ASTM D936-89

(Test Method)Method of Test for Aromatic Hydrocarbons in Olefin-Free Gasolines by Silica Gel Absorption (Withdrawn 1990)

Method of Test for Aromatic Hydrocarbons in Olefin-Free Gasolines by Silica Gel Absorption (Withdrawn 1990)

General Information

Standards Content (Sample)

ASTM DY36 89 M 0759510 OOLl0309 T 9

24 - I6

An American National Standard

41)) Designation: D 936 - 89 AMERICAN SOCIETY FOR TESTINO AND MATERIALS

1016 ASCO SI., PhMe@hm , PI. 19103

Reprinted hOm lh. Anmiil Boa oi ASTM Standards, COplrQhi ASTM

II rol ïikd in lha cum cmbined krdai. will wir hi lha wnt rdiiim.

Standard Test Method for

Aromatic Hydrocarbons in Olefin-Free Gasolines by Silica Gel

Adsorption’

This standard is issued under the fixed designation D 936; the number imrnediafely foliowing the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Deparimeni of Dejiense and repiaces Method 3702 of Federal Test Method

Standard No. 791b. Consult the DoD Index of Specijications and Standardsfor the spec$c year of issue which has been adopted by the

Department of Defense.

1. Scope saturates, saturates plus aromatics, aromatics, aromatics plus

alcohol, and alcohol. The percolate is collected in small frac-

1.1 This test method covers the determination of total

tions and the aromatic content of the sample is calculated

aromatic content of gasolines and other debutanized hydro-

from measured volumes and refractive indices of the frac-

carbon mixtures that distill below 204°C (400°F) and contain

tions. Samples containing less than 4 % aromatics are fortified

less than 1 % of olefinic hydrocarbons.

with a known amount of toluene and those containing more

1.2 The values stated in SI units are to be regarded as the

than 80 % aromatics are diluted with a saturated hydrocarbon

standard. The values in parentheses are for information only.

or hydrocarbon mixture boiling in the gasoline range; correc-

1.3 This standard may involve hazardous materials, oper-

tion is made in the calculation for the toluene or diluent added.

ations, and equipment. This standard does not purport to

address all of the safety problems associated with its use. It is

4. Significance and Use

the responsibility of the user of this standard to establish

appropriate safity and health practices and determine the

4.1 A precise knowledge of the liquid volume percent of

applicability of regulatory limitations prior to use. Specific

the aromatic hydrocarbons of gasolines and petroleum

hazard statements are given in Section 7 and Annex Al.

fractions from which gasolines are blended is of value in

of the gasolines. Such

assessing the performance properties

2. Referenced Documents

knowledge is also of value in measuring the conversion of

paraffins and cycloparaffins to aromatics by catalytic re-

2.1 ASTM Standards:

forming. This test method provides a procedure for making

D941 Test Method for Density and Relative Density

such a precise determination.

(Specific Gravity) of Liquids by Lipkin Bicapillary

Pycnomete?

D 1319 Test Method for Hydrocarbon Types in Liquid 5. Interference

Petroleum Products by Fluorescent Indicator Adsorp-

5.1 Paraffins and cycloparaffins do not interfere, regard-

tion2

less of their concentration. Olefinic hydrocarbons, when

E 11 Specification of Wire-Cloth Sieves for Testing Pur-

present in concentrations greater than one percent, interfere

poses3

in the normal use of this test method. Compounds con-

taining sulfur or nitrogen interfere by being included with

3. Summary of Test Method4

the aromatic hydrocarbons. ’

3.1 The sample is passed downward through a column

packed with fine, activated silica gel and, when all of the

6. Apparatus

sample has been adsorbed on the gel, alcohol is added as an

6J Adsorption Column, as shown in Fig. 1, consisting of

eluent. The alcohol causes desorption of the hydrocarbons, -

an eluent reservoir, a sample reservoir, and wide and narrow

forcing them down the column. In this process of adsorption

sections of a water-jacketed tubing. The column should be

and desorption, the hydrocarbons are separated according to

surrounded with a transparent protective shield when oper-

their adsorption affinities so that the components issue from

ating at pressures in excess of 69 kpa (10 psi).

the bottom of the silica gel column in the following order:

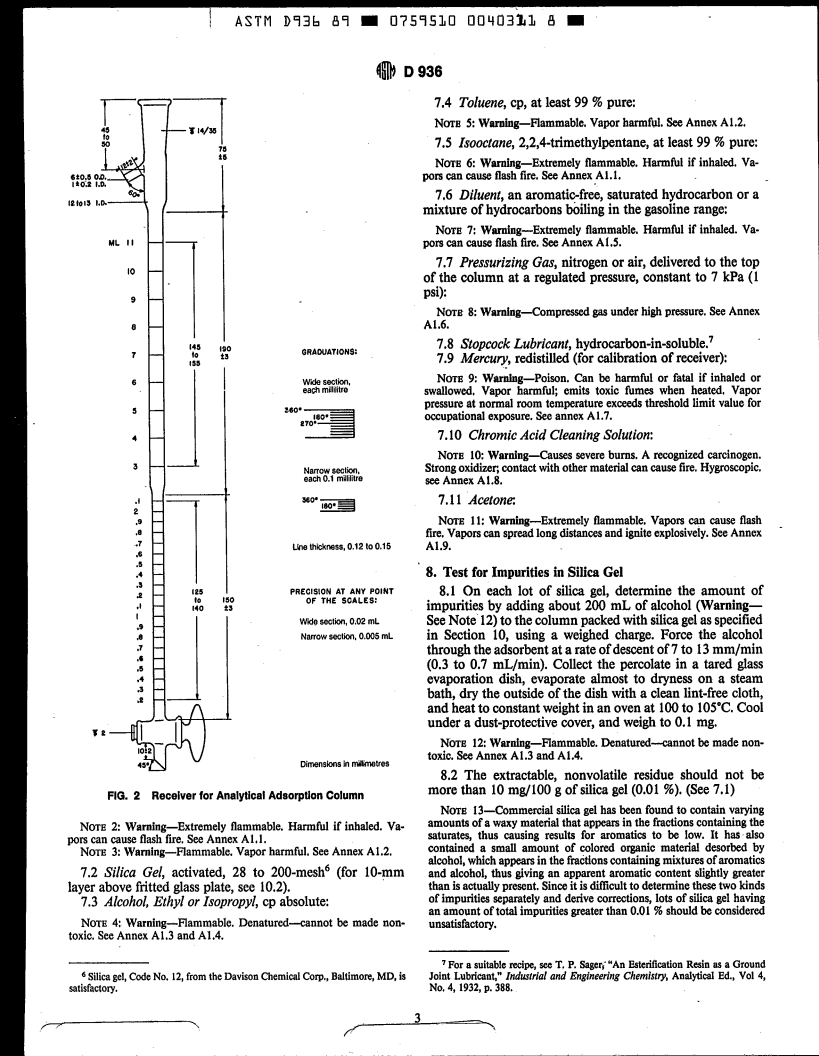

6.2 Receiver, graduated, of 1 1-mL capacity, as shown in

Fig. 2.

* This test method is under the jurisdiction of ASTM Committee D2 on

NOTE 1-Whiie not strictly required, a cathetometer, capable of

Petroleum Products and Lubricants and is the direct responsibility of Subcom-

measuring liquid levels to IO. 1 mm, is desirable for more accurate and

mittee Dû2.04 on Hydrocarbon Analysis.

convenient calibration of the receiver (see Section 9).

Current edition approved Oct. 27, 1989. Published December 1989. Originally

published as D 936 - 47. Last previous edition D 936 - 83.

6.3 Sample Containers, of approximately 5,

...

This May Also Interest You

ABSTRACT

This specification describes the various characteristics and requirements of automotive fuels for use over a wide range of operating conditions in ground vehicles equipped with spark-ignition engines. It provides for a variation of the volatility and water tolerance of automotive fuel in accordance with seasonal climatic changes at the locality where the fuel is used. This specification neither necessarily includes all types of fuels that are satisfactory for automotive vehicles, nor necessarily excludes fuels that can perform unsatisfactorily under certain operating conditions or in certain equipment. The spark-ignition engine fuels covered here are gasoline and its blends with oxygenates, such as alcohols and ethers, and not fuels that contain an oxygenate as the primary component, such as fuel methanol (M85). This specification does not address the emission characteristics of reformulated spark-ignition engine fuel. However, in addition to the legal requirements, reformulated spark-ignition engine fuel should meet the performance requirements as well.

SCOPE

1.1 This specification covers the establishment of requirements of liquid automotive fuels for ground vehicles equipped with spark-ignition engines.

1.2 This specification describes various characteristics of automotive fuels for use over a wide range of operating conditions. It provides for a variation of the volatility and water tolerance of automotive fuel in accordance with seasonal climatic changes at the locality where the fuel is used. For the period May 1 through September 15, the maximum vapor pressure limits issued by the United States (U.S.) Environmental Protection Agency (EPA) are specified for each geographical area except Alaska, Hawaii, and the U.S. Territories. Variation of the antiknock index with seasonal climatic changes and altitude is discussed in Appendix X1. This specification neither necessarily includes all types of fuels that are satisfactory for automotive vehicles, nor necessarily excludes fuels that can perform unsatisfactorily under certain operating conditions or in certain equipment. The significance of each of the properties of this specification is shown in Appendix X1.

1.3 The spark-ignition engine fuels covered in this specification are gasoline and its blends with oxygenates, such as alcohols and ethers and where gasoline is the primary component by volume in the blend. The concentrations and types of oxygenates are not specifically limited in this specification. The composition of fuel is limited by economic, legal, and technical consideration, but its properties, including volatility, are defined by this specification. In many countries, regulatory authorities having jurisdiction have set laws and regulations that limit the concentration of oxygenates and certain other compounds found in spark-ignition engine fuel. In the United States, oxygenate types and concentrations are limited to those approved under the U.S. Environmental Protection Agency's (EPA) substantially similar rule (see X3.3.1), waivers, and partial waivers including some restrictions on vehicle and equipment use (see X3.3.2). With regard to fuel properties, including volatility, this specification can be more or less restrictive than the EPA rules, regulations, and waivers. Refer to Appendix X3 for discussions of EPA rules relating to fuel volatility, lead and phosphorous contents, sulfur content, benzene content, deposit control additive certification, and use of oxygenates in the fuel. Contact the EPA for the latest versions of the rules and additional requirements.

1.4 This specification does not address the emission characteristics of reformulated spark-ignition engine fuel. Reformulated spark-ignition engine fuel is required in some areas to lower emissions from automotive vehicles, and its characteristics are described in Monograph 12 (MONO12) on reformulated spark-ignition engine fuel.2 However, in addition to the legal requi...

- Technical specification34 pagesEnglish languagesale 15% off

- Technical specification34 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers seven grades of diesel fuel oils suitable for various types of diesel engines. These grades are: Grade No. 1-D S15; Grade No. 1-D S500; Grade No. 1-D S5000; Grade No. 2-D S15; Grade No. 2-D S500; Grade No. 2-D S5000; and Grade No. 4-D. The requirements specified for diesel fuel oils shall be determined in accordance with the following test methods: flash point; cloud point; water and sediment; carbon residue; ash; distillation; viscosity; sulfur; copper corrosion; cetane number; cetane index; aromaticity; lubricity; and conductivity.

SCOPE

1.1 This specification covers seven grades of diesel fuel suitable for various types of diesel engines. These grades are described as follows:

1.1.1 Grade No. 1-D S15—A special-purpose, light middle distillate fuel for use in diesel engine applications requiring a fuel with 15 ppm sulfur (maximum) and higher volatility than that provided by Grade No. 2-D S15 fuel.2

1.1.2 Grade No. 1-D S500—A special-purpose, light middle distillate fuel for use in diesel engine applications requiring a fuel with 500 ppm sulfur (maximum) and higher volatility than that provided by Grade No. 2-D S500 fuel.2

1.1.3 Grade No. 1-D S5000—A special-purpose, light middle distillate fuel for use in diesel engine applications requiring a fuel with 5000 ppm sulfur (maximum) and higher volatility than that provided by Grade No. 2-D S5000 fuels.

1.1.4 Grade No. 2-D S15—A general purpose, middle distillate fuel for use in diesel engine applications requiring a fuel with 15 ppm sulfur (maximum). It is especially suitable for use in applications with conditions of varying speed and load.2

1.1.5 Grade No. 2-D S500—A general-purpose, middle distillate fuel for use in diesel engine applications requiring a fuel with 500 ppm sulfur (maximum). It is especially suitable for use in applications with conditions of varying speed and load.2

1.1.6 Grade No. 2-D S5000—A general-purpose, middle distillate fuel for use in diesel engine applications requiring a fuel with 5000 ppm sulfur (maximum), especially in conditions of varying speed and load.

1.1.7 Grade No. 4-D—A heavy distillate fuel, or a blend of distillate and residual oil, for use in low- and medium-speed diesel engines in applications involving predominantly constant speed and load.

Note 1: A more detailed description of the grades of diesel fuels is given in X1.2.

Note 2: The Sxxx designation has been adopted to distinguish grades by sulfur rather than using words such as “Low Sulfur” as previously because the number of sulfur grades is growing and the word descriptions were thought to be not precise. S5000 grades correspond to the so-called “regular” sulfur grades, the previous No. 1-D and No. 2-D. S500 grades correspond to the previous “Low Sulfur” grades. S15 grades were not in the previous grade system and are commonly referred to as “Ultra-Low Sulfur” grades or ULSD.

1.2 This specification, unless otherwise provided by agreement between the purchaser and the supplier, prescribes the required properties of diesel fuels at the time and place of delivery.

1.2.1 Nothing in this specification shall preclude observance of federal, state, or local regulations which can be more restrictive.

Note 3: The generation and dissipation of static electricity can create problems in the handling of distillate diesel fuels. For more information on the subject, see Guide D4865.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification29 pagesEnglish languagesale 15% off

- Technical specification29 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the material, manufacturing, and specialized property requirements for producing special-purpose aviation distillate test fuels that are intended only for engineering and certification testing of aircraft, engines, and aircraft equipment. It deals with special-purpose test fuels that may be used to evaluate the operability, performance and durability of aviation compression-ignition engines when operating with fuels of marginal performance. Aviation distillate fuel, except as otherwise specified in this specification, shall consist predominantly of refined hydrocarbons derived from conventional sources such as crude oil, natural gas liquid condensates, heavy oil, shale oil, and oil sands. The use of middle distillate fuel blends containing components from other sources is permitted. This specification also lists acceptable additives for aviation distillate special-purpose test fuels. Use of this specification for engineering and certification testing of aircraft is not mandatory. It is directed at civil applications, and maintained as such, but may be adopted for military, government, or other specialized uses.

SCOPE

1.1 This specification is intended to support purchasing agencies when formulating specifications for purchases of aviation distillate fuel under contract.

1.2 This specification defines specialized property requirements to produce special-purpose aviation distillate test fuels that are intended only for engineering and certification testing of aircraft, engines, and aircraft equipment. Use of this specification for engineering and certification testing of aircraft is not mandatory. Its use is at the discretion of the aircraft manufacturer, engine manufacturer, or certification authorities when determining criteria for validation of aircraft equipment design.

1.3 This specification defines special-purpose test fuels that may be used to evaluate the operability, performance and durability of aviation compression-ignition engines when operating with fuels of marginal performance. The aviation distillate test fuels defined in this specification are not intended for general purpose use in aircraft. This specification also lists acceptable additives for aviation distillate special-purpose test fuels.

1.4 Specification D8147 is directed at civil applications, and maintained as such, but may be adopted for military, government, or other specialized uses.

1.5 This specification can be used as a standard in describing the quality of aviation distillate fuel from production to the aircraft. However, this specification does not define the quality assurance testing and procedures necessary to ensure that fuel continues to comply with this specification after batch certification.

1.6 This specification does not include all fuels satisfactory for aviation compression-ignition (CI) engines.

1.7 The values stated in SI units are to be regarded as standard.

1.7.1 Exception—Other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Sulfur present as mercaptans or as hydrogen sulfide in distillate fuels and solvents can attack many metallic and non-metallic materials in fuel and other distribution systems. A negative result in the doctor test ensures that the concentration of these compounds is insufficient to cause such problems in normal use.

SCOPE

1.1 This test method covers and is intended primarily for the detection of mercaptans in motor fuel, kerosine, and similar petroleum products. This method may also provide information on hydrogen sulfide and elemental sulfur that may be present in these sample types.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.3.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is intended to provide a tool for assessing whether fuel storage and distribution facilities, or end user fuel tanks, are subject to microbial growth, and to alert fuel suppliers or users to the potential for fuel quality or operational problems or the requirement for preventative or remedial measures, or both.

5.2 This test method allows assessment of whether antigens generated by microbial activity in the specimens are present within specific defined ranges.

5.3 This test method measures the presence of microbial and metabolite antigens in a specimen. The antigens are generated from the living cells and metabolites created by fungi and bacteria during growth on fuel. Consequently, the presence of antigens is an indicator of microbial contamination in fuel systems. Antigens are not associated with matter of nonbiological origin.

5.3.1 Some of the antigens detected by this test method can persist after treatment with a biocide. See 11.4.

5.4 This test method is semi-quantitative and can be used to determine whether contamination in samples drawn from fuel tanks and systems is negligible or present at moderate or heavy levels.

5.4.1 Further information on using the test to assess biodeterioration risk is provided in Appendix X1.

5.5 The significance of these levels to the operator will depend on the fuel type, the sampling location, the equipment or facility sampled, and the specific operating circumstances.

5.6 Further guidance on interpretation of test results can be found in Guide D6469, in Energy Institute guidelines for the investigation of the microbial content of petroleum fuels, and in the IATA Guidance Material on Microbial Contamination in Aircraft Fuel Tanks.

5.7 Further guidance on sampling can be found in Practice D7464.

5.8 Testing can be conducted on a routine basis or to investigate incidents.

5.9 Microbiological tests are not intended to be used to determine compliance with fuel specifications or lim...

SCOPE

1.1 This test method describes a procedure that can be used in the field or in a laboratory to detect antigens indicative of microbial contamination in liquid fuels, including those blended with synthesized hydrocarbons or biofuels, with kinematic viscosities (at 40 °C) of ≤24 mm2s–1 (for example, Specifications D396, D975, and D1655) and in fuel-associated water.

1.1.1 This test method has been validated by an ILS for a range of middle distillate fuels meeting Specification D1655, EN590, Specification D975, and ISO 8217:2012.

1.2 This test method semi-quantitatively assesses the concentration of specific antigens generated by commonly recovered, fuel-associated, aerobic microorganisms during active growth in fuel systems.

1.2.1 A proprietary formulation of antibodies and antibody mixtures is used to detect three types of microbial antigen contamination: antigens generally found in aerobic bacteria, antigens generally present in common fungi (yeast and molds), and an antigen that is characteristic of Hormoconis resinae (the fungus most commonly associated with fuel biodeterioration).

1.2.2 Although the antibodies and antibody mixtures are characteristic of diverse types of bacteria and fungi, it is unlikely that they are universal. Recognizing that for every microbe that has been isolated and characterized, it is likely that there are a billion that have not. Consequently, as is the case with all microbiological test methods, this test method does not purport to detect 100 % of the microbes present in a fuel or fuel-associated water sample.

1.3 For each of the three sets of antigen detected (H. resinae, common fungi, and aerobic bacteria), the test detects whether the antigen concentration present is within set ranges representing negligible, moderate, or heavy microbial contamination.

1.3.1 For fuel specimens, the antigen concentration ranges detected are 750 µg/L (heavy).

1.3.2 For specimens of wat...

- Standard17 pagesEnglish languagesale 15% off

- Standard17 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers purchases of aviation turbine fuel under contract and is intended primarily for use by purchasing agencies. This specification does not include all fuels satisfactory for reciprocating aviation turbine engines, but rather, defines the following specific types of aviation fuel for civil use: Jet A; and Jet A-1. The fuels shall be sampled and tested appropriately to examine their conformance to detailed requirements as to composition, volatility, fluidity, combustion, corrosion, thermal stability, contaminants, and additives.

SCOPE

1.1 This specification covers the use of purchasing agencies in formulating specifications for purchases of aviation turbine fuel under contract.

1.2 This specification defines the minimum property requirements for Jet A and Jet A-1 aviation turbine fuel and lists acceptable additives for use in civil and military operated engines and aircraft. Specification D1655 was developed initially for civil applications, but has also been adopted for military aircraft. Guidance information regarding the use of Jet A and Jet A-1 in specialized applications is available in the appendix.

1.3 This specification can be used as a standard in describing the quality of aviation turbine fuel from production to the aircraft. However, this specification does not define the quality assurance testing and procedures necessary to ensure that fuel in the distribution system continues to comply with this specification after batch certification. Such procedures are defined elsewhere, for example in ICAO 9977, EI/JIG Standard 1530, JIG 1, JIG 2, API 1543, API 1595, and ATA-103.

1.4 This specification does not include all fuels satisfactory for aviation turbine engines. Certain equipment or conditions of use may permit a wider, or require a narrower, range of characteristics than is shown by this specification.

1.5 Aviation turbine fuels defined by this specification may be used in other than turbine engines that are specifically designed and certified for this fuel.

1.6 This specification no longer includes wide-cut aviation turbine fuel (Jet B). FAA has issued a Special Airworthiness Information Bulletin which now approves the use of Specification D6615 to replace Specification D1655 as the specification for Jet B and refers users to this standard for reference.

1.7 The values stated in SI units are to be regarded as standard. However, other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification23 pagesEnglish languagesale 15% off

- Technical specification23 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers Grade 82 unleaded aviation gasoline for use only in engines and associated aircraft that are specifically approved by the engine and aircraft manufacturers, and certified by the National Certifying Agencies to use this fuel. Aviation gasoline shall consist of blends of refined hydrocarbons derived from crude petroleum, natural gasoline or blends thereof, with specific aliphatic ethers, synthetic hydrocarbons, or aromatic hydrocarbons, and when applicable, methyl tertiarybutyl ether (MTBE). They may also contain antioxidants (oxidation inhibitors), metal deactivators, corrosion inhibitors, and fuel system icing inhibitors. The gasoline shall be tested and conform accordingly to the following property requirements: lean mixture knock value and motor method octane number; color; blue and red dye content; distillation temperature at % evaporated, end point, and residue content; distillation recovery; distillation loss; net heat of combustion; freezing point; vapor pressure; lead content; copper strip corrosion; sulfur content; potential gum; and alcohols and ether content (aliphatic ethers, methanol, and ethanol).

SCOPE

1.1 This specification covers Grades UL82 and UL87 unleaded aviation gasolines, which are defined by this specification and are only for use in engines and associated aircraft that are specifically approved by the engine and aircraft manufacturers, and certified by the National Certifying Agencies to use these fuels. Components containing hetro-atoms (oxygenates) may be present within the limits specified.

1.2 A fuel may be certified to meet this specification by a producer as Grade UL82 or UL87 aviation gasoline only if blended from component(s) approved for use in these grades of aviation gasoline by the refiner(s) of such components, because only the refiner(s) can attest to the component source and processing, absence of contamination, and the additives used and their concentrations. Consequently, reclassifying of any other product to Grade UL82 or Grade UL87 aviation gasoline does not meet this specification.

1.3 Appendix X1 contains an explanation for the rationale of the specification. Appendix X2 details the reasons for the individual specification requirements.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This guide is intended for the developers or sponsors of new aviation gasolines or additives to describe the data requirements necessary to support the development of specifications for these new products by ASTM members. The ultimate goal of the data generated in accordance with this guide is to provide an understanding of the performance of the new fuel or additive within the property constraints and compositional bounds of the proposed specification criteria.

5.2 This guide is not an approval process. It is intended to describe test and analysis requirements necessary to generate data to support specification development. This guide does not address the approval process for ASTM International standards.

5.3 This guide will reduce the uncertainty and risk to developers or sponsors of new aviation gasolines or additives by describing the test and analysis requirements necessary to proceed with the development of an ASTM International specification for aviation gasoline or specification revision for an aviation gasoline additive. There are certain sections within this guide that do not specify an exact number of data points required. For example, 6.2.4.3 requires viscosity to be measured from freezing point to room temperature; 6.2.4.4, 6.2.4.5, and 6.3.2.3 require measurements over the operating temperature range; 6.3.2.4 and 6.3.2.5 require measurements versus temperature. In these cases, the developers or sponsors of new aviation gasolines or additives should attempt to generate data close to the upper and lower boundaries indicated. If no boundary is specified (for example, generate data versus temperature), then data at the widest practical test limits should be generated. A minimum of three data points is required in all cases (for example, upper, middle, lower), while five or more data points are preferred.

5.4 This guide does not purport to specify an all-inclusive listing of test and analysis requirements to achieve ASTM International approval ...

SCOPE

1.1 This guide provides procedures to develop data for use in research reports for new aviation gasolines or new aviation gasoline additives.

1.2 This data is intended to be used by the ASTM subcommittee to make a determination of the suitability of the fuel for use as an aviation fuel in either a fleet-wide or limited capacity, and to make a determination that the proposed properties and criteria in the associated standard specification provide the necessary controls to ensure this fuel maintains this suitability during high-volume production.

1.3 These research reports are intended to support the development and issuance of new specifications or specification revisions for these products. Guidance to develop ASTM International standard specifications for aviation gasoline is provided in Subcommittee J on Aviation Fuels Operating Procedures, Annex A6, “Guidelines for the Development and Acceptance of a New Aviation Fuel Specification for Spark-Ignition Reciprocating Engines.”

1.4 The procedures, tests, selection of materials, engines, and aircraft detailed in this guide are based on industry expertise to give appropriate data for review. Because of the diversity of aviation hardware and potential variation in fuel/additive formulations, not every aspect may be encompassed and further work may be required. Therefore, additional data beyond that described in this guide may be requested by the ASTM task force, Subcommittee J, or Committee D02 upon review of the specific composition, performance, or other characteristics of the candidate fuel or additive.

1.5 While it is beyond the scope of this guide, investigation of the future health and environmental impacts of the new aviation gasoline or new aviation gasoline additive and the requirements of environmental agencies is recommended.

1.6 The values stated in SI units are to be regarded as standard.

1.6.1 Exception—Some industry standard methodologies uti...

- Guide27 pagesEnglish languagesale 15% off

- Guide27 pagesEnglish languagesale 15% off

ABSTRACT

This specification details the physical and chemical requirements for pyrolysis liquid biofuels produced from biomass that are intended for use in industrial burners equipped to handle these types of fuels. The type of biofuel covered here is not intended for use in residential heaters, small commercial boilers, engines, or marine applications. It shall remain uniform in medium-term storage and shall not separate into layers due to gravity. Properly sampled test specimens shall undergo test procedures to determine their adherence to the following requirements: gross heat of combustion; water content; pyrolysis solids content; kinematic viscosity; density; sulfur content; ash content; pH; flash point; and pour point.

SCOPE

1.1 This specification covers grades of pyrolysis liquid biofuel produced from biomass intended for use in various types of fuel-burning equipment under various climatic and operating conditions. These grades are described as follows:

1.1.1 Grade G is intended for use in industrial burners equipped to handle the pyrolysis liquid biofuels meeting the requirements listed for Grade G in Table 1. The pyrolysis liquid biofuel listed under Grade G in Table 1 is not intended for use in residential heaters, small commercial boilers, engines, or marine applications.

1.1.2 Grade D is intended for use in commercial/industrial burners requiring lower solids and ash content and which are equipped to handle the pyrolysis liquid biofuels meeting the requirements listed for Grade D in Table 1. The pyrolysis liquid biofuel listed under Grade D in Table 1 is not intended for use in residential heaters, engines, or marine applications not modified to handle these types of fuels.

Note 1: For information on the significance of the physical, chemical, and performance properties identified in this specification, see Appendix X1.

1.2 This specification is for use in contracts for the purchase of pyrolysis liquid biofuel and for guidance of consumers of this type of fuel.

1.3 Nothing in this specification should preclude observance of national or local regulations, which may be more restrictive.

Note 2: The generation and dissipation of static electricity may create problems in the handling of pyrolysis liquid biofuel. For more information on the subject, see Guide D4865.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4.1 Exception—BTU units are included for information only in 3.2.3.1.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

- Technical specification5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Mercaptan sulfur has an objectionable odor, an adverse effect on fuel system elastomers, and is corrosive to fuel system components.

SCOPE

1.1 This test method covers the determination of mercaptan sulfur in gasolines, kerosines, aviation turbine fuels, and distillate fuels containing from 0.0003 % to 0.01 % by mass of mercaptan sulfur. Organic sulfur compounds such as sulfides, disulfides, and thiophene, do not interfere. Elemental sulfur in amounts less than 0.0005 % by mass does not interfere. Hydrogen sulfide will interfere if not removed, as described in 10.2.

1.2 The values in acceptable SI units are to be regarded as the standard.

1.2.1 Exception—The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Sections 7, 9, 10, and Appendix X1.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard8 pagesEnglish languagesale 15% off

- Standard8 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.