ASTM D3930-08(2023)

(Specification)Standard Specification for Adhesives for Wood-Based Materials for Construction of Manufactured Homes

Standard Specification for Adhesives for Wood-Based Materials for Construction of Manufactured Homes

ABSTRACT

This specification provides the means to measure and evaluate the performance of adhesives for structural or semistructural bonding of wood-to-wood in manufactured homes. Wood as used in this specification includes lumber, plywood, particleboard, gypsum board, and all materials having woodbased surfaces at the bondline. The adhesives can be classified according to resistance to deformation: Group A or structural, and Group B or semistructural. Also, the adhesives may be designated into three types, according to their recommended use based on their resistance to water and water vapor: Type 1 for interior and exterior use, Type 2 for weather-protected interior use, and Type 3 for interior use only. Different tests shall be performed in order to determine the following properties of adhesives: shear strength, gap-filling ability, total deformation resistance, moisture and temperature limitation during fabrication, high-temperature resistance, low-temperature resistance, moisture resistance, aging, oxidation resistance, and mold resistance.

SCOPE

1.1 This specification provides the means to measure and evaluate the performance of adhesives for structural or semi-structural bonding of wood-to-wood in manufactured homes. Wood as used in this specification includes lumber, plywood, particleboard, gypsum board, and all materials having wood-based surfaces at the bondline. This specification does not cover other adhesives used in manufactured homes such as adhesives for carpet, floor tile, ceramic fixtures, plastic laminates, trim and millwork, and similar nonstructural applications.

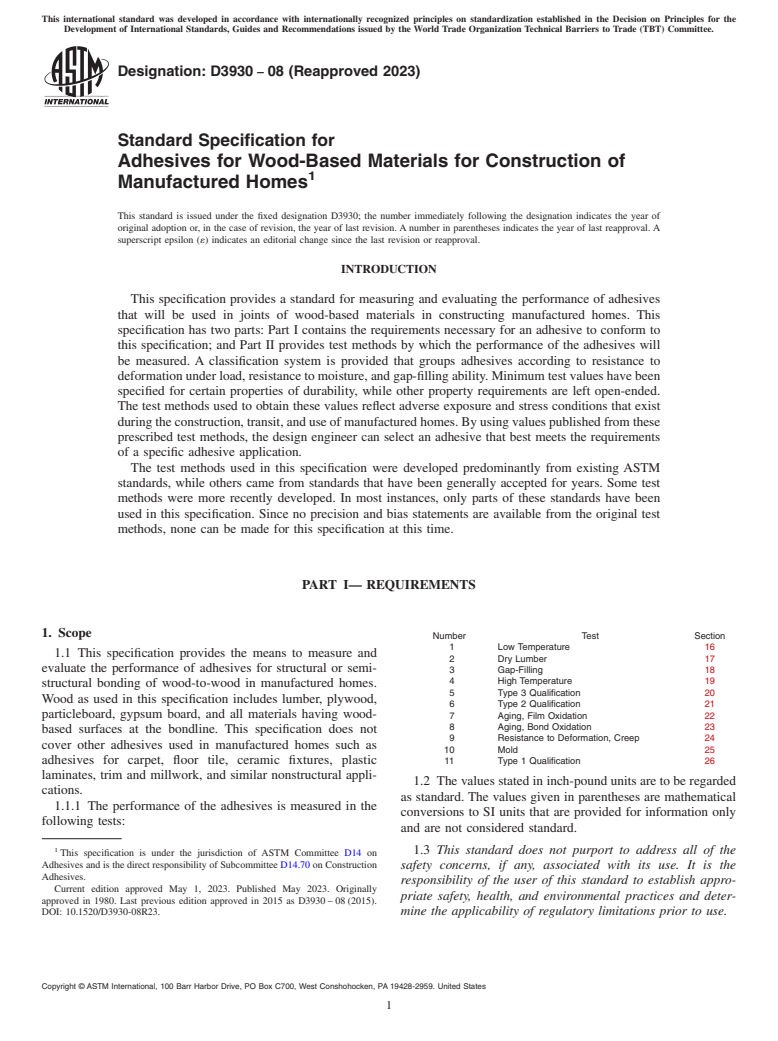

1.1.1 The performance of the adhesives is measured in the following tests:

Number

Test

Section

1

Low Temperature

16

2

Dry Lumber

17

3

Gap-Filling

18

4

High Temperature

19

5

Type 3 Qualification

20

6

Type 2 Qualification

21

7

Aging, Film Oxidation

22

8

Aging, Bond Oxidation

23

9

Resistance to Deformation, Creep

24

10

Mold

25

11

Type 1 Qualification

26

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3930 − 08 (Reapproved 2023)

Standard Specification for

Adhesives for Wood-Based Materials for Construction of

1

Manufactured Homes

This standard is issued under the fixed designation D3930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification provides a standard for measuring and evaluating the performance of adhesives

that will be used in joints of wood-based materials in constructing manufactured homes. This

specification has two parts: Part I contains the requirements necessary for an adhesive to conform to

this specification; and Part II provides test methods by which the performance of the adhesives will

be measured. A classification system is provided that groups adhesives according to resistance to

deformation under load, resistance to moisture, and gap-filling ability. Minimum test values have been

specified for certain properties of durability, while other property requirements are left open-ended.

The test methods used to obtain these values reflect adverse exposure and stress conditions that exist

during the construction, transit, and use of manufactured homes. By using values published from these

prescribed test methods, the design engineer can select an adhesive that best meets the requirements

of a specific adhesive application.

The test methods used in this specification were developed predominantly from existing ASTM

standards, while others came from standards that have been generally accepted for years. Some test

methods were more recently developed. In most instances, only parts of these standards have been

used in this specification. Since no precision and bias statements are available from the original test

methods, none can be made for this specification at this time.

PART I— REQUIREMENTS

1. Scope

Number Test Section

1 Low Temperature 16

1.1 This specification provides the means to measure and

2 Dry Lumber 17

evaluate the performance of adhesives for structural or semi-

3 Gap-Filling 18

4 High Temperature 19

structural bonding of wood-to-wood in manufactured homes.

5 Type 3 Qualification 20

Wood as used in this specification includes lumber, plywood,

6 Type 2 Qualification 21

particleboard, gypsum board, and all materials having wood- 7 Aging, Film Oxidation 22

8 Aging, Bond Oxidation 23

based surfaces at the bondline. This specification does not

9 Resistance to Deformation, Creep 24

cover other adhesives used in manufactured homes such as

10 Mold 25

adhesives for carpet, floor tile, ceramic fixtures, plastic 11 Type 1 Qualification 26

laminates, trim and millwork, and similar nonstructural appli-

1.2 The values stated in inch-pound units are to be regarded

cations.

as standard. The values given in parentheses are mathematical

1.1.1 The performance of the adhesives is measured in the

conversions to SI units that are provided for information only

following tests:

and are not considered standard.

1

1.3 This standard does not purport to address all of the

This specification is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

safety concerns, if any, associated with its use. It is the

Adhesives.

responsibility of the user of this standard to establish appro-

Current edition approved May 1, 2023. Published May 2023. Originally

priate safety, health, and environmental practices and deter-

approved in 1980. Last previous edition approved in 2015 as D3930 – 08 (2015).

DOI: 10.1520/D3930-08R23. mine the applicability of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3930 − 08 (2023)

1.4 This international standard was developed in accor- differ from standards in electronics. Some adhesives will bond

dance with internationally recognized principles on standard- by bridging without completely filling the gap; others by filling

ization established in the Decision on Principles for the the gap completely.

Development of International Standards, Guides and Recom-

3.2 Definitions of Terms Specific to This Standard:

mendations issued by the World Trade Organization Technical 4

3.2.1 manufactured home —a structure, transportable in

Barriers to Trade (TBT) Committee.

one or more sections which in the traveling mode is 8 body feet

or more in width or 40 body feet or more in length or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.