ASTM D323-08(2014)

(Test Method)Standard Test Method for Vapor Pressure of Petroleum Products (Reid Method)

Standard Test Method for Vapor Pressure of Petroleum Products (Reid Method)

SIGNIFICANCE AND USE

5.1 Vapor pressure is an important physical property of volatile liquids. This test method is used to determine the vapor pressure at 37.8°C (100°F) of petroleum products and crude oils with initial boiling point above 0°C (32°F).

5.2 Vapor pressure is critically important for both automotive and aviation gasolines, affecting starting, warm-up, and tendency to vapor lock with high operating temperatures or high altitudes. Maximum vapor pressure limits for gasoline are legally mandated in some areas as a measure of air pollution control.

5.3 Vapor pressure of crude oils is of importance to the crude producer and the refiner for general handling and initial refinery treatment.

5.4 Vapor pressure is also used as an indirect measure of the evaporation rate of volatile petroleum solvents.

SCOPE

1.1 This test method covers procedures for the determination of vapor pressure (see Note 1) of gasoline, volatile crude oil, and other volatile petroleum products.

1.2 Procedure A is applicable to gasoline and other petroleum products with a vapor pressure of less than 180 kPa (26 psi).

1.3 Procedure B may also be applicable to these other materials, but only gasoline was included in the interlaboratory test program to determine the precision of this test method.

1.4 Procedure C is for materials with a vapor pressure of greater than 180 kPa (26 psi).

1.5 Procedure D for aviation gasoline with a vapor pressure of approximately 50 kPa (7 psi).

Note 1: Because the external atmospheric pressure is counteracted by the atmospheric pressure initially present in the vapor chamber, the Reid vapor pressure is an absolute pressure at 37.8°C (100°F) in kilopascals (pounds-force per square inch). The Reid vapor pressure differs from the true vapor pressure of the sample due to some small sample vaporization and the presence of water vapor and air in the confined space.

1.6 This test method is not applicable to liquefied petroleum gases or fuels containing oxygenated compounds other than methyl t-butyl ether (MTBE). For determination of the vapor pressure of liquefied petroleum gases, refer to Test Method D1267 or Test Method D6897. For determination of the vapor pressure of gasoline-oxygenate blends, refer to Test Method D4953. The precision for crude oil has not been determined since the early 1950s (see Note 3). Test Method D6377 has been approved as a method for determination of vapor pressure of crude oil. IP 481 is a test method for determination of the air-saturated vapor pressure of crude oil.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Sections 7 and 18, and 12.5.3, 15.5, 21.2, A1.1.2, A1.1.6, and A2.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D323 − 08(Reapproved 2014)

Standard Test Method for

Vapor Pressure of Petroleum Products (Reid Method)

This standard is issued under the fixed designation D323; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers procedures for the determina-

responsibility of the user of this standard to establish appro-

tion of vapor pressure (see Note 1) of gasoline, volatile crude

priate safety and health practices and determine the applica-

oil, and other volatile petroleum products.

bility of regulatory limitations prior to use. Specific warning

1.2 Procedure A is applicable to gasoline and other petro-

statements are given in Sections 7 and 18, and 12.5.3, 15.5,

leum products with a vapor pressure of less than 180 kPa

21.2, A1.1.2, A1.1.6, and A2.3.

(26 psi).

2. Referenced Documents

1.3 Procedure B may also be applicable to these other

2.1 ASTM Standards:

materials, but only gasoline was included in the interlaboratory

D1267 Test Method for Gage Vapor Pressure of Liquefied

test program to determine the precision of this test method.

Petroleum (LP) Gases (LP-Gas Method)

1.4 Procedure C is for materials with a vapor pressure of

D4057 Practice for Manual Sampling of Petroleum and

greater than 180 kPa (26 psi).

Petroleum Products

1.5 Procedure D for aviation gasoline with a vapor pressure

D4175 Terminology Relating to Petroleum, Petroleum

of approximately 50 kPa (7 psi).

Products, and Lubricants

NOTE 1—Because the external atmospheric pressure is counteracted by

D4953 Test Method for Vapor Pressure of Gasoline and

the atmospheric pressure initially present in the vapor chamber, the Reid

Gasoline-Oxygenate Blends (Dry Method)

vapor pressure is an absolute pressure at 37.8°C (100°F) in kilopascals

D6377 Test Method for Determination of Vapor Pressure of

(pounds-force per square inch). The Reid vapor pressure differs from the

Crude Oil: VPCR (Expansion Method)

true vapor pressure of the sample due to some small sample vaporization

x

and the presence of water vapor and air in the confined space. D6897 Test Method for Vapor Pressure of Liquefied Petro-

leum Gases (LPG) (Expansion Method)

1.6 This test method is not applicable to liquefied petroleum

E1 Specification for ASTM Liquid-in-Glass Thermometers

gases or fuels containing oxygenated compounds other than

2.2 Energy Institute Standards:

methyl t-butyl ether (MTBE). For determination of the vapor

IP 481 Test Method for Determination of the Air Saturated

pressure of liquefied petroleum gases, refer to Test Method

Vapour Pressure (ASVP) of Crude Oil

D1267 or Test Method D6897. For determination of the vapor

pressure of gasoline-oxygenate blends, refer to Test Method

3. Terminology

D4953. The precision for crude oil has not been determined

3.1 Definitions:

since the early 1950s (see Note 3). Test Method D6377 has

3.1.1 Bourdon spring gauge, n—pressure measuring device

been approved as a method for determination of vapor pressure

that employs a Bourdon tube connected to an indicator.

of crude oil. IP 481 is a test method for determination of the

air-saturated vapor pressure of crude oil.

3.1.2 Bourdon tube, n—flattened metal tube bent to a curve

that straightens under internal pressure.

1.7 The values stated in SI units are to be regarded as the

3.1.3 gasoline-oxygenate blend, n—spark-ignition engine

standard. The values given in parentheses are for information

only. fuel consisting primarily of gasoline with one or more oxygen-

ates.

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.08 on Volatility. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedJune1,2014.PublishedJuly2014.Originallyapproved the ASTM website.

in 1930. Last previous edition approved in 2008 as D323–08. DOI: 10.1520/D0323- Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

08R14. U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D323 − 08 (2014)

3.1.4 oxygenate, n—oxygen-containing ashless organic following list emphasizes the importance of strict adherence to

compound, such as an alcohol or ether, which may be used as the precautions given in the procedure:

a fuel or fuel supplement. D4175 7.1.1 Checking the Pressure Gauge—Check all gauges

against a pressure measuring device (see A1.6) after each test

3.1.5 Reid vapor pressure (RVP), n—resultant total pressure

to ensure higher precision of results (see 12.4). Read the gauge

reading, corrected for measuring error, of a specific empirical

while in a vertical position and after tapping it lightly.

test method (Test Method D323) for measuring the vapor

7.1.2 Checking for Leaks—Check all apparatus before and

pressure of gasoline and other volatile products.

during each test for both liquid and vapor leaks (see Note 5).

3.1.6 vapor pressure, n—pressure exerted by the vapor of a

7.1.3 Sampling—Because initial sampling and the handling

liquid when in equilibrium with the liquid. D4175

of samples will greatly affect the final results, employ the

3.2 Abbreviations:

utmost precaution and the most meticulous care to avoid losses

3.2.1 ASVP, n—air saturated vapor pressure.

through evaporation and even slight changes in composition

(see Section 8 and 12.1). In no case shall any part of the Reid

3.2.2 LPG, n—liquefied petroleum gases.

apparatus itself be used as the sample container prior to

3.2.3 MTBE, n—methyl t-butyl ether.

actually conducting the test.

3.2.4 RVP, n—Reid Vapor Pressure.

7.1.4 Purging the Apparatus—Thoroughly purge the pres-

sure gauge, the liquid chamber, and the vapor chamber to be

4. Summary of Test Method

sure that they are free of residual sample. This is most

4.1 The liquid chamber of the vapor pressure apparatus is

conveniently done at the end of the test in preparation for the

filled with the chilled sample and connected to the vapor

next test (see 12.5 and 15.5).

chamber that has been heated to 37.8°C (100°F) in a bath. The

7.1.5 Coupling the Apparatus—Carefully observe the re-

assembled apparatus is immersed in a bath at 37.8°C (100°F)

quirements of 12.2.

until a constant pressure is observed. The reading, suitably

7.1.6 Shaking the Apparatus—Shake the apparatus vigor-

corrected, is reported as the Reid vapor pressure.

ously as directed to ensure equilibrium.

4.2 All four procedures utilize liquid and vapor chambers of

the same internal volume. Procedure B utilizes a semiauto-

8. Sampling

matic apparatus immersed in a horizontal bath and rotated

8.1 The extreme sensitivity of vapor pressure measurements

while attaining equilibrium. Either a Bourdon gauge or pres-

to losses through evaporation and the resulting changes in

sure transducer may be used with this procedure. Procedure C

composition is such as to require the utmost precaution and the

utilizes a liquid chamber with two valved openings. Procedure

most meticulous care in the handling of samples. The provi-

D requires more stringent limits on the ratio of the liquid and

sions of this section shall apply to all samples for vapor

vapor chambers.

pressure determinations, except as specifically excluded for

samples having vapor pressures above 180 kPa (26 psi); see

5. Significance and Use

Section 19.

5.1 Vapor pressure is an important physical property of

8.2 Sampling shall be done in accordance with Practice

volatileliquids.Thistestmethodisusedtodeterminethevapor

D4057.

pressure at 37.8°C (100°F) of petroleum products and crude

oils with initial boiling point above 0°C (32°F).

8.3 Sample Container Size—The size of the sample con-

tainer from which the vapor pressure sample is taken shall be

5.2 Vapor pressure is critically important for both automo-

1 L (1 qt). It shall be 70 to 80 % filled with sample.

tive and aviation gasolines, affecting starting, warm-up, and

8.3.1 The present precision statement has been derived

tendency to vapor lock with high operating temperatures or

using samples in 1-L (1-qt) containers. However, samples

high altitudes. Maximum vapor pressure limits for gasoline are

taken in containers of other sizes as prescribed in Practice

legally mandated in some areas as a measure of air pollution

D4057 can be used if it is recognized that the precision could

control.

be affected. In the case of referee testing, the 1-L(1-qt) sample

5.3 Vapor pressure of crude oils is of importance to the

container shall be mandatory.

crude producer and the refiner for general handling and initial

8.4 The Reid vapor pressure determination shall be per-

refinery treatment.

formed on the first test specimen withdrawn from the sample

5.4 Vapor pressure is also used as an indirect measure of the

container. The remaining sample in the container cannot be

evaporation rate of volatile petroleum solvents.

used for a second vapor pressure determination. If necessary,

obtain a new sample.

6. Apparatus

8.4.1 Protect samples from excessive heat prior to testing.

6.1 The required apparatus for Procedures A, C, and D is

8.4.2 Do not test samples in leaky containers. They should

describedinAnnexA1.ApparatusforProcedureBisdescribed

be discarded and new samples obtained.

in Annex A2.

8.5 Sampling Handling Temperature—In all cases, cool the

7. Hazards

sample container and contents to 0 to 1°C (32 to 34°F) before

7.1 Gross errors can be obtained in vapor pressure measure- the container is opened. Sufficient time to reach this tempera-

mentsiftheprescribedprocedureisnotfollowedcarefully.The ture shall be ensured by direct measurement of the temperature

D323 − 08 (2014)

of a similar liquid in a like container placed in the cooling bath PROCEDURE A

at the same time as the sample.

FOR PETROLEUM PRODUCTS HAVING REID

VAPOR PRESSURES BELOW 180 kPa (26 psi)

9. Report

9.1 Report the result observed in 12.4 or 15.4, after correct-

11. Preparation for Test

ing for any difference between the gauge and the pressure

11.1 Verification of Sample Container Filling—With the

measuring device (see A1.6), to the nearest 0.25 kPa (0.05 psi)

sampleatatemperatureof0to1°C,takethecontainerfromthe

as the Reid vapor pressure.

cooling bath or refrigerator and wipe dry with absorbent

material. If the container is not transparent, unseal it, and using

10. Precison and Bias

a suitable gauge, confirm that the sample volume equals 70 to

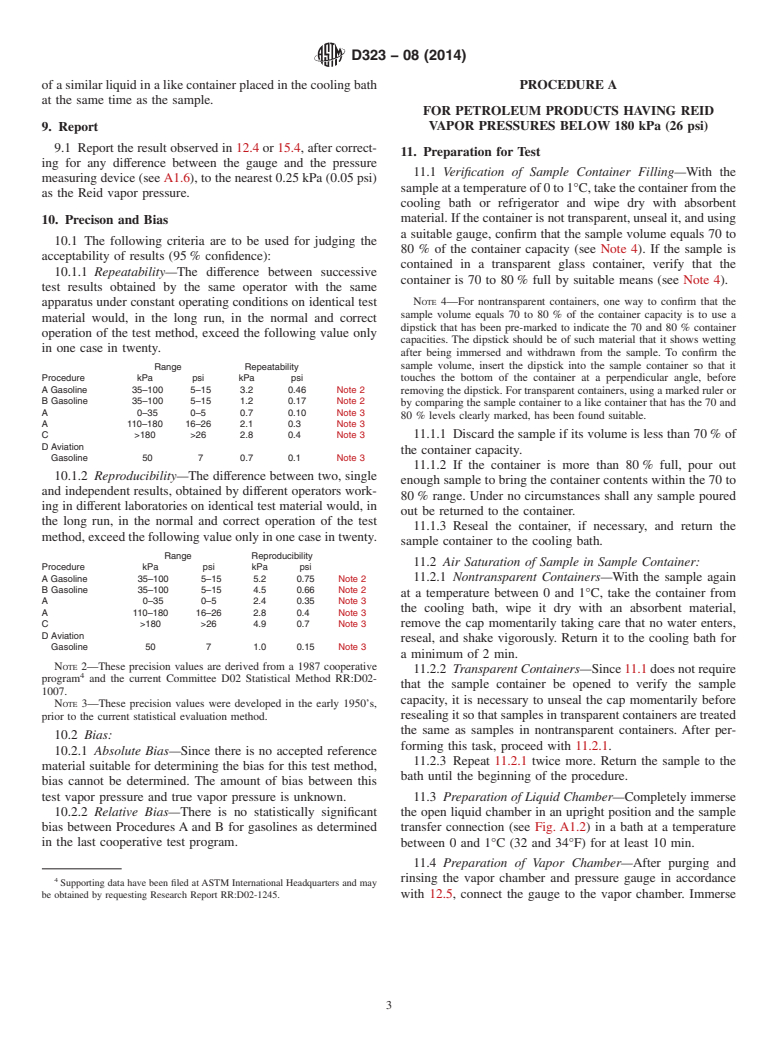

10.1 The following criteria are to be used for judging the

80 % of the container capacity (see Note 4). If the sample is

acceptability of results (95 % confidence):

contained in a transparent glass container, verify that the

10.1.1 Repeatability—The difference between successive

container is 70 to 80 % full by suitable means (see Note 4).

test results obtained by the same operator with the same

NOTE 4—For nontransparent containers, one way to confirm that the

apparatus under constant operating conditions on identical test

sample volume equals 70 to 80 % of the container capacity is to use a

material would, in the long run, in the normal and correct

dipstick that has been pre-marked to indicate the 70 and 80 % container

operation of the test method, exceed the following value only

capacities. The dipstick should be of such material that it shows wetting

in one case in twenty.

after being immersed and withdrawn from the sample. To confirm the

sample volume, insert the dipstick into the sample container so that it

Range Repeatability

Procedure kPa psi kPa psi touches the bottom of the container at a perpendicular angle, before

A Gasoline 35–100 5–15 3.2 0.46 Note 2 removing the dipstick. For transparent containers, using a marked ruler or

B Gasoline 35–100 5–15 1.2 0.17 Note 2

by comparing the sample container to a like container that has the 70 and

A 0–35 0–5 0.7 0.10 Note 3

80 % levels clearly marked, has been found suitable.

A 110–180 16–26 2.1 0.3 Note 3

C >180 >26 2.8 0.4 Note 3 11.1.1 Discard the sample if its volume is less than 70 % of

D Aviation

the container capacity.

Gasoline 50 7 0.7 0.1 Note 3

11.1.2 If the container is more than 80 % full, pour out

10.1.2 Reproducibility—The difference between two, single

enough sample to bring the container contents within the 70 to

and independent results, obtained by different operators work-

80 % range. Under no circumstances shall any sample poured

ing in different laboratories on identical test material would, in

out be returned to the container.

the long run, in the normal and correct operation of the test

11.1.3 Reseal the container, if necessary, and return the

method, exceed the following value only in one case in twenty.

sample container to the cooling bath.

Range Reproducibility

11.2 Air Saturation of Sample in Sample Container:

Procedure kPa psi kPa psi

A Gasoline 35–100 5–15 5.2 0.75 Note 2 11.2.1 Nontransparent Containers—With the sample again

B Gasoline 35–100 5–15 4.5 0.66 Note 2

at a temperature between 0 and 1°C, take the container from

A 0–35 0–5 2.4 0.35 Note 3

the cooling bath, wipe it dry with an absorbent material,

A 110–180 16–26 2.8 0.4 Note 3

C >180 >26 4.9 0.7 Note 3 remove the cap momentarily taking care that no water enters,

D Aviation

reseal, and shake vigorously. Return it to the cooling bath for

Gasoline 50 7 1.0 0.15 Note 3

a minimum of 2 min.

NOTE 2—These precision values are derived from a 1987 cooperative

11.2.2 Transparent Containers—Since 11.1 does not require

program and the current Committee D02 Statistical Method RR:D02-

that the sample container be opened to verify the sample

1007.

capacity, it is necessary to unseal the cap momentarily before

NOTE 3—These precision values were developed in the early 1950’s,

resealing it so that samples in transparent containers are treated

prior to the current statistical evaluation method.

the same as samples in nontransparent containers. After per-

10.2 Bias:

forming this task, proceed with 11.2.1.

10.2.1 Absolute Bias—Since there is no accepted reference

11.2.3 Repeat 11.2.1 twice more. Return the sample to the

material suitable for determining the bias for this test method,

bath until the begin

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D323 − 08 D323 − 08 (Reapproved 2014)

Standard Test Method for

Vapor Pressure of Petroleum Products (Reid Method)

This standard is issued under the fixed designation D323; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This test method covers procedures for the determination of vapor pressure (see Note 1) of gasoline, volatile crude oil, and

other volatile petroleum products.

1.2 Procedure A is applicable to gasoline and other petroleum products with a vapor pressure of less than 180 kPa (26

psi).180 kPa (26 psi).

1.3 Procedure B may also be applicable to these other materials, but only gasoline was included in the interlaboratory test

program to determine the precision of this test method.

1.4 Procedure C is for materials with a vapor pressure of greater than 180 kPa (26 psi).

1.5 Procedure D for aviation gasoline with a vapor pressure of approximately 50 kPa (7 psi).

NOTE 1—Because the external atmospheric pressure is counteracted by the atmospheric pressure initially present in the vapor chamber, the Reid vapor

pressure is an absolute pressure at 37.8°C (100°F) in kilopascals (pounds-force per square inch). The Reid vapor pressure differs from the true vapor

pressure of the sample due to some small sample vaporization and the presence of water vapor and air in the confined space.

1.6 This test method is not applicable to liquefied petroleum gases or fuels containing oxygenated compounds other than methyl

t-butyl ether (MTBE). For determination of the vapor pressure of liquefied petroleum gases, refer to Test Method D1267 or Test

Method D6897. For determination of the vapor pressure of gasoline-oxygenate blends, refer to Test Method D4953. The precision

for crude oil has not been determined since the early 1950s (see Note 3). Test Method D6377 has been approved as a method for

determination of vapor pressure of crude oil. IP 481 is a test method for determination of the air-saturated vapor pressure of crude

oil.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements are given in Sections 7 and 18, and 12.5.3, 15.5, 21.2, A1.1.2, A1.1.6, and

A2.3.

2. Referenced Documents

2.1 ASTM Standards:

D1267 Test Method for Gage Vapor Pressure of Liquefied Petroleum (LP) Gases (LP-Gas Method)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D4953 Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

D6377 Test Method for Determination of Vapor Pressure of Crude Oil: VPCR (Expansion Method)

x

D6897 Test Method for Vapor Pressure of Liquefied Petroleum Gases (LPG) (Expansion Method)

E1 Specification for ASTM Liquid-in-Glass Thermometers

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.08 on Volatility.

Current edition approved Dec. 15, 2008June 1, 2014. Published February 2009July 2014. Originally approved in 1930. Last previous edition approved in 20062008 as

D323–06.–08. DOI: 10.1520/D0323-08.10.1520/D0323-08R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D323 − 08 (2014)

2.2 Energy Institute Standards:

IP 481 Test Method for Determination of the Air Saturated Vapour Pressure (ASVP) of Crude Oil

3. Terminology

3.1 Definitions:

3.1.1 Bourdon spring gauge, n—pressure measuring device that employs a Bourdon tube connected to an indicator.

3.1.2 Bourdon tube, n—flattened metal tube bent to a curve that straightens under internal pressure.

3.1.3 gasoline-oxygenate blend, n—spark-ignition engine fuel consisting primarily of gasoline with one or more oxygenates.

3.1.4 oxygenate, n—oxygen-containing ashless organic compound, such as an alcohol or ether, which may be used as a fuel or

fuel supplement.D4175 D4175

3.1.5 Reid vapor pressure (RVP), n—resultant total pressure reading, corrected for measuring error, of a specific empirical test

method (Test Method D323) for measuring the vapor pressure of gasoline and other volatile products.

3.1.6 vapor pressure, n—pressure exerted by the vapor of a liquid when in equilibrium with the liquid.D4175 D4175

3.2 Abbreviations:

3.2.1 ASVP, n—air saturated vapor pressure.

3.2.2 LPG, n—liquefied petroleum gases.

3.2.3 MTBE, n—methyl t-butyl ether.

3.2.4 RVP, n—Reid Vapor Pressure.

4. Summary of Test Method

4.1 The liquid chamber of the vapor pressure apparatus is filled with the chilled sample and connected to the vapor chamber

that has been heated to 37.8°C (100°F) in a bath. The assembled apparatus is immersed in a bath at 37.8°C (100°F) until a constant

pressure is observed. The reading, suitably corrected, is reported as the Reid vapor pressure.

4.2 All four procedures utilize liquid and vapor chambers of the same internal volume. Procedure B utilizes a semiautomatic

apparatus immersed in a horizontal bath and rotated while attaining equilibrium. Either a Bourdon gauge or pressure transducer

may be used with this procedure. Procedure C utilizes a liquid chamber with two valved openings. Procedure D requires more

stringent limits on the ratio of the liquid and vapor chambers.

5. Significance and Use

5.1 Vapor pressure is an important physical property of volatile liquids. This test method is used to determine the vapor pressure

at 37.8°C (100°F) of petroleum products and crude oils with initial boiling point above 0°C (32°F).

5.2 Vapor pressure is critically important for both automotive and aviation gasolines, affecting starting, warm-up, and tendency

to vapor lock with high operating temperatures or high altitudes. Maximum vapor pressure limits for gasoline are legally mandated

in some areas as a measure of air pollution control.

5.3 Vapor pressure of crude oils is of importance to the crude producer and the refiner for general handling and initial refinery

treatment.

5.4 Vapor pressure is also used as an indirect measure of the evaporation rate of volatile petroleum solvents.

6. Apparatus

6.1 The required apparatus for Procedures A, C, and D is described in Annex A1. Apparatus for Procedure B is described in

Annex A2.

7. Hazards

7.1 Gross errors can be obtained in vapor pressure measurements if the prescribed procedure is not followed carefully. The

following list emphasizes the importance of strict adherence to the precautions given in the procedure:

7.1.1 Checking the Pressure Gauge—Check all gauges against a pressure measuring device (see A1.6) after each test to ensure

higher precision of results (see 12.4). Read the gauge while in a vertical position and after tapping it lightly.

7.1.2 Checking for Leaks—Check all apparatus before and during each test for both liquid and vapor leaks (see Note 5).

7.1.3 Sampling—Because initial sampling and the handling of samples will greatly affect the final results, employ the utmost

precaution and the most meticulous care to avoid losses through evaporation and even slight changes in composition (see Section

8 and 12.1). In no case shall any part of the Reid apparatus itself be used as the sample container prior to actually conducting the

test.

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

D323 − 08 (2014)

7.1.4 Purging the Apparatus—Thoroughly purge the pressure gauge, the liquid chamber, and the vapor chamber to be sure that

they are free of residual sample. This is most conveniently done at the end of the test in preparation for the next test (see 12.5 and

15.5).

7.1.5 Coupling the Apparatus—Carefully observe the requirements of 12.2.

7.1.6 Shaking the Apparatus—Shake the apparatus vigorously as directed to ensure equilibrium.

8. Sampling

8.1 The extreme sensitivity of vapor pressure measurements to losses through evaporation and the resulting changes in

composition is such as to require the utmost precaution and the most meticulous care in the handling of samples. The provisions

of this section shall apply to all samples for vapor pressure determinations, except as specifically excluded for samples having

vapor pressures above 180 kPa (26 psi); see Section 19.

8.2 Sampling shall be done in accordance with Practice D4057.

8.3 Sample Container Size—The size of the sample container from which the vapor pressure sample is taken shall be 1 L (1 qt).

It shall be 70 to 80 % filled with sample.

8.3.1 The present precision statement has been derived using samples in 1-L (1-qt) containers. However, samples taken in

containers of other sizes as prescribed in Practice D4057 can be used if it is recognized that the precision could be affected. In the

case of referee testing, the 1-L (1-qt) sample container shall be mandatory.

8.4 The Reid vapor pressure determination shall be performed on the first test specimen withdrawn from the sample container.

The remaining sample in the container cannot be used for a second vapor pressure determination. If necessary, obtain a new

sample.

8.4.1 Protect samples from excessive heat prior to testing.

8.4.2 Do not test samples in leaky containers. They should be discarded and new samples obtained.

8.5 Sampling Handling Temperature —Temperature—In all cases, cool the sample container and contents to 0 to 1°C (32 to

34°F) before the container is opened. Sufficient time to reach this temperature shall be ensured by direct measurement of the

temperature of a similar liquid in a like container placed in the cooling bath at the same time as the sample.

9. Report

9.1 Report the result observed in 12.4 or 15.4, after correcting for any difference between the gauge and the pressure measuring

device (see A1.6), to the nearest 0.25 kPa (0.05 psi) as the Reid vapor pressure.

10. Precison and Bias

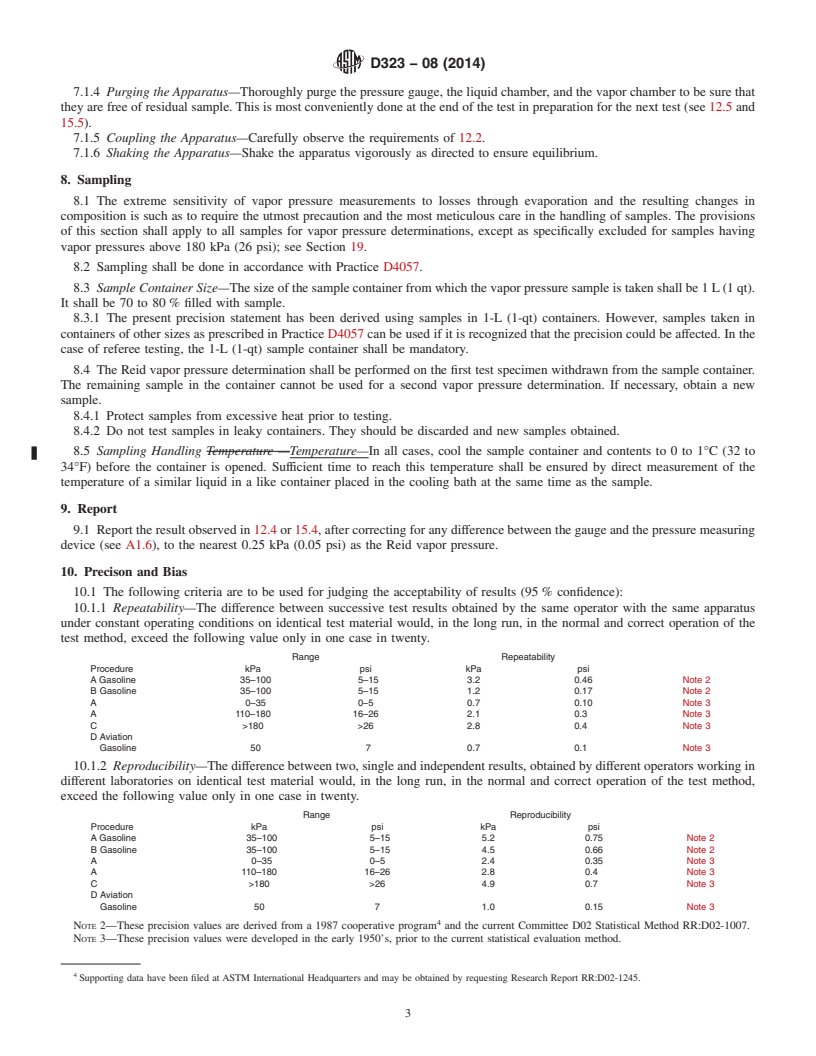

10.1 The following criteria are to be used for judging the acceptability of results (95 % confidence):

10.1.1 Repeatability—The difference between successive test results obtained by the same operator with the same apparatus

under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the

test method, exceed the following value only in one case in twenty.

Range Repeatability

Procedure kPa psi kPa psi

A Gasoline 35–100 5–15 3.2 0.46 Note 2

B Gasoline 35–100 5–15 1.2 0.17 Note 2

A 0–35 0–5 0.7 0.10 Note 3

A 110–180 16–26 2.1 0.3 Note 3

C >180 >26 2.8 0.4 Note 3

D Aviation

Gasoline 50 7 0.7 0.1 Note 3

10.1.2 Reproducibility—The difference between two, single and independent results, obtained by different operators working in

different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method,

exceed the following value only in one case in twenty.

Range Reproducibility

Procedure kPa psi kPa psi

A Gasoline 35–100 5–15 5.2 0.75 Note 2

B Gasoline 35–100 5–15 4.5 0.66 Note 2

A 0–35 0–5 2.4 0.35 Note 3

A 110–180 16–26 2.8 0.4 Note 3

C >180 >26 4.9 0.7 Note 3

D Aviation

Gasoline 50 7 1.0 0.15 Note 3

NOTE 2—These precision values are derived from a 1987 cooperative program and the current Committee D02 Statistical Method RR:D02-1007.

NOTE 3—These precision values were developed in the early 1950’s, prior to the current statistical evaluation method.

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02-1245.

D323 − 08 (2014)

10.2 Bias:

10.2.1 Absolute Bias—Since there is no accepted reference material suitable for determining the bias for this test method, bias

cannot be determined. The amount of bias between this test vapor pressure and true vapor pressure is unknown.

10.2.2 Relative Bias—There is no statistically significant bias between Procedures A and B for gasolines as determined in the

last cooperative test program.

PROCEDURE A

FOR PETROLEUM PRODUCTS HAVING REID VAPOR PRESSURES BELOW 180 kPa (26 psi)

PROCEDURE A

FOR PETROLEUM PRODUCTS HAVING REID VAPOR PRESSURES BELOW 180 kPa (26 psi)

11. Preparation for Test

11.1 Verification of Sample Container Filling—With the sample at a temperature of 0 to 1°C, take the container from the cooling

bath or refrigerator and wipe dry with absorbent material. If the container is not transparent, unseal it, and using a suitable gauge,

confirm that the sample volume equals 70 to 80 % of the container capacity (see Note 4). If the sample is contained in a transparent

glass container, verify that the container is 70 to 80 % full by suitable means (see Note 4).

NOTE 4—For nontransparent containers, one way to confirm that the sample volume equals 70 to 80 % of the container capacity is to use a dipstick

that has been pre-marked to indicate the 70 and 80 % container capacities. The dipstick should be of such material that it shows wetting after being

immersed and withdrawn from the sample. To confirm the sample volume, insert the dipstick into the sample container so that it touches the bottom of

the container at a perpendicular angle, before removing the dipstick. For transparent containers, using a marked ruler or by comparing the sample

container to a like container that has the 70 and 80 % levels clearly marked, has been found suitable.

11.1.1 Discard the sample if its volume is less than 70 % of the container capacity.

11.1.2 If the container is more than 80 % full, pour out enough sample to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.