ASTM E747-18

(Practice)Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology

Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology

ABSTRACT

This practice covers the design, material grouping classification, and manufacture of wire image quality indicators (IQI) used to indicate the quality of radiologic images. This practice, applicable to X-ray and gamma-ray radiology, covers the use of wire penetrameters as the controlling image quality indicator for the material thickness range from 6.4 to 152 mm [0.25 to 6.0 in.]. The alloy group(s) of the material, the thickness or thickness range of the material, and the applicable IQI's that represent the required IQI thickness(s) and alloy(s) shall be considered when selecting IQI's.

SCOPE

1.1 This practice2 covers the design, material grouping classification, and manufacture of wire image quality indicators (IQI) used to indicate the quality of radiographic images.

1.2 This practice is applicable to X-ray and gamma-ray radiography.

1.3 This practice covers the use of wire penetrameters as the controlling image quality indicator for the material thickness range from 6.4 to 152 mm (0.25 to 6.0 in.).

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E747 −18

Standard Practice for

Design, Manufacture and Material Grouping Classification of

1

Wire Image Quality Indicators (IQI) Used for Radiology

This standard is issued under the fixed designation E747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope Shapes [Metric] (Withdrawn 2002)

B161Specification for Nickel Seamless Pipe and Tube

2

1.1 This practice covers the design, material grouping

B164Specification for Nickel-Copper Alloy Rod, Bar, and

classification, and manufacture of wire image quality indica-

Wire

tors (IQI) used to indicate the quality of radiographic images.

B166Specification for Nickel-Chromium-IronAlloys (UNS

1.2 This practice is applicable to X-ray and gamma-ray N06600, N06601, N06603, N06690, N06693, N06025,

radiography.

N06045, and N06696), Nickel-Chromium-Cobalt-

Molybdenum Alloy (UNS N06617), and Nickel-Iron-

1.3 Thispracticecoverstheuseofwirepenetrametersasthe

Chromium-TungstenAlloy (UNS N06674) Rod, Bar, and

controlling image quality indicator for the material thickness

Wire

range from 6.4 to 152 mm (0.25 to 6.0 in.).

E1025 Practice for Design, Manufacture, and Material

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

Grouping Classification of Hole-Type Image Quality In-

as standard.

dicators (IQI) Used for Radiography

E1316Terminology for Nondestructive Examinations

1.5 This standard does not purport to address all of the

5

2.2 ISO Standards:

safety concerns, if any, associated with its use. It is the

ISO 19232–1Non-Destructive Testing—Image Quality of

responsibility of the user of this standard to establish appro-

Radiographs-Part 1: Image Quality Indicators (Wire-

priate safety, health, and environmental practices and deter-

Type)-Determination of Image Quality Value

mine the applicability of regulatory limitations prior to use.

ISO 19232–2Non-Destructive Testing—Image Quality of

1.6 This international standard was developed in accor-

Radiographs-Part 2: Determination of the Image Quality

dance with internationally recognized principles on standard-

Value using Step/hole Type Image Quality Iindicators

ization established in the Decision on Principles for the

ISO 19232–3Non-Destructive Testing—Image Quality of

Development of International Standards, Guides and Recom-

Radiographs-Part 3: Image Quality Classes

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3. Terminology

3.1 Definitions—The definitions of terms in Terminology

2. Referenced Documents

E1316, Section D, relating to gamma and X-radiography, shall

3

2.1 ASTM Standards:

apply to the terms used in this practice.

B139/B139MSpecification for Phosphor Bronze Rod, Bar,

4. Wire IQI Requirements

and Shapes

B150MSpecification for Aluminum Bronze, Rod, Bar, and

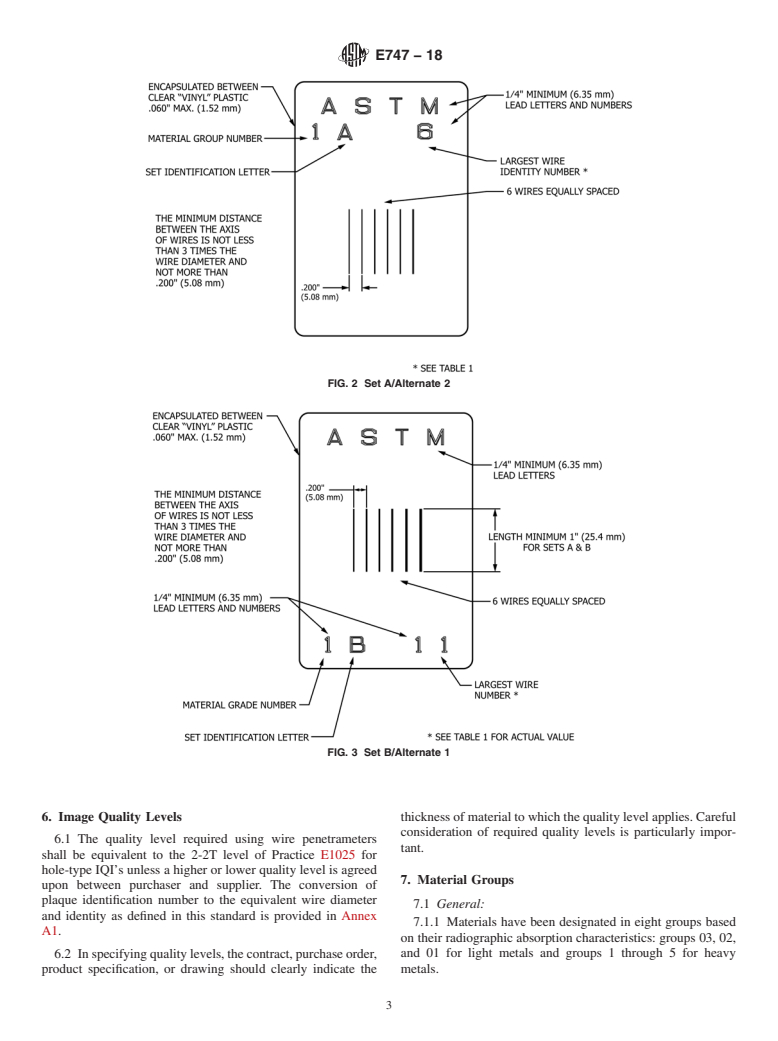

4.1 The quality of all levels of examination shall be deter-

mined by a set of wires conforming to the following require-

ments:

1 4.1.1 Wires shall be fabricated from materials or alloys

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.01 on

identifiedorlistedinaccordancewith7.2.Othermaterialsmay

Radiology (X and Gamma) Method.

be used in accordance with 7.3.

Current edition approved June 1, 2018. Published September 2018. Originally

4.1.2 The IQI consists of sets of wires arranged in order of

approvedin1980.Lastpreviouseditionapprovedin2010asE747-04(2010).DOI:

increasingdiameter.ThediametersizesspecifiedinTable1are

10.1520/E0747-18.

2

For ASME Boiler and Pressure Vessel Code applications see related Practice

SE-747 in Section II of that Code.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E747−18

TABLE 1 Wire IQI Sizes and Wire Identity Numbers

established from a consecutive series of numbers taken in

SET A SET B general from the ISO/R 10 series. The IQI shall be fabricated

W

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E747 − 04 (Reapproved 2010) E747 − 18

Standard Practice for

Design, Manufacture and Material Grouping Classification of

1

Wire Image Quality Indicators (IQI) Used for Radiology

This standard is issued under the fixed designation E747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This practice covers the design, material grouping classification, and manufacture of wire image quality indicators (IQI)

used to indicate the quality of radiologicradiographic images.

1.2 This practice is applicable to X-ray and gamma-ray radiology.radiography.

1.3 This practice covers the use of wire penetrameters as the controlling image quality indicator for the material thickness range

from 6.4 to 152 mm (0.25 to 6.0 in.).

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B139/B139M Specification for Phosphor Bronze Rod, Bar, and Shapes

4

B150M Specification for Aluminum Bronze, Rod, Bar, and Shapes [Metric] (Withdrawn 2002)

B161 Specification for Nickel Seamless Pipe and Tube

B164 Specification for Nickel-Copper Alloy Rod, Bar, and Wire

B166 Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045,

and N06696), Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617), and Nickel-Iron-Chromium-Tungsten Alloy

(UNS N06674) Rod, Bar, and Wire

E1025 Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI)

Used for Radiography

E1316 Terminology for Nondestructive Examinations

5

2.2 OtherISO Standards:

EN 462–1ISO 19232–1 Non-Destructive Testing—Image Quality of Radiographs-Part 1: Image Quality Indicators (Wire-Type)-

Determination of Image Quality Value

ISO 19232–2 Non-Destructive Testing—Image Quality of Radiographs-Part 2: Determination of the Image Quality Value using

Step/hole Type Image Quality Iindicators

ISO 19232–3 Non-Destructive Testing—Image Quality of Radiographs-Part 3: Image Quality Classes

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology (X and

Gamma) Method.

Current edition approved Nov. 1, 2010June 1, 2018. Published March 2011September 2018. Originally approved in 1980. Last previous edition approved in 20042010

as E747 - 04.E747 - 04(2010). DOI: 10.1520/E0747-04R10.10.1520/E0747-18.

2

For ASME Boiler and Pressure Vessel Code applications see related Practice SE-747 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

5

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E747 − 18

3. Terminology

3.1 Definitions—The definitions of terms in Terminology E1316, Section D, relating to gamma and X-radiology,X-radiography,

shall apply to the terms used in this practice.

4. Wire IQI Requirements

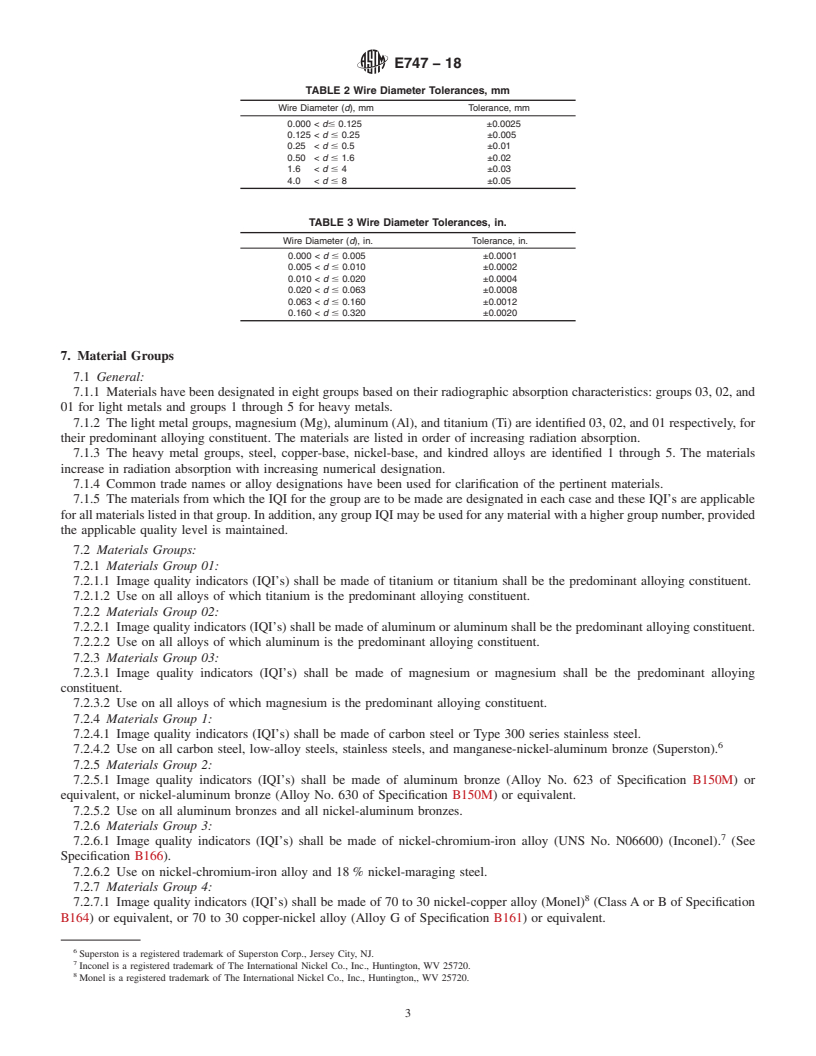

4.1 The quality of all levels of examination shall be determined by a set of wires conforming to the following requirements:

4.1.1 Wires shall be fabricated from materials or alloys identified or listed in accordance with 7.2. Other materials may be used

in accordance with 7.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.