ASTM D8004-15

(Test Method)Standard Test Method for Fuel Dilution of In-Service Lubricants Using Surface Acoustic Wave Sensing

Standard Test Method for Fuel Dilution of In-Service Lubricants Using Surface Acoustic Wave Sensing

SIGNIFICANCE AND USE

5.1 This test method provides a means for a reliable field determination of fuel dilution that is quick and preparation-free. Results are obtained in approximately 1 min. Such a method is used, for example, at remote railroad depots where it is impractical to carry out a standard laboratory method for determination of fuel dilution, such as described in Test Method D7593, but it is a critical need to determine if fuel has contaminated the lubricant. If fuel has contaminated the lubricant, this is significantly detrimental to the machinery and it is typically serviced immediately. Further, the fuel can ignite at the high temperatures encountered in machinery lubricant paths.

SCOPE

1.1 This test method describes a means for determining the amount of fuel dilution present in an in-service lubricant. This is achieved by drawing into a surface acoustic wave (SAW) sensor vapor from the lubricant. Fuel vapor will be absorbed by the SAW sensor’s polymer coating. The amount of absorbance is then related to fuel content in the lubricant.

1.2 The range of fuel dilution capable of being measured by the test method is from 0.1 % to 10.0 % by mass fuel dilution.

1.3 This test method is specifically tailored to determining the fuel dilution of in-service lubricants, including newly utilized lubricants. The method is applicable to contamination with diesel, gasoline, and jet fuels.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.See Section 9.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8004 − 15

Standard Test Method for

Fuel Dilution of In-Service Lubricants Using Surface

1

Acoustic Wave Sensing

This standard is issued under the fixed designation D8004; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Using Relevant ASTM Standard Practices

D7593 Test Method for Determination of Fuel Dilution for

1.1 This test method describes a means for determining the

In-Service Engine Oils by Gas Chromatography

amount of fuel dilution present in an in-service lubricant. This

D7669 Guide for Practical Lubricant Condition Data Trend

is achieved by drawing into a surface acoustic wave (SAW)

Analysis

sensor vapor from the lubricant. Fuel vapor will be absorbed by

D7720 Guide for Statistically Evaluating Measurand Alarm

the SAW sensor’s polymer coating. The amount of absorbance

Limits when Using Oil Analysis to Monitor Equipment

is then related to fuel content in the lubricant.

and Oil for Fitness and Contamination

1.2 The range of fuel dilution capable of being measured by

the test method is from 0.1 % to 10.0 % by mass fuel dilution.

3. Terminology

1.3 This test method is specifically tailored to determining

3.1 Definitions of Terms Specific to This Standard:

the fuel dilution of in-service lubricants, including newly

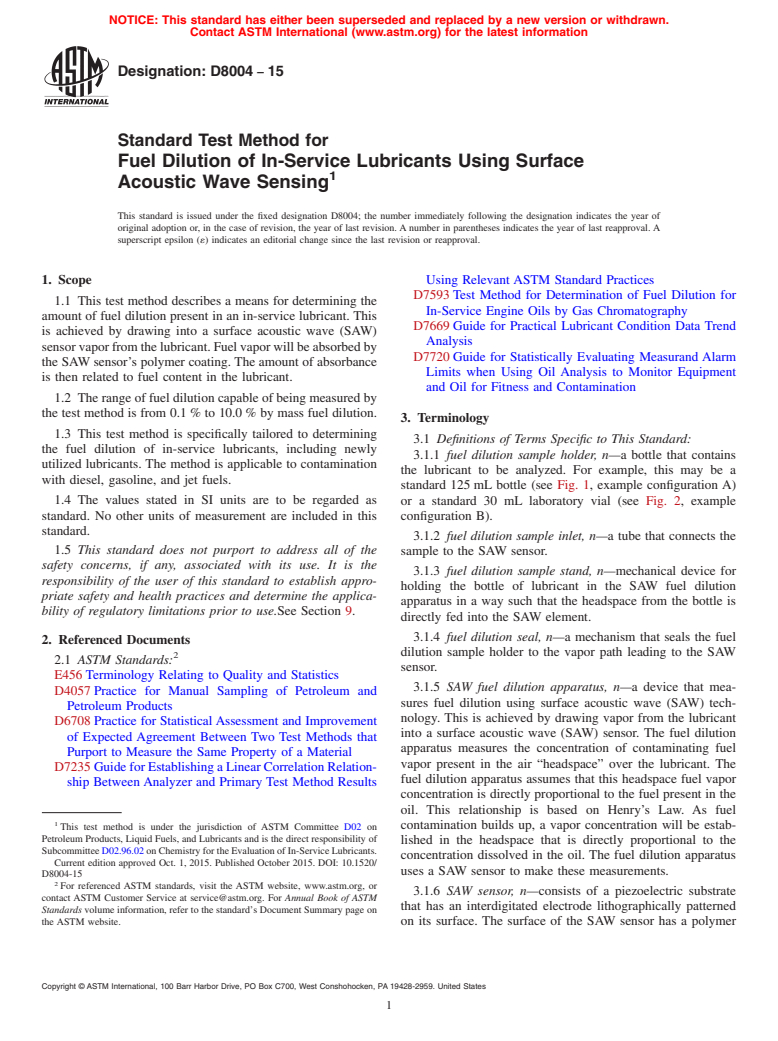

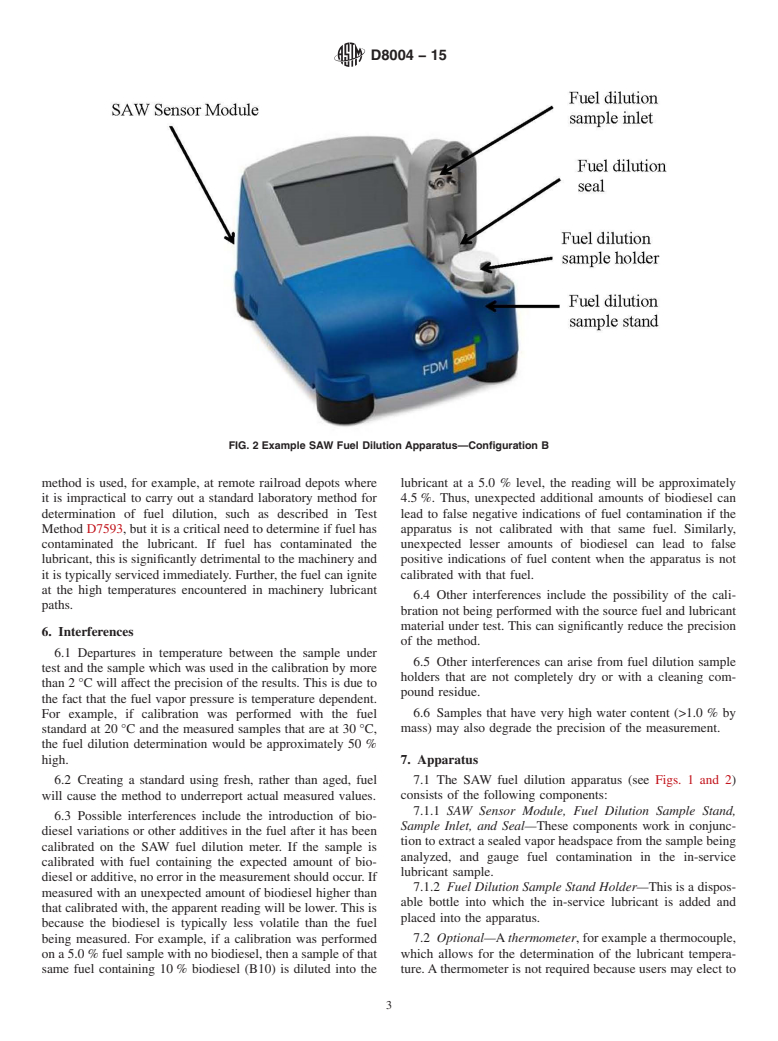

3.1.1 fuel dilution sample holder, n—a bottle that contains

utilized lubricants. The method is applicable to contamination

the lubricant to be analyzed. For example, this may be a

with diesel, gasoline, and jet fuels.

standard 125 mL bottle (see Fig. 1, example configuration A)

1.4 The values stated in SI units are to be regarded as or a standard 30 mL laboratory vial (see Fig. 2, example

standard. No other units of measurement are included in this configuration B).

standard.

3.1.2 fuel dilution sample inlet, n—a tube that connects the

1.5 This standard does not purport to address all of the

sample to the SAW sensor.

safety concerns, if any, associated with its use. It is the

3.1.3 fuel dilution sample stand, n—mechanical device for

responsibility of the user of this standard to establish appro-

holding the bottle of lubricant in the SAW fuel dilution

priate safety and health practices and determine the applica-

apparatus in a way such that the headspace from the bottle is

bility of regulatory limitations prior to use.See Section 9.

directly fed into the SAW element.

3.1.4 fuel dilution seal, n—a mechanism that seals the fuel

2. Referenced Documents

dilution sample holder to the vapor path leading to the SAW

2

2.1 ASTM Standards:

sensor.

E456 Terminology Relating to Quality and Statistics

3.1.5 SAW fuel dilution apparatus, n—a device that mea-

D4057 Practice for Manual Sampling of Petroleum and

sures fuel dilution using surface acoustic wave (SAW) tech-

Petroleum Products

nology. This is achieved by drawing vapor from the lubricant

D6708 Practice for Statistical Assessment and Improvement

into a surface acoustic wave (SAW) sensor. The fuel dilution

of Expected Agreement Between Two Test Methods that

apparatus measures the concentration of contaminating fuel

Purport to Measure the Same Property of a Material

vapor present in the air “headspace” over the lubricant. The

D7235 Guide for Establishing a Linear Correlation Relation-

fuel dilution apparatus assumes that this headspace fuel vapor

ship Between Analyzer and Primary Test Method Results

concentration is directly proportional to the fuel present in the

oil. This relationship is based on Henry’s Law. As fuel

1

contamination builds up, a vapor concentration will be estab-

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

lished in the headspace that is directly proportional to the

Subcommittee D02.96.02 on Chemistry for the Evaluation of In-Service Lubricants.

concentration dissolved in the oil. The fuel dilution apparatus

Current edition approved Oct. 1, 2015. Published October 2015. DOI: 10.1520/

uses a SAW sensor to make these measurements.

D8004-15

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.6 SAW sensor, n—consists of a piezoelectric substrate

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

that has an interdigitated electrode lithographically patterned

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. on its surface. The surface of the SAW sensor has a polymer

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-----------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.