ASTM C470/C470M-02a

(Specification)Standard Specification for Molds for Forming Concrete Test Cylinders Vertically

Standard Specification for Molds for Forming Concrete Test Cylinders Vertically

SCOPE

1.1 This specification covers molds for use in forming cylindrical concrete specimens. The provisions of this specification include the requirements for both reusable and single-use molds.

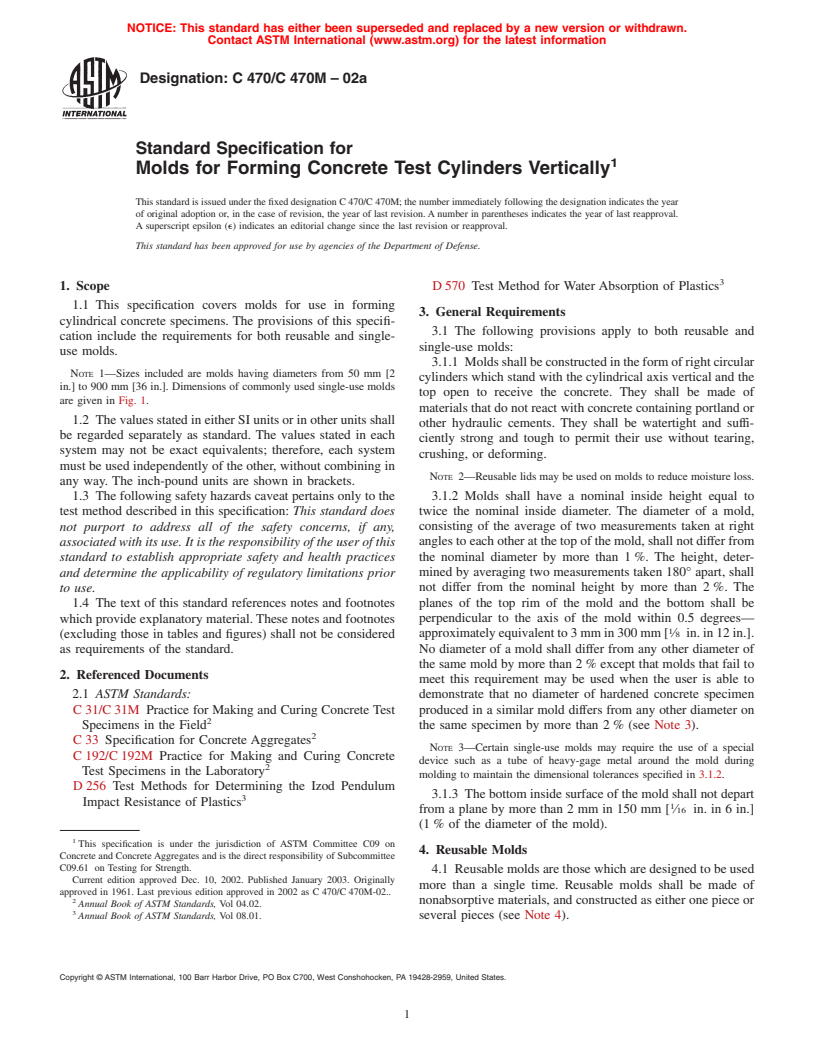

Note 1—Sizes included are molds having diameters from 50 mm [2 in.] to 900 mm [36 in.]. Dimensions of commonly used single-use molds are given in Fig 1.

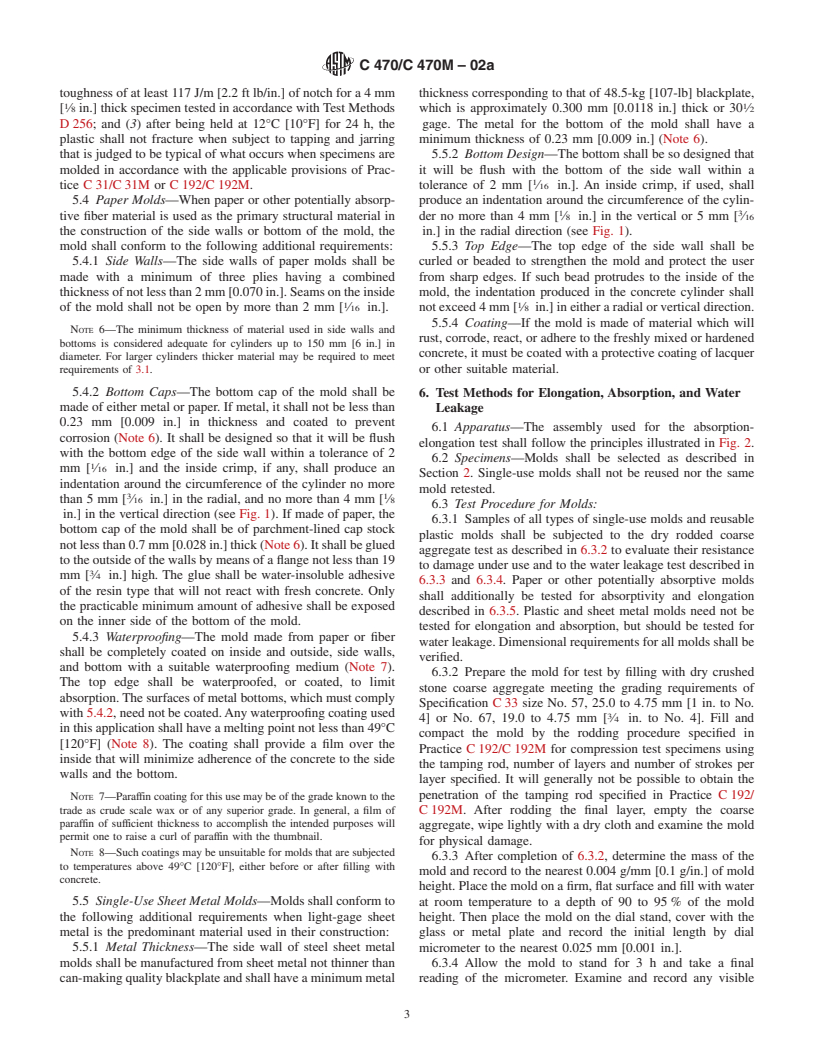

1.2 The values stated in either SI units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way. The inch-pound units are shown in brackets.

1.3 The following safety hazards caveat pertains only to the test method described in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 470/C 470M – 02a

Standard Specification for

1

Molds for Forming Concrete Test Cylinders Vertically

This standard is issued under the fixed designation C 470/C 470M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope D 570 Test Method for Water Absorption of Plastics

1.1 This specification covers molds for use in forming

3. General Requirements

cylindrical concrete specimens. The provisions of this specifi-

3.1 The following provisions apply to both reusable and

cation include the requirements for both reusable and single-

single-use molds:

use molds.

3.1.1 Moldsshallbeconstructedintheformofrightcircular

NOTE 1—Sizes included are molds having diameters from 50 mm [2

cylinders which stand with the cylindrical axis vertical and the

in.] to 900 mm [36 in.]. Dimensions of commonly used single-use molds

top open to receive the concrete. They shall be made of

are given in Fig. 1.

materials that do not react with concrete containing portland or

1.2 The values stated in either SI units or in other units shall

other hydraulic cements. They shall be watertight and suffi-

be regarded separately as standard. The values stated in each

ciently strong and tough to permit their use without tearing,

system may not be exact equivalents; therefore, each system

crushing, or deforming.

must be used independently of the other, without combining in

NOTE 2—Reusable lids may be used on molds to reduce moisture loss.

any way. The inch-pound units are shown in brackets.

3.1.2 Molds shall have a nominal inside height equal to

1.3 The following safety hazards caveat pertains only to the

test method described in this specification: This standard does twice the nominal inside diameter. The diameter of a mold,

consisting of the average of two measurements taken at right

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this angles to each other at the top of the mold, shall not differ from

the nominal diameter by more than 1 %. The height, deter-

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior mined by averaging two measurements taken 180° apart, shall

to use. not differ from the nominal height by more than 2 %. The

planes of the top rim of the mold and the bottom shall be

1.4 The text of this standard references notes and footnotes

which provide explanatory material. These notes and footnotes perpendicular to the axis of the mold within 0.5 degrees—

1

approximately equivalent to 3 mmin 300 mm [ ⁄8 in.in12in.].

(excluding those in tables and figures) shall not be considered

as requirements of the standard. No diameter of a mold shall differ from any other diameter of

the same mold by more than 2 % except that molds that fail to

2. Referenced Documents

meet this requirement may be used when the user is able to

2.1 ASTM Standards: demonstrate that no diameter of hardened concrete specimen

C 31/C 31M Practice for Making and Curing Concrete Test produced in a similar mold differs from any other diameter on

2

Specimens in the Field the same specimen by more than 2 % (see Note 3).

2

C33 Specification for Concrete Aggregates

NOTE 3—Certain single-use molds may require the use of a special

C 192/C 192M Practice for Making and Curing Concrete

device such as a tube of heavy-gage metal around the mold during

2

Test Specimens in the Laboratory

molding to maintain the dimensional tolerances specified in 3.1.2.

D 256 Test Methods for Determining the Izod Pendulum

3.1.3 The bottom inside surface of the mold shall not depart

3

Impact Resistance of Plastics

1

from a plane by more than 2 mm in 150 mm [ ⁄16 in. in 6 in.]

(1 % of the diameter of the mold).

1

This specification is under the jurisdiction of ASTM Committee C09 on

4. Reusable Molds

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.61 on Testing for Strength.

4.1 Reusable molds are those which are designed to be used

Current edition approved Dec. 10, 2002. Published January 2003. Originally

more than a single time. Reusable molds shall be made of

approved in 1961. Last previous edition approved in 2002 as C 470/C 470M-02.

2 nonabsorptive materials, and constructed as either one piece or

Annual Book of ASTM Standards, Vol 04.02.

3

Annual Book of ASTM Standards, Vol 08.01. several pieces (see Note 4).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United St

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.