ASTM G140-02(2008)

(Test Method)Standard Test Method for Determining Atmospheric Chloride Deposition Rate by Wet Candle Method

Standard Test Method for Determining Atmospheric Chloride Deposition Rate by Wet Candle Method

SIGNIFICANCE AND USE

This test method is capable of generating quantitative values of atmospheric chloride deposition specifying milligrams of chloride ions per square metre per day (or other units derived from such values).

Note 1—Chlorides in the atmosphere exist as a suspension of liquid droplets or solid particles. They are transported to solid surfaces by gravity, wind, or brownian motions. These transport mechanisms are direction-sensitive so that a vertical cylinder will not necessarily receive the same flux as a horizontal plate, or objects with different sizes and orientations. Therefore, the use of this approach to provide an indication of the deposition of chlorides on objects in atmospheric exposures may not be quantitatively accurate; however, this technique has been successful in classifying the severity of exposure in a variety of marine locations.

The sites where samples are to be taken and the sampling time periods should be established. A continuous program of monthly or 30-day exposures is recommended for site characterization. Seasonal monitoring may be performed if there are specific periods of interest.

SCOPE

1.1 This test method covers a wet candle device and its use in measuring atmospheric chloride deposition (amount of chloride salts deposited from the atmosphere on a given area per unit time).

1.2 Data on atmospheric chloride deposition can be useful in classifying the corrosivity of a specific area, such as an atmospheric test site. Caution must be exercised, however, to take into consideration the season because airborne chlorides vary widely between seasons.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G140 − 02(Reapproved 2008)

Standard Test Method for

Determining Atmospheric Chloride Deposition Rate by Wet

Candle Method

This standard is issued under the fixed designation G140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope grams of chloride ions per square metre per day (or other units

derived from such values).

1.1 This test method covers a wet candle device and its use

in measuring atmospheric chloride deposition (amount of

NOTE 1—Chlorides in the atmosphere exist as a suspension of liquid

droplets or solid particles. They are transported to solid surfaces by

chloride salts deposited from the atmosphere on a given area

gravity, wind, or brownian motions. These transport mechanisms are

per unit time).

direction-sensitive so that a vertical cylinder will not necessarily receive

1.2 Data on atmospheric chloride deposition can be useful

the same flux as a horizontal plate, or objects with different sizes and

orientations. Therefore, the use of this approach to provide an indication

in classifying the corrosivity of a specific area, such as an

ofthedepositionofchloridesonobjectsinatmosphericexposuresmaynot

atmospheric test site. Caution must be exercised, however, to

be quantitatively accurate; however, this technique has been successful in

take into consideration the season because airborne chlorides

classifying the severity of exposure in a variety of marine locations.

vary widely between seasons.

3.2 The sites where samples are to be taken and the

1.3 This standard does not purport to address all of the

sampling time periods should be established. A continuous

safety concerns, if any, associated with its use. It is the

program of monthly or 30-day exposures is recommended for

responsibility of the user of this standard to establish appro-

sitecharacterization.Seasonalmonitoringmaybeperformedif

priate safety and health practices and determine the applica-

there are specific periods of interest.

bility of regulatory limitations prior to use.

4. Apparatus

2. Referenced Documents

4.1 Components—The components needed to construct one

2.1 ASTM Standards:

wet candle device are as follows:

D1193Specification for Reagent Water

4.1.1 Erlenmeyer Flask, narrow mouth, 500 mL, (glass or

D4458Test Method for Chloride Ions in Brackish Water,

polypropylene). Other size flasks may be used, but dimensions

Seawater, and Brines

in Fig. 1 will have to be adjusted accordingly.

G92Practice for Characterization ofAtmospheric Test Sites

NOTE 2—Polypropylene flasks are recommended during threat of

2.2 ISO Standard:

freezing weather.

ISO 9225Corrosion of Metals and Alloys. Aggressivity of

4.1.2 Glass Test Tube, general purpose, 16 by 150-mm

Atmospheres—Methods of Measurement of Pollution

length.

Data

4.1.3 SolidRubberorNeopreneStopper,No.7,diametertop

38 mm, bottom 30 mm.

3. Significance and Use

4.1.4 Cotton Bandage Gauze, strip, 50 mm wide and ap-

3.1 This test method is capable of generating quantitative

proximately 1500 mm long.

values of atmospheric chloride deposition specifying milli-

NOTE 3—The overall length of the gauze may vary with installation.

4.1.5 Type IV Reagent Water, 1 L, 200 mL CHOH

This test method is under the jurisdiction of ASTM Committee G01 on

(CH OH ) (glycerin) and 20 drops CH (CH ) COOH (oc-

2 2 3 2 6

Corrosion of Metals and is the direct responsibility of Subcommittee G01.04 on

tanoic acid) should be added to prevent freezing, if necessary

Atmospheric Corrosion.

(See Specification D1193).

Current edition approved May 1, 2008. Published May 2008. Originally

approved in 1996. Last previous edition approved in 2002 as G140–02. DOI:

4.1.6 Gloves, vinyl, one pair.

10.1520/G0140-02R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or NOTE4—Poly(vinylchloride)(PVC)isrecommended.Latexglovesare

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

not acceptable, as their chloride content is reported to be comparable to

Standards volume information, refer to the standard’s Document Summary page on

that of human hands.

the ASTM website.

4.2 SupportStand—Asuitablesupportstandshallbeerected

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. at the site where the atmosphere is to be sampled. A treated

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G140 − 02 (2008)

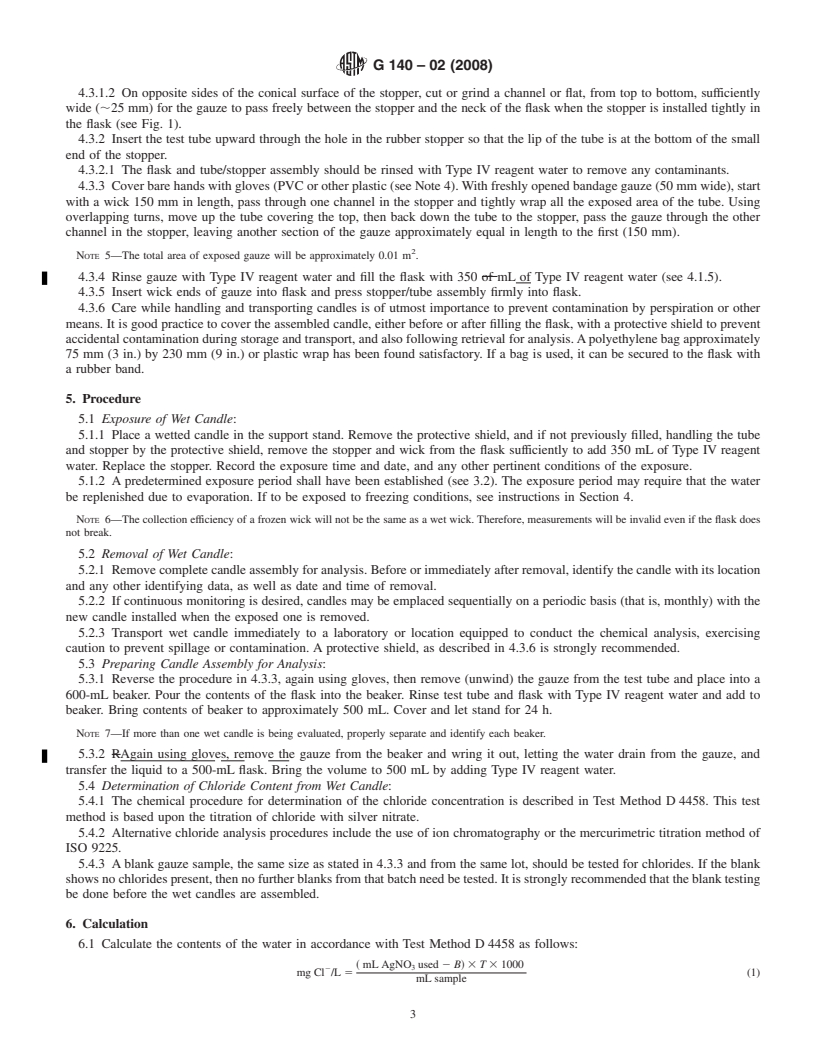

NOTE 1—Dimensions are in millimetres (mm).

FIG. 1 Wet Candle Chloride Apparatus

wood post (100 by 100 by 2250 mm) or galvanized pipe the tube. Using overlapping turns, move up the tube covering

(42-mm diameter by 2250-mm length) with an attached plate the top, then back down the tube to the stopper, pass the gauze

on top is suitable, with 750 mm in the ground and 1500 mm through the other channel in the stopper, leaving another

abovethegroundonwhichtheapparatustoholdthecandlecan section of the gauze approximately equal in length to the first

be mounted (see Fig. 1). The apparatus shall be mounted so (150 mm).

that the arms supporting the rain cover do not shield the gauze

NOTE 5—The total area of exposed gauze will be approximately 0.01

from a known source of chloride.

m .

4.3 Assembly of the Wet Candle Apparatus (see Fig. 1):

4.3.4 Rinse gauze with Type IV reagent water and fill the

4.3.1 The rubber stopper must be modified.

flask with 350 mL of Type IV reagent water (see 4.1.5).

4.3.1.1 Inthecenter,boreahole15mmindiameterthrough

4.3.5 Insert wick ends of gauze into flask and press stopper/

the stopper.

tube assembly firmly into flask.

4.3.1.2 On opposite sides of the conical surface of the

4.3.6 Care while handling and transporting candles is of

stopper, cut or grind a channel or flat, from top to bottom,

utmost importance to prevent contamination by perspiration or

sufficiently wide (;25 mm) for the gauze to pass freely

other means. It is good practice to cover the assembled candle,

between the stopper and the neck of the flask when the stopper

eitherbeforeorafterfillingtheflask,withaprotectiveshieldto

is installed tightly in the flask (see Fig. 1).

prevent accidental contamination during storage and transport,

4.3.2 Insert the test tube upward

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:G140–96 Designation:G140–02 (Reapproved 2008)

Standard Test Method for

Determining Atmospheric Chloride Deposition Rate by Wet

Candle Method

This standard is issued under the fixed designation G140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describescovers a wet candle device and its use in measuring atmospheric chloride deposition (amount of

chloride salts deposited from the atmosphere on a given area per unit time).

1.2 Data on atmospheric chloride deposition can be useful in classifying the corrosivity of a specific area, such as an

atmospheric test site. Caution must be exercised, however, to take into consideration the season because airborne chlorides vary

widely between seasons.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1129Terminology Relating to Water

D1193Specification for Reagent Water

D2777Practice for Determination of Precision and Bias of Applicable Test Methods of Committee D-19 on Water

D1193 Specification for Reagent Water

D4458 Test Method for Chloride Ions in Brackish Water, Seawater, and Brines

G92 Practice for Characterization of Atmospheric Test Sites

2.2 ISO Standard: ISO Standard:

ISO 9225 Corrosion of Metals and Alloys. Aggressivity of Atmospheres—Methods of Measurement of Pollution Data

3. Significance and Use

3.1 This test method is capable of generating quantitative values of atmospheric chloride deposition specifying milligrams of

chloride ions per square metre per day (or other units derived from such values).

NOTE 1—Chloridesintheatmosphereexistasasuspensionofliquiddropletsorsolidparticles.Theyaretransportedtosolidsurfacesbygravity,wind,

or brownian motions. These transport mechanisms are direction-sensitive so that a vertical cylinder will not necessarily receive the same flux as a

horizontalplate,orobjectswithdifferentsizesandorientations.Therefore,theuseofthisapproachtoprovideanindicationofthedepositionofchlorides

on objects in atmospheric exposures may not be quantitatively accurate; however, this technique has been successful in classifying the severity of

exposure in a variety of marine locations.

3.2 The sites where samples are to be taken and the sampling time periods should be established. A program of six 30-day

exposures per year for a period of three years is recommended. More extensive testing may be desirable if large variability is

encountered in the results. The sites where samples are to be taken and the sampling time periods should be established. A

continuous program of monthly or 30-day exposures is recommended for site characterization. Seasonal monitoring may be

performed if there are specific periods of interest.

This test method is under the jurisdiction of ASTM Committee G-1 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

Corrosion.

Current edition approved July 10, 1996. Published September 1996.

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

Corrosion.

Current edition approved May 1, 2008. Published May 2008. Originally approved in 1996. Last previous edition approved in 2002 as G140–02.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 03.02.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G140–02 (2008)

4. Apparatus

4.1 Components—The components needed to construct one wet candle device are as follows:

4.1.1 ErlenmeyerFlask,narrowmouth,500mL,(glassorpolypropylene).Othersizeflasksmaybeused,butdimensionsinFig.

1 will have to be adjusted accordingly.

NOTE 2—Polypropylene flasks are recommended during threat of freezing weather.

4.1.2 Glass Test Tube, general purpose, 16 by 150-mm length.

4.1.3 Solid Rubber or Neoprene Stopper , No. 7, diameter top 38 mm, bottom 30 mm.

4.1.4 Cotton Bandage Gauze, strip, 50 mm wide and approximately 1500 mm long.

NOTE 3—The overall length of the gauze may vary with installation.

4.1.5 Type IVReagent Water,1L,200mLCHOH(CH OH )(glycerin)and20dropsCH (CH ) COOH(octanoicacid)should

2 2 3 2 6

be added to prevent freezing, if necessary. COOH (octanoic acid) should be added to prevent freezing, if necessary (See

Specification D1193).

4.1.6 Gloves, vinyl, one pair.

NOTE 4—Poly(vinyl chloride) (PVC) is recommended. Latex gloves are not acceptable, as their chloride content is reported to be comparable to that

of human hands.

4.2 Support Stand—Asuitable support stand shall be erected at the site where the atmosphere is to be sampled.Atreated wood

post (100 by 100 by 2250 mm) or galvanized pipe (42-mm diameter by 2250-mm length) with an attached plate on top areis

suitable, with 750 mm in the ground and 1500 mm above the ground on which the apparatus to hold the candle can be mounted

(seeFig.1).Theapparatusshallbemountedsothatthearmssupportingtheraincoverdonotshieldthegauzefromaknownsource

of chloride.

4.3 Assembly of the Wet Candle Apparatus (see Fig. 1):

4.3.1 The rubber stopper must be modified.

4.3.1.1 In the center, bore a hole 15 mm in diameter through the stopper.

NOTE 1—Dimensions are in millimetres (mm).

FIG. 1 Wet Candle Chloride Apparatus

G140–02 (2008)

4.3.1.2 On opposite sides of the conical surface of the stopper, cut or grind a channel or flat, from top to bottom, sufficiently

wide (;25 mm) for the gauze to pass freely between the stopper and the neck of the flask when the stopper is installed tightly in

the flask (see Fig. 1).

4.3.2 Insert the test tube upward through the hole in the rubber stopper so that the lip of the tube is at the bottom of the small

end of the stopper.

4.3.2.1 The flask and tube/stopper assembly should be rinse

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.