ASTM D1587-00(2007)e1

(Practice)Standard Practice for Thin-Walled Tube Sampling of Soils for Geotechnical Purposes

Standard Practice for Thin-Walled Tube Sampling of Soils for Geotechnical Purposes

SCOPE

1.1 This practice covers a procedure for using a thin-walled metal tube to recover relatively undisturbed soil samples suitable for laboratory tests of engineering properties, such as strength, compressibility, permeability, and density. Thin-walled tubes used in piston, plug, or rotary-type samplers should comply with Section 6.3 of this practice which describes the thin-walled tubes. Note 1 - This practice does not apply to liners used within the samplers.

1.2 This Practice is limited to soils that can be penetrated by the thin-walled tube. This sampling method is not recommended for sampling soils containing gravel or larger size soil particles cemented or very hard soils. Other soil samplers may be used for sampling these soil types. Such samplers include driven split barrel samplers and soil coring devices (D 1586, D 3550, and D 6151). For information on appropriate use of other soil samplers refer to D 6169.

1.3 This practice is often used in conjunction with fluid rotary drilling (D 1452, D 5783) or hollow-stem augers (D 6151). Subsurface geotechnical explorations should be reported in accordance with practice (D 5434). This practice discusses some aspects of sample preservation after the sampling event. For information on preservation and transportation process of soil samples, consult Practice D 4220. This practice does not address environmental sampling; consult D 6169 and D 6232for information on sampling for environmental investigations.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are provided for information purposes only. The tubing tolerances presented in are from sources available in North America. Use of metric equivalent is acceptable as long as thickness and proportions are similar to those required in this standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "Standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D1587–00 (Reapproved 2007)

Standard Practice for

Thin-Walled Tube Sampling of Soils for Geotechnical

Purposes

This standard is issued under the fixed designation D 1587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial changes were made in June 2007.

1. Scope* America. Use of metric equivalent is acceptable as long as

thickness and proportions are similar to those required in this

1.1 This practice covers a procedure for using a thin-walled

standard.

metal tube to recover relatively undisturbed soil samples

1.5 This standard does not purport to address all of the

suitable for laboratory tests of engineering properties, such as

safety concerns, if any, associated with its use. It is the

strength, compressibility, permeability, and density. Thin-

responsibility of the user of this standard to establish appro-

walled tubes used in piston, plug, or rotary-type samplers

priate safety and health practices and determine the applica-

should comply with Section 6.3 of this practice which de-

bility of regulatory limitations prior to use.

scribes the thin-walled tubes.

1.6 This practice offers a set of instructions for performing

NOTE 1—This practice does not apply to liners used within the

one or more specific operations. This document cannot replace

samplers.

educationorexperienceandshouldbeusedinconjunctionwith

1.2 ThisPractice islimitedtosoilsthatcanbepenetrated by

professional judgment. Not all aspects of this practice may be

the thin-walled tube. This sampling method is not recom-

applicable in all circumstances. This ASTM standard is not

mended for sampling soils containing gravel or larger size soil

intended to represent or replace the standard of care by which

particles cemented or very hard soils. Other soil samplers may

the adequacy of a given professional service must be judged,

be used for sampling these soil types. Such samplers include

nor should this document be applied without consideration of

driven split barrel samplers and soil coring devices (D 1586,

a project’s many unique aspects. The word “Standard” in the

D 3550, and D 6151). For information on appropriate use of

title of this document means only that the document has been

other soil samplers refer to D 6169.

approved through the ASTM consensus process.

1.3 This practice is often used in conjunction with fluid

2. Referenced Documents

rotary drilling (D 1452, D 5783) or hollow-stem augers

(D 6151). Subsurface geotechnical explorations should be

2.1 ASTM Standards:

reported in accordance with practice (D 5434). This practice

D 653 Terminology Relating to Soil, Rock, and Contained

discusses some aspects of sample preservation after the sam-

Fluids

plingevent.Forinformationonpreservationandtransportation

D 1452 Practice for Soil Investigation and Sampling by

process of soil samples, consult Practice D 4220. This practice

Auger Borings

does not address environmental sampling; consult D 6169 and

D 1586 Test Method for Penetration Test and Split-Barrel

D 6232for information on sampling for environmental investi-

Sampling of Soils

gations.

D 2488 Practice for Description and Identification of Soils

1.4 The values stated in inch-pound units are to be regarded

(Visual-Manual Procedure)

as the standard. The SI values given in parentheses are

D 3550 Practice for Thick Wall, Ring-Lined, Split Barrel,

provided for information purposes only. The tubing tolerances

Drive Sampling of Soils

presented in Table 1 are from sources available in North

D 3740 Practice for Minimum Requirements for Agencies

Engaged in the Testing and/or Inspection of Soil and Rock

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Related Field Testing for Soil Evaluations. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

CurrenteditionapprovedMay1,2007.PublishedJuly2007.Originallyapproved Standards volume information, refer to the standard’s Document Summary page on

in 1958. Last previous edition approved in 2003 as D 1587 – 03. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D1587–00 (2007)

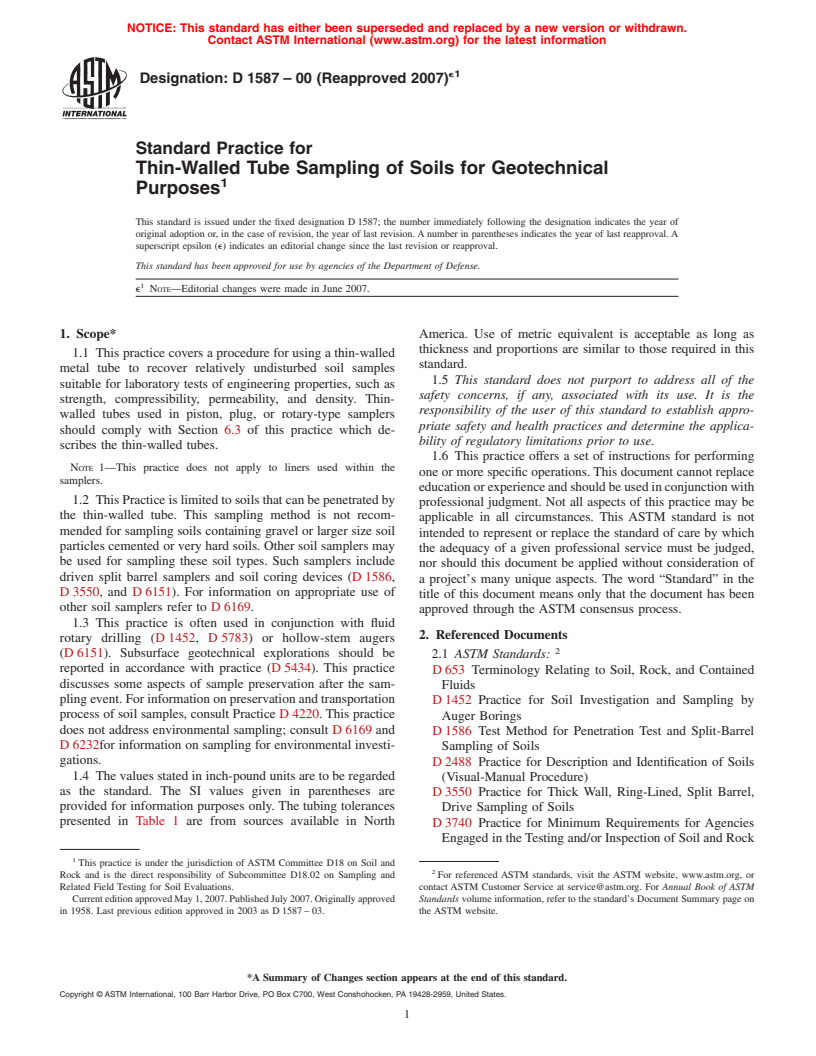

TABLE 1 Dimensional Tolerances for Thin-Walled Tubes

3.1.1 Forcommondefinitionsoftermsinthisstandard,refer

A

Nominal Tube Diameters from Table 2 Tolerances to Terminology D 653.

3.2 Definitions of Terms Specific to This Standard:

Size Outside 2 50.8 3 76.2 5 127

Diameter in. mm in. mm in. mm

3.2.1 inside clearance ratio, %, n—the ratio of the differ-

Outside diameter, D +0.007 +0.179 +0.010 +0.254 +0.015 0.381 ence in the inside diameter of the tube, D, minus the inside

o i

-0.000 -0.000 -0.000 -0.000 -0.000 -0.000

diameter of the cutting edge, D , to the inside diameter of the

e

Inside diameter, D +0.000 +0.000 +0.000 +0.000 +0.000 +0.000

i

tube, D expressed as a percentage (see Fig. 1).

i

-0.007 -0.179 -0.010 -0.254 -0.015 -0.381

Wall thickness 60.007 60.179 60.010 60.254 60.015 60.381 3.2.2 ovality, n—the cross section of the tube that deviates

Ovality 0.015 0.381 0.020 0.508 0.030 0.762

from a perfect circle.

Straightness 0.030/ft 2.50/m 0.030/ft 2.50/m 0.030/ft 2.50/m

A

Intermediate or larger diameters should be proportional. Specify only two of

4. Summary of Practice

thefirstthreetolerances;thatis,D andD,orD andWallthickness,orD andWall

o i o i

4.1 Arelatively undisturbed sample is obtained by pressing

thickness.

a thin-walled metal tube into the in-situ soil at the bottom of a

boring, removing the soil-filled tube, and applying seals to the

soil surfaces to prevent soil movement and moisture gain or

as Used in Engineering Design and Construction

loss.

D 4220 Practices for Preserving and Transporting Soil

Samples

5. Significance and Use

D 5434 Guide for Field Logging of Subsurface Explora-

5.1 This practice, or Practice D 3550 with thin wall shoe, is

tions of Soil and Rock

used when it is necessary to obtain a relatively undisturbed

D 5783 Guide for Use of Direct Rotary Drilling with

specimen suitable for laboratory tests of engineering properties

Water-Based Drilling Fluid for Geoenvironmental Explo-

or other tests that might be influenced by soil disturbance.

ration and the Installation of Subsurface Water-Quality

Monitoring Devices

NOTE 2—The quality of the result produced by this standard is

D 6151 Practice for Using Hollow-Stem Augers for Geo-

dependent on the competence of the personnel performing it, and the

technical Exploration and Soil Sampling suitability of the equipment and facilities used. Agencies that meet the

criteria of Practice D 3740 are generally considered capable of competent

D 6169 Guide for Selection of Soil and Rock Sampling

and objective sampling. Users of this practice. are cautioned that compli-

Devices Used With Drill Rigs for Environmental Investi-

ance with Practice D 3740 does not in itself assure reliable results.

gations

Reliable results depend on many factors; Practice D 3740 provides a

D 6232 Guide for Selection of Sampling Equipment for

means of evaluating some of those factors.

Waste and Contaminated Media Data CollectionActivities

6. Apparatus

3. Terminology

6.1 Drilling Equipment—When sampling in a boring, any

3.1 Definitions:

drilling equipment may be used that provides a reasonably

NOTE 1—Minimum of two mounting holes on opposite sides for D smaller than 4 in. (101.6 mm).

o

NOTE 2—Minimum of four mounting holes equally spaced for D 4 in. (101.6 mm) and larger.

o

NOTE 3—Tube held with hardened screws or other suitable means.

NOTE 4—2-in (50.8 mm) outside-diameter tubes are specified with an 18-gage wall thickness to comply with area ratio criteria accepted for

“undisturbed samples.” Users are advised that such tubing is difficult to locate and can be extremely expensive in small quantities. Sixteen-gage tubes

are generally readily available.

Metric Equivalent Conversions

in. mm

⁄8 9.53

⁄2 12.7

1 25.4

2 50.8

3 76.2

4 101.6

5 127

FIG. 1 Thin-Walled Tube for Sampling

e1

D1587–00 (2007)

A

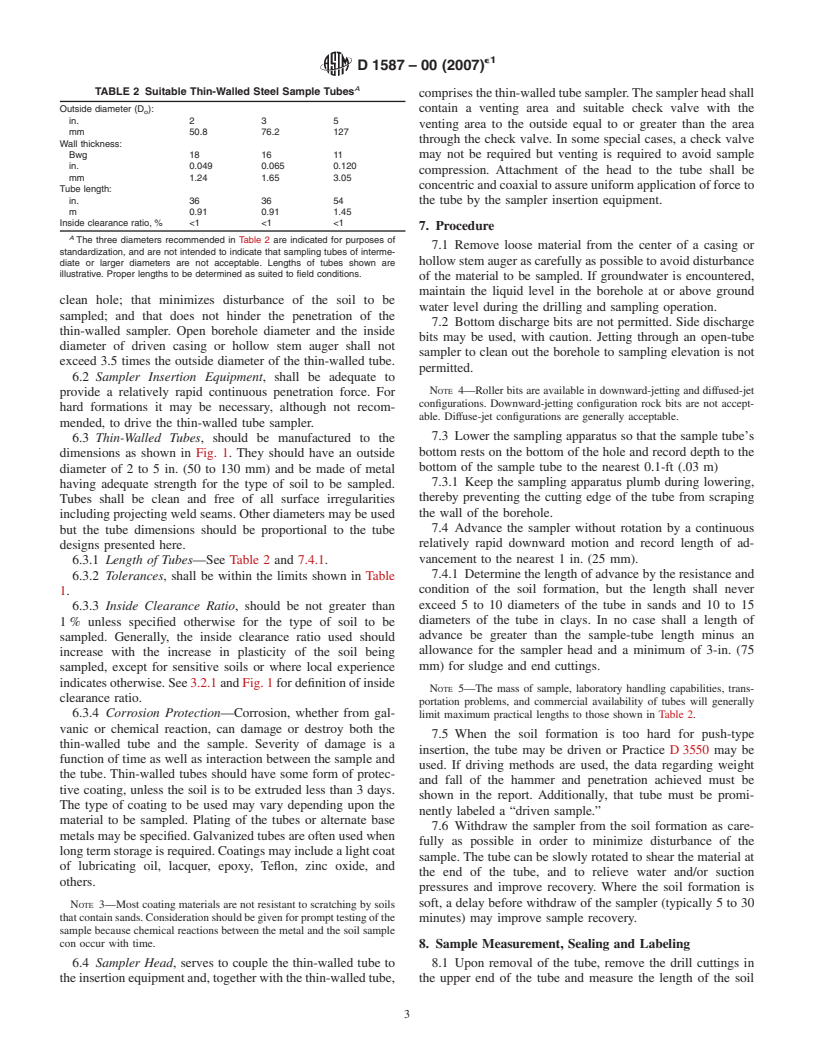

TABLE 2 Suitable Thin-Walled Steel Sample Tubes

comprisesthethin-walledtubesampler.Thesamplerheadshall

Outside diameter (D ): contain a venting area and suitable check valve with the

o

in. 2 3 5

venting area to the outside equal to or greater than the area

mm 50.8 76.2 127

through the check valve. In some special cases, a check valve

Wall thickness:

Bwg 18 16 11 may not be required but venting is required to avoid sample

in. 0.049 0.065 0.120

compression. Attachment of the head to the tube shall be

mm 1.24 1.65 3.05

concentricandcoaxialtoassureuniformapplicationofforceto

Tube length:

in. 36 36 54

the tube by the sampler insertion equipment.

m 0.91 0.91 1.45

Inside clearance ratio, % <1 <1 <1

7. Procedure

A

The three diameters recommended in Table 2 are indicated for purposes of

7.1 Remove loose material from the center of a casing or

standardization, and are not intended to indicate that sampling tubes of interme-

hollow stem auger as carefully as possible to avoid disturbance

diate or larger diameters are not acceptable

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.