ASTM D1440-07

(Test Method)Standard Test Method for Length and Length Distribution of Cotton Fibers (Array Method)

Standard Test Method for Length and Length Distribution of Cotton Fibers (Array Method)

SCOPE

1.1 This test method covers the determination of the fiber length and length distribution in loose cotton fibers. Note 1

For another method for measuring fiber length, see Test Method D 1447.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1440–07

Standard Test Method for

Length and Length Distribution of Cotton Fibers (Array

1

Method)

This standard is issued under the fixed designation D1440; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 For all other terminology related to textiles see Termi-

nology D123.

1.1 This test method covers the determination of the fiber

length and length distribution in loose cotton fibers.

4. Summary of Test Method

NOTE 1—For another method for measuring fiber length, see Test

4.1 A sorting apparatus consisting of two banks of parallel

Method D1447.

combs is used to straighten and align the fibers in a 75-mg test

1.2 This standard does not purport to address all of the

specimen. The fibers are pulled from one bank of combs and

safety concerns, if any, associated with its use. It is the

transferred to the other in such a manner that one end of each

responsibility of the user of this standard to establish appro-

fiber is aligned with the base comb. The transfer is repeated to

priate safety and health practices and determine the applica-

straighten the other ends of the fibers. As the fibers are

bility of regulatory limitations prior to use.

withdrawn from the combs for the third time, they are placed

in order of length on velvet covered boards. The pulls are

2. Referenced Documents

measured, and those that fall within each length interval are

2

2.1 ASTM Standards:

collected and weighed. From these weight-length data, the

D123 Terminology Relating to Textiles

upper quartile length, mean length, and coefficient of length

D1441 Practice for Sampling Cotton Fibers for Testing

variation are calculated.

D1447 Test Method for Length and Length Uniformity of

5. Significance and Use

Cotton Fibers by Photoelectric Measurement

D1776 Practice for Conditioning and Testing Textiles

5.1 The array method provides objective measurements for

D7139 Terminology for Cotton Fibers

determining the fiber length and length distribution in a sample

of cotton. The results can be plotted to show the length-weight

3. Terminology

distribution of all the fibers in the sample. Data obtained from

3.1 ForallterminologyrelatedtoD13.11,CottonFibers,see

array tests are useful in fiber length research studies, for

Terminology D7139.

investigation of changes in fiber length distribution in ginning

3.1.1 The following terms are relevant to this standard:

and mill processing, and for other research purposes.

coefficient of variation, length group, length interval, mean

5.2 Upper quartile length is correlated with, but usually

length, pull, upper quartile length.

longer than, Fibrograph and 2.5 % span length as defined in

Test Method D1447. Judgment must be used in making

comparisons between length measures from arrays and mea-

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

sures obtained by other methods, which may be basically

and is the direct responsibility of Subcommittee D13.11 on Cotton Fibers.

different.

Current edition approved Jan. 1, 2007. Published January 2007. Originally

5.3 The coefficient of length variation is a measure of length

approved in 1955. Last previous edition approved in 2002 as D1440 – 96(2002).

DOI: 10.1520/D1440-07.

distribution, or nonuniformity of length. Because the fiber

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

weight-length distribution is usually highly skewed, statistical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

judgments based on the assumption of normality are not

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. justified.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1440–07

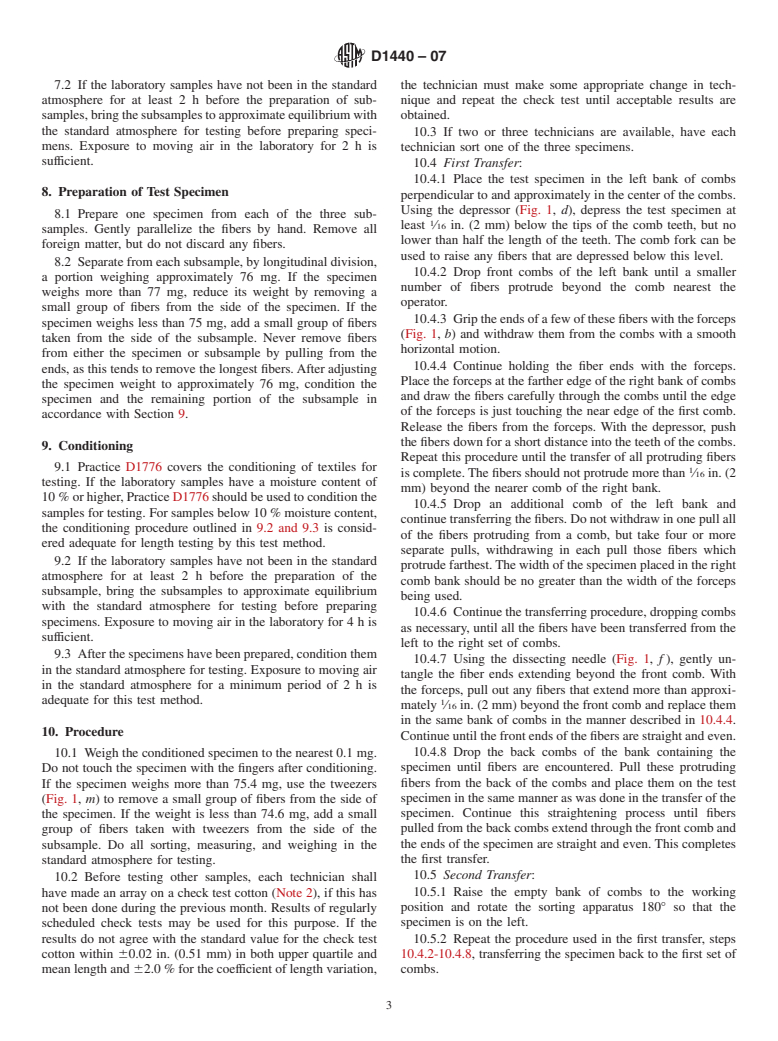

a and c—Banks of combs.

b—Forceps, tips padded with hard leather, for transferring fibers from one set of combs to the other.

d—Depressor for placing fibers in combs.

f—Dissecting needle.

g—Fork for scooping up fiber groups off velvet surface.

h—Aluminum plate covered with velvet cloth.

i—Special rule for measuring length of fiber groups.

k—Smooth plate for placing fibers onto velvet surfaces.

l—Wire rack for holding fiber groups wrapped in papers.

m—Smooth pointed tweezers.

n—Lift for raising combs in place.

o—Rack for holding velvet-covered boards.

p—Velvet-covered boards on which several pulls have been arrayed.

NOTE 1—Other accessories required for length arraying, not shown above, consist of the following: small whisk broom for cleaning velvet surfaces,

o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.