ASTM E2408-04

(Test Method)Standard Test Method for Relative Extensional Viscosity of Agricultural Spray Tank Mixes

Standard Test Method for Relative Extensional Viscosity of Agricultural Spray Tank Mixes

SIGNIFICANCE AND USE

Extensional viscosity is a measure of the resistance of a liquid to stretching forces, such as those occurring during the disruption of liquid films and the formation of sprays used in agriculture and other purposes including painting operations or metal working. This method for measurement of a Screen Factor, gives a relative value for extensional viscosity, which may be used:

4.1.1 To compare the potential for drift control of different polymers.

4.1.2 To compare the relative extensional viscosity component of different spray tank mixtures.

4.1.3 To determine the extent of breakdown of polymer solutions used as drift control additives during the recirculation of the solutions through pumps and screens.

4.1.4 To use as a parameter in the Spray Drift Task Force Models for droplet size prediction.

It should also be noted that many drift control polymers are irreversibly destroyed during the recirculation of spray mixes by pumping with high shear pumps such as gear or centrifugal pumps. It is advisable to subject the test mixture to similar pumping regimes to simulate practical conditions before carrying out the extensional viscosity test. Measurements of extensional viscosity are the only presently known method of determining the extent of this breakdown properties of dilute polymer solutions.

This method is intended to produce a relative value for extensional viscosity. The purpose of the method is to compare the extensional viscosity produced by different polymer types or concentrations of polymer in spray tank mixes.

SCOPE

1.1 This test method covers the determination of the relative extensional viscosity or Screen Factor (SF) of dilute agricultural spray mixes.

1.2 The test can be used for tank mixes containing dissolved, emulsified or dispersed materials, or mixtures.

1.3 Results may be affected by the quality of the water used. Make-up water quality should therefore be specified in the presentation of results.

1.4 Proper safety and hygiene precautions must be taken when working with pesticide formulations to prevent skin or eye contact, vapor inhalation, and environmental contamination. Read and follow all handling instructions for the specific formulation and conduct the test in accordance with good laboratory practice.Note 1

References to the development of extensional viscosity from dissolved polymers, extensional viscosity effects on the droplet size distribution of sprays, and measurements of screen factor on recirculated spray mixes containing polymers are available.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2408–04

Standard Test Method for

Relative Extensional Viscosity of Agricultural Spray Tank

Mixes

This standard is issued under the fixed designation E2408; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E609 Terminology Relating to Pesticides

E1116 Test Method for Emulsification Characteristics of

1.1 Thistestmethodcoversthedeterminationoftherelative

Pesticide Emulsifiable Concentrates

extensional viscosity or Screen Factor (SF) of dilute agricul-

2.2 CIPAC Documents:

tural spray mixes.

CIPAC Monograph 1 (Instructions for the preparation of

1.2 The test can be used for tank mixes containing dis-

hard water)

solved, emulsified or dispersed materials, or mixtures.

CIPAC Method MT 18.1.1 to 18.1.7 (Instructions for the

1.3 Resultsmaybeaffectedbythequalityofthewaterused.

preparation of standard waters)

Make-up water quality should therefore be specified in the

presentation of results.

3. Terminology

1.4 Proper safety and hygiene precautions must be taken

3.1 Definitions:

when working with pesticide formulations to prevent skin or

3.1.1 screen factor, (SF)—the ratio of the flow time of a test

eye contact, vapor inhalation, and environmental contamina-

fluid (t ) to the flow time of water (t ) through the screen

p w

tion. Read and follow all handling instructions for the specific

viscometer apparatus.

formulation and conduct the test in accordance with good

3.1.2 extensional viscosity, (E)—a measure of the resistance

laboratory practice.

of a fluid to distortion by a stretching force.

NOTE 1—References to the development of extensional viscosity from

dissolved polymers, extensional viscosity effects on the droplet size

4. Significance and Use

distribution of sprays, and measurements of screen factor on recirculated

4.1 Extensional viscosity is a measure of the resistance of a

2,3

spray mixes containing polymers are available .

liquid to stretching forces, such as those occurring during the

1.5 This standard does not purport to address all of the

disruption of liquid films and the formation of sprays used in

safety concerns, if any, associated with its use. It is the

agriculture and other purposes including painting operations or

responsibility of the user of this standard to establish appro-

metal working. This method for measurement of a Screen

priate safety and health practices and determine the applica-

Factor, gives a relative value for extensional viscosity, which

bility of regulatory limitations prior to use.

may be used:

4.1.1 To compare the potential for drift control of different

2. Referenced Documents

polymers.

2.1 ASTM Standards:

4.1.2 To compare the relative extensional viscosity compo-

D1193 Specification for Reagent Water

nent of different spray tank mixtures.

4.1.3 To determine the extent of breakdown of polymer

solutionsusedasdriftcontroladditivesduringtherecirculation

This test method is under the jurisdiction of ASTM Committee E35 on

Pesticides and Alternative Control Agents and is the direct responsibility of

of the solutions through pumps and screens.

Subcommittee E35.22 on Pesticide Formulations and Delivery Systems.

4.1.4 To use as a parameter in the Spray Drift Task Force

Current edition approved Oct. 1, 2004. Published November 2004. DOI:

Models for droplet size prediction.

10.1520/E2408-04.

4.2 It should also be noted that many drift control polymers

Dexter,R.W.,MeasurementsofExtensionalViscosityofPolymerSolutionsand

its Effect on Atomization from a Spray Nozzle,” Atomization and Sprays, 6, 1996,

are irreversibly destroyed during the recirculation of spray

pp. 167-191

mixes by pumping with high shear pumps such as gear or

Zhu, H., Dexter, R. W., Fox, R. D., Reichard, D. L., Brazee, R. D., and Okzan,

centrifugal pumps. It is advisable to subject the test mixture to

H.E.,“DropletSizeandViscosityEffectsinRecirculatedPolymerSpraySolutions,”

J. Agric. Engr. Res., 67, 1997, pp. 35-45 similar pumping regimes to simulate practical conditions

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

before carrying out the extensional viscosity test. Measure-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ments of extensional viscosity are the only presently known

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2408–04

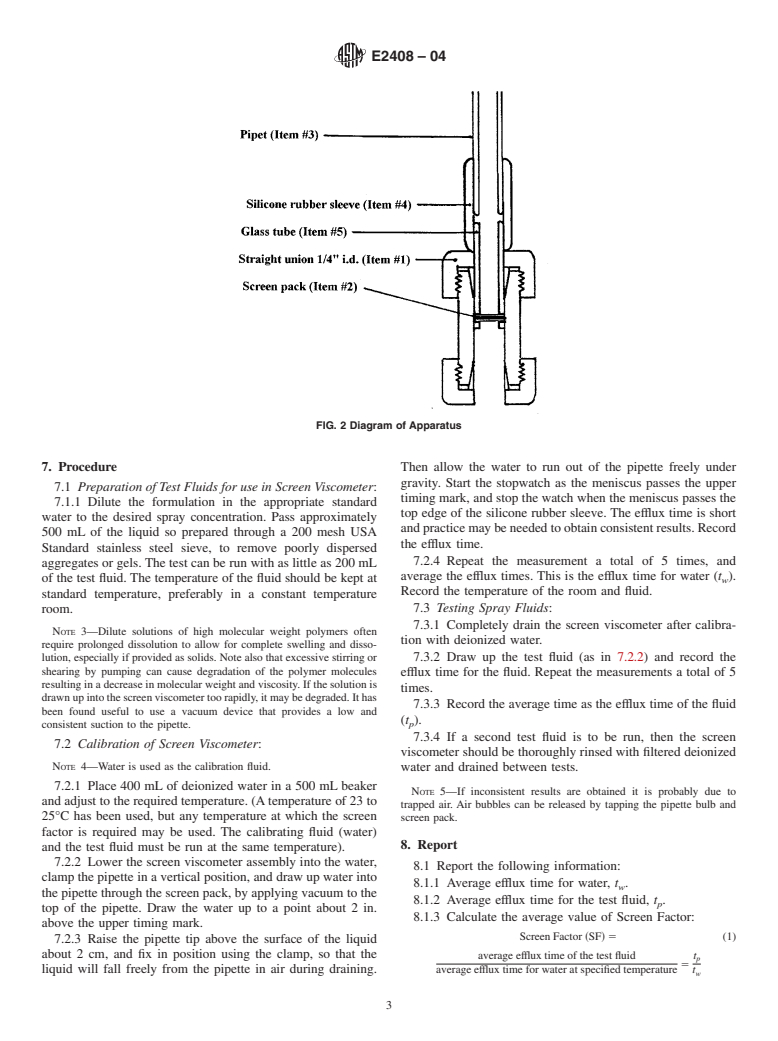

method of determining the extent of this breakdown properties 5.2.1 Push the five stainless screen discs, one at a time, into

of dilute polymer solutions. the ⁄4 in. (0.635 cm) plastic union. Push each screen down to

4.3 This method is intended to produce a relative value for the central lug in the union, using a piece of ⁄4 in. glass tubing.

extensional viscosity.The purpose of the method is to compare Ensure that the last of the 5 screens fits tightly into the plastic

the extensional viscosity produced by different polymer types tube to keep the pack of screens well compacted and fixed in

or concentrations of polymer in spray tank mixes. place.

5.2.2 Push the silicone rubber sleeve (Item 4) on to the

5. Apparatus

lowerendofthepipettetube(Item3).Leaveapproximately0.8

cm of the silicone tube projecting beyond the glass.

5.1 List of Materials for Construction of Screen Viscometer:

5.2.3 Pushtheshortglasstube(Item5)intotheplasticunion

5.1.1 Item 1—Fluorinated plastic ⁄4 in. (0.635 cm) straight

firmlyandpressdownonthepackofscreens.Screwontheend

union, reference SKU-II4, P#D1O77019. Norton Performance

cap of the union to retain the position of the screen pack.

Plastics, 150 Dey Road, Wayne, New Jersey, 07470, USA.

Ensure that the Teflon cone supplied with the union is fitted

5.1.2 Item 2—Cut five (5) ⁄4 in. diameter discs (see 5.2)

properly, to provide a leak tight seal.About 0.6 cm of the glass

from100mesh(150µmaperture)USAStandardTestingSieve,

tube should protrude from the end cap of the union.

ASTM E11 specification, stainless steel plain weave screen, so

5.2.4 Push together the glass tube protruding from the end

as to fit tightly into the ⁄4 in. plastic union.

cap, into the silicone rubber sleeve attached to the pipette.

5.1.3 Item 3—Glass 25 mL pipette, {VWR catalog #7102

Check the alignment of the pipette and screen pack for

(1999)} or equivalent. External diameter of the tube below the

straightness.

bulb of the pipette = 0.82 cm. Cut off the lower part of the

5.3 Other Accessories Required:

pipette at a point 2.5 cm below the bulb. Round off the sharp

edges of the tube with a flame. 5.3.1 Two 500 mL beakers.

5.1.4 Item 4—Silicone rubber tubing, flexible, for use as a 5.3.2 A stand and clamp to hold the pipette firmly in a

sleeve to join a glass tube (Item 5) to the lower end of the

vertical position.

pipette (Item 3).

5.3.3 A stopwatch, reading to 0.01 s.

5.1.5 Item 5—Glass tube, cut froma2mL pipette, Kimax

5.3.4 A 200 mesh USA Standard Testing (75 µm aperture)

#37000, or equivalent (American Scientific catalog #P4140-2).

stainless steel sieve, 4 in. diameter.

Dimensionsoftubeare:length=3cm;outsidediameter=0.62

5.3.5 A pipette bulb, or preferably, a low vacuum suction

cm. Round off the sharp ends of the tube in a flam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.