ASTM D7499/D7499M-09(2023)

(Test Method)Standard Test Method for Measuring Geosynthetic-Soil Resilient Interface Shear Stiffness

Standard Test Method for Measuring Geosynthetic-Soil Resilient Interface Shear Stiffness

SIGNIFICANCE AND USE

5.1 This test method is intended as a performance test to provide the user with a set of design values for the test conditions examined.

5.1.1 The test method is applicable to all geosynthetics and all soils when loaded in a cyclic manner.

5.1.2 This test method produces test data, which can be used in the design of geosynthetic-reinforced pavement structures or in applications where geosynthetics are subjected to cyclic loads.

5.1.3 The test results may also provide information related to the in-soil stress-strain response of a geosynthetic under confined loading conditions.

5.2 Information derived from this test may be a function of soil gradation, plasticity, as-placed dry unit weight, moisture content, length and surface characteristics of the geosynthetic, and other test parameters. Therefore, results are expressed in terms of the actual test conditions. The test measures the net effect of a combination of interface shear mechanisms, which may vary depending on type of geosynthetic specimen, embedment length, relative opening size, soil type, displacement rate, normal stress, and other factors.

5.3 Information between laboratories on precision is incomplete. In cases of dispute, comparative tests to determine if there is a statistical bias between laboratories may be advisable.

SCOPE

1.1 This test method details how cyclic loading is applied to geosynthetics embedded in soil to determine the apparent stiffness of the soil–geosynthetic interface.

1.2 Resilient interface shear stiffness describes the shear stiffness between a geosynthetic and its surrounding soil under conditions of small cyclic loads.

1.3 This test method is intended to provide properties for design. The test method was developed for mechanistic empirical pavement design methods requiring input of the resilient interface shear stiffness. The use of this parameter from this test method for other applications involving cyclic loading should be evaluated on a case-by-case basis. It can also be used to compare different geosynthetics, soil types, etc., and thereby be used as a research and development test procedure.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7499/D7499M − 09 (Reapproved 2023)

Standard Test Method for

Measuring Geosynthetic-Soil Resilient Interface Shear

Stiffness

This standard is issued under the fixed designation D7499/D7499M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method details how cyclic loading is applied to

D123 Terminology Relating to Textiles

geosynthetics embedded in soil to determine the apparent

D653 Terminology Relating to Soil, Rock, and Contained

stiffness of the soil–geosynthetic interface.

Fluids

1.2 Resilient interface shear stiffness describes the shear

D3080/D3080M Test Method for Direct Shear Test of Soils

stiffness between a geosynthetic and its surrounding soil under

Under Consolidated Drained Conditions (Withdrawn

conditions of small cyclic loads.

2020)

D4354 Practice for Sampling of Geosynthetics and Rolled

1.3 This test method is intended to provide properties for

Erosion Control Products (RECPs) for Testing

design. The test method was developed for mechanistic em-

D4439 Terminology for Geosynthetics

pirical pavement design methods requiring input of the resilient

interface shear stiffness. The use of this parameter from this

3. Terminology

test method for other applications involving cyclic loading

3.1 For definitions of other terms used in this test method

should be evaluated on a case-by-case basis. It can also be used

refer to Terminologies D123, D653, and D4439.

to compare different geosynthetics, soil types, etc., and thereby

be used as a research and development test procedure.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 apertures, n—the open spaces in geogrids which

1.4 The values stated in either SI units or inch-pound units

enable soil interlocking to occur.

are to be regarded separately as standard. The values stated in

3.2.2 atmosphere for testing geosynthetics, n—air main-

each system may not be exact equivalents; therefore, each

tained at a relative humidity of 60 6 10 % and a temperature

system shall be used independently of the other. Combining

of 21 6 2 °C [70 6 4 °F].

values from the two systems may result in nonconformance

with the standard. 3.2.3 cross-machine direction, n—the direction in the plane

of the geosynthetic perpendicular to the direction of manufac-

1.5 This standard does not purport to address all of the

ture.

safety concerns, if any, associated with its use. It is the

3.2.4 failure, n—an arbitrary point at which a material

responsibility of the user of this standard to establish appro-

ceases to be functionally capable of its intended use.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.2.5 geosynthetic, n—a planar product manufactured from

polymeric material used with soil, rock, earth, or other geo-

1.6 This international standard was developed in accor-

technical engineering related material as an integral part of a

dance with internationally recognized principles on standard-

man-made project, structure, or system.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3.2.6 geosynthetic-soil resilient interface shear stiffness,

mendations issued by the World Trade Organization Technical n—a parameter that describes the apparent stiffness of the

Barriers to Trade (TBT) Committee. interface between the soil and the geosynthetic determined by

1 2

This test method is under the jurisdiction of ASTM Committee D35 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cal Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2023. Published February 2023. Originally the ASTM website.

approved in 2009. Last previous edition approved in 2014 as D7499/D7499M – 09 The last approved version of this historical standard is referenced on www.ast-

(2014). DOI: 10.1520/D7499_D7499M-09R23. m.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7499/D7499M − 09 (2023)

calculating the slope of the shear stress, shear displacement 5. Significance and Use

curve as the embedded geosynthetic is subjected to a cyclic

5.1 This test method is intended as a performance test to

load.

provide the user with a set of design values for the test

3.2.7 junction, n—the point where geogrid ribs are intercon-

conditions examined.

nected in order to provide structure and dimensional stability.

5.1.1 The test method is applicable to all geosynthetics and

all soils when loaded in a cyclic manner.

3.2.8 machine direction, n—the direction in the plane of the

5.1.2 This test method produces test data, which can be used

geosynthetic parallel to the direction of manufacture.

in the design of geosynthetic-reinforced pavement structures or

3.2.9 pullout, n—the movement of a geosynthetic over its

in applications where geosynthetics are subjected to cyclic

entire embedded length, with initial pullout occurring when the

loads.

back of the specimen moves, and ultimate pullout occurring

5.1.3 The test results may also provide information related

when the movement is uniform over the entire embedded

to the in-soil stress-strain response of a geosynthetic under

length.

confined loading conditions.

3.2.10 pullout force, (kN), n—force required to pull a

5.2 Information derived from this test may be a function of

geosynthetic out of the soil during a pullout test.

soil gradation, plasticity, as-placed dry unit weight, moisture

3.2.11 pullout resistance, (kN/m), n—the pullout force per

content, length and surface characteristics of the geosynthetic,

width of geosynthetic measured at a specified condition of

and other test parameters. Therefore, results are expressed in

displacement.

terms of the actual test conditions. The test measures the net

3.2.12 rib, n—the continuous elements of a geogrid which

effect of a combination of interface shear mechanisms, which

are either in the machine or cross-machine direction as

may vary depending on type of geosynthetic specimen, em-

manufactured.

bedment length, relative opening size, soil type, displacement

rate, normal stress, and other factors.

3.2.13 wire gage, n—a displacement gage consisting of a

non-extensible wire attached to the geosynthetic and monitored

5.3 Information between laboratories on precision is incom-

by connection to a dial extensometer, or electronic displace-

plete. In cases of dispute, comparative tests to determine if

ment transducer.

there is a statistical bias between laboratories may be advis-

able.

4. Summary of Test Method

4.1 In this test method, a horizontal layer of geosynthetic is 6. Apparatus

embedded between two layers of soil. Six prescribed levels of

6.1 Test Box—An open rigid box consisting of two smooth

horizontal cyclic force are applied to the geosynthetic at five

parallel sides, a back wall, a horizontal split removable door, a

specified levels of normal stress confinement. The maximum

bottom plate, and a load transfer sleeve. The door is at the front

and minimum forces and corresponding displacements are

as defined by the direction of applied cyclic force. A typical

recorded for the last ten cycles of each combination of normal

box is shown in Fig. 1.

stress and cyclic force (loading sequence).

6.1.1 The box should be square or rectangular with mini-

4.2 The resilient interface shear stiffness (kPa/m or psi/in.) mum dimensions 457 mm [18 in.] long by 457 mm [18 in.]

of the test specimen can be calculated for any loading sequence wide by 305 mm [12 in.] deep, if sidewall friction is

by dividing the cyclic shear stress by the corresponding net minimized, otherwise the minimum width should be 760 mm

recoverable horizontal displacement of the embedded geosyn- [30 in.]. The dimensions should be increased, if necessary, so

thetic that minimum width is the greater of 20 times the D85 of the

FIG. 1 Side View of Typical Test Device

D7499/D7499M − 09 (2023)

soil or six times the maximum soil particle size, and the load in the direction of the opening of the box. The force must

minimum length greater than five times the maximum geosyn- be at the same level with the specimen.

thetic aperture size. The box shall allow for a minimum depth

6.3.1 The cyclic force system must be able to apply multiple

of 150 mm [6 in.] above and below the geosynthetic. The depth

load repetitions using a haversine-shaped load pulse consisting

of the soil in the box above or below the geosynthetic shall be

of a 0.2 s load followed by a 0.80 s rest period. The loading

a minimum of six times the D85 of the soil or three times the

system must also be able to simultaneously maintain a mini-

maximum particle size of the soil, whichever is greater. The

mum seating load on the material during cyclic loading.

box must allow for at least 305 mm [12 in.] embedment length

6.3.2 Also, a device to measure the cyclic force (that is, a

beyond the load transfer sleeve.

load cell) must be incorporated into the system and shall be

NOTE 1—To remove side wall friction as much as possible a high

accurate within 60.5 % of its full-scale range.

density polyethylene (HDPE) geomembrane should be bonded to the

inside surfaces of the pullout box. The sidewalls may also be covered with 6.4 Displacement Indicators—Horizontal displacement of

a layer of silk fabric, which has been shown to eliminate adhesion and has

the geosynthetic is measured at the entrance of the box and at

a very low friction value. Alternatively, a lubricant can be spread on the

several locations on the embedded portion of the specimen.

sidewalls of the box and thin sheets of polyethylene film used to minimize

Measurements outside the door at the box entrance are made by

the side wall friction. It should be also noted that the effect of sidewall

friction on the soil-geosynthetic interface can also be eliminated if a electronic displacement transducers (for example, linear vari-

minimum distance is kept between the specimen and the side wall. This

able differential transformers (LVDTs) can be used) mounted to

minimum distance is recommended to be 150 mm [6 in.].

the box frame to read against a plate attached to the specimen

6.1.2 The box shall be fitted with a pair of metal sleeves

near the door.

(load transfer sleeves) at the entrance of the box to transfer the

6.4.1 Displacement measurements within the box may em-

force into the soil to a sufficient horizontal distance so as to

ploy any of several methods, which place sensors or gauge

significantly reduce the stress on the door of the box. The

connectors directly on the geosynthetic and monitor their

sleeves shall consist of two tapered (illustrated in Fig. 3) or

change in location remotely. One such device utilizes wire

non-tapered (no more than 13 mm [0.5 in.] thick) plates

gages, which are protected from normal stress by a surrounding

extending the full width of the pullout box and into the pullout

tube, which runs from a location mounted on the specimen to

box a minimum distance of 150 mm [6 in.], but it is

the outside of the box where displacements are measured by

recommended that this distance equal the total soil depth above

displacement transducers.

or below the geosynthetic. Both design types must possess

6.4.2 All electronic measurement devices must be accurate

tapered edges at the point of load application in the soil that are

to 60.01 mm. Locations of the devices must be accurately

no more then 3 mm [0.12 in.] thick. The plates shall be rigidly

determined and recorded. Minimum extension capabilities of

separated at the sides with spacers and be sufficiently stiff such

50 mm [2 in.] are recommended.

that normal stress is not transferred to the geosynthetic between

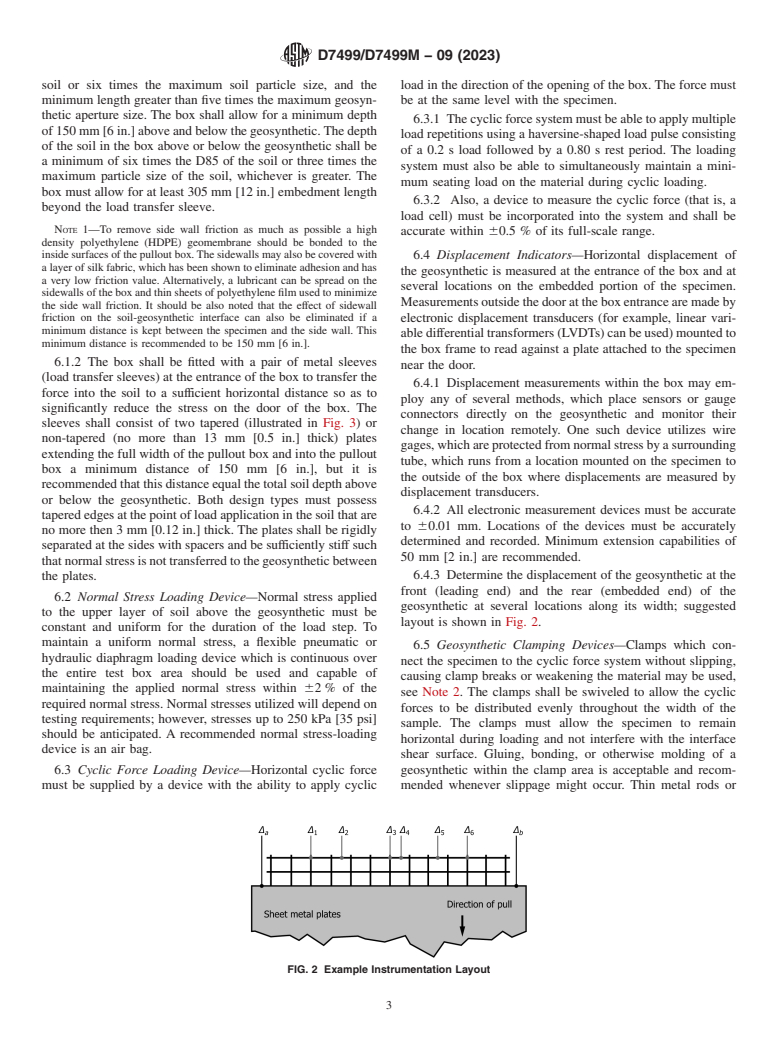

6.4.3 Determine the displacement of the geosynthetic at the

the plates.

front (leading end) and the rear (embedded end) of the

6.2 Normal Stress Loading Device—Normal stress applied

geosynthetic at several locations along its width; suggested

to the upper layer of soil above the geosynthetic must be

layout is shown in Fig. 2.

constant and uniform for the duration of the load step. To

maintain a uniform normal stress, a flexible pneumatic or

6.5 Geosynthetic Clamping Devices—Clamps which con-

hydraulic diaphragm loading device which is continuous over

nect the specimen to the cyclic force system without slipping,

the entire test box area should be used and capable of

causing clamp breaks or weakening the material may be used,

maintaining the applied normal stress within 62 % of the

see Note 2. The clamps shall be swiveled to allow the cyclic

required normal stress. Normal stresses utilized will depend on

forces to be distributed evenly throughout the width of the

testing requirements; however, stresses up to 250 kPa [35 psi]

sample. The clamps must allow the specimen to remain

should be anticipated. A recommended normal stress-loading

horizontal during loading and not interfere with the interface

device is an air bag.

shear surface. Gluing, bonding, or otherwise molding of a

geosynthetic within the clamp area is acceptable and recom-

6.3 Cyclic Force Loading Device—Horizontal cyclic force

must be supplied by a device with the ability to apply cyclic mended whenever slippage might occur. Thin metal rods or

FIG. 2 Example Instrumentation Layout

D7499/D7499M − 09 (2023)

FIG. 3 Side View of Load Transfer Sleeve Arrangement

tubes may be used to reduce friction between the geosynthetic 7.2 Laboratory Sample—Consider the units in the lot

clamp/sample and the top edge of the lower load transfer sleeve sample as the units in the laboratory sample for the lot to be

(Fig. 3). tested. Take for a laboratory sample, a sample extending the

full width of the geosynthetic production unit, of sufficient

NOTE 2—A suggested method of clamping is shown in Fig. 4 and

length along the selvage or edge from each sample roll so that

includes a simple clamp consisting of two pieces of 22 gauge sheet metal

the requirement of 7.3 can be met. Take a sample that will

glued to both

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.