ASTM D7310-11

(Guide)Standard Guide for Defect Detection and Rating of Plastic Films Using Optical Sensors

Standard Guide for Defect Detection and Rating of Plastic Films Using Optical Sensors

SIGNIFICANCE AND USE

Defects in film are not acceptable to the end-user as there is a reduction in the fitness-for-use in many applications. This document is intended to be a guide to assist users in the inspection and observation of defects.

This guide is applicable in a laboratory environment as a quality control or as a research tool. It is also appropriate for use in any commercial process used to produce film including calendering and solvent casting.

This guide is also suitable for use as an evaluation or screening tool for materials intended to be used in other processes where defects of this nature are also critical, such as fiber spinning and non-wovens.

The individual user must establish the relationship between the criteria and acceptance for fitness-for-use and the observed defects, as it varies by polymer and application. This is attained by the collection of data over a time-period to establish acceptable control limits.

SCOPE

1.1 This guide is intended to provide suggested approaches and criteria for the observation and reporting of defects in various types of plastic film, by means of an optical scanning system.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7310 − 11

Standard Guide for

Defect Detection and Rating of Plastic Films Using Optical

1

Sensors

This standard is issued under the fixed designation D7310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope use in any commercial process used to produce film including

calendering and solvent casting.

1.1 This guide is intended to provide suggested approaches

and criteria for the observation and reporting of defects in 4.3 This guide is also suitable for use as an evaluation or

various types of plastic film, by means of an optical scanning screening tool for materials intended to be used in other

system. processes where defects of this nature are also critical, such as

fiber spinning and non-wovens.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.4 The individual user must establish the relationship

responsibility of the user of this standard to establish appro-

between the criteria and acceptance for fitness-for-use and the

priate safety and health practices and determine the applica-

observed defects, as it varies by polymer and application. This

bility of regulatory limitations prior to use.

is attained by the collection of data over a time-period to

establish acceptable control limits.

NOTE 1—There is no known ISO equivalent to this standard.

5. Apparatus

2. Referenced Documents

2

5.1 Extruder—Adevice for melting polymer that produces a

2.1 ASTM Standards:

flat or blown (tubular) film with sizes varying from lab-scale to

D883 Terminology Relating to Plastics

production-scale.

3. Terminology

NOTE 2—Although this technique is utilized for many different pro-

3.1 Definitions of Terms Specific to This Standard: cesses used for producing films, the extrusion systems described in the

following section represent the more prevalent process used.This is not to

3.1.1 defect—for the purpose of this guide any entity in the

imply that the guidance provided for utilizing this type of instrumentation

filmthatislargeenoughtobedetectedbyanopticalsensorand

cannot be applied to other processes or other applications.

is either polymeric in nature or caused by degradation, external

5.1.1 Flat Film Extrusion—An extrusion system that pro-

contamination, undispersed additives or pigments, or similar

duces a flat film that is quenched immediately after extrusion

sources.

by means of one or more cooling devices such as an air knife,

chill roll or water bath.

4. Significance and Use

5.1.2 Blown or tubular extrusion –An extrusion system that

4.1 Defects in film are not acceptable to the end-user as

produces a tubular “bubble” of film from a circular die, usually

there is a reduction in the fitness-for-use in many applications.

equipped with an air-ring to cool the polymer.

This document is intended to be a guide to assist users in the

5.2 Screen Pack—Although commonly used in commercial

inspection and observation of defects.

or semi-commercial environments, screen packs are not gen-

4.2 This guide is applicable in a laboratory environment as

erally used in laboratory units intended for research or quality

a quality control or as a research tool. It is also appropriate for

functions.

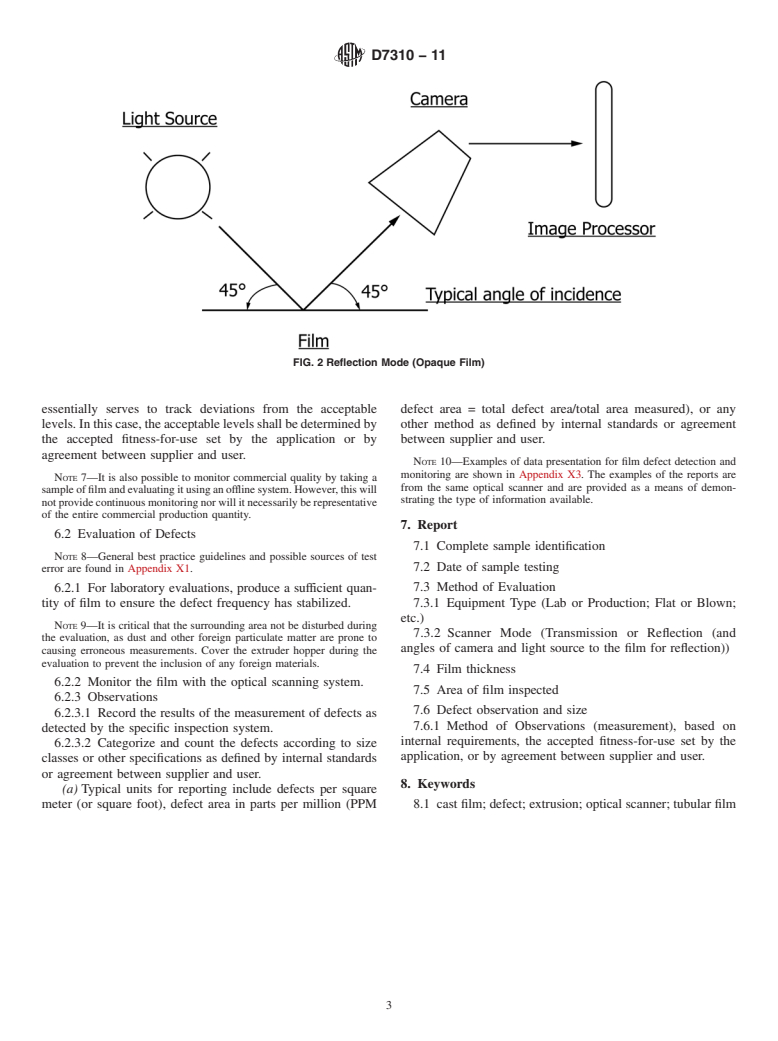

5.3 Defect Detection System—An optical scanning system

1

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and with a light source, an analog or digital camera, and an image

is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

processor. The optical characteristics of the camera are critical

Products.

for detecting small (30 µm) defects and it is important that the

Current edition approved Dec. 1, 2011. Published January 2012. Originally

instrument manufacturer be informed of the detection needs

approved in 2007. Last previous edition approved in 2007 as D7310 - 07.

DOI:10.1520/D7310-11.

when choosing a system.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 3—Other types of detection systems than the ones described in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on this guide are available, but are outside the scope of the guide and are not

the ASTM website. defined.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7310 − 11

5.3.1 Transmission Mode (Transparent or Translucent Film same conditions must be used consistently to ensure repeatable

Configuration)—Theca

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7310–07 Designation: D7310 – 11

Standard Guide for

Defect Detection and Rating of Plastic Films Using Optical

1

Sensors

This standard is issued under the fixed designation D7310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide is intended to provide suggested approaches and criteria for the observation and reporting of defects in various

types of plastic film, by means of an optical scanning system.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 defect—for the purpose of this guide,guide any entity in the film that is large enough to be detected by an optical sensor

and is either polymeric in nature or caused by degradation, external contamination, undispersed additives or pigments, or similar

sources.

4. Significance and Use

4.1 Defects in film are not acceptable to the end-user as there is a reduction in the fitness-for-use, in many applications. This

document is intended to be a guide to assist users in the inspection and observation of defects.

4.2 This guide is applicable in a laboratory environment as a quality control or as a research tool. It is also appropriate for use

in any commercial process used to produce film including calendering and solvent casting.

4.3 This guide is also suitable for use as an evaluation or screening tool for materials intended to be used in other processes

where defects of this nature are also critical, such as fiber spinning and non-wovens.

4.4 The individual user must agree uponestablish the relationship between the criteria and acceptance for fitness-for-use and the

observed defects, as it varies by polymer and application. This is attained by the collection of data over a time-period to establish

acceptable control limits.

5. Apparatus

5.1 Extruder—Adevice for melting polymer that produces a flat or blown (tubular) film,film with sizes varying from lab-scale

to production-scale.

NOTE 2—Although this technique is utilized for many different processes used for producing films, the extrusion systems described in the following

section represent the more prevalent process used. This is not to imply that the guidance provided for utilizing this type of instrumentation cannot be

applied to other processes or other applications.

5.1.1 Flat Film Extrusion—An extrusion system that produces a flat film that is quenched immediately after extrusion by means

of one or more cooling devices such as an air knife, chill roll or water bath.

5.1.2 Blown or tubular extrusion – An extrusion system that produces a tubular “bubble” of film from a circular die, usually

1

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

Current edition approved Sept. 1, 2007. Published September 2007. DOI: 10.1520/D7310-07.on Molded and Extruded Products.

Current edition approved Dec. 1, 2011. Published January 2012. Originally approved in 2007. Last previous edition approved in 2007 as D7310 - 07. DOI:10.1520/

D7310-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7310 – 11

equipped with an air-ring to cool the polymer.

5.2 Screen Pack—Although commonly used in commercial or semi-commercial environments, screen packs are not generally

used in laboratory units intended for research or quality functions.

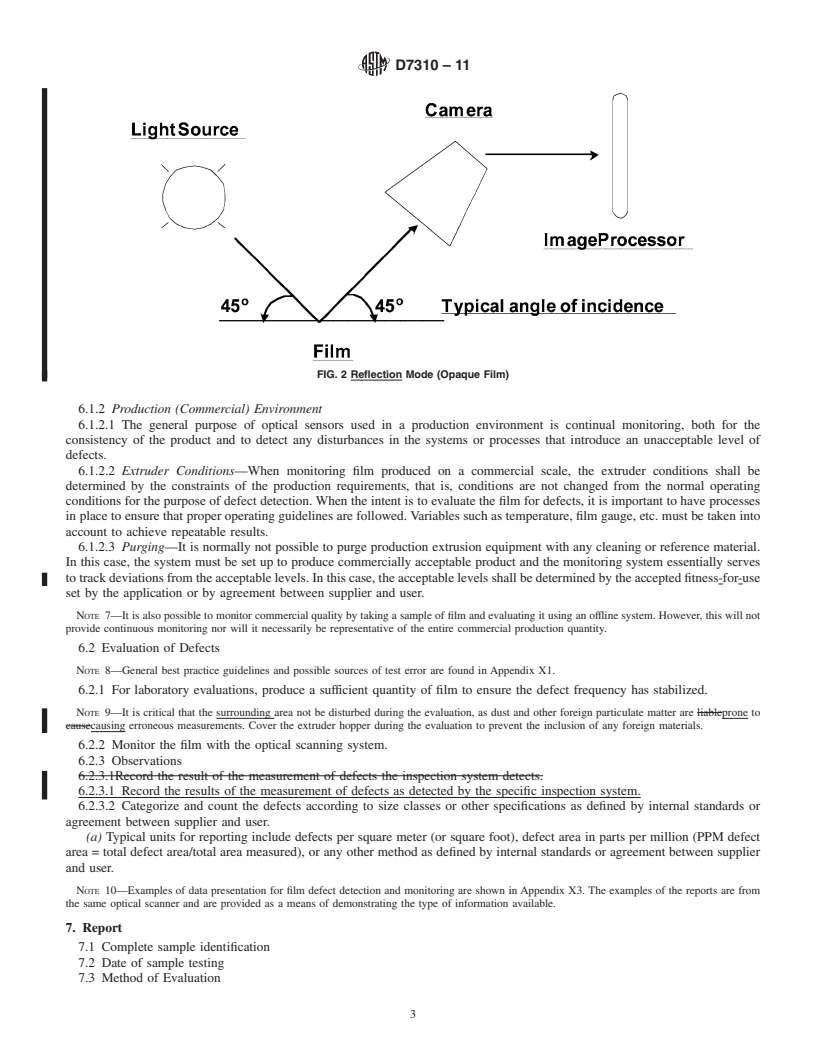

5.3 Defect Detection System—An optical scanning system with a light source, an analog or digital camera, and an image

processor. The optical characteristics of the camera are critical for detectin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.