ASTM A485-09

(Specification)Standard Specification for High Hardenability Antifriction Bearing Steel

Standard Specification for High Hardenability Antifriction Bearing Steel

ABSTRACT

This specification covers high hardenability modifications of high-carbon bearing quality steel to be used in the manufacture of antifriction bearings. The grades of steels covered here are: Grade 1, Grade 2, Grade 3, Grade 4, Grade B2, Grade B3, Grade B4, Grade B5, Grade B6, Grade B7, and Grade B8. Heat and product analyses shall be performed wherein specimens shall conform to required chemical composition of carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, titanium, copper, molybdenum, oxygen, and aluminum. The steels shall undergo normalizing followed by spheroidize annealing before heating for end quenching. Test for hardenability shall be performed wherein specimens shall conform to required Brinell and Rockwell hardness.

SCOPE

1.1 This specification covers high hardenability modifications of high-carbon bearing quality steel to be used in the manufacture of antifriction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A485 −09

StandardSpecification for

1

High Hardenability Antifriction Bearing Steel

This standard is issued under the fixed designation A485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2.2 Other Standards:

3

SAE J148a Grain Size Determination of Steel

1.1 This specification covers high hardenability modifica-

4

ISO 683 Part 17: Ball and Roller Bearing Steels

tions of high-carbon bearing quality steel to be used in the

manufacture of antifriction bearings.

3. Ordering Information

1.2 Supplementary requirements of an optional nature are 3.1 Orders for material under this specification should

provided and when desired shall be so stated in the order. include the following information:

3.1.1 Quantity (weight or number of pieces),

1.3 The values stated in inch-pound units are to be regarded

3.1.2 Grade identification,

as standard. The values given in parentheses are mathematical

3.1.3 ASTM designation and year of issue,

conversions to SI units that are provided for information only

3.1.4 Dimensions,

and are not considered standard.

3.1.5 Supplementary requirements, if included.

2. Referenced Documents

4. Process

2

2.1 ASTM Standards: 4.1 The steel shall be made by a process that is capable of

A29/A29M Specification for Steel Bars, Carbon and Alloy, providing a high quality product meeting the requirements of

Hot-Wrought, General Requirements for this specification.

A255 Test Methods for Determining Hardenability of Steel

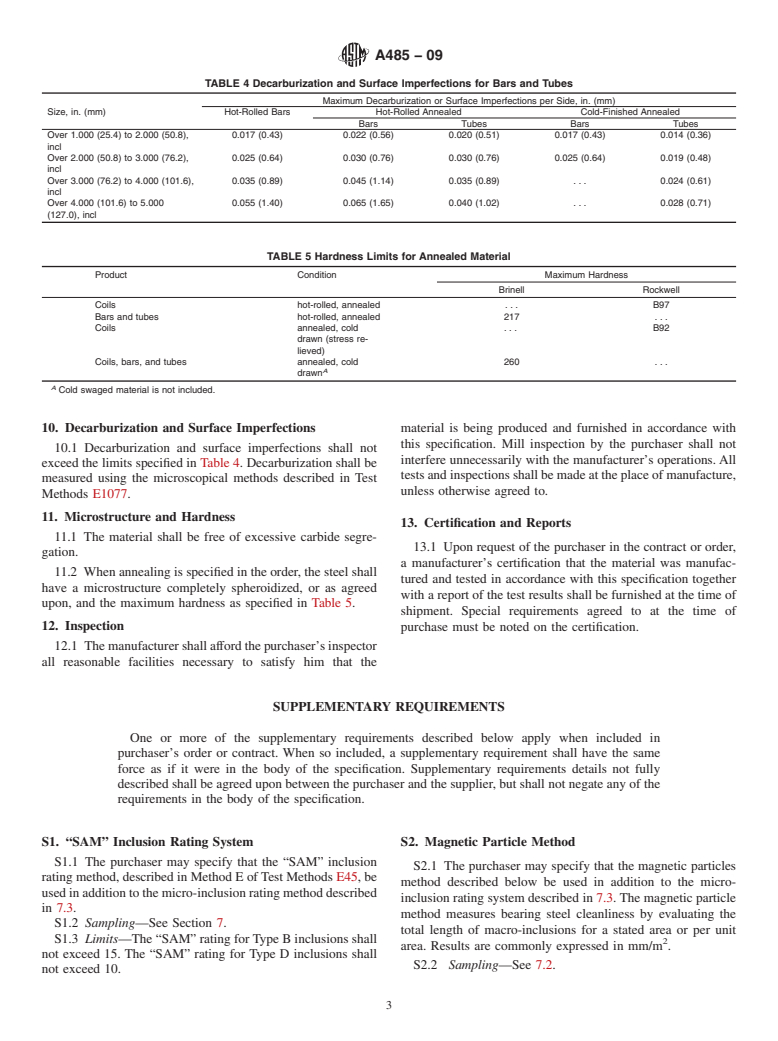

5. Chemical Composition and Analysis

A751 Test Methods, Practices, and Terminology for Chemi-

5.1 Typical examples of chemical compositions are shown

cal Analysis of Steel Products

in Table 1. Other compositions may be specified.

E45 Test Methods for Determining the Inclusion Content of

Steel

5.2 An analysis of each heat of steel shall be made by the

E381 Method of Macroetch Testing Steel Bars, Billets, steel manufacturer in accordance withTest Methods, Practices,

Blooms, and Forgings

and Terminology A751. The chemical composition thus deter-

E1019 Test Methods for Determination of Carbon, Sulfur, mined shall conform to the requirements specified in Table 1

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

for the ordered grade or to other requirements agreed upon

Alloys by Various Combustion and Fusion Techniques between manufacturer and purchaser.

E1077 Test Methods for Estimating the Depth of Decarbur-

5.3 Product analysis may be made by the purchaser in

ization of Steel Specimens

accordance with Test Methods, Practices, and Terminology

A751. Permissible variations in product analysis shall be in

accordance with Specification A29/A29M.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

6. Sizes, Shapes, and Dimensional Tolerances

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

A01.28 on Bearing Steels.

6.1 The physical size and shape of the material shall be

Current edition approved Oct. 1, 2009. Published November 2009. Originally

agreed upon between manufacturer and purchaser.

approved in 1963. Last previous edition approved in 2003 as A485 – 03. DOI:

10.1520/A0485-09.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from The Engineering Society for Advanced Mobility of Land, Sea,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Air and Space, 400 Commonwealth Drive, Warrendale, PA 15096-001.

4

Standards volume information, refer to the standard’s Document Summary page on Available from the International Organization for Standardization (ISO), 1, rue

the ASTM website. de Varembé, Case postale 56, CH-1211, Genève 20, Switzerland.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A485−09

A,B

TABLE 1 Chemical Composition

C D

Number Name C Mn P (max) S (max) Si Cr Ni (max) Ti (max) Cu (max) Mo O (max) Al (max)

1 Grade 1 0.90–1.05 0.90–1.20 0.025 0.015 0.45–0.75 0.90–1.20 0.25 0.0050 0.30 0.10 (max) 0.0015 0.050

2 Grade 2 0.85–1.00 1.40–1.70 0.025 0.015 0.50–0.80 1.40–1.80 0.25 0.0050 0.30 0.10 (max) 0.0015 0.050

3 Grade 3 0.95–1.10 0.65–0.90 0.025 0.015 0.15–0.35 1.10–1.50 0.25 0.0050 0.30 0.20–0.30 0.0015 0.050

4 Grade 4 0.95–1.10 1.05–1.35 0.025 0.015 0.15–0.35 1.10–1.50 0.25 0.0050 0.30 0.45–0.60 0.0015 0.050

E

B2 100CrMnSi4–4 0.93–1.05 0.90–1.20 0.025 0.015 0.45–0.75

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A485–03 Designation: A485 – 09

Standard Specification for

1

High Hardenability Antifriction Bearing Steel

This standard is issued under the fixed designation A485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thisspecificationcovershighhardenabilitymodificationsofhigh-carbonbearingqualitysteeltobeusedinthemanufacture

of antifriction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3The values stated in inch-pound units are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A29/A29M Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for

A255 Test Methods for Determining Hardenability of Steel

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E45 Test Methods for Determining the Inclusion Content of Steel

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E1019 Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by

Various Combustion and Fusion Techniques

E1077 Test Methods for Estimating the Depth of Decarburization of Steel Specimens

2.2 Other Standards:

3

SAE J148a Grain Size Determination of Steel

4

ISO 683 Part 17: Ball and Roller Bearing Steels

3. Ordering Information

3.1 Orders for material under this specification should include the following information:

3.1.1 Quantity (weight or number of pieces),

3.1.2 Grade identification,

3.1.3 ASTM designation and year of issue,

3.1.4 Dimensions,

3.1.5 Supplementary requirements, if included.

4. Process

4.1 The steel shall be made by a process that is capable of providing a high quality product meeting the requirements of this

specification.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloys,andisthedirectresponsibilityofSubcommitteeA01.28

on Bearing Steels.

Current edition approvedApril 10, 2003. Published July 2003. Originally approved in 1963. Last previous edition approved in 2000 asA485–00. DOI: 10.1520/A0485-03.

Current edition approved Oct. 1, 2009. Published November 2009. Originally approved in 1963. Last previous edition approved in 2003 as A485 – 03. DOI:

10.1520/A0485-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 01.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 01.03.

3

Available from The Engineering Society for Advanced Mobility of Land, Sea, Air and Space, 400 Commonwealth Drive, Warrendale, PA 15096-001.

4

Annual Book of ASTM Standards, Vol 03.01.

4

Available from the International Organization for Standardization (ISO), 1, rue de Varembé, Case postale 56, CH-1211, Genève 20, Switzerland.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A485 – 09

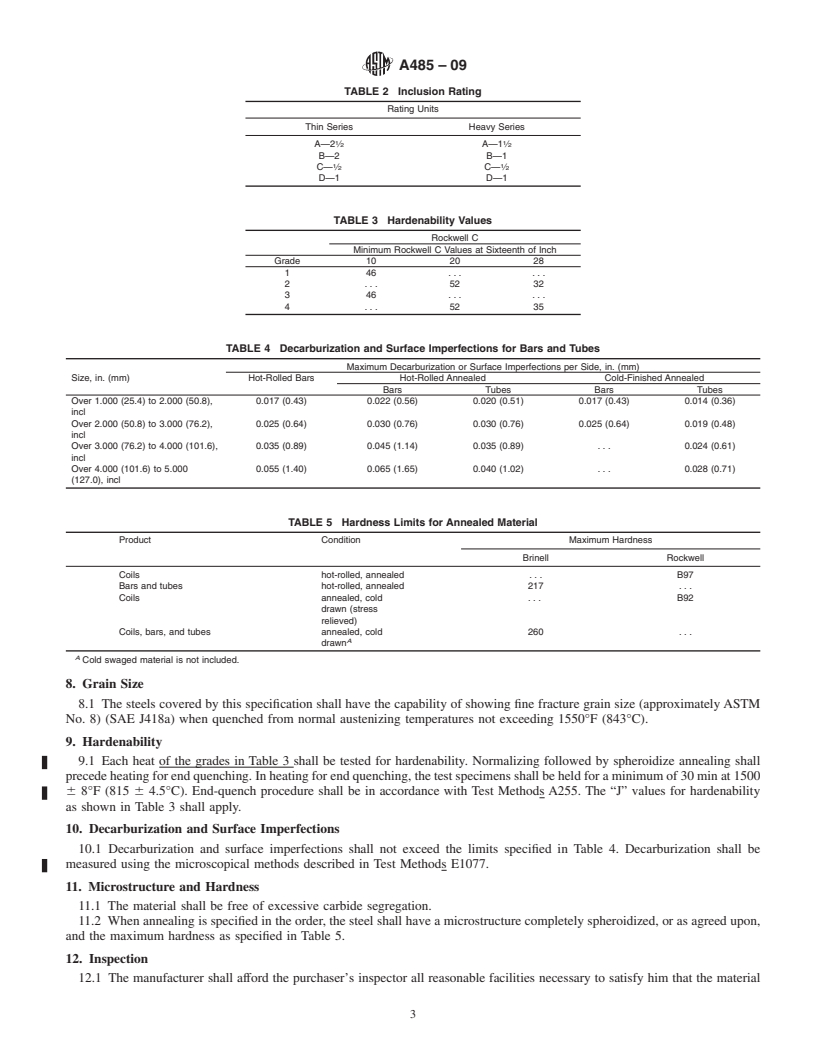

5. Chemical Composition and Analysis

5.1 Typical examples of chemical compositions are shown in Table 1. Other compositions may be specified.

5.2 An analysis of each heat of steel shall be made by the steel manufacturer in accordance with Test Methods, Practices, and

Terminology A751. The chemical composition thus determined shall conform to the requirements specified in Table 1 for the

ordered grade or to other requirements agreed upon between manufacturer and purchaser.

5.3 Product analysis may be made by the purchaser in accordance with Test Methods, Practices, and Terminology A751.

Permissible variations in product analysis shall be in accordance with Specification A29/A29M.

6. Sizes, Shapes, and Dimensional Tolerances

6.1 The physical size and shape of the material shall be agreed upon between manufacturer and purchase

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.