ASTM D4397-08

(Specification)Standard Specification for Polyethylene Sheeting for Construction, Industrial, and Agricultural Applications

Standard Specification for Polyethylene Sheeting for Construction, Industrial, and Agricultural Applications

ABSTRACT

This specification covers polyethylene sheeting with a determined thickness intended for construction, industrial and agricultural applications. The sheeting shall be made from polyethylene or modified polyethylene, such as an ethylene copolymer consisting of a major portion of ethylene in combination with a minor portion of some other monomer, or a mixture of polyethylene with a lesser amount of other polymers. General requirements for the material are also observed according to their appearance, dimensions in size and tolerance and minimum net weight. The sheeting may be natural, color-tinted, translucent or opaque. The tests given are intended primarily for use as production tests in conjunction with manufacturing processes and inspection methods to insure conformity of sheeting with the requirements of this specification. These tests shall be done in order to determine the following properties: thickness, length and width, weight, impact resistance, tensile properties, reflectance, luminous transmittance, water vapor transmission, and heat sealability.

SCOPE

1.1 This specification covers polyethylene sheeting, 250 μm (0.010 in. or 10 mils) or less in thickness, intended for construction, industrial, and agricultural applications.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary statement pertains only to the test methods portion, Section 8 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4397 – 08

Standard Specification for

Polyethylene Sheeting for Construction, Industrial, and

1

Agricultural Applications

This standard is issued under the fixed designation D4397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D4976 SpecificationforPolyethylenePlasticsMoldingand

Extrusion Materials

1.1 Thisspecificationcoverspolyethylenesheeting,250µm

E96/E96M Test Methods forWaterVaporTransmission of

(0.010 in. or 10 mils) or less in thickness, intended for

Materials

construction, industrial, and agricultural applications.

E1347 Test Method for Color and Color-Difference Mea-

1.2 The values stated in SI units are to be regarded as the

surement by Tristimulus Colorimetry

standard.

F88 Test Method for Seal Strength of Flexible Barrier

1.3 The following precautionary statement pertains only to

Materials

the test methods portion, Section 8 of this specification: This

2.2 Military Standard:

standard does not purport to address all of the safety concerns,

MIL-STD-105 Sampling Procedures and Tables for Inspec-

if any, associated with its use. It is the responsibility of the user

3

tion by Attributes

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

3. Terminology

tions prior to use.

3.1 Definitions—The plastics terminology used in this

NOTE 1—There is no known ISO equivalent to this specification.

specification is in accordance with the definitions given in

Terminology D883.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2

2.1 ASTM Standards:

3.2.1 nominal length—the length of sheeting in any roll, as

D374 Test Methods for Thickness of Solid Electrical Insu-

specified on product labels, invoices, sales literature, and the

lation

like.

D618 Practice for Conditioning Plastics for Testing

3.2.2 nominal net weight—the weight of sheeting in any

D882 Test Method for Tensile Properties of Thin Plastic

roll, as specified on product labels, invoices, sales literature,

Sheeting

and the like.

D883 Terminology Relating to Plastics

3.2.3 nominal thickness—the thickness of sheeting in any

D1505 Test Method for Density of Plastics by the Density-

roll, as specified on product labels, invoices, sales literature,

Gradient Technique

and the like.

D1709 Test Methods for Impact Resistance of Plastic Film

3.2.4 nominal width—the width of sheeting in any rolls, as

by the Free-Falling Dart Method

specified on product labels, invoices, sales literature, and the

D1898 Practice for Sampling of Plastics

like.

D2103 Specification for Polyethylene Film and Sheeting

D3892 Practice for Packaging/Packing of Plastics 4. Materials

4.1 The sheeting shall be made from polyethylene or modi-

1 fied polyethylene, such as an ethylene copolymer consisting of

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.19 on Film and a major portion of ethylene in combination with a minor

Sheeting.

portion of some other monomer, or a mixture of polyethylene

Current edition approved Nov. 1, 2008. Published November 2008. Originally

with a lesser amount of other polymers.

approved in 1984. Last previous edition approved in 2002 as D4397–02.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

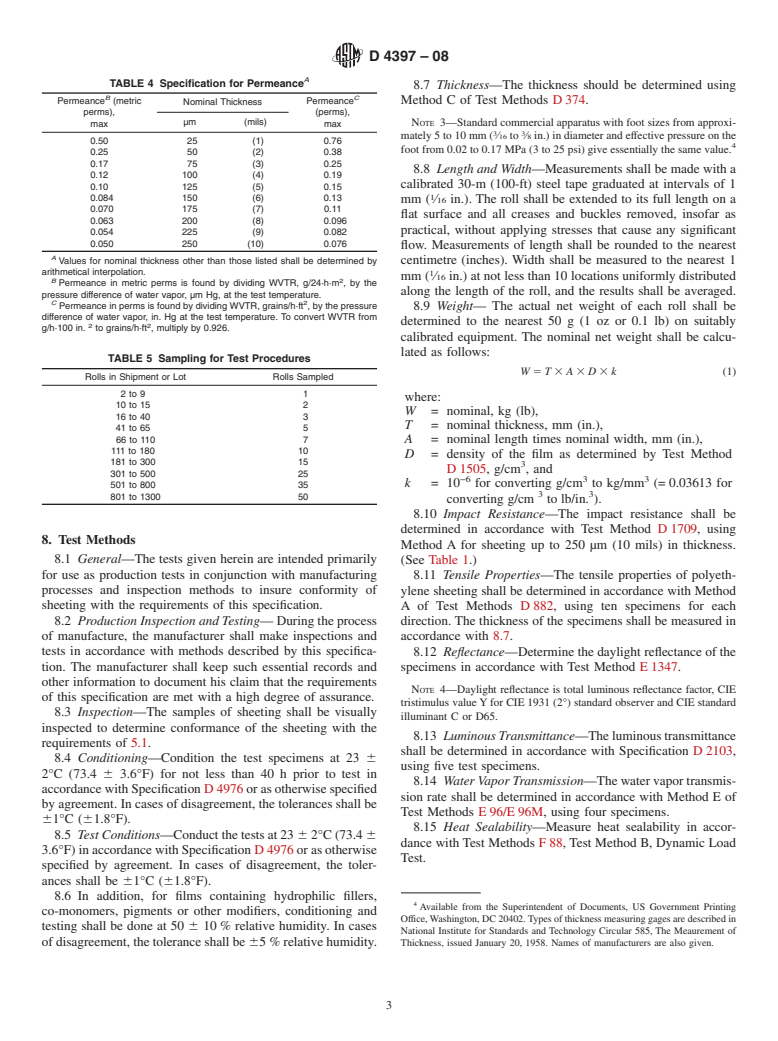

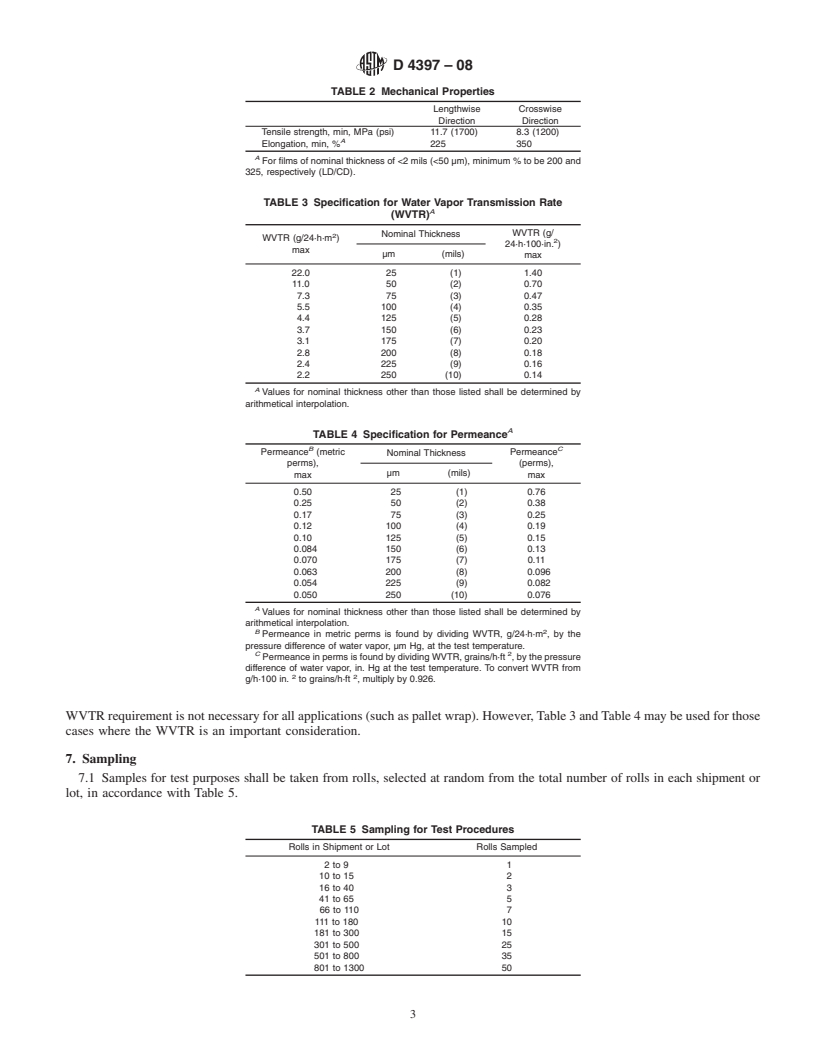

D4397–08

NOTE 2—Polyethylene sheeting is made in a variety of colors, opaci- TABLE 2 Mechanical Properties

ties, translucencies, and dimensions. It is recommended that manufactur-

Lengthwise Crosswise

ers be consulted on the varieties available.

Direction Direction

Tensile strength, min, MPa (psi) 11.7 (1700) 8.3 (1200)

A

Elongation, min, % 225 350

5. General Requirements General Requirements

A

For films of nominal thickness of <2 mils (<50 µm), minimum % to be 200 and

5.1 Appearance—Thesheetingshallhaveappearancequali-

325, respectively (LD/CD).

ties conforming with those produced by good commercial

practices.Itshallbeasfreeasiscommerciallypossibleofgel

...

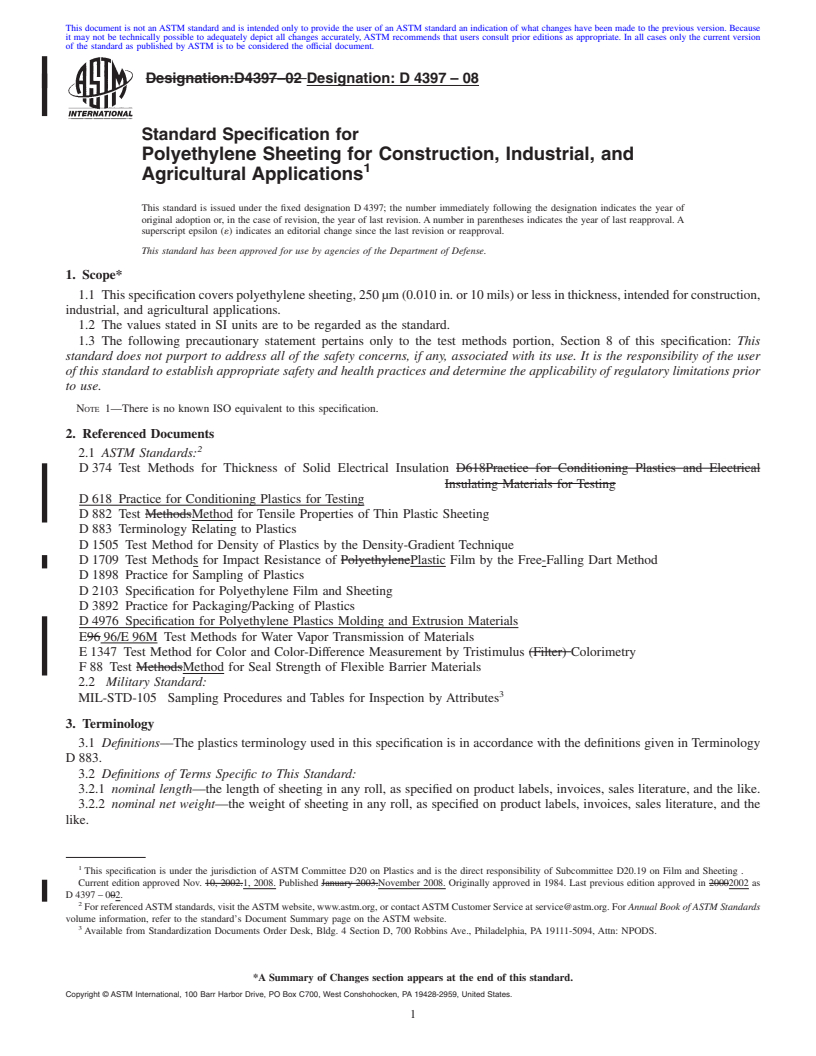

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4397–02 Designation: D 4397 – 08

Standard Specification for

Polyethylene Sheeting for Construction, Industrial, and

1

Agricultural Applications

This standard is issued under the fixed designation D4397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thisspecificationcoverspolyethylenesheeting,250µm(0.010in.or10mils)orlessinthickness,intendedforconstruction,

industrial, and agricultural applications.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary statement pertains only to the test methods portion, Section 8 of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

NOTE 1—There is no known ISO equivalent to this specification.

2. Referenced Documents

2

2.1 ASTM Standards:

D374 Test Methods for Thickness of Solid Electrical Insulation D618Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

D618 Practice for Conditioning Plastics for Testing

D882 Test MethodsMethod for Tensile Properties of Thin Plastic Sheeting

D883 Terminology Relating to Plastics

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D1709 Test Methods for Impact Resistance of PolyethylenePlastic Film by the Free-Falling Dart Method

D1898 Practice for Sampling of Plastics

D2103 Specification for Polyethylene Film and Sheeting

D3892 Practice for Packaging/Packing of Plastics

D4976 Specification for Polyethylene Plastics Molding and Extrusion Materials

E9696/E96M Test Methods for Water Vapor Transmission of Materials

E1347 Test Method for Color and Color-Difference Measurement by Tristimulus (Filter) Colorimetry

F88 Test MethodsMethod for Seal Strength of Flexible Barrier Materials

2.2 Military Standard:

3

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions—The plastics terminology used in this specification is in accordance with the definitions given in Terminology

D883.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 nominal length—the length of sheeting in any roll, as specified on product labels, invoices, sales literature, and the like.

3.2.2 nominal net weight—the weight of sheeting in any roll, as specified on product labels, invoices, sales literature, and the

like.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved Nov. 10, 2002.1, 2008. Published January 2003.November 2008. Originally approved in 1984. Last previous edition approved in 20002002 as

D4397–002.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4397–08

3.2.3 nominal thickness—the thickness of sheeting in any roll, as specified on product labels, invoices, sales literature, and the

like.

3.2.4 nominal width—the width of sheeting in any rolls, as specified on product labels, invoices, sales literature, and the like.

4. Materials

4.1 The sheeting shall be made from polyethylene or modified polyethylene, such as an ethylene copolymer consisting of a

major portion of ethylene in combination with a minor portion of some other monomer, or a mixture of polyethylene with a lesser

amount of other polymers.

NOTE 2—Polyethylene sheeting is made in a variety of colors, opacities, translucencies, and dimensions. It is recommended that manufacturers be

consulted on the varieties available.

5. General Requirements General Requireme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.