ASTM D6521-04

(Practice)Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

SCOPE

1.1 This practice covers the accelerated aging (oxidation) of asphalt binders by means of pressurized air and elevated temperature. This is intended to simulate the type of changes which occur in asphalt binders during in-service oxidative aging but may not accurately simulate the relative rates of aging. It is intended for use with residue from Test Method D 2872 (RTFOT) which is designed to simulate plant aging.

Note 1—Modified asphalt binders may phase separate or form skins during oven conditioning in Test Method D 2872 (RTFOT); the results from subsequent testing of this residue may not be representative of modified asphalts short-term aged under field conditions. Phase separation, or formation of skins, or both can also occur during PAV aging. Therefore, the practice may not be suitable for some modified asphalts.Note 2

PAV has not been validated for materials containing particulate materials.

1.2 The aging of asphalt binders during service is affected by ambient temperature and air pressure and by mixture-associated variables such as the volumetric proportions of the mix, the permeability of the mix, properties of the aggregates, and possibly other factors. This conditioning process is intended to provide an evaluation of the relative resistance of different asphalt binders to oxidative aging at selected elevated aging temperatures and pressures but cannot account for mixture variables or provide the relative resistance to aging at in-service conditions.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6521–04

Standard Practice for

Accelerated Aging of Asphalt Binder Using a Pressurized

1

Aging Vessel (PAV)

This standard is issued under the fixed designation D 6521; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This practice covers the accelerated aging (oxidation) of 2.1 ASTM Standards:

asphalt binders by means of pressurized air and elevated D 8 Terminology Relating to Materials for Roads and Pave-

temperature. This is intended to simulate the type of changes ments

which occur in asphalt binders during in-service oxidative D 1754 Test Method for Effect of Heat andAir onAsphaltic

aging but may not accurately simulate the relative rates of Materials (Thin-Film Oven Test)

aging. It is intended for use with residue from Test Method D 2872 Test Method for Effect of Heat andAir on a Moving

D 2872 (RTFOT), which is designed to simulate plant aging. Film of Asphalt (Rolling Thin-Film Oven Test)

D 4753 Guide for Evaluating, Selecting and Specifying

NOTE 1—Modified asphalt binders may phase separate or form skins

Balances and Standard Masses for Use in Soil, Rock and

during oven conditioning in Test Method D 2872 (RTFOT); the results

Construction Materials Testing

from subsequent testing of this residue may not be representative of

D 6373 Specification for Performance Graded Asphalt

modified asphalts short-term aged under field conditions. Phase separa-

tion, or formation of skins, or both can also occur during PAV aging.

Binder

Therefore, the practice may not be suitable for some modified asphalts.

E 1137 Specification for Industrial Platinum Resistance

NOTE 2—PAV has not been validated for materials containing particu-

Thermometers

late materials.

3

2.2 AASHTO Standards:

1.2 The aging of asphalt binders during service is affected

M 320 Specification for Performance-Graded Asphalt

by ambient temperature and air pressure and by mixture-

Binder

associated variables, such as the volumetric proportions of the

MP 1a Specification for Performance-Graded Asphalt

mix, the permeability of the mix, properties of the aggregates,

Binder

4

and possibly other factors. This conditioning process is in-

2.3 CGA Standards:

tended to provide an evaluation of the relative resistance of

CGA G-7.1–1997 Commodity Specification for Air, Fourth

different asphalt binders to oxidative aging at selected elevated

Edition

aging temperatures and pressures, but cannot account for

3. Terminology

mixture variables or provide the relative resistance to aging at

in-service conditions.

3.1 Definitions:

1.3 The values stated in SI units are to be regarded as the

3.1.1 Definitionsoftermsusedinthispracticemaybefound

standard. Values in parentheses in inch-pound units are pro-

in Terminology D 8 determined from common English usage,

vided for informational purposes only.

or combinations of both.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

2

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and the ASTM website.

3

Paving Materials and is the direct responsibility of Subcommittee D04.46 on Available from American Association of State Highway and Transportation

Durability and Distillation Tests. Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

4

CurrenteditionapprovedJune1,2004.PublishedJuly2004.Originallyapproved Available from Compressed Gas Association (CGA), 1725 Jefferson Davis

in 2000. Last previous edition approved in 2003 as D 6521–03a. Hwy., Suite 1004, Arlington, VA 22202-4102.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

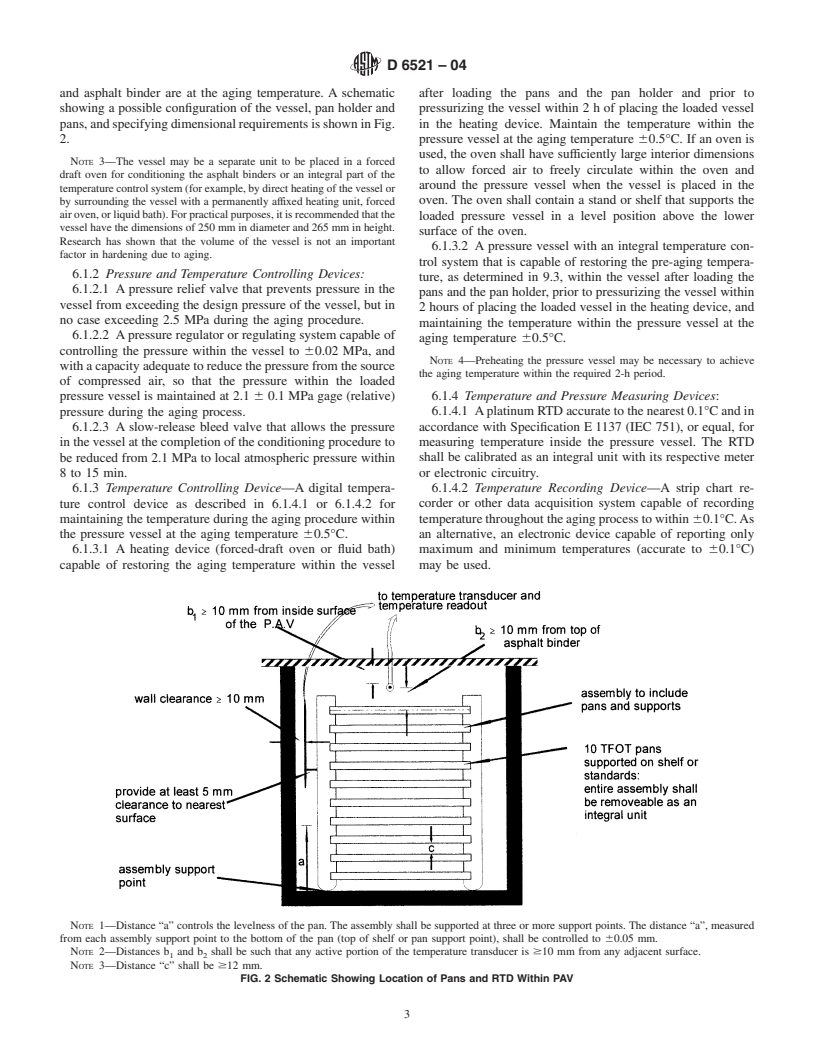

D6521–04

4. Summary of Practice that will predict the properties or the relative rankings of the

properties of all asphalt binders after a specific set of in-service

4.1 Asphalt binder is first aged using Test Method D 2872

exposure conditions.

(RTFOT). A specified thickness of residue from the RTFOT is

5.4 The relative degree of hardening of different asphalt

then placed in standard TFOT stainless steel pans and aged at

binders varies wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.