ASTM D257-14(2021)e1

(Test Method)Standard Test Methods for DC Resistance or Conductance of Insulating Materials

Standard Test Methods for DC Resistance or Conductance of Insulating Materials

SIGNIFICANCE AND USE

5.1 Insulating materials are used to isolate components of an electrical system from each other and from ground, as well as to provide mechanical support for the components. For this purpose, it is generally desirable to have the insulation resistance as high as possible, consistent with acceptable mechanical, chemical, and heat-resisting properties. Since insulation resistance or conductance combines both volume and surface resistance or conductance, its measured value is most useful when the test specimen and electrodes have the same form as is required in actual use. Surface resistance or conductance changes rapidly with humidity, while volume resistance or conductance changes slowly with the total change being greater in some cases.

5.2 Resistivity or conductivity is used to predict, indirectly, the low-frequency dielectric breakdown and dissipation factor properties of some materials. Resistivity or conductivity is often used as an indirect measure of: moisture content, degree of cure, mechanical continuity, or deterioration of various types. The usefulness of these indirect measurements is dependent on the degree of correlation established by supporting theoretical or experimental investigations. A decrease of surface resistance results either in an increase of the dielectric breakdown voltage because the electric field intensity is reduced, or a decrease of the dielectric breakdown voltage because the area under stress is increased.

5.3 All the dielectric resistances or conductances depend on the length of time of electrification and on the value of applied voltage (in addition to the usual environmental variables). These must be known and reported to make the measured value of resistance or conductance meaningful. Within the electrical insulation materials industry, the adjective “apparent” is generally applied to resistivity values obtained under conditions of arbitrarily selected electrification time. See X1.4.

5.4 Volume resistivity or conductivi...

SCOPE

1.1 These test methods cover direct-current procedures for the measurement of dc insulation resistance, volume resistance, and surface resistance. From such measurements and the geometric dimensions of specimen and electrodes, both volume and surface resistivity of electrical insulating materials can be calculated, as well as the corresponding conductances and conductivities.

1.2 These test methods are not suitable for use in measuring the electrical resistance/conductance of moderately conductive materials. Use Test Method D4496 to evaluate such materials.

1.3 These test methods describe several general alternative methodologies for measuring resistance (or conductance). Specific materials can be tested most appropriately by using standard ASTM test methods applicable to the specific material that define both voltage stress limits and finite electrification times as well as specimen configuration and electrode geometry. These individual specific test methodologies would be better able to define the precision and bias for the determination.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D257 − 14 (Reapproved 2021)

Standard Test Methods for

DC Resistance or Conductance of Insulating Materials

This standard is issued under the fixed designation D257; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial changes were made to 4.1 (grammar correction) and Table 1 (“p” changed to “ρ”) in March 2021.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover direct-current procedures for

D150 Test Methods forAC Loss Characteristics and Permit-

themeasurementofdcinsulationresistance,volumeresistance,

tivity (Dielectric Constant) of Solid Electrical Insulation

and surface resistance. From such measurements and the

D374/D374M Test Methods for Thickness of Solid Electri-

geometric dimensions of specimen and electrodes, both vol-

cal Insulation

ume and surface resistivity of electrical insulating materials

D1169 Test Method for Specific Resistance (Resistivity) of

can be calculated, as well as the corresponding conductances

Electrical Insulating Liquids

and conductivities.

D1711 Terminology Relating to Electrical Insulation

1.2 These test methods are not suitable for use in measuring

D4496 Test Method for D-C Resistance or Conductance of

the electrical resistance/conductance of moderately conductive

Moderately Conductive Materials

materials. Use Test Method D4496 to evaluate such materials. D5032 Practice for Maintaining Constant Relative Humidity

by Means of Aqueous Glycerin Solutions

1.3 These test methods describe several general alternative

D6054 Practice for Conditioning Electrical Insulating Mate-

methodologies for measuring resistance (or conductance). 3

rials for Testing (Withdrawn 2012)

Specific materials can be tested most appropriately by using

E104 Practice for Maintaining Constant Relative Humidity

standardASTMtestmethodsapplicabletothespecificmaterial

by Means of Aqueous Solutions

that define both voltage stress limits and finite electrification

times as well as specimen configuration and electrode geom-

3. Terminology

etry. These individual specific test methodologies would be

3.1 Definitions:

better able to define the precision and bias for the determina-

3.1.1 The following definitions are taken from Terminology

tion.

D1711 and apply to the terms used in the text of these test

methods.

1.4 This standard does not purport to address all of the

3.1.2 conductance, insulation, n—the ratio of the total

safety concerns, if any, associated with its use. It is the

volume and surface current between two electrodes (on or in a

responsibility of the user of this standard to establish appro-

specimen) to the dc voltage applied to the two electrodes.

priate safety, health, and environmental practices and deter-

3.1.2.1 Discussion—Insulation conductance is the recipro-

mine the applicability of regulatory limitations prior to use.

cal of insulation resistance.

1.5 This international standard was developed in accor-

3.1.3 conductance, surface, n—the ratio of the current

dance with internationally recognized principles on standard-

betweentwoelectrodes(onthesurfaceofaspecimen)tothedc

ization established in the Decision on Principles for the

voltage applied to the electrodes.

Development of International Standards, Guides and Recom-

3.1.3.1 Discussion—(Somevolumeconductanceisunavoid-

mendations issued by the World Trade Organization Technical

ably included in the actual measurement.) Surface conductance

Barriers to Trade (TBT) Committee.

is the reciprocal of surface resistance.

1 2

These test methods are under the jurisdiction of ASTM Committee D09 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical and Electronic Insulating Materials and are the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D09.12 on Electrical Tests. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2021. Published May 2021. Originally the ASTM website.

approved in 1925. Last previous edition approved in 2014 as D257 – 14. DOI: The last approved version of this historical standard is referenced on

10.1520/D0257-14R21E01. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D257 − 14 (2021)

3.1.4 conductance,volume,n—the ratio of the current in the the measured resistance to that resistance obtained if the

volume of a specimen between two electrodes (on or in the electrodes had formed the opposite sides of a unit cube.

specimen) to the dc voltage applied to the two electrodes. 3.1.12.1 Discussion—Volume resistivity is usually ex-

3.1.4.1 Discussion—Volume conductance is the reciprocal pressed in ohm-centimetres (preferred) or in ohm-metres.

Volume resistivity is the reciprocal of volume conductivity.

of volume resistance.

3.1.5 conductivity, surface, n—the surface conductance

4. Summary of Test Methods

multiplied by that ratio of specimen surface dimensions (dis-

4.1 The resistance or conductance of a material specimen or

tance between electrodes divided by the width of electrodes

of a capacitor is determined from a measurement of current or

defining the current path) which transforms the measured

of voltage drop under specified conditions. By using the

conductance to that obtained if the electrodes had formed the

appropriate electrode systems, surface and volume resistance

opposite sides of a square.

or conductance are measured separately. The resistivity or

3.1.5.1 Discussion—Surface conductivity is expressed in

conductivity is calculated when the known specimen and

siemens. It is popularly expressed as siemens/square (the size

electrode dimensions are known.

of the square is immaterial). Surface conductivity is the

reciprocal of surface resistivity.

5. Significance and Use

3.1.6 conductivity, volume, n—the volume conductance

5.1 Insulatingmaterialsareusedtoisolatecomponentsofan

multiplied by that ratio of specimen volume dimensions

electrical system from each other and from ground, as well as

(distance between electrodes divided by the cross-sectional

to provide mechanical support for the components. For this

area of the electrodes) which transforms the measured conduc-

purpose, it is generally desirable to have the insulation resis-

tance to that conductance obtained if the electrodes had formed

tance as high as possible, consistent with acceptable

the opposite sides of a unit cube.

mechanical, chemical, and heat-resisting properties. Since

3.1.6.1 Discussion—Volume conductivity is usually ex-

insulation resistance or conductance combines both volume

pressed in siemens/centimetre or in siemens/metre and is the

and surface resistance or conductance, its measured value is

reciprocal of volume resistivity.

most useful when the test specimen and electrodes have the

same form as is required in actual use. Surface resistance or

3.1.7 moderatelyconductive,adj—describesasolidmaterial

conductance changes rapidly with humidity, while volume

having a volume resistivity between 1 and 10 000 000 Ω-cm.

resistance or conductance changes slowly with the total change

3.1.8 resistance, insulation, (R), n—the ratio of the dc

i

being greater in some cases.

voltage applied to two electrodes (on or in a specimen) to the

5.2 Resistivity or conductivity is used to predict, indirectly,

total volume and surface current between them.

the low-frequency dielectric breakdown and dissipation factor

3.1.8.1 Discussion—Insulation resistance is the reciprocal

properties of some materials. Resistivity or conductivity is

of insulation conductance.

often used as an indirect measure of: moisture content, degree

3.1.9 resistance, surface, (R ), n—the ratio of the dc voltage

s

of cure, mechanical continuity, or deterioration of various

applied to two electrodes (on the surface of a specimen) to the

types. The usefulness of these indirect measurements is depen-

current between them.

dent on the degree of correlation established by supporting

3.1.9.1 Discussion—(Some volume resistance is unavoid-

theoretical or experimental investigations. A decrease of sur-

ably included in the actual measurement.) Surface resistance is

face resistance results either in an increase of the dielectric

the reciprocal of surface conductance.

breakdown voltage because the electric field intensity is

3.1.10 resistance, volume, (R ), n—the ratio of the dc

v reduced, or a decrease of the dielectric breakdown voltage

voltage applied to two electrodes (on or in a specimen) to the

because the area under stress is increased.

current in the volume of the specimen between the electrodes.

5.3 All the dielectric resistances or conductances depend on

3.1.10.1 Discussion—Volume resistance is the reciprocal of

the length of time of electrification and on the value of applied

volume conductance.

voltage (in addition to the usual environmental variables).

3.1.11 resistivity, surface, (ρ ), n—the surface resistance

Thesemustbeknownandreportedtomakethemeasuredvalue

s

multiplied by that ratio of specimen surface dimensions (width

of resistance or conductance meaningful. Within the electrical

of electrodes defining the current path divided by the distance

insulation materials industry, the adjective “apparent” is gen-

between electrodes) which transforms the measured resistance

erally applied to resistivity values obtained under conditions of

to that obtained if the electrodes had formed the opposite sides

arbitrarily selected electrification time. See X1.4.

of a square.

5.4 Volume resistivity or conductivity is calculated from

3.1.11.1 Discussion—Surface resistivity is expressed in

resistance and dimensional data for use as an aid in designing

ohms.Itispopularlyexpressedalsoasohms/square(thesizeof

an insulator for a specific application. Studies have shown

thesquareisimmaterial).Surfaceresistivityisthereciprocalof

changes of resistivity or conductivity with temperature and

surface conductivity. 4

humidity (1-4). These changes must be known when design-

3.1.12 resistivity, volume, (ρ ), n—the volume resistance

ing for operating conditions.Volume resistivity or conductivity

v

multiplied by that ratio of specimen volume dimensions

(cross-sectional area of the specimen between the electrodes

The boldface numbers in parentheses refer to a list of references at the end of

divided by the distance between electrodes) which transforms this standard.

´1

D257 − 14 (2021)

determinations are often used in checking the uniformity of an insulating material. Resistance or conductance values obtained

insulatingmaterial,eitherwithregardtoprocessingortodetect are highly influenced by the individual contact between each

conductive impurities that affect the quality of the material and pin and the dielectric material, the surface roughness of the

that are not readily detectable by other methods. pins, and the smoothness of the hole in the dielectric material.

21 19 Reproducibility of results on different specimens is difficult to

5.5 Volume resistivities above 10 Ω·cm (10 Ω·m), cal-

obtain.

culated from data obtained on specimens tested under usual

6.1.2 Metal Bars, in the arrangement of Fig. 3, were

laboratory conditions, are of doubtful validity, considering the

primarily devised to evaluate the insulation resistance or

limitations of commonly used measuring equipment.

conductance of flexible tapes and thin, solid specimens as a

5.6 Surface resistance or conductance cannot be measured

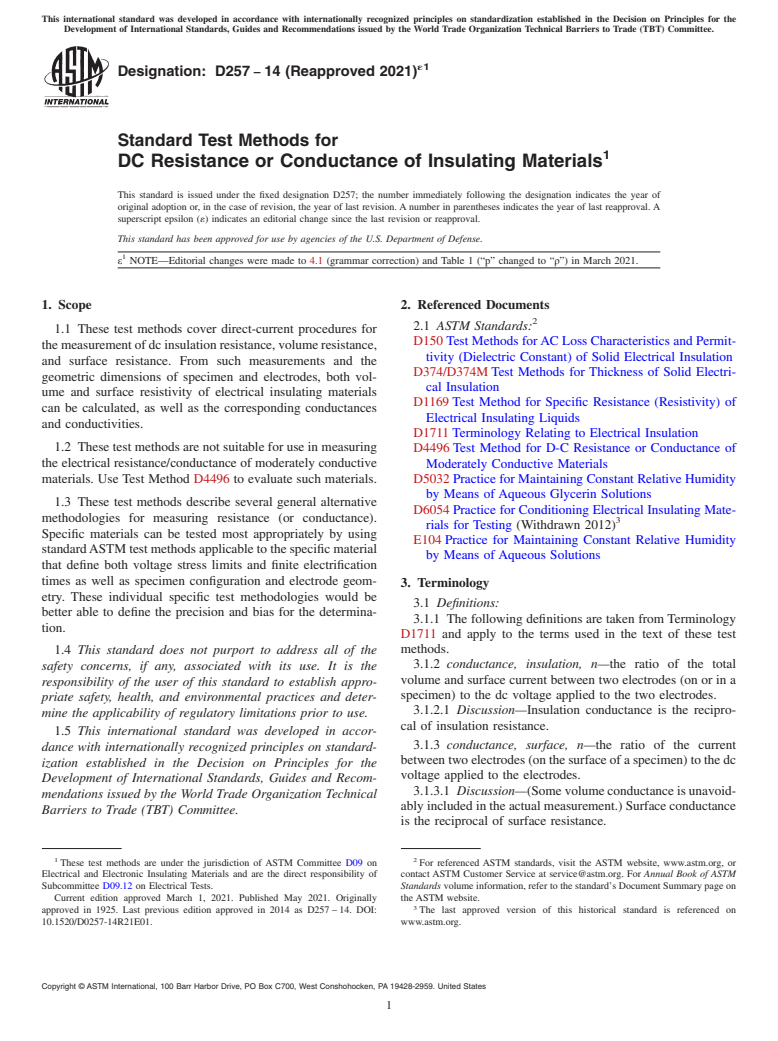

FIG. 1 Binding-post Electrodes for Flat, Solid Specimens

accurately,onlyapproximated,becausesomedegreeofvolume fairly simple and convenient means of electrical quality con-

resistance or conductance is always involved in the measure- trol. This arrangement is more satisfactory for obtaining

ment. The measured value is also affected by the surface approximate values of surface resistance or conductance when

contamination. Surface contamination, and its rate of the width of the insulating material is much greater than its

accumulation, is affected by many factors including electro- thickness.

static charging and interfacial tension.These, in turn, affect the

6.1.3 Silver Paint, Figs. 4-6, are available commercially

surface resistivity. Surface resistivity or conductivity is con-

with a high conductivity, either air-drying or low-temperature-

sidered to be related to material properties when contamination

baking varieties, which are sufficiently porous to permit

isinvolvedbutisnotamaterialpropertyofelectricalinsulation

diffusion of moisture through them and thereby allow the test

material in the usual sense.

specimen to be conditioned after the application of the elec-

trodes. This is a particularly useful feature in studying

6. Electrode Systems

resistance-humidity effects, as well as change with tempera-

ture. However, before conductive paint is used as an electrode

6.1 The electrodes for insulating materials are to allow

material, it shall be established that the solvent in the paint

intimate contact with the specimen surface, without introduc-

does not attack the material changing its electrical properties.

ingsignificanterrorbecauseofelectroderesistanceorcontami-

Smooth edges of guard electrodes are obtained by using a

nation of the specimen (5). The electrode material is to be

fine-bristle brush. However, for circular electrodes, sharper

corrosion-resistant under the conditions of the test. For tests of

edges are obtained by the use of a ruling compass and silver

fabricated specimens such as feed-through bushings, cables,

paintfordrawingtheoutlinecirclesoftheelectrodesandfilling

etc., the electrodes employed are a part of the specimen or its

in the enclosed areas by brush.

mounting.Insuchcases,measurementsofinsulationresistance

6.1.4 Sprayed Metal, Figs. 4-6 are used if satisfactory

or conductance include the contaminating effects of electrode

adhesiontothetestspecimencanbeobtained.itispossiblethat

or mounting materials and are generally related to the perfor-

thin sprayed electrodes will have certain advantages in that

mance of the specimen in actual use.

they are ready for use as soon as applied.

6.1.1 Binding-post and Taper-pin Electrodes, Figs. 1 and 2,

6.1.5 Evaporated Metal are used under the same condit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.