ASTM B438/B438M-00

(Specification)Standard Specification for Sintered Bronze Bearings (Oil-Impregnated)

Standard Specification for Sintered Bronze Bearings (Oil-Impregnated)

SCOPE

1.1 This specification covers sintered bronze, oil-impregnated bearings made primarily from elemental copper, tin, and graphite powders. The manufacturer may, at his discretion, use prealloyed bronze powder in the blend.

1.2 This specification covers the following variables:

1.2.1 Grades--Available in three bronze base composition grades identifiable by different graphite contents.

1.2.2 Type--Grades 1 and 2 are available in four types described by specific density ranges.

1.3 Bearings ordered to this specification will normally be sized after sintering and will be impregnated with a lubricating oil unless otherwise specified by print.

1.4 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 438/B 438M – 00

Standard Specification for

1

Sintered Bronze Bearings (Oil-Impregnated)

This standard is issued under the fixed designation B 438/B 438M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

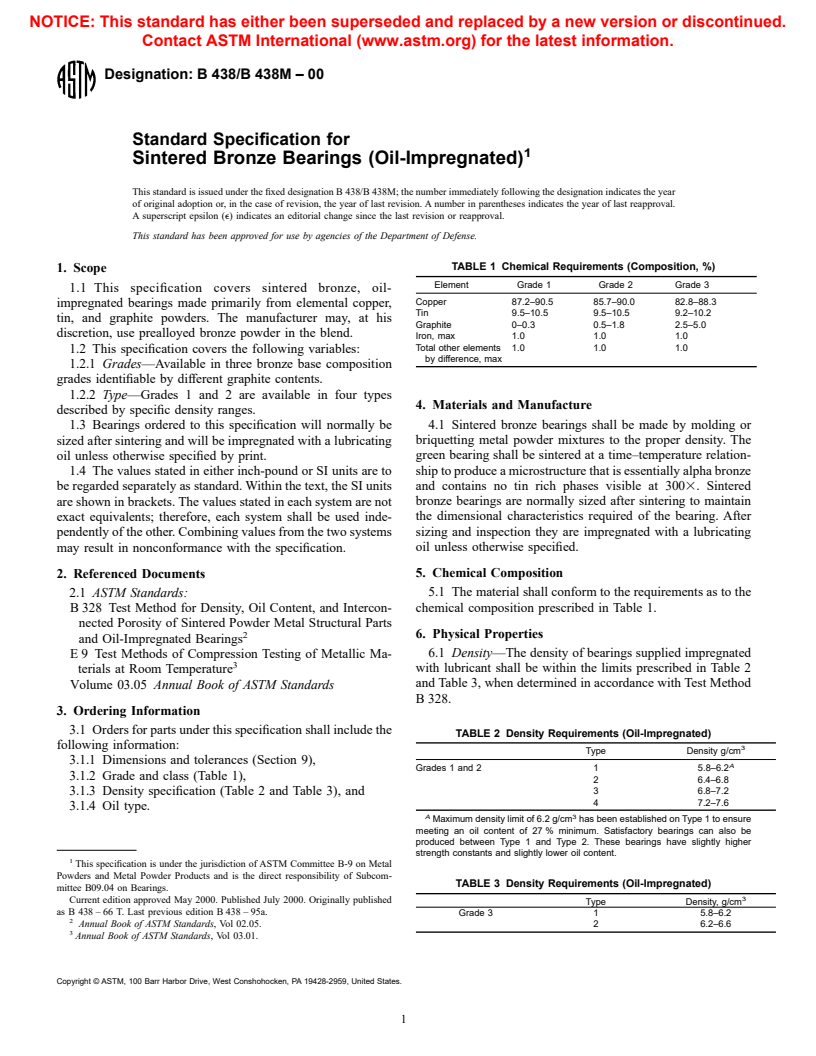

TABLE 1 Chemical Requirements (Composition, %)

1. Scope

Element Grade 1 Grade 2 Grade 3

1.1 This specification covers sintered bronze, oil-

Copper 87.2–90.5 85.7–90.0 82.8–88.3

impregnated bearings made primarily from elemental copper,

Tin 9.5–10.5 9.5–10.5 9.2–10.2

tin, and graphite powders. The manufacturer may, at his

Graphite 0–0.3 0.5–1.8 2.5–5.0

discretion, use prealloyed bronze powder in the blend.

Iron, max 1.0 1.0 1.0

Total other elements 1.0 1.0 1.0

1.2 This specification covers the following variables:

by difference, max

1.2.1 Grades—Available in three bronze base composition

grades identifiable by different graphite contents.

1.2.2 Type—Grades 1 and 2 are available in four types

4. Materials and Manufacture

described by specific density ranges.

1.3 Bearings ordered to this specification will normally be 4.1 Sintered bronze bearings shall be made by molding or

briquetting metal powder mixtures to the proper density. The

sized after sintering and will be impregnated with a lubricating

oil unless otherwise specified by print. green bearing shall be sintered at a time–temperature relation-

ship to produce a microstructure that is essentially alpha bronze

1.4 The values stated in either inch-pound or SI units are to

be regarded separately as standard. Within the text, the SI units and contains no tin rich phases visible at 3003. Sintered

bronze bearings are normally sized after sintering to maintain

are shown in brackets. The values stated in each system are not

exact equivalents; therefore, each system shall be used inde- the dimensional characteristics required of the bearing. After

sizing and inspection they are impregnated with a lubricating

pendently of the other. Combining values from the two systems

may result in nonconformance with the specification. oil unless otherwise specified.

5. Chemical Composition

2. Referenced Documents

2.1 ASTM Standards: 5.1 The material shall conform to the requirements as to the

chemical composition prescribed in Table 1.

B 328 Test Method for Density, Oil Content, and Intercon-

nected Porosity of Sintered Powder Metal Structural Parts

2 6. Physical Properties

and Oil-Impregnated Bearings

6.1 Density—The density of bearings supplied impregnated

E 9 Test Methods of Compression Testing of Metallic Ma-

3

with lubricant shall be within the limits prescribed in Table 2

terials at Room Temperature

and Table 3, when determined in accordance with Test Method

Volume 03.05 Annual Book of ASTM Standards

B 328.

3. Ordering Information

3.1 Orders for parts under this specification shall include the

TABLE 2 Density Requirements (Oil-Impregnated)

following information:

3

Type Density g/cm

3.1.1 Dimensions and tolerances (Section 9),

A

Grades 1 and 2 1 5.8–6.2

3.1.2 Grade and class (Table 1),

2 6.4–6.8

3 6.8–7.2

3.1.3 Density specification (Table 2 and Table 3), and

4 7.2–7.6

3.1.4 Oil type.

A 3

Maximum density limit of 6.2 g/cm has been established on Type 1 to ensure

meeting an oil content of 27 % minimum. Satisfactory bearings can also be

produced between Type 1 and Type 2. These bearings have slightly higher

strength constants and slightly lower oil content.

1

This specification is under the jurisdiction of ASTM Committee B-9 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

TABLE 3 Density Requirements (Oil-Impregnated)

mittee B09.04 on Bearings.

3

Current edition approved May 2000. Published July 2000. Originally published

Type Density, g/cm

as B 438 – 66 T. Last previous edition B 438 – 95a.

Grade 3 1 5.8–6.2

2

Annual Book of ASTM Standards, Vol 02.05. 2 6.2–6.6

3

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 438/B 438M

A

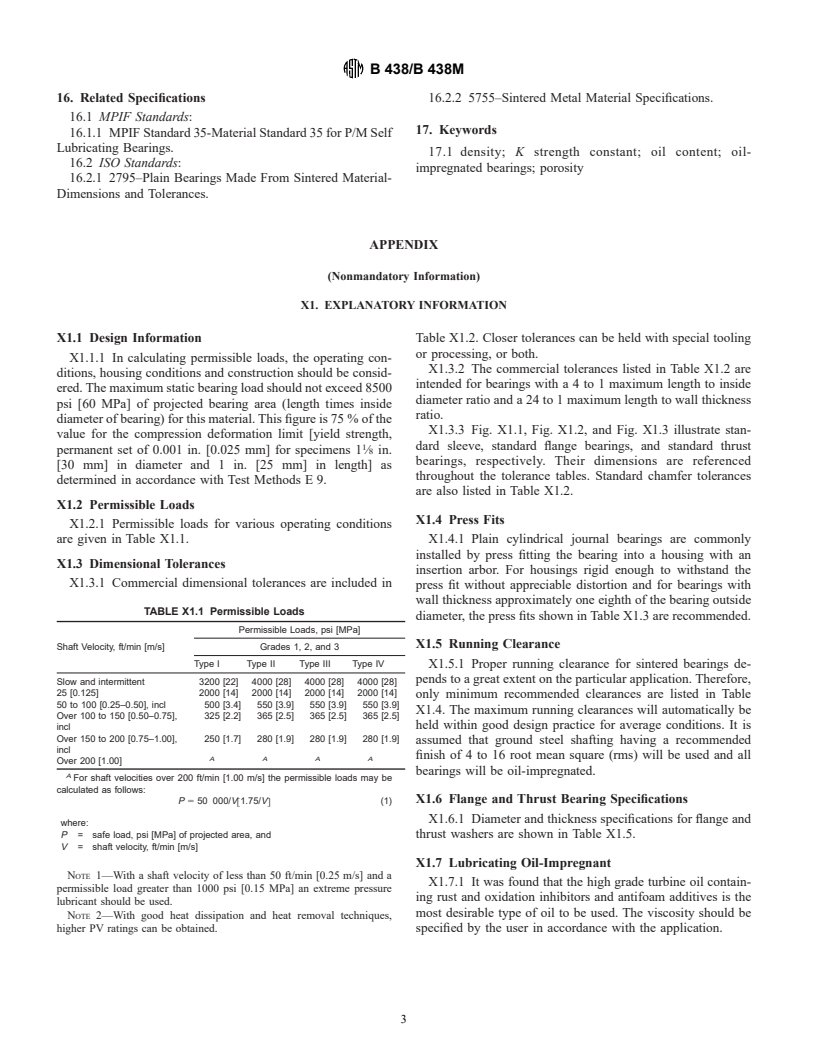

TABLE 5 Strength Constant K (Strength Constants, Min) , psi

6.2 Oil Content—Oil content of bearings shall not be less

[MPa]

than shown in Table 4 for each grade and type when deter-

Type Grade 1 Grade 2 Grade 3

mined in accordance with Test Method B 328.

1 15 000 [105] 13 000 [90] 10 000 [70]

2 26 000 [180] 23 000 [160] 15 000 [105]

7. Mechanical Properties

3 37 000 [255] 30 000 [205] . [.]

7.1 The manufacturer and purchaser shall agree on a repre-

4 40 000 [275] 34 000 [235

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.