ASTM D4967-99(2004)e1

(Guide)Standard Guide for Selecting Materials to Be Used for Insulation, Jacketing and Strength Components in Fiber-Optic Cables

Standard Guide for Selecting Materials to Be Used for Insulation, Jacketing and Strength Components in Fiber-Optic Cables

SIGNIFICANCE AND USE

The lists of components and materials are useful in enhancing the user’understanding of the technology and construction of fiber-optics cables and the development of performance standards for cables.

This guide is intended for use by all parties involved with fiber optics: materials suppliers, cable manufacturers, and end-users.

SCOPE

1.1 This guide is intended to provide a list of materials commonly used in components that provide insulation, jacketing and strength in fiber-optic cables. Where these materials are covered by ASTM standards, an appropriate reference is made. Due to changing technology, not all materials being used are necessarily listed here.

1.2 This guide does not include materials used in components for optical purposes (optical fiber and its coating) or external metallic armoring (such as for a barrier to rodents).

1.3 This guide offers two general lists of materials:

1.3.1 A subdivision of fiber-optic cable construction into components that are used for insulation, jacketing, or strength, with a generic material classification for specific applications in each component (see Section ); and

1.3.2 An alphabetical list of the generic material classifications, showing ASTM standards where they exist (see ).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

´1

Designation:D4967–99 (Reapproved 2004)

Standard Guide for

Selecting Materials to Be Used for Insulation, Jacketing and

Strength Components in Fiber-Optic Cables

This standard is issued under the fixed designation D4967; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Non-mandatory language was replaced throughout editorially in November 2004.

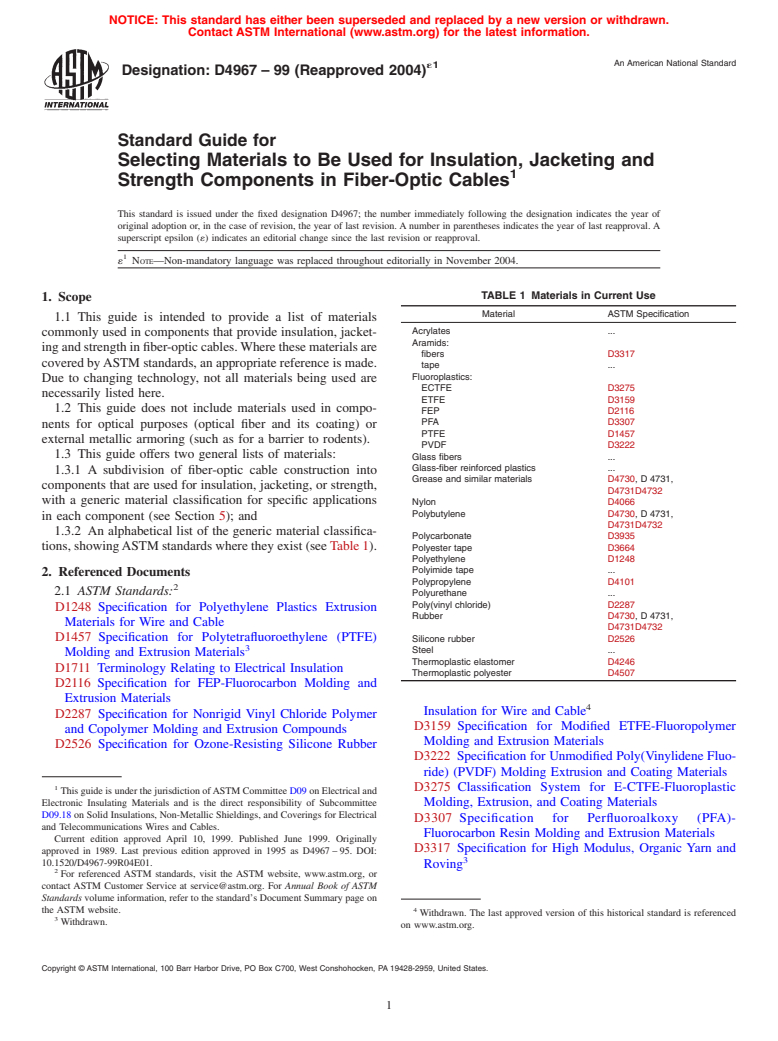

TABLE 1 Materials in Current Use

1. Scope

Material ASTM Specification

1.1 This guide is intended to provide a list of materials

Acrylates .

commonly used in components that provide insulation, jacket-

Aramids:

ingandstrengthinfiber-opticcables.Wherethesematerialsare

fibers D3317

covered byASTM standards, an appropriate reference is made.

tape .

Fluoroplastics:

Due to changing technology, not all materials being used are

ECTFE D3275

necessarily listed here.

ETFE D3159

1.2 This guide does not include materials used in compo-

FEP D2116

PFA D3307

nents for optical purposes (optical fiber and its coating) or

PTFE D1457

external metallic armoring (such as for a barrier to rodents).

PVDF D3222

1.3 This guide offers two general lists of materials:

Glass fibers .

Glass-fiber reinforced plastics .

1.3.1 A subdivision of fiber-optic cable construction into

Grease and similar materials D4730, D 4731,

components that are used for insulation, jacketing, or strength,

D4731D4732

with a generic material classification for specific applications

Nylon D4066

Polybutylene D4730, D 4731,

in each component (see Section 5); and

D4731D4732

1.3.2 An alphabetical list of the generic material classifica-

Polycarbonate D3935

tions, showingASTM standards where they exist (seeTable 1). Polyester tape D3664

Polyethylene D1248

Polyimide tape .

2. Referenced Documents

Polypropylene D4101

2.1 ASTM Standards:

Polyurethane .

Poly(vinyl chloride) D2287

D1248 Specification for Polyethylene Plastics Extrusion

Rubber D4730, D 4731,

Materials for Wire and Cable

D4731D4732

D1457 Specification for Polytetrafluoroethylene (PTFE) Silicone rubber D2526

Steel .

Molding and Extrusion Materials

Thermoplastic elastomer D4246

D1711 Terminology Relating to Electrical Insulation

Thermoplastic polyester D4507

D2116 Specification for FEP-Fluorocarbon Molding and

Extrusion Materials

Insulation for Wire and Cable

D2287 Specification for Nonrigid Vinyl Chloride Polymer

D3159 Specification for Modified ETFE-Fluoropolymer

and Copolymer Molding and Extrusion Compounds

Molding and Extrusion Materials

D2526 Specification for Ozone-Resisting Silicone Rubber

D3222 Specification for Unmodified Poly(Vinylidene Fluo-

ride) (PVDF) Molding Extrusion and Coating Materials

D3275 Classification System for E-CTFE-Fluoroplastic

This guide is under the jurisdiction ofASTM Committee D09 on Electrical and

Electronic Insulating Materials and is the direct responsibility of Subcommittee

Molding, Extrusion, and Coating Materials

D09.18 on Solid Insulations, Non-Metallic Shieldings, and Coverings for Electrical

D3307 Specification for Perfluoroalkoxy (PFA)-

and Telecommunications Wires and Cables.

Fluorocarbon Resin Molding and Extrusion Materials

Current edition approved April 10, 1999. Published June 1999. Originally

D3317 Specification for High Modulus, Organic Yarn and

approved in 1989. Last previous edition approved in 1995 as D4967 – 95. DOI:

10.1520/D4967-99R04E01.

Roving

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Withdrawn. The last approved version of this historical standard is referenced

Withdrawn.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4967–99 (2004)

D3664 Specification for Biaxially Oriented Polymeric 5. Construction Terminology and Material Selection

Resin Film for Capacitors in Electrical Equipment Options

D3935 Specification for Polycarbonate (PC) Unfilled and

5.1 Fiber-optic cable components and materials that have

Reinforced Material

been used for each:

5.1.1 Buffers/Tubes:

D4066 Classification System for Nylon Injection and Ex-

trusion Materials (PA) 5.1.1.1 Tight Buffers:

(a) (a) Fluoroplastic.

D4101 Specification for Polypropylene Injection and Extru-

(b) (b) Nylon.

sion Materials

(c) (c) Thermoplastic Polyester.

D4246 Specification for Ozone-Resistant Thermoplastic

(d) (d) Poly(vinyl chloride).

Elastomer Insulation For Wire and Cable, 90°C Operation

5.1.1.2 Loose Tubes:

D4507 Specification for Thermoplastic Polyester (TPES)

(a) (a) Fluoroplastic.

Materials

(b) (b) Nylon.

D4730 Specification for Flooding Compounds forTelecom-

(c) (c) Thermoplastic Polyester.

municatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.