ASTM D5007-99(2017)

(Test Method)Standard Test Method for Wet-to-Dry Hiding Change

Standard Test Method for Wet-to-Dry Hiding Change

SIGNIFICANCE AND USE

5.1 Many architectural paints, particularly white and light tints, change significantly in film opacity as they dry. An increase in hiding is sometimes associated with porosity and poor film integrity with conventionally formulated coatings. A decrease can result in a disappointing paint job. The wet-to-dry hiding change is therefore a property of great practical importance.

5.2 This test method can be used in paint specifications and as a short, simple procedure for evaluation and quality control.

SCOPE

1.1 This test method covers the determination of the change in hiding power of an architectural coating during drying, by visual evaluation of the wet and dry film.

1.2 This test method is not recommended for colors other than white and tints.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5007 − 99 (Reapproved 2017)

Standard Test Method for

Wet-to-Dry Hiding Change

This standard is issued under the fixed designation D5007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 hiding index (h ), n—the Spreading Index at a stan-

S

dard film opacity.

1.1 Thistestmethodcoversthedeterminationofthechange

3.1.1.1 Discussion—In this test method the latter is a visual

in hiding power of an architectural coating during drying, by

contrast standard prepared by applying a semi-opaque white

visual evaluation of the wet and dry film.

coating on a black and white hiding-power chart to give a

1.2 This test method is not recommended for colors other

contrast ratio of 0.98 (98%) which is just short of complete

than white and tints.

hiding, and is the conventional so-called full hiding end point

1.3 The values stated in SI units are to be regarded as the

in photometric hiding-power methods such as Test Method

standard. The values given in parentheses are for information

D2805. Refer to the hiding indices of the wet and dry films as

only.

h and h respectively.

SW SD

1.4 This standard does not purport to address all of the Since this test method is intended to measure hiding-power

difference rather than hiding power itself, a 0.98 (98%)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- contrast ratio standard is not required. It is necessary only that

the same standard be used for measuring both wet and dry

priate safety and health practices and determine the applica-

films. See 3.1.8. For this purpose the standard needs to lie

bility of regulatory limitations prior to use.

withinthecontrastrangeofboththewetanddrystripes,which

1.5 This international standard was developed in accor-

is true of the 0.98 (98%) contrast-ratio standard for most

dance with internationally recognized principles on standard-

commercial paints. With paints of unusually low hiding, a

ization established in the Decision on Principles for the

lower contrast standard may be required, which can be simply

Development of International Standards, Guides and Recom-

one of the stripes taken from a drawdown of the test paint.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.1.2 hiding power, n—the spreading rate of a paint applied

uniformly on a standard black and white hiding power chart to

2. Referenced Documents

giveastandarddegreeofcontrastjustshortofcompletehiding.

2.1 ASTM Standards:

3.1.2.1 Discussion—In reflectometry the standard contrast

D2805Test Method for Hiding Power of Paints by Reflec-

for hiding power measurements is generally accepted as the

tometry

contrast ratio C =0.98 (98%), which with white and light

D3924Specification for Environment for Conditioning and

tinted coatings is equivalent to a visual color difference of

Testing Paint, Varnish, Lacquer, and Related Materials

about0.75CIELABunits.Thatamountofcolordifferencecan

(Withdrawn 2016)

reasonably be described as “just-short-of complete-hiding.”

Sincethisisavisualmethoditemploysavisualcomparatoras

3. Terminology

a standard, which is a hiding power chart with a white coating

3.1 Definitions of Terms Specific to This Standard:

applied at a contrast ratio of 0.98 (98%).

3.1.3 logicator, n—amulti-notchapplicatorwithclearances,

and corresponding wet film thicknesses and spreading rates, in

This test method is under the jurisdiction of ASTM Committee D01 on Paint

equal percentage steps.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

3.1.4 logicator scale, n—a scale with values directly related

Current edition approved June 1, 2017. Published June 2017. Originally

to the logarithms of corresponding spreading rates.

approved in 1989. Last previous edition approved in 2013 as D5007–99(2013).

DOI: 10.1520/D5007-99R17.

3.1.4.1 Discussion—A specified change in scale value rep-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

resents the same percentage change in spreading rate over any

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

part of such a scale.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3.1.5 spreading index (h), n—the spreading rate expressed

The last approved version of this historical standard is referenced on

www.astm.org. in logicator scale units (LU) as described in 3.1.4 and 3.1.7.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5007 − 99 (2017)

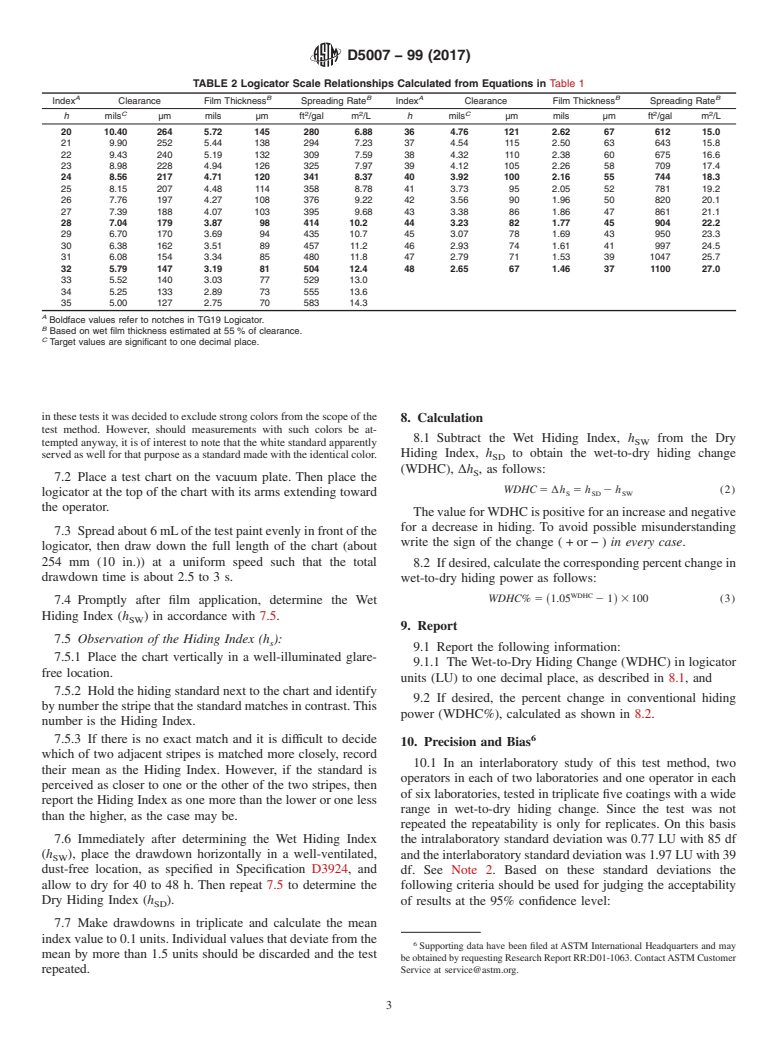

TABLE 1 Equations Relating the Logicator Scale Value or

3.1.6 spreading rate (H), n—the area covered per unit

Spreading Index, h, to the Notch Clearance, N, Wet Film

quantity of coating.

Thickness, T, and Spreading Rate, H

3.1.6.1 Discussion—In this test method the quantity is

NOTE 1—The relationships involving T and H are based on a presumed

volumetric.

T/N ratio of 0.55, which ratio is approximate and somewhat variable,

3.1.7 TG19 logicator, n—a logicator designed for this test

depending on coating rheology, drawdown technique, and clearance.

methodwitheightnotchesnumberedatfour-unitintervalsona

Inch-Pound Units Metric Units

2 2

scale from 20 to 48, the notch clearances ranging from 67 to

(mils, ft /gal): (µm, m /L):

68-h h 68-h h

N = 1.05 = 27.6 ÷ 1.05 N =25.4×1.05 =701÷1.05

264 µm (2.65 to 10.4 mils) corresponding to wet film thick-

h = 68 − 47.2 logNh = 134.3 − 47.2 log N

nessesfrom37to145µm(1.46to5.7mils)andspreadingrates

h h

T = 0.55 N = 15.18÷ 1.05 T = 0.55 N = 385.5÷ 1.05

2 2

from 6.9 to 27 m /L (280 to 1100 ft /gal), with one scale unit

h = 55.75 − 47.2 logTh = 122.05 − 47.2 log T

h h

H = 105.7 × 1.05 H =2.594×1.05

representingachangeof5%andthefour-unitintervalbetween

h = 47.2 log H − 95.52 h = 47.2 log H − 19.54

notches a cumulative change of 21.55% in the clearance and

corresponding film thicknesses and spreading rates. Refer to

this scale unit as a logicator unit (LU). (See Fig. 1.)

4.4 If desired, the percent change in hiding power corre-

3.1.7.1 Discussion—The percentage difference between

sponding to the WDHC value is calculated and reported.

notches is calculated as (1.05 −1)×100=21.55. This per-

centage is applicable precisely to the notch clearances and

5. Significance and Use

approximatelytotheirrelatedwet-filmthicknessesandspread-

5.1 Many architectural paints, particularly white and light

ing rates. The detailed relationships between scalar value and

tints, change significantly in film opacity as they dry. An

the notch clearance, wet film thickness, and spreading rate are

increase in hiding is sometimes associated with porosity and

given in Table 1 and Table 2.

poor film integrity with conventionally formulated coatings.A

3.1.8 wet-to-dry hiding change (WDHC), n—the difference

decreasecanresultinadisappointingpaintjob.Thewet-to-dry

in the Hiding Index of a paint between the wet and the dry

hiding change is therefore a property of great practical impor-

state, expressed in logicator units (LU) as follows:

tance.

WDHC 5∆h 5 h 2 h (1)

S SD SW

5.2 This test method can be used in paint specifications and

3.1.8.1 Discussion—The WDHC is unchanged if the con-

as a short, simple procedure for evaluation and quality control.

trastlevelofthehidingstandardisvaried,becausetheresultant

changes in the two hiding power values are proportional and

6. Apparatus

their ratio therefore constant.

6.1 TG19 Logicator —A multi-notch, varied-clearance ap-

3.1.8.2 Discussion—TheWDHCisunaffectedbydeviations

plicatordesignedspecificallyforthistestmethod(see3.1.7and

fromtheestimatedfilmthickness/clearanceratio T/N(seeNote

Fig. 1).

1, Table 1), because the ratio of the two recalculated hiding-

6.2 Logicator Test Charts —Black and white hiding charts

power values is unchanged.

with a chevron-stripe pattern and scale numbers printed at the

4. Summary of Test Method

top corresponding to the paint stripes applied by the Logicator

(see Fig. 2).

4.1 The test paint is applied with a TG19 Logicator on a

logicator test chart (see 6.2 and Fig. 2) and the drawdown

6.3 Vacuum Plate, for holding the chart flat while the

examined in comparison wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.