ASTM D1586-99

(Test Method)Standard Test Method for Penetration Test and Split-Barrel Sampling of Soils

Standard Test Method for Penetration Test and Split-Barrel Sampling of Soils

SCOPE

1.1 This test method describes the procedure, generally known as the Standard Penetration Test (SPT), for driving a split-barrel sampler to obtain a representative soil sample and a measure of the resistance of the soil to penetration of the sampler.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.> For a specific precautionary statement, see 5.4.1.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1586 – 99

Standard Test Method for

Penetration Test and Split-Barrel Sampling of Soils

This standard is issued under the fixed designation D 1586; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3.1.1 anvil—that portion of the drive-weight assembly

which the hammer strikes and through which the hammer

1.1 This test method describes the procedure, generally

energy passes into the drill rods.

known as the Standard Penetration Test (SPT), for driving a

3.1.2 cathead—the rotating drum or windlass in the rope-

split-barrel sampler to obtain a representative soil sample and

cathead lift system around which the operator wraps a rope to

a measure of the resistance of the soil to penetration of the

lift and drop the hammer by successively tightening and

sampler.

loosening the rope turns around the drum.

1.2 This standard does not purport to address all of the

3.1.3 drill rods—rods used to transmit downward force and

safety problems, if any, associated with its use. It is the

torque to the drill bit while drilling a borehole.

responsibility of the user of this standard to establish appro-

3.1.4 drive-weight assembly—a device consisting of the

priate safety and health practices and determine the applica-

hammer, hammer fall guide, the anvil, and any hammer drop

bility of regulatory limitations prior to use. For a specific

system.

precautionary statement, see 5.4.1.

3.1.5 hammer—that portion of the drive-weight assembly

1.3 The values stated in inch-pound units are to be regarded

consisting of the 140 6 2 lb (63.5 6 1 kg) impact weight

as the standard.

which is successively lifted and dropped to provide the energy

NOTE 1—Practice D 6066 can be used when testing loose sands below

that accomplishes the sampling and penetration.

the water table for liquefaction studies or when a higher level of care is

3.1.6 hammer drop system—that portion of the drive-weight

required when drilling these soils. This practice provides information on

assembly by which the operator accomplishes the lifting and

drillingmethods,equipmentvariables,energycorrections,andblow-count

dropping of the hammer to produce the blow.

normalization.

3.1.7 hammer fall guide—that part of the drive-weight

2. Referenced Documents

assembly used to guide the fall of the hammer.

3.1.8 N-value—theblowcountrepresentationofthepenetra-

2.1 ASTM Standards:

tion resistance of the soil. The N-value, reported in blows per

D 2487 Practice for Classification of Soils for Engineering

foot, equals the sum of the number of blows required to drive

Purposes (Unified Soil Classification System)

the sampler over the depth interval of 6 to 18 in. (150 to 450

D 2488 Practice for Description and Identification of Soils

mm) (see 7.3).

(Visual-Manual Procedure)

3.1.9 DN—the number of blows obtained from each of the

D 4220 Practices for Preserving and Transporting Soil

6-in. (150-mm) intervals of sampler penetration (see 7.3).

Samples

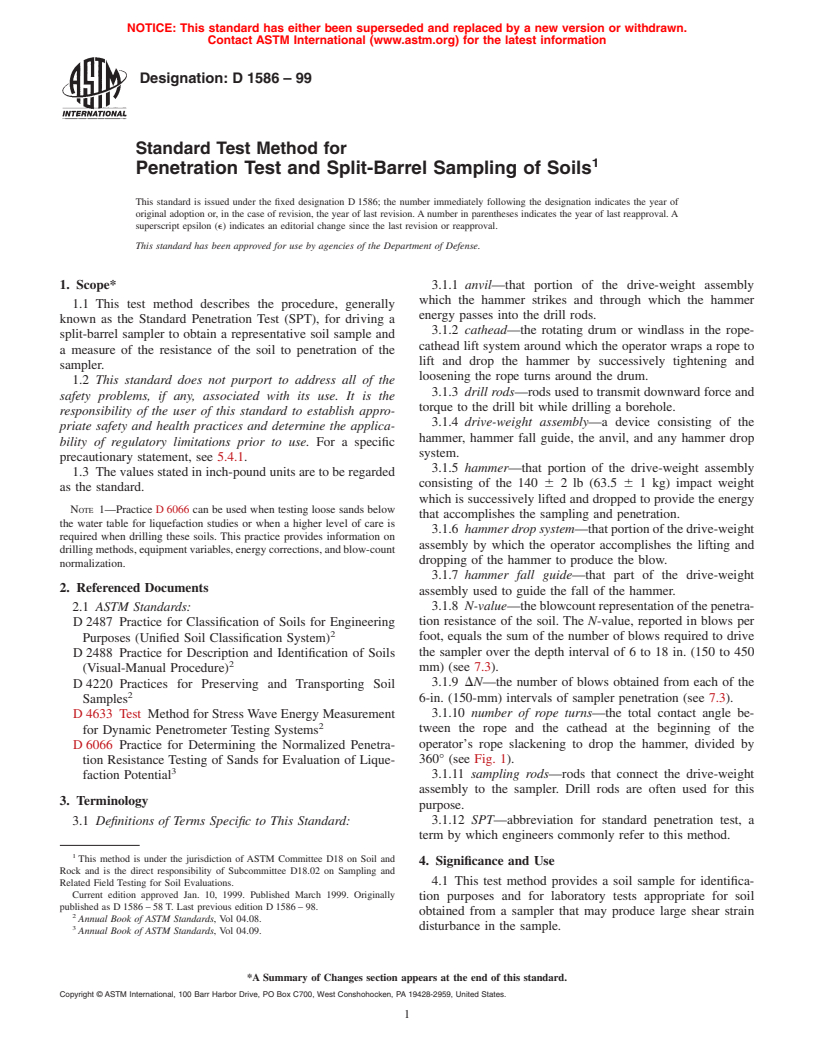

3.1.10 number of rope turns—the total contact angle be-

D 4633 Test Method for Stress Wave Energy Measurement

tween the rope and the cathead at the beginning of the

for Dynamic Penetrometer Testing Systems

operator’s rope slackening to drop the hammer, divided by

D 6066 Practice for Determining the Normalized Penetra-

360° (see Fig. 1).

tion Resistance Testing of Sands for Evaluation of Lique-

3.1.11 sampling rods—rods that connect the drive-weight

faction Potential

assembly to the sampler. Drill rods are often used for this

3. Terminology

purpose.

3.1 Definitions of Terms Specific to This Standard: 3.1.12 SPT—abbreviation for standard penetration test, a

term by which engineers commonly refer to this method.

This method is under the jurisdiction of ASTM Committee D18 on Soil and

4. Significance and Use

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and

4.1 This test method provides a soil sample for identifica-

Related Field Testing for Soil Evaluations.

Current edition approved Jan. 10, 1999. Published March 1999. Originally

tion purposes and for laboratory tests appropriate for soil

published as D 1586 – 58 T. Last previous edition D 1586 – 98.

obtained from a sampler that may produce large shear strain

Annual Book of ASTM Standards, Vol 04.08.

3 disturbance in the sample.

Annual Book of ASTM Standards, Vol 04.09.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1586–99

(a) counterclockwise rotation

approximately 1 ⁄4 turns

(b) clockwise rotation

approximately 2 ⁄4 turns

FIG. 1 Definitions of the Number of Rope Turns and the Angle for (a) Counterclockwise Rotation and (b) Clockwise Rotation of the

Cathead

4.2 This test method is used extensively in a great variety of 5.1.4 Solid, Continuous Flight, Bucket and Hand Augers,

geotechnical exploration projects. Many local correlations and less than 6.5 in. (162 mm) and greater than 2.2 in. (56 mm) in

widely published correlations which relate SPT blowcount, or diameter may be used if the soil on the side of the boring does

N-value, and the engineering behavior of earthworks and not cave onto the sampler or sampling rods during sampling.

foundations are available. 5.2 Sampling Rods—Flush-joint steel drill rods shall be

used to connect the split-barrel sampler to the drive-weight

5. Apparatus

assembly. The sampling rod shall have a stiffness (moment of

inertia) equal to or greater than that of parallel wall “A” rod (a

5.1 Drilling Equipment—Any drilling equipment that pro-

vides at the time of sampling a suitably clean open hole before steel rod which has an outside diameter of 1 ⁄8 in. (41.2 mm)

insertion of the sampler and ensures that the penetration test is and an inside diameter of 1 ⁄8 in. (28.5 mm).

performed on undisturbed soil shall be acceptable. The follow-

NOTE 2—Recent research and comparative testing indicates the type

ing pieces of equipment have proven to be suitable for

rod used, with stiffness ranging from “A” size rod to “N” size rod, will

advancing a borehole in some subsurface conditions.

usually have a negligible effect on the N-values to depths of at least 100

5.1.1 Drag, Chopping, and Fishtail Bits, less than 6.5 in.

ft (30 m).

(162 mm) and greater than 2.2 in. (56 mm) in diameter may be

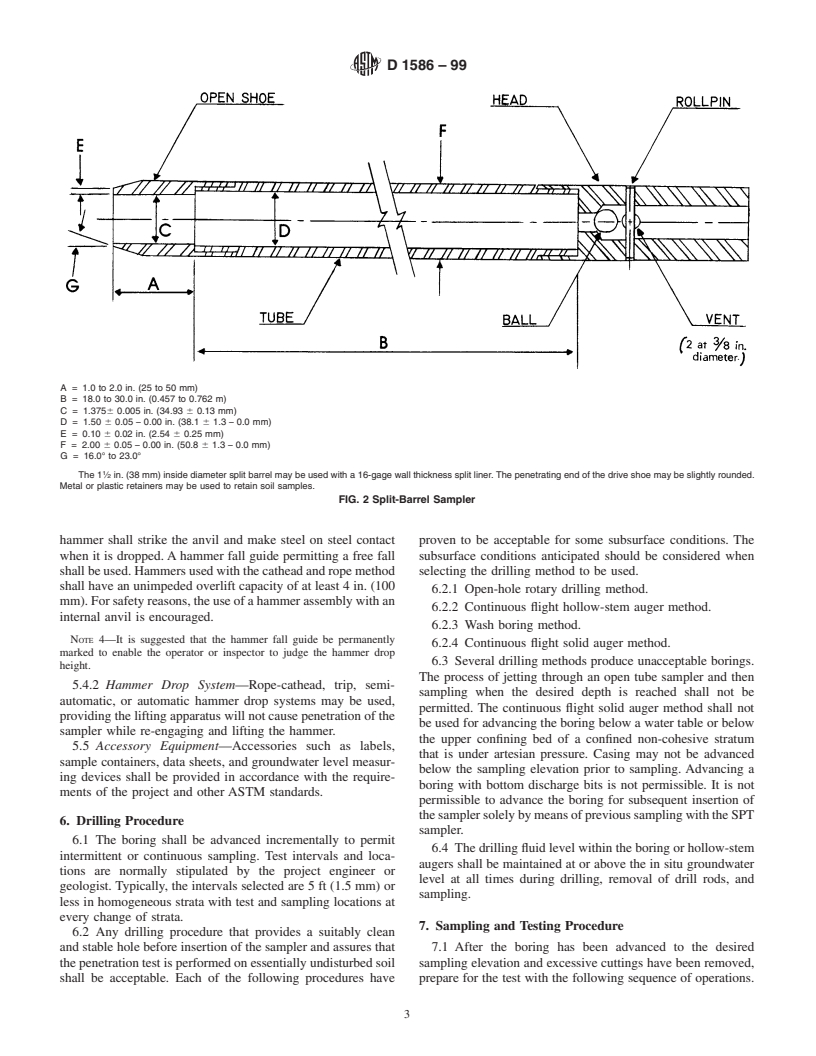

5.3 Split-Barrel Sampler—The sampler shall be constructed

used in conjuction with open-hole rotary drilling or casing-

with the dimensions indicated in Fig. 2. The driving shoe shall

advancement drilling methods. To avoid disturbance of the

be of hardened steel and shall be replaced or repaired when it

underlying soil, bottom discharge bits are not permitted; only

becomes dented or distorted. The use of liners to produce a

side discharge bits are permitted.

constant inside diameter of 1 ⁄8 in. (35 mm) is permitted, but

5.1.2 Roller-Cone Bits, less than 6.5 in. (162 mm) and

shall be noted on the penetration record if used. The use of a

greater than 2.2 in. (56 mm) in diameter may be used in

sample retainer basket is permitted, and should also be noted

conjunction with open-hole rotary drilling or casing-

on the penetration record if used.

advancement drilling methods if the drilling fluid discharge is

NOTE 3—Both theory and available test data suggest that N-values may

deflected.

increase between 10 to 30 % when liners are used.

5.1.3 Hollow-Stem Continuous Flight Augers, with or with-

out a center bit assembly, may be used to drill the boring. The 5.4 Drive-Weight Assembly:

inside diameter of the hollow-stem augers shall be less than 6.5 5.4.1 Hammer and Anvil—The hammer shall weigh 140 6

in. (162 mm) and greater than 2.2 in. (56 mm). 2 lb (63.5 6 1 kg) and shall be a solid rigid metallic mass. The

D1586–99

A = 1.0to2.0in.(25to50mm)

B = 18.0 to 30.0 in. (0.457 to 0.762 m)

C=1.3756 0.005 in. (34.93 6 0.13 mm)

D=1.50 6 0.05 − 0.00 in. (38.1 6 1.3 − 0.0 mm)

E=0.10 6 0.02 in. (2.54 6 0.25 mm)

F=2.00 6 0.05 − 0.00 in. (50.8 6 1.3 − 0.0 mm)

G = 16.0° to 23.0°

The 1 ⁄2 in. (38 mm) inside diameter split barrel may be used with a 16-gage wall thickness split liner.The penetrating end of the drive shoe may be slightly rounded.

Metal or plastic retainers may be used to retain soil samples.

FIG. 2 Split-Barrel Sampler

hammer shall strike the anvil and make steel on steel contact proven to be acceptable for some subsurface conditions. The

when it is dropped. A hammer fall guide permitting a free fall subsurface conditions anticipated should be considered when

shallbeused.Hammersusedwiththecatheadandropemethod selecting the drilling method to be used.

shall have an unimpeded overlift capacity of at least 4 in. (100

6.2.1 Open-hole rotary drilling method.

mm).Forsafetyreasons,theuseofahammerassemblywithan

6.2.2 Continuous flight hollow-stem auger method.

internal anvil is encouraged.

6.2.3 Wash boring method.

NOTE 4—It is suggested that the hammer fall guide be permanently

6.2.4 Continuous flight solid auger method.

marked to enable the operator or inspector to judge the hammer drop

6.3 Several drilling methods produce unacceptable borings.

height.

The process of jetting through an open tube sampler and then

5.4.2 Hammer Drop System—Rope-cathead, trip, semi-

sampling when the desired depth is reached shall not be

automatic, or automatic hammer drop systems may be used,

permitted. The continuous flight solid auger method shall not

providing the lifting apparatus will not cause penetration of the

be used for advancing the boring below a water table or below

sampler while re-engaging and lifting the hammer.

the upper confining bed of a confined non-cohesive stratum

5.5 Accessory Equipment—Accessories such as labels,

that is under artesian pressure. Casing may not be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.