ASTM B298-12(2017)

(Specification)Standard Specification for Silver-Coated Soft or Annealed Copper Wire

Standard Specification for Silver-Coated Soft or Annealed Copper Wire

ABSTRACT

This specification covers silver-coated, soft or annealed, round copper wire, intended for use in electrical equipment. The silver-coated wires are classified according to the total weight of the coated wires, namely; Class A, B, C, D, and E. Tensile strength test, resistivity test, weight of coating, and dimensional measurements shall be performed to conform to the requirements specified.

SCOPE

1.1 This specification covers silver-coated, soft or annealed, round copper wire, intended for use in electrical equipment, as follows:

1.1.1 Class A—Wire whose silver coating is at least 1.25 % of the total weight of the coated wire.

1.1.2 Class B—Wire whose silver coating is at least 2.50 % of the total weight of the coated wire.

1.1.3 Class C—Wire whose silver coating is at least 4.00 % of the total weight of the coated wire.

1.1.4 Class D—Wire whose silver coating is at least 6.10 % of the total weight of the coated wire.

1.1.5 Class E—Wire whose silver coating is at least 10.00 % of the total weight of the coated wire.

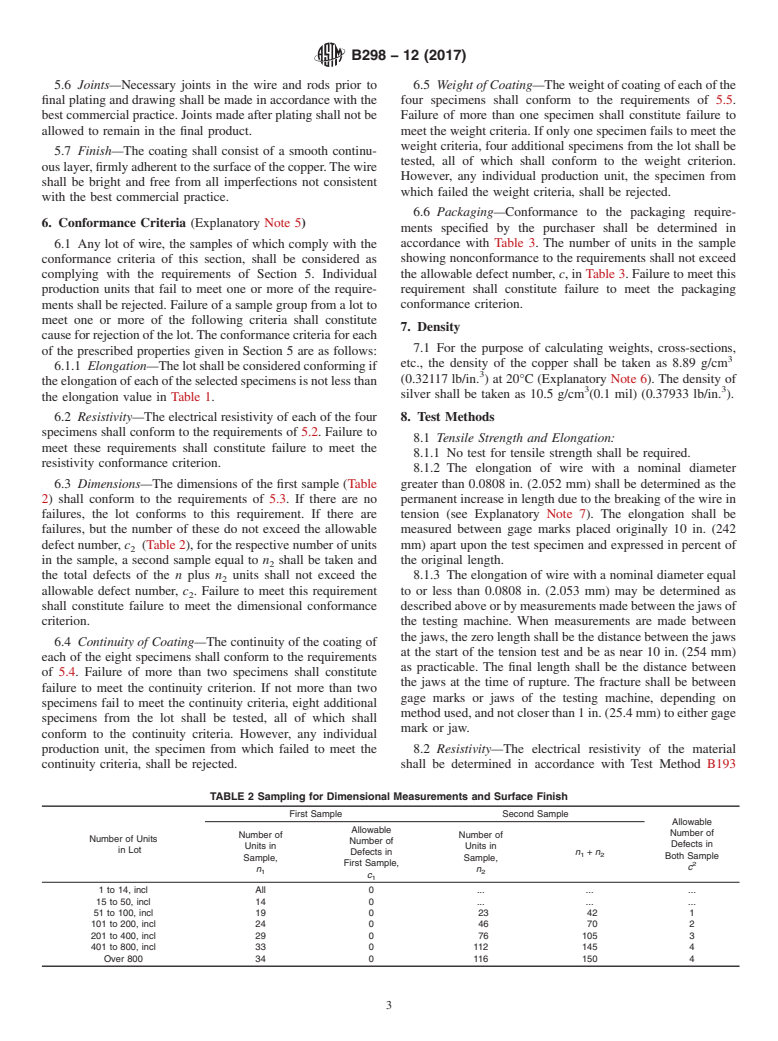

1.2 Silver-coated wire having different minimum percentages of silver by weight may be obtained by mutual agreement between the manufacturer and the purchaser. For information purposes the thickness of coating in microinches provided by the percentages listed above is shown in Table 1 (Explanatory Note 1).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exceptions—The SI values for density, resistivity, and volume are to be regarded as standard.

1.4 The following precautionary caveat pertains only to the test method section of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements see 8.4.1.2 and Explanatory Note 2.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B298 −12 (Reapproved 2017)

Standard Specification for

1

Silver-Coated Soft or Annealed Copper Wire

This standard is issued under the fixed designation B298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 Thisspecificationcoverssilver-coated,softorannealed,

ization established in the Decision on Principles for the

round copper wire, intended for use in electrical equipment, as

Development of International Standards, Guides and Recom-

follows:

mendations issued by the World Trade Organization Technical

1.1.1 Class A—Wire whose silver coating is at least 1.25%

Barriers to Trade (TBT) Committee.

of the total weight of the coated wire.

1.1.2 Class B—Wire whose silver coating is at least 2.50%

2. Referenced Documents

of the total weight of the coated wire.

1.1.3 Class C—Wire whose silver coating is at least 4.00% 2.1 The following documents of the issue in effect at the

of the total weight of the coated wire. time of reference form a part of this specification to the extent

1.1.4 Class D—Wire whose silver coating is at least 6.10% referenced herein:

of the total weight of the coated wire. 2

2.2 ASTM Standards:

1.1.5 Class E—Wirewhosesilvercoatingisatleast10.00%

B49Specification for Copper Rod for Electrical Purposes

of the total weight of the coated wire.

B193Test Method for Resistivity of Electrical Conductor

1.2 Silver-coated wire having different minimum percent- Materials

agesofsilverbyweightmaybeobtainedbymutualagreement B258 Specification for Nominal Diameters and Cross-

between the manufacturer and the purchaser. For information SectionalAreasofAWGSizesofSolidRoundWiresUsed

purposes the thickness of coating in microinches provided by as Electrical Conductors

the percentages listed above is shown in Table 1 (Explanatory E50Practices for Apparatus, Reagents, and Safety Consid-

Note 1). erations for Chemical Analysis of Metals, Ores, and

Related Materials

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Ordering Information

conversions to SI units that are provided for information only

and are not considered standard.

3.1 Ordersformaterialunderthisspecificationshallinclude

1.3.1 Exceptions—The SI values for density, resistivity, and the following information:

volume are to be regarded as standard.

3.1.1 Quantity of each size,

1.4 The following precautionary caveat pertains only to the 3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

testmethodsectionofthisspecification: This standard does not 3.1.3 Class of coating (Section 1 and Table 1),

purport to address all of the safety concerns, if any, associated

3.1.4 Type of copper, if special (see 4.2),

with its use. It is the responsibility of the user of this standard

3.1.5 Place of inspection (see 9.1), and

to establish appropriate safety and health practices and

3.1.6 Packaging and Package Marking (Section 10).

determine the applicability of regulatory limitations prior to

3.1.7 In addition supplementary requirements shall apply

use. For specific precautionary statements see 8.4.1.2 and

onlywhenspecifiedbythepurchaserintheinquiry,contract,or

Explanatory Note 2.

purchase order for direct procurement by agencies of the U.S.

Government (see S1, S2, and S3).

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

2

Conductors of Copper and Copper Alloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2017. Published April 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1955. Last previous edition approved in 2012 as B298–12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0298-12R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B298−12 (2017)

TABLE 1 Tensile Requirements

Area at 20°C Thickness of Coating, µin. (For Information Only)

Elongation

Diameter,

in 10 in.,

Class A, 1.25 Class B, 2.50 Class C, 4.00

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.