ASTM D2718-00

(Test Method)Standard Test Methods for Structural Panels in Planar Shear (Rolling Shear)

Standard Test Methods for Structural Panels in Planar Shear (Rolling Shear)

SCOPE

1.1 These test methods determine the shear properties of structural panels associated with shear distortion of the planes parallel to the edge planes of the panels. Both shear strength and modulus of rigidity may be determined. Primarily, the tests measure the planar shear (rolling shear) strength developed in the plane of the panel.

1.2 Structural panels in use include plywood, waferboard, oriented strand board, and composites of veneer and of wood-based layers.

1.3 Two test methods are included:

1.3.1 Test Method A—Planar shear loaded by plates.

1.3.2 Test Method B—Planar shear induced by five-point bending.

1.3.3 The choice of method will be dictated by the purpose of the test and equipment available.

1.3.4 Test Method A, Planar Shear Loaded by Plates—This test method uses a rectangular panel section adhered between steel plates with protruding knife edges to create load at the panel faces. This test method has been used to develop shear properties of plywood and oriented strand board for the purpose of confirming design values. This test method does not produce pure shear, but the specimen length is prescribed so that the secondary stresses have a minimum effect. The method determines shear strength and modulus of rigidity.

1.3.5 Test Method B, Planar Shear Induced by Five Point Bending—Planar shear stress is induced on the panel while loaded in bending using two continuous spans. This test method determines planar shear strength consistent with panel applications under transverse loading. This test method is able to determine shear strength at any moisture condition.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2718 – 00

Standard Test Methods for

Structural Panels in Planar Shear (Rolling Shear)

This standard is issued under the fixed designation D 2718; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Wood-Based Materials

D 4442 Test Methods for Direct Moisture Content Measure-

1.1 These test methods determine the shear properties of

ment of Wood and Wood-Base Materials

structural panels associated with shear distortion of the planes

parallel to the edge planes of the panels. Both shear strength

3. Significance and Use

and modulus of rigidity may be determined. Primarily, the tests

3.1 Planar shear (rolling shear) characteristics of structural

measure the planar shear (rolling shear) strength developed in

panels determined by these test methods are essential for the

the plane of the panel.

rigorous design of various glued wood-panel structural com-

1.2 Structural panels in use include plywood, waferboard,

ponents, such as box beams, folded plate roofs, and stressed

oriented strand board, and composites of veneer and of

skin panels. Planar shear also may govern the design at low

wood-based layers.

span-depth ratios encountered in floors subjected to high

1.3 Two test methods are included:

concentrated loads, concrete forms at high pouring pressures,

1.3.1 Test Method A—Planar shear loaded by plates.

and bulk storage structures.

1.3.2 Test Method B—Planar shear induced by five-point

3.2 The modulus of rigidity determined from Test Method A

bending.

is a composite of the entire specimen acting as a unit. For

1.3.3 The choice of method will be dictated by the purpose

plywood panels for which the ratio between the shear moduli

of the test and equipment available.

of the plies with grain oriented parallel and perpendicular to the

1.3.4 Test Method A, Planar Shear Loaded by Plates—This

shear forces is known, the rolling shear modulus of the

test method uses a rectangular panel section adhered between

perpendicular plies can be calculated.

steel plates with protruding knife edges to create load at the

3.3 Veneer produced by slicing or rotary peeling may

panel faces. This test method has been used to develop shear

contain fine checks or separations parallel to the grain on the

properties of plywood and oriented strand board for the

knife side of the veneer that are produced as the knife is forced

purpose of confirming design values. This test method does not

through the wood. These checks are termed “knife checks” to

produce pure shear, but the specimen length is prescribed so

distinguish them from occasional checks that may be formed

that the secondary stresses have a minimum effect. The method

on the opposite side of the veneer by forces at the compression

determines shear strength and modulus of rigidity.

bar, and from checks caused by drying. Knife checks can have

1.3.5 Test Method B, Planar Shear Induced by Five-Point

a significant effect on rolling shear properties in plywood

Bending—Planar shear stress is induced on the panel while

panels and may be of significance in other veneer containing

loaded in bending using two continuous spans. This test

panels. Test Method A requires (when applicable) the testing of

method determines planar shear strength consistent with panel

matching specimens having knife checks oriented both open

applications under transverse loading. This test method is able

and closed wherever possible (see Fig. 1).

to determine shear strength at any moisture condition.

3.4 To control or define other variables influencing rolling

1.4 This standard does not purport to address all of the

shear, these test methods require determination of moisture

safety concerns, if any, associated with its use. It is the

content, specific gravity, and elapsed time-to-failure. Condi-

responsibility of the user of this standard to establish appro-

tioning of test material in controlled atmospheres, determina-

priate safety and health practices and determine the applica-

tion of depth of knife checks (when applicable), and determi-

bility of regulatory limitations prior to use.

nation of percent of wood and plywood glueline failure (when

2. Referenced Documents applicable) are recommended.

2.1 ASTM Standards:

4. Control of Moisture Content

D 2395 Test Methods for Specific Gravity of Wood and

4.1 The structural panel samples to be tested at specific

moisture contents or equilibrium relative humidities shall be

This test method is under the jurisdiction of ASTM Committee D-7 on Wood

conditioned to approximately constant weight in controlled

and is the direct responsibility of Subcommittee D07.03 on Panel Products.

Current edition approved June 10, 2000. Published August 2000. Originally

published as D 2718 – 69 T. Last previous edition D 2718 – 95.

Annual Book of ASTM Standards, Vol 04.10.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2718

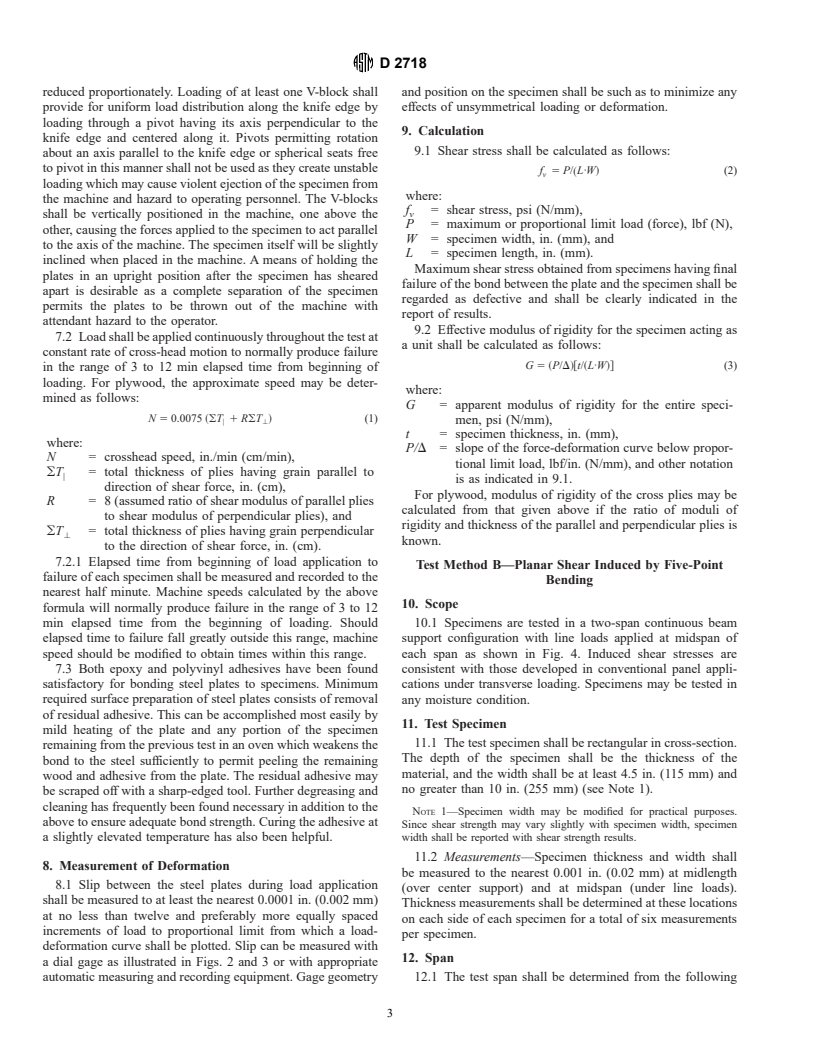

(a) Knife Checks Open

NOTE 1—The “V” block is supported on a seat that provides rotation

(b) Knife Checks Closed

about the axis perpendicular to the knife edge only.

FIG. 1 Orientation of Knife Checks in Plywood

Metric Equivalents

in. 6 18

mm 15 45

atmospheric conditions before gluing to plates. For approxi-

mating moisture conditions of structural panel used under dry FIG. 2 Planar (Rolling) Shear Test Using a Dial Gage for

Measuring Plate Slip

conditions a relative humidity of 65 6 2 % at a temperature of

68 6 6°F (20 6 3°C) is recommended. Specimens shall be

directions or for plywood to cause knife checks to close during

tested without undue delay after the adhesive is cured. Testing

test as shown in Fig. 1(b). Proper plywood orientation may be

in similarly controlled atmospheres is recommended wherever

determined from check depth specimens described in 16.3. It

possible.

may not be possible to test samples having two or more plies

Test Method A—Planar Shear Loaded by Plates

stressed in rolling shear in both “open” and “closed” orienta-

tions if these plies are oriented in opposite directions causing

5. Scope

a“ checks open” failure regardless of direction of loading.

5.1 The specimen having the form of a rectangular flat plate

6.3 Specimen length and width shall be measured to the

is bonded between steel plates beveled at opposite ends of the

nearest 0.01 in. (0.25 mm) and thickness to the nearest 0.001

specimen to provide knife edges for loading the plate at the

in. (0.025 mm). When applicable, the direction of knife checks

face bonded to the specimen. The knife edges project beyond

in plies having grain perpendicular to its length shall be

the ends of the specimen. This test method is conducted by

determined and the specimens marked for position of knife

loading the knife edges in compression at a uniform rate while

edges. At the time specimens are cut matching samples for

a suitable gage measures slip between the plates due to

determination of moisture content and specific gravity in

specimen deformation. Shear strength is computed from maxi-

accordance with 16.1 and 16.2 shall be obtained. When

mum load, and effective shear modulus for the specimen is

measurement of knife checks is included as discussed in 16.3,

determined from a plot of load versus slip.

a sample for this measurement also may be cut at this time.

6. Test Specimen 7. Loading

6.1 Specimen thickness shall be that of the material. Speci- 7.1 Figs. 1 and 2 illustrate the specimen and suitable loading

mens from material that is expected to vary significantly within plates and blocks for loading the knife edges of the plates. The

the specimen due to growth or manufacturing features or from specimen shall be loaded by steel plates bonded to both faces

other causes shall be 6 in. (15 cm) wide by 18 in. (45 cm) long of the specimen with an adhesive sufficiently rigid to preclude

or larger as shown in Fig. 2. This size is recommended for contribution of adhesive creep to measured deformation. Width

uniform material as well. However, smaller specimens of

of plates shall be that of the specimen. One end of each plate

uniform material may be used if these are not less than four shall be provided with a knife edge projecting ⁄4 in. (6 mm)

times the thickness in width nor twelve times the thickness in

beyond the end of the specimen at one end and flush with the

length. surface glued to the specimen. The other end of the plate shall

6.2 From each sample of panels containing veneer, two be square and flush with the end of the specimen. Knife edges

matching specimens shall be cut. Knife edges of loading plates of the two plates shall be at opposite ends of the specimen and

for one specimen of each matching pair shall be oriented shall be oriented to load the specimen in the desired direction

perpendicular to one of the primary panel directions or for in relation to the knife checks. Planar shear properties of

plywood to cause opening of knife checks during test as shown structural panels should be determined in both directions.

in Fig. 1(a). Knife edges of plates loading the other specimen Plates for specimens 18 in. (45 cm) long shall be 1 in. (2.5 cm)

shall be positioned perpendicular to one of the primary panel thick. The thickness of plates for shorter specimens may be

D 2718

reduced proportionately. Loading of at least one V-block shall and position on the specimen shall be such as to minimize any

provide for uniform load distribution along the knife edge by effects of unsymmetrical loading or deformation.

loading through a pivot having its axis perpendicular to the

9. Calculation

knife edge and centered along it. Pivots permitting rotation

9.1 Shear stress shall be calculated as follows:

about an axis parallel to the knife edge or spherical seats free

to pivot in this manner shall not be used as they create unstable

f 5 P/~L·W! (2)

v

loading which may cause violent ejection of the specimen from

where:

the machine and hazard to operating personnel. The V-blocks

f = shear stress, psi (N/mm),

v

shall be vertically positioned in the machine, one above the

P = maximum or proportional limit load (force), lbf (N),

other, causing the forces applied to the specimen to act parallel

W = specimen width, in. (mm), and

to the axis of the machine. The specimen itself will be slightly

L = specimen length, in. (mm).

inclined when placed in the machine. A means of holding the

Maximum shear stress obtained from specimens having final

plates in an upright position after the specimen has sheared

failure of the bond between the plate and the specimen shall be

apart is desirable as a complete separation of the specimen

regarded as defective and shall be clearly indicated in the

permits the plates to be thrown out of the machine with

report of results.

attendant hazard to the operator.

9.2 Effective modulus of rigidity for the specimen acting as

7.2 Load shall be applied continuously throughout the test at

a unit shall be calculated as follows:

constant rate of cross-head motion to normally produce failure

G 5 ~P/D!@t/~L·W!# (3)

in the range of 3 to 12 min elapsed time from beginning of

loading. For plywood, the approximate speed may be deter-

where:

mined as follows:

G = apparent modulus of rigidity for the entire speci-

N 5 0.0075 ~(T 1 R(T ! (1)

men, psi (N/mm),

| ’

t = specimen thickness, in. (mm),

where:

P/D = slope of the force-deformation curve below propor-

N = crosshead speed, in./min (cm/min),

tional limit load, lbf/in. (N/mm), and other notation

(T = total thickness of plies having grain parallel to

|

is as indicated in 9.1.

direction of shear force, in. (cm),

For plywood, modulus of rigidity of the cross plies may be

R = 8 (assumed ratio of shear modulus of parallel plies

calculated from that given above if the ratio of moduli of

to shear modulus of perpendicular plies), and

rigidity and thickness of the parallel and perpendicular plies is

(T = total thickness of plies having grain perpendicular

’

known.

to the direction of shear force, in. (cm).

7.2.1 Elapsed time from beginning of load application to

Test Method B—Planar Shear Induced by Five-Point

failure of each specimen shall be measured and recorded to the

Bending

nearest half minute. Machine speeds calculated by the above

10. Scope

formula will normally produce failure in the range of 3 to 12

min elapsed time from the beginning of loading. Should 10.1 Specimens are tested in a two-span continuous beam

elapsed time to failure fall greatly outside this range, machine support configuration with line loads applied at midspan of

speed should be modified to obtain times within this range. each span as shown in Fig. 4. Induced shear stresses are

7.3 Both epoxy and polyvinyl adhesives have been found consistent with those developed in conventional panel appli-

satisfactory for bonding steel plates to specimens. Minimum cations under transverse loading. Specimens may be tested in

required surface preparation of steel plates consists of removal any moisture condition.

of residual adhesive. This can be accomplished most easily by

11. Test Specimen

mild heating of the plate and any portion of the specimen

11.1 The test specimen shall be rectangular in cross-section.

remaining from the previous test in an oven which weakens the

The depth of the specimen shall be the thickness of the

bond to the steel sufficiently to permit peeling the remaining

material, and the width shall be at least 4.5 in. (115 mm) and

wood and adhesive from the plate. The residual adhesive may

no greater than 10 in. (255 mm) (see Note 1).

be scraped off with a sharp-edged tool. Further degreasing and

cleaning has frequently been found necessary in addition to the

NOTE 1—Specimen width may be modified for practical purposes.

above to ensure adequate bond strength. Curing the adhesive at

Since shear strength may vary slightly with specimen width, specimen

a slightly elevated temperature has also been helpful.

width shall be reported with shear strength results.

11.2 Measurements—Specimen thickness and width shall

8. Measurement of Deformation

be measured to the nearest 0.001 in. (0.02 mm) at midlength

8.1 Slip between the steel plates during load application

(over center support) and at midspan (under line loads).

shall be measured to at least the nearest 0.0001 in. (0.002 mm)

Thickness measurements shall be determined at these locations

at no less than twelve and preferably more equally spaced

on each side of each specimen for a total of six measurements

increments of load to proportional limit from which a load-

per specimen.

deformat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.