ASTM D4291-04(2017)

(Test Method)Standard Test Method for Trace Ethylene Glycol in Used Engine Oil

Standard Test Method for Trace Ethylene Glycol in Used Engine Oil

SIGNIFICANCE AND USE

4.1 Leakage of aqueous engine coolant into the crank case weakens the ability of the oil to lubricate. If ethylene glycol is present, it promotes varnish and deposit formation. This test method is designed for early detection to prevent coolant from accumulating and seriously damaging the engine.

SCOPE

1.1 This test method covers the determination of ethylene glycol as a contaminant in used engine oil. This test method is designed to quantitate ethylene glycol in the range from 5 mass ppm to 200 mass ppm.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 6.

Note 1: A qualitative determination of glycol-base antifreeze is provided in Test Methods D2982. Procedure A is sensitive to about 100 ppm.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4291 − 04 (Reapproved 2017)

Standard Test Method for

1

Trace Ethylene Glycol in Used Engine Oil

This standard is issued under the fixed designation D4291; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope using on-column injection and the eluting compounds are

detected by a flame ionization detector. The ethylene glycol

1.1 This test method covers the determination of ethylene

peak area is determined and compared with areas obtained

glycol as a contaminant in used engine oil. This test method is

from the injection of freshly prepared known standards.

designed to quantitate ethylene glycol in the range from

5 mass ppm to 200 mass ppm.

4. Significance and Use

1.2 This standard does not purport to address all of the

4.1 Leakage of aqueous engine coolant into the crank case

safety concerns, if any, associated with its use. It is the

weakens the ability of the oil to lubricate. If ethylene glycol is

responsibility of the user of this standard to establish appro-

present, it promotes varnish and deposit formation. This test

priate safety, health, and environmental practices and deter-

method is designed for early detection to prevent coolant from

mine the applicability of regulatory limitations prior to use.

accumulating and seriously damaging the engine.

For specific warning statements, see Section 6.

NOTE 1—A qualitative determination of glycol-base antifreeze is

5. Apparatus

provided in Test Methods D2982. Procedure A is sensitive to about

100 ppm.

5.1 Gas Chromatograph—Any gas chromatograph

1.3 This international standard was developed in accor-

equipped with the following:

dance with internationally recognized principles on standard-

5.1.1 Flame Ionization Detector, capable of operating con-

ization established in the Decision on Principles for the

tinuously at a temperature equivalent to the maximum column

Development of International Standards, Guides and Recom-

temperature employed, and connected to the column so as to

mendations issued by the World Trade Organization Technical

avoid any cold spots.

Barriers to Trade (TBT) Committee.

5.1.2 Sample Inlet System, providing for on-column injec-

tion and capable of operating continuously at a temperature

2. Referenced Documents

equivalent to the maximum column temperature employed.

2

2.1 ASTM Standards:

5.2 Recorder—Recording potentiometer with a full-scale

D1193 Specification for Reagent Water

response time of 2 s or less may be used.

D2982 Test Methods for Detecting Glycol-Base Antifreeze

1

5.3 Columns—1.2 m by 6.4 mm (4 ft by ⁄4 in.) copper tube

in Used Lubricating Oils

D4057 Practice for Manual Sampling of Petroleum and packed with 5 % by mass Carbowax 20-M liquid phase on

30/60 mesh Chromosorb T solid support. As an alternative, a

Petroleum Products

fused silica capillary column, 15 m long with a 0.53 mm ID

3. Summary of Test Method

and 2.0 micron film thickness of a bonded polyethylene glycol

can be used.

3.1 The sample of oil is extracted with water and the

analysis is performed on the water extract. A reproducible

5.4 Integrator—Manual, mechanical, or electronic integra-

volume of the extract is injected into a gas chromatograph

tion is required to determine the peak area. However, best

precision and automated operation can be achieved with

electronic integration.

1

This test method is under the jurisdiction of ASTM Committee D02 on

5.5 Centrifuge—RCF 600 minimum and centrifuge tubes

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0L on Gas Chromatography Methods.

with stoppers.

Current edition approved Oct. 1, 2017. Published November 2017. Originally

approved in 1983. Last previous edition approved in 2013 as D4291 – 04 (2013). 5.6 Syringe—A microsyringe, 10 µL is needed for sample

DOI: 10.1520/D4291-04R17.

introduction.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.7 Pasteur Pipets.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.8 Vials, 2 mL, with crimped septum caps.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

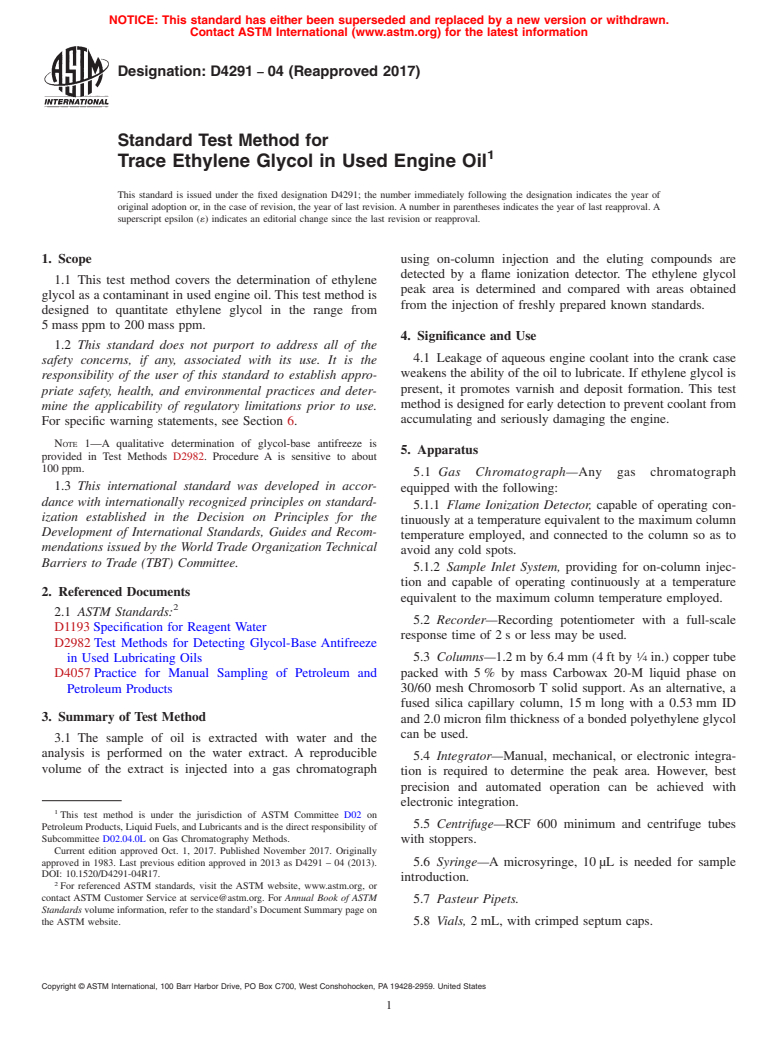

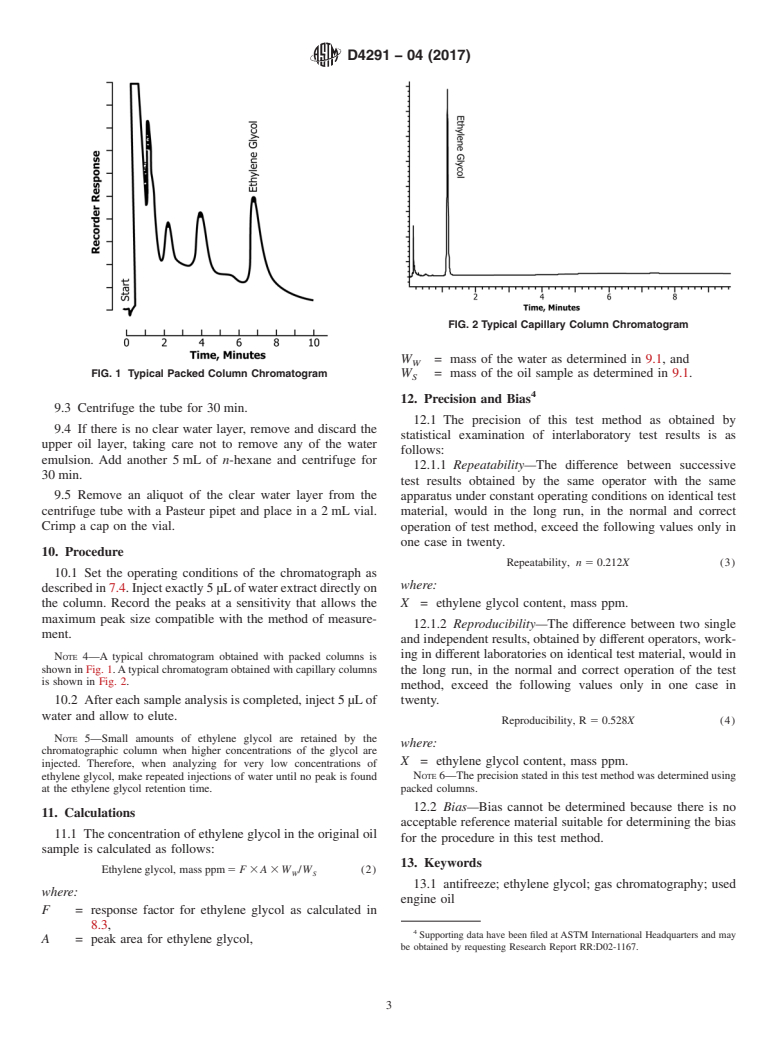

---------------------- Page: 1 ----------------------

D4291 − 04 (2017)

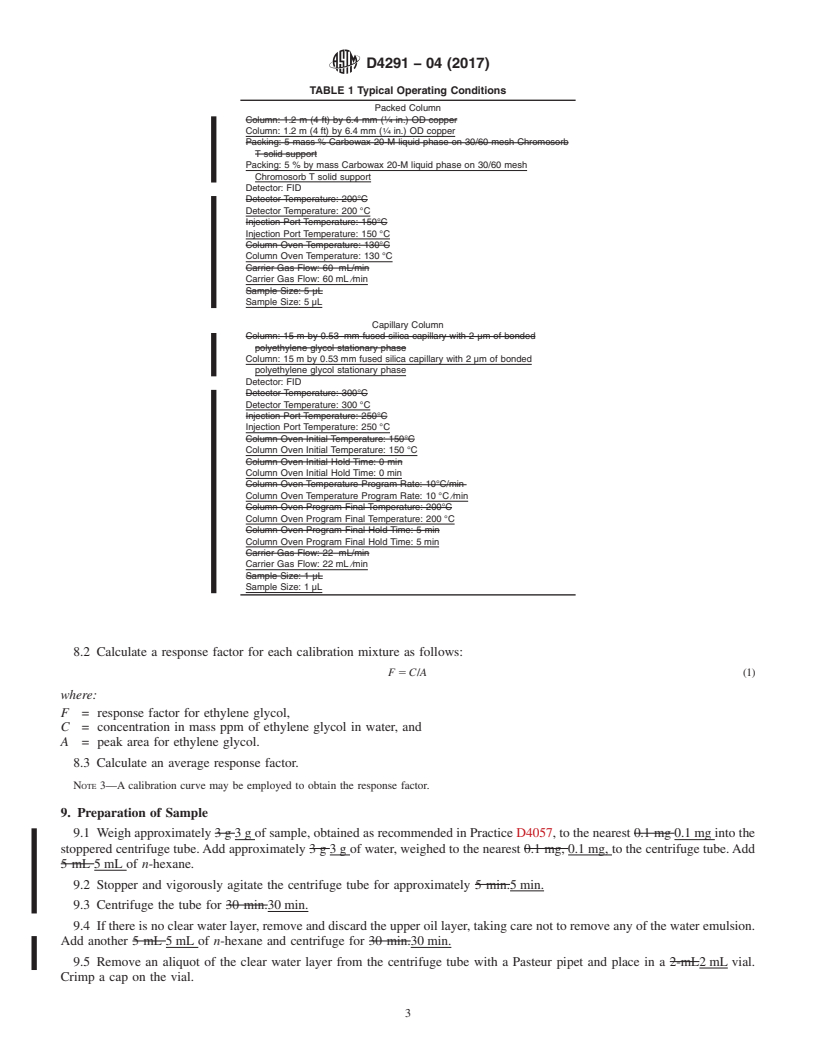

TABLE 1 Typical Operating Conditions

6. Reagents and Materials

Packed Column

6.1 Purity of Reagents—Reagent grade chemicals shall be

1

Column: 1.2 m (4 ft) by 6.4 mm ( ⁄4 in.) OD copper

used in all tests. Unless otherwise indicated, it is intended that

Packing

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4291 − 04 (Reapproved 2013) D4291 − 04 (Reapproved 2017)

Standard Test Method for

1

Trace Ethylene Glycol in Used Engine Oil

This standard is issued under the fixed designation D4291; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of ethylene glycol as a contaminant in used engine oil. This test method is

designed to quantitate ethylene glycol in the range from 55 mass ppm to 200 mass 200 mass ppm.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific warning statements, see Section 6.FOR SPECIFIC WARNING STATEMENTS,

SEE SECTION 6.

NOTE 1—A qualitative determination of glycol-base antifreeze is provided in Test Methods D2982. Procedure A is sensitive to about 100 ppm.100 ppm.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D2982 Test Methods for Detecting Glycol-Base Antifreeze in Used Lubricating Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

3. Summary of Test Method

3.1 The sample of oil is extracted with water and the analysis is performed on the water extract. A reproducible volume of the

extract is injected into a gas chromatograph using on-column injection and the eluting compounds are detected by a flame

ionization detector. The ethylene glycol peak area is determined and compared with areas obtained from the injection of freshly

prepared known standards.

4. Significance and Use

4.1 Leakage of aqueous engine coolant into the crank case weakens the ability of the oil to lubricate. If ethylene glycol is

present, it promotes varnish and deposit formation. This test method is designed for early detection to prevent coolant from

accumulating and seriously damaging the engine.

5. Apparatus

5.1 Gas Chromatograph—Any gas chromatograph equipped with the following:

5.1.1 Flame Ionization Detector, capable of operating continuously at a temperature equivalent to the maximum column

temperature employed, and connected to the column so as to avoid any cold spots.

5.1.2 Sample Inlet System, providing for on-column injection and capable of operating continuously at a temperature equivalent

to the maximum column temperature employed.

5.2 Recorder—Recording potentiometer with a full-scale response time of 2 s 2 s or less may be used.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.04.0L on Gas Chromatography Methods.

Current edition approved Oct. 1, 2013Oct. 1, 2017. Published October 2013November 2017. Originally approved in 1983. Last previous edition approved in 20092013

as D4291 – 04 (2009).(2013). DOI: 10.1520/D4291-04R13.10.1520/D4291-04R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4291 − 04 (2017)

1

5.3 Columns—1.2-m (4-ft) by 6.4-mm (1.2 m by 6.4 mm (4 ft by ⁄4-in.) in.) copper tube packed with 5 mass % 5 % by mass

Carbowax 20-M liquid phase on 30/60 mesh Chromosorb T solid support. As an alternative, a fused silica capillary column, 15

m 15 m long with a 0.53–mm0.53 mm ID and 2.0–micron2.0 micron film thickness of a bonded polyethylene glycol can be used.

5.4 Integrator—Manual, mechanical, or electronic integration is required to determine the peak area. However, best precision

and automated operation can be achieved

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.