ASTM F1106-87(2012)

(Specification)Standard Specification for Warping Heads, Rope Handling (Gypsy Head, Capstan Head)

Standard Specification for Warping Heads, Rope Handling (Gypsy Head, Capstan Head)

ABSTRACT

This specification covers warping heads used with windlass, winch, and capstan drive units to pull rope on board ships. Warping heads are primarily for use with fiber rope, natural, or synthetic. Warping heads with external ribs or whelps on the barrel, notched flanges, attached storage drums, unfinished drums, or non heat-treated fabrications, are considered special. The size of the warping head shall be identified by the nominal barrel diameter measured at the smallest point of the barrel. These warping heads are furnished in two types: Type I is with a cylindrical barrel which is generally used in but not restricted to horizontal shaft applications and Type II is with a conical barrel which is mounted with the large end of the barrel toward the drive machinery. It is generally used in but not restricted to vertical shaft applications. On the other hand, the warping heads are divided into four grades according to composition: Grade 1 is fabricated from any combination of structural steel plate, pipe, tubing, or steel castings and joined by electric welding; Grade 2 is made from mild to medium strength steel; Grade 3 is fabricated from any combination of steel plate or steel castings and joined by electric welding; and Grade 4 is cast from high strength steel castings. Principal dimensions, tolerances, and strength requirements are discussed.

SCOPE

1.1 This specification covers warping heads used with windlass, winch, and capstan drive units to pull rope on board ships. Warping heads are primarily for use with fiber rope, natural, or synthetic.

1.2 Warping heads with external ribs or whelps on the barrel, notched flanges, attached storage drums, unfinished drums, or non heat-treated fabrications, are considered special and are permitted within the scope of this specification when fully described under special ordering information.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1106 −87 (Reapproved 2012) An American National Standard

Standard Specification for

Warping Heads, Rope Handling (Gypsy Head, Capstan

Head)

This standard is issued under the fixed designation F1106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 AWS Standard:

D 1.1 Structural Welding Code

1.1 This specification covers warping heads used with

windlass, winch, and capstan drive units to pull rope on board 2.3 ANSI Standard:

ships. Warping heads are primarily for use with fiber rope, ASA B 46.1 Surface Texture

natural, or synthetic.

2.4 Military Standards:

1.2 Warping heads with external ribs or whelps on the Fed-Spec T-R-605 Manila, Three Strand

MIL-R-24050 Nylon, Double Braided

barrel, notched flanges, attached storage drums, unfinished

drums, or non heat-treated fabrications, are considered special

3. Definitions of Terms Specific to This Standard

and are permitted within the scope of this specification when

fully described under special ordering information.

3.1 barrel—cylindrical or conical midbody portion of a

warping head.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for 3.1.1 Discussion—The barrel may have a uniform diameter

throughthelengthormaybetaperedfromoneendtotheother.

information only.

3.2 flanges—circumferential rims at the ends of the barrel

2. Referenced Documents

used to retain wraps of rope on the barrel portion of the

2.1 ASTM Standards:

warping head.

A27/A27M Specification for Steel Castings, Carbon, for

3.3 rope contact surfaces—portions of the barrel, flanges,

General Application

and connecting fillets that a rope will contact when led in

A36/A36M Specification for Carbon Structural Steel

tangent to the barrel and normal to the shaft centerline,

A53/A53M Specification for Pipe, Steel, Black and Hot-

wrapped around the barrel, and led away tangent to the barrel

Dipped, Zinc-Coated, Welded and Seamless

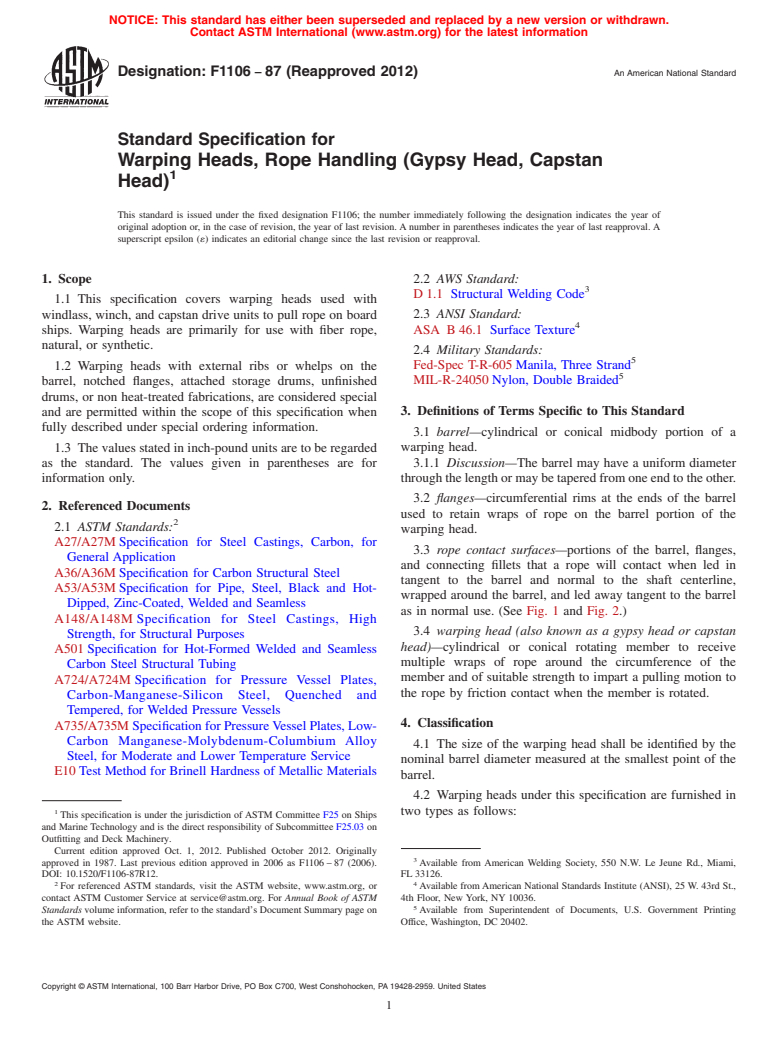

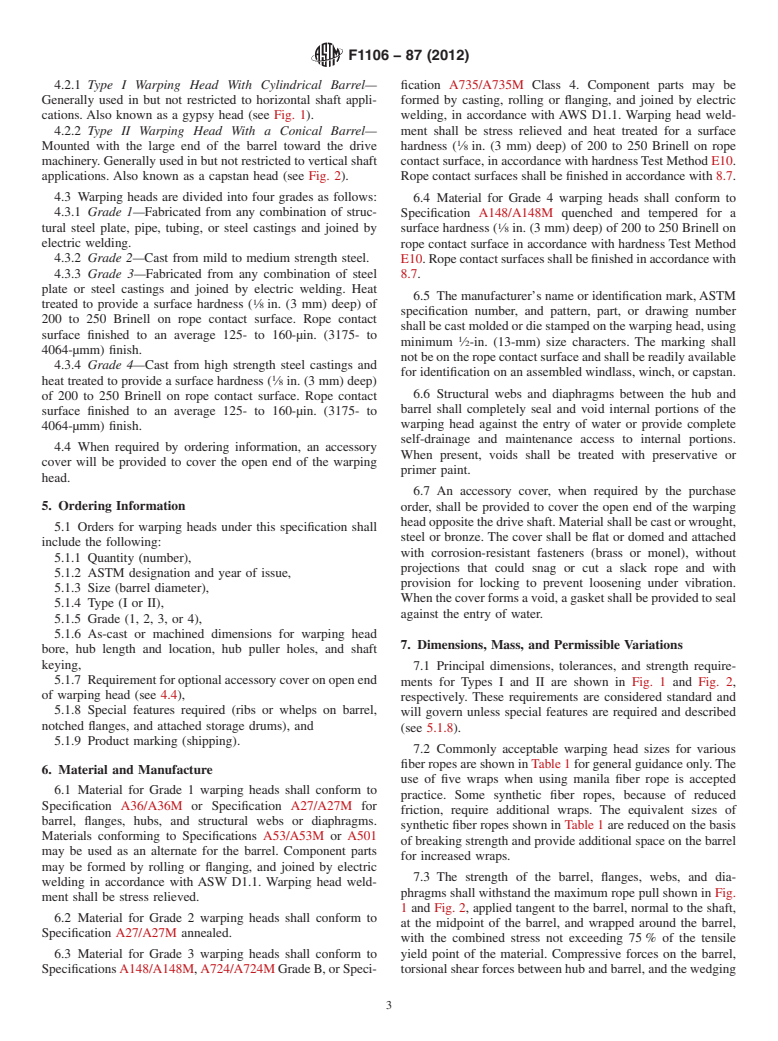

as in normal use. (See Fig. 1 and Fig. 2.)

A148/A148M Specification for Steel Castings, High

3.4 warping head (also known as a gypsy head or capstan

Strength, for Structural Purposes

head)—cylindrical or conical rotating member to receive

A501 Specification for Hot-Formed Welded and Seamless

multiple wraps of rope around the circumference of the

Carbon Steel Structural Tubing

member and of suitable strength to impart a pulling motion to

A724/A724M Specification for Pressure Vessel Plates,

the rope by friction contact when the member is rotated.

Carbon-Manganese-Silicon Steel, Quenched and

Tempered, for Welded Pressure Vessels

4. Classification

A735/A735M Specification for PressureVessel Plates, Low-

Carbon Manganese-Molybdenum-Columbium Alloy

4.1 The size of the warping head shall be identified by the

Steel, for Moderate and Lower Temperature Service

nominal barrel diameter measured at the smallest point of the

E10 Test Method for Brinell Hardness of Metallic Materials

barrel.

4.2 Warping heads under this specification are furnished in

1 two types as follows:

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery.

Current edition approved Oct. 1, 2012. Published October 2012. Originally

approved in 1987. Last previous edition approved in 2006 as F1106 – 87 (2006). Available from American Welding Society, 550 N.W. Le Jeune Rd., Miami,

DOI: 10.1520/F1106-87R12. FL 33126.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from Superintendent of Documents, U.S. Government Printing

the ASTM website. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1106−87 (2012)

A B C D E

A B

Rope Pull, 1000 lb Tolerance, in. ± Concentricity, in.

Diameter, in. Diameter, in. Diameter, in. Length, in. Length, in.

1 3 15 1 1

6 12.5 8 9 ⁄16 2 ⁄4 5 ⁄32 ⁄4 ⁄8

5 1 3

9 25.0 12 13 ⁄8 4 ⁄16 8 ⁄16

3 3

⁄8 ⁄16

J J

3 7 31

12 37.5 16 18 ⁄16 5 ⁄16 10 ⁄32

3 3 11

15 50.0 20 22 ⁄4 6 ⁄4 13 ⁄16

1 1

⁄2 ⁄4

J J

5 1 13

18 75.0 24 27 ⁄16 8 ⁄16 16 ⁄32

7 7 3

21 100.0 28 31 ⁄8 9 ⁄16 19 ⁄16

5 5

⁄8 ⁄16

J J

3 13 7

24 125.0 32 36 ⁄8 10 ⁄16 21 ⁄8

15 3 31

27 150.0 36 41 ⁄16 12 ⁄16 24 ⁄32

3 3

⁄4 ⁄8

J J

1 1 3

30 175.0 40 45 ⁄2 13 ⁄2 27 ⁄8

1 13 3

33 200.0 44 50 ⁄16 14 ⁄16 30 ⁄32

7 7

⁄8 ⁄16

J J

5 3 7

36 225.0 48 54 ⁄8 16 ⁄16 32 ⁄8

A

Tolerance for dimensions A, B, C, D, and E.

B

Concentricity of rope contact surface and flanges relative to bore.

NOTE 1—1 in. = 25.4 mm.

FIG. 1Type I Warping Head

A B C D E

A B

Rope Pull, 1000 lb Tolerance, in. ± Concentricity, in.

Diameter, in. Diameter, in. Diameter, in. Length, in. Length, in.

1 3 15 1 1

6 12.5 8 9 ⁄4 2 ⁄4 5 ⁄32 ⁄4 ⁄8

15 1 3

9 25.0 12 13 ⁄16 4 ⁄16 8 ⁄16

3 3

⁄8 ⁄16

J J

5 7 31

12 37.5 16 18 ⁄8 5 ⁄16 10 ⁄32

1 3 11

15 50.0 20 23 ⁄4 6 ⁄4 13 ⁄16

1 1

⁄2 ⁄4

J J

7 1 13

18 75.0 24 27 ⁄8 8 ⁄16 16 ⁄32

9 7 3

21 100.0 28 32 ⁄16 9 ⁄16 19 ⁄16

5 5

⁄8 ⁄16

J J

3 13 7

24 125.0 32 37 ⁄16 10 ⁄16 21 ⁄8

7 3 31

27 150.0 36 41 ⁄8 12 ⁄16 24 ⁄32

3 3

⁄4 ⁄8

J J

1 1 3

30 175.0 40 46 ⁄2 13 ⁄2 27 ⁄8

1 13 3

33 200.0 44 51 ⁄8 14 ⁄16 30 ⁄32

7 7

⁄8 ⁄16

J J

13 3 7

36 225.0 48 55 ⁄16 16 ⁄16 32 ⁄8

A

Tolerance for dimensions A, B, C, D, and E.

B

Concentricity of rope contact surface and flanges relative to bore.

NOTE 1—1 in. = 25.4 mm.

FIG. 2Type II Warping Head

F1106−87 (2012)

4.2.1 Type I Warping Head With Cylindrical Barrel— fication A735/A735M Class 4. Component parts may be

Generally used in but not restricted to horizontal shaft appli- formed by casting, rolling or flanging, and joined by electric

cations. Also known as a gypsy head (see Fig. 1). welding, in accordance with AWS D1.1. Warping head weld-

4.2.2 Type II Warping Head With a Conical Barrel— ment shall be stress relieved and heat treated for a surface

Mounted with the large end of the barrel toward the drive hardness ( ⁄8 in. (3 mm) deep) of 200 to 250 Brinell on rope

machinery. Generally used in but not restricted to vertical shaft contact surface, in accordance with hardnessTest Method E10.

applications. Also known as a capstan head (see Fig. 2). Rope contact surfaces shall be finished in accordance with 8.7.

4.3 Warping heads are divided into four grades as follows: 6.4 Material for Grade 4 warping heads shall conform to

4.3.1 Grade 1—Fabricated from any combination of struc-

Specification A148/A148M quenched and tempered for a

tural steel plate, pipe, tubing, or steel castings and joined by surface hardness ( ⁄8 in. (3 mm) deep) of 200 to 250 Brinell on

electric welding.

rope contact surface in accordance with hardness Test Method

4.3.2 Grade 2—Cast from mild to medium strength steel. E10.Ropecontactsurfacesshallbefinishedinaccordancewith

4.3.3 Grade 3—Fabricated from any combination of steel

8.7.

plate or steel castings and joined by electric welding. Heat

6.5 The manufacturer’s name or identification mark,ASTM

treated to provide a surface hardness ( ⁄8 in. (3 mm) deep) of

specification number, and pattern, part, or drawing number

200 to 250 Brinell on rope contact surface. Rope contact

shallbecastmoldedordiestampedonthewarpinghead,using

surface finished to an average 125- to 160-µin. (3175- to

minimum ⁄2-in. (13-mm) size characters. The marking shall

4064-µmm) finish.

notbeontheropecontactsurfaceandshallbereadilyavailable

4.3.4 Grade 4—Cast from high strength steel castings and

for identification on an assembled windlass, winch, or capstan.

heat treated to provide a surface hardness ( ⁄8 in. (3 mm) deep)

6.6 Structural webs and diaphragms between the hub and

of 200 to 250 Br

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.