determination of the flash

with solids, petroleum liquids that tend to form a surface film

point of petroleum products in the temperature range from

under test conditions, or are petroleum liquids of such kine-

40 °C to 370 °C by a manual Pensky-Martens closed-cup

matic viscosity that they are not uniformly heated under the

apparatus or an automated Pensky-Martens closed-cup

stirring and heating conditions of Procedure A.

apparatus, and the determination of the flash point of biodiesel

in the temperature range of 60 °C to 190 °C by an automated

1.4 Procedure C is applicable to biodiesel (B100). Since a

Pensky-Martens closed cup apparatus. flashpointofresidualalcoholinbiodieselisdifficulttoobserve

by manual flash point techniques, automated apparatus with

NOTE 1—Flash point determinations above 250 °C can be performed,

electronic flash point detection have been found suitable.

however, the precision has not been determined above this temperature.

For residual fuels, precision has not been determined for flash points

1.5 These test methods are applicable for the detection of

above 100 °C. The precision of in-use lubricating oils has not been

contamination of relatively nonvolatile or nonflammable ma-

determined. Some specifications state a D93 minimum flash point below

terials with volatile or flammable materials.

40 °C, however, the precision has not been determined below this

temperature.

1.6 The values stated in SI units are to be regarded as the

1.2 Procedure A is applicable to distillate fuels (diesel,

standard.

biodiesel blends, kerosine, heating oil, turbine fuels), new and

1.6.1 Exception—The values given in parentheses are for

in-use lubricating oils, and other homogeneous petroleum

information only.

liquids not included in the scope of Procedure B or Procedure

NOTE2—Ithasbeencommonpracticeinflashpointstandardsformany

C.

decades to alternately use a C-scale or an F-scale thermometer for

temperature measurement. Although the scales are close in increments,

they are not equivalent. Because the F-scale thermometer used in this

procedure is graduated in 5 °F increments, it is not possible to read it to

1

ThesetestmethodsareunderthejointjurisdictionofASTMCommitteeD02on

the 2 °C equivalent increment of 3.6 °F. Therefore, for the purposes of

Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility

application of the procedure of the test method for the separate tempera-

of Subcommittee D02.08 on Volatility. In the IP, these test methods are under the

ture scale thermometers, different increments must be used. In this test

jurisdiction of the Standardization Committee.

method, the following protocol has been adopted: When a temperature is

Current edition approved Aug. 1, 2020. Published August 2020. Originally

approved in 1921. Last previous edition approved in 2019 as D93 – 19. DOI: intended to be a converted equivalent, it will appear in parentheses

10.1520/D0093-20. following the SI unit, for example 370 °C (698 °F). When a temperature

*A Summary of Changes section appea

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D93 − 19 D93 − 20

Designation: 34/99

Standard Test Methods for

1

Flash Point by Pensky-Martens Closed Cup Tester

This standard is issued under the fixed designation D93; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

This flash point test method is a dynamic test method which depends on specified rates of heating

to be able to meet the precision of the test method. The rate of heating may not in all cases give the

precision quoted in the test method because of the low thermal conductivity of some materials. There

are flash point test methods with slower heating rates available, such as Test Method D3941 (for

paints, resins, and related products, and high viscosity products in the range of 0 °C to 110 °C), where

the test conditions are closer to equilibrium.

Flash point values are a function of the apparatus design, the condition of the apparatus used, and

the operational procedure carried out. Flash point can therefore only be defined in terms of a standard

test method, and no general valid correlation can be guaranteed between results obtained by different

test methods, or with test apparatus different from that specified.

1. Scope*

1.1 These test methods cover the determination of the flash point of petroleum products in the temperature range from 40 °C

to 370 °C by a manual Pensky-Martens closed-cup apparatus or an automated Pensky-Martens closed-cup apparatus, and the

determination of the flash point of biodiesel in the temperature range of 60 °C to 190 °C by an automated Pensky-Martens closed

cup apparatus.

NOTE 1—Flash point determinations above 250 °C can be performed, however, the precision has not been determined above this temperature. For

residual fuels, precision has not been determined for flash points above 100 °C. The precision of in-use lubricating oils has not been determined. Some

specifications state a D93 minimum flash point below 40 °C, however, the precision has not been determined below this temperature.

1.2 Procedure A is applicable to distillate fuels (diesel, biodiesel blends, kerosine, heating oil, turbine fuels), new and in-use

lubricating oils, and other homogeneous petroleum liquids not included in the scope of Procedure B or Procedure C.

1.3 Procedure B is applicable to residual fuel oils, cutback residua, used lubricating oils, mixtures of petroleum liquids with

solids, petroleum liquids that tend to form a surface film under test conditions, or are petroleum liquids of such kinematic viscosity

that they are not uniformly heated under the stirring and heating conditions of Procedure A.

1.4 Procedure C is applicable to biodiesel (B100). Since a flash point of residual alcohol in biodiesel is difficult to observe by

manual flash point techniques, automated apparatus with electronic flash point detection have been found suitable.

1.5 These test methods are applicable for the detection of contamination of relatively nonvolatile or nonflammable materials

with volatile or flammable materials.

1.6 The values stated in SI units are to be regarded as the standard.

1.6.1 Exception—The values given in parentheses are for information only.

NOTE 2—It has been common practice in flash point standards for many decades to alternately use a C-scale or an F-scale thermometer for temperature

measurement. Although the scales are close in increments, they are not equivalent. Because the F-scale thermometer used in this procedure is graduated

in 5 °F increments, it is not possible to read it to the 2 °C equivalent increment of 3.6 °F. Therefore, for the purposes of application of the procedure of

1

These test methods are under the joint jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility of

Subcommittee D02.08 on Volatility. In the IP, these test methods are under the jurisdiction of the Standardization Committee.

Current edition approved Nov. 1, 2019Aug. 1, 2020. Published November 2019August 2020. Originally approved in 1921. Last previous edition approved in 20182019

as D93 – 18.D93 – 19. DOI: 10.1520/D0093-19.10.1520/D0093-20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.