ASTM F2299/F2299M-03(2010)

(Test Method)Standard Test Method for Determining the Initial Efficiency of Materials Used in Medical Face Masks to Penetration by Particulates Using Latex Spheres

Standard Test Method for Determining the Initial Efficiency of Materials Used in Medical Face Masks to Penetration by Particulates Using Latex Spheres

SIGNIFICANCE AND USE

This test method measures the initial filtration efficiency of materials used in medical face masks by sampling representative volumes of the upstream and downstream latex aerosol concentrations in a controlled airflow chamber.

This test method provides specific test techniques for both manufacturers and users to evaluate materials when exposed to aerosol particle sizes between 0.1 and 5.0 μm.

This test method establishes a basis of efficiency comparison between medical face mask materials.

This test method does not establish a comprehensive characterization of the medical face mask material for a specific protective application.

This test method does not assess the overall effectiveness of medical face masks in preventing the inward leakage of harmful particles.

The design of the medical face mask and the integrity of the seal of the medical face mask to the wearer's face are not evaluated in this test.

This test method is not suitable for evaluating materials used in protective clothing for determining their effectiveness against particulate hazards.

In general, clothing design is a significant factor, which must be considered in addition to the penetration of penetration of particulates.

SCOPE

1.1 This test method establishes procedures for measuring the initial particle filtration efficiency of materials used in medical facemasks using monodispersed aerosols.

1.1.1 This test method utilizes light scattering particle counting in the size range of 0.1 to 5.0 μm and airflow test velocities of 0.5 to 25 cm/s.

1.2 The test procedure measures filtration efficiency by comparing the particle count in the feed stream (upstream) to that in the filtrate (downstream).

1.3 The values stated in SI units or in other units shall be regarded separately as standard. The values stated in each system must be used independently of the other, without combining values in any way.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2299/F2299M − 03 (Reapproved 2010)

Standard Test Method for

Determining the Initial Efficiency of Materials Used in

Medical Face Masks to Penetration by Particulates Using

Latex Spheres

ThisstandardisissuedunderthefixeddesignationF2299/F2299M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3776Test Methods for Mass Per Unit Area (Weight) of

Fabric

1.1 This test method establishes procedures for measuring

E691Practice for Conducting an Interlaboratory Study to

the initial particle filtration efficiency of materials used in

Determine the Precision of a Test Method

medical facemasks using monodispersed aerosols.

F50Practice for Continuous Sizing and Counting of Air-

1.1.1 This test method utilizes light scattering particle

borne Particles in Dust-Controlled Areas and Clean

counting in the size range of 0.1 to 5.0 µm and airflow test

Rooms Using Instruments Capable of Detecting Single

velocities of 0.5 to 25 cm/s.

Sub-Micrometre and Larger Particles

1.2 The test procedure measures filtration efficiency by

F328Practice for Calibration of anAirborne Particle Coun-

comparing the particle count in the feed stream (upstream) to

ter Using Monodisperse Spherical Particles (Withdrawn

that in the filtrate (downstream).

2007)

F778Methods for Gas Flow ResistanceTesting of Filtration

1.3 The values stated in SI units or in other units shall be

regarded separately as standard. The values stated in each Media

F1471Test Method for Air Cleaning Performance of a

system must be used independently of the other, without

combining values in any way. High-Efficiency Particulate Air Filter System

F1494Terminology Relating to Protective Clothing

1.4 The following precautionary caveat pertains only to the

F2053Guide for Documenting the Results of Airborne

test methods portion, Section 10, of this specification. This

Particle Penetration Testing of Protective Clothing Mate-

standard does not purport to address all of the safety concerns,

rials

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

3. Terminology

practices and determine the applicability of regulatory limita-

3.1 Definitions:

tions prior to use.

3.1.1 aerosol, n—a suspension of a liquid or solid particles

in a gas with the particles being in the colloidal size range.

2. Referenced Documents

3.1.1.1 Discussion—In this test method, aerosols include

2.1 ASTM Standards:

solid particles having a diameter of 0.1 to 5 µm suspended or

D1356Terminology Relating to Sampling and Analysis of

dispersed in an airflow at concentrations of less than 102

Atmospheres

particles/cm .

D1777Test Method for Thickness of Textile Materials

3.1.2 isokinetic sampling, n—aconditionwherethevelocity

D2905Practice for Statements on Number of Specimens for

of the airflow entering the sampling nozzle is the same as the

Textiles (Withdrawn 2008)

velocity of the airflow passing around the sampling nozzle.

3.1.3 monodispersion, n—scattering of discrete particles in

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal

anairflowwherethesizeiscentralizedaboutaspecificparticle

ProtectiveClothingandEquipmentandisthedirectresponsibilityofSubcommittee

size.

F23.40 on Biological.

CurrenteditionapprovedJune1,2010.PublishedJuly2010.Originallyapproved 3.1.3.1 Discussion—In this test method, the monodispersed

in2003.Lastpreviouseditionapprovedin2003asF2299-03.DOI:10.1520/F2299

particle distribution has a mean diameter size of the aerosol in

_F2299M-03R10.

the 0.1 to 5 µm range, with a coefficient of variation of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mean diameter of 610% or less, as certified by the manufac-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

turer.

the ASTM website.

3.2 Fordefinitionsofotherprotectiveclothing-relatedterms

The last approved version of this historical standard is referenced on

www.astm.org. used in this test method, refer to Terminology F1494.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2299/F2299M − 03 (2010)

4. Summary of Test Method 7. System Preparation and Control

4.1 Filtered and dried air is passed through an atomizer to 7.1 Totestintheaerosolparticlesizerangeof0.1to5.0µm,

produce an aerosol containing suspended latex spheres. itisnecessarytomaintainaverycleaninletairsupply.Achieve

4.1.1 This aerosol is then passed through a charge neutral- acceptable levels of background aerosol by passing the atom-

izer. izing air supply sequentially through a silica-gel dryer (for

4.1.2 The aerosol is then mixed and diluted with additional reductionofmoisture),amolecularsievematerial(forremoval

preconditioned air to produce a stable, neutralized, and dried of oil vapor) and an ultra low penetrating aerosol (better than

aerosol of latex spheres to be used in the efficiency test. 99.9999%efficientat0.6µm)filter.Then,supplytheairtothe

test chamber of aerosol generator through pressure regulators

5. Significance and Use of 67kPa[61psi]accuracy.Forthrottlingofthemainairflow

as well as other flow splitting requirements, use needle valves

5.1 Thistestmethodmeasurestheinitialfiltrationefficiency

to maintain adequate flow stability and back pressure. For

of materials used in medical face masks by sampling represen-

recommended flow control measurement, see 7.6. Monitor and

tative volumes of the upstream and downstream latex aerosol

recordthetemperatureandrelativehumidityattheexhaustport

concentrations in a controlled airflow chamber.

ofthetestchamber.Toavoidinterferencefromthetestaerosol,

5.2 This test method provides specific test techniques for

take the humidity measurement from the outlet side of the

both manufacturers and users to evaluate materials when

HEPA filter (see 7.6.2) with an in-line probe.

exposed to aerosol particle sizes between 0.1 and 5.0 µm.

7.1.1 To provide a stable, reproducible aerosol through the

5.2.1 This test method establishes a basis of efficiency

test material that remains constant over the sampling time of

comparison between medical face mask materials.

the efficiency test, maintain the main test duct and filter

5.2.2 This test method does not establish a comprehensive

medium specimen holder in a vertical orientation to minimize

characterization of the medical face mask material for a

aerosol sedimentation losses.

specific protective application.

7.2 Aerosol Generation:

5.3 This test method does not assess the overall effective-

7.2.1 The aerosol generator must be capable of a latex

7 8 3

nessofmedicalfacemasksinpreventingtheinwardleakageof

sphere count concentrations output of 10 to 10 particles/m .

harmful particles.

The suspension reservoir must be large enough to sustain a

5.3.1 The design of the medical face mask and the integrity

stabilized output greater than 1 h.Two commercially available

ofthesealofthemedicalfacemasktothewearer’sfacearenot

atomizing techniques that provide these concentrations of the

evaluated in this test.

latex spheres are presented in Figs. 2 and 3.

7.2.2 AsviewedinFigs.2and3,thesetechniquesutilizethe

5.4 This test method is not suitable for evaluating materials

atomizing of suspended uniform latex spheres from dilute

used in protective clothing for determining their effectiveness

water suspensions. One liter quantities of these suspensions

against particulate hazards.

can be made by diluting the 10% by volume solids of the

5.4.1 In general, clothing design is a significant factor,

uniform latex spheres at 1000 to 1 or greater dilution ratios in

which must be considered in addition to the penetration of

deionized, filtered distilled water.

penetration of particulates.

NOTE 1—The suspensions havea3to6 month usable life. Ideal

6. Apparatus

suspension dilutions are a function of the latex particle size to the aerosol

generatordropletsize.Inordertominimizetheatomizationofdoubletsor

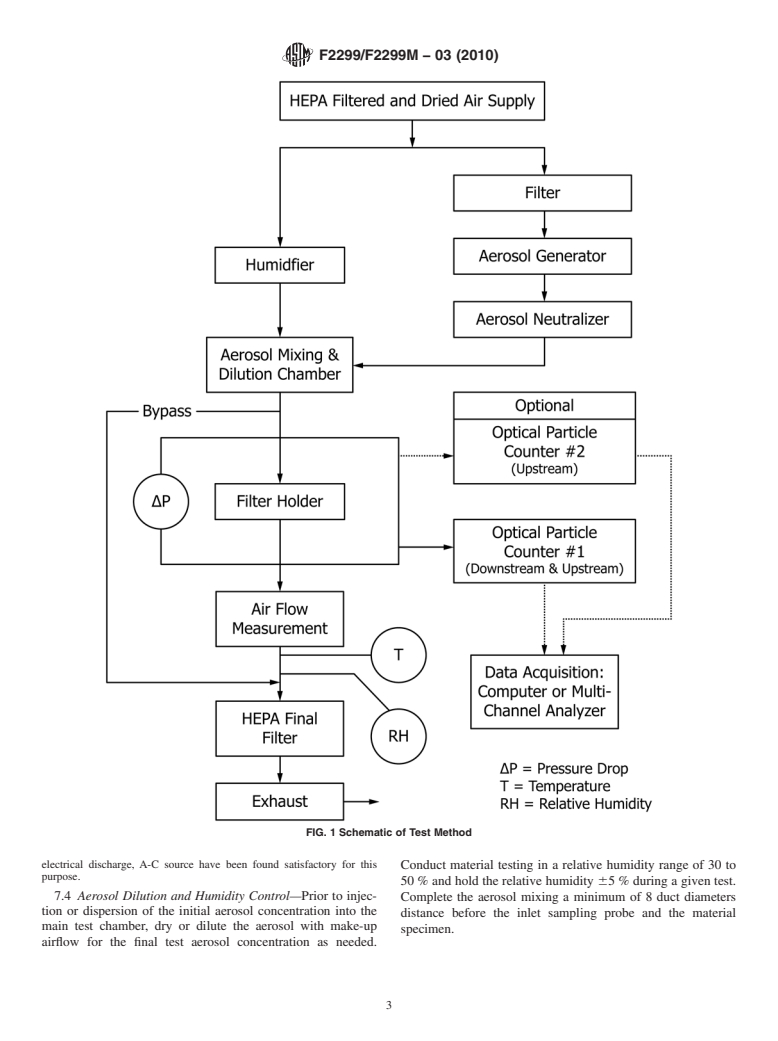

6.1 The aerosol test system incorporates the components as

higher aerosol multiples in the drying process, a recommended latex

shown in Fig. 1. A more detailed diagram of test system

suspensiondilutionratiohasbeenestablishedsothatdilutionratiosareon

components and equipment is found in STP 975. the order of 1000:1 to 10000:1. Other aerosols produced from these

atomizers can be classified into monodispersed systems but for an

6.2 Equipment:

industrially recognized standard of particle size and composition the

6.2.1 Clean, dry compressed air supply,

uniform latex spheres are the most reproducible and readily available

particles.

6.2.2 HEPA filters (2),

6.2.3 Aerosol generator,

7.3 Aerosol Neutralizer—This procedure recommends the

6.2.4 Charge neutralizer,

use of an aerosol charge neutralizer at the inlet of the test

6.2.5 Humidifier,

system. This technique generally will ensure aerosol surface

6.2.6 Test filter holder and duct assembly,

charge stability.The aerosol neutralizer can be in the form of a

6.2.7 Pressure drop measuring device,

radioactive decay ionizer. The desired Boltzmann’s charge

6.2.8 Air flow rate measuring device,

equilibrium for the aerosol has been described. Typically, an

3 3

6.2.9 Temperature and relative humidity detectors,

ionizing flux of 10 mCi/m /s provides the required aerosol

6.2.10 Air blower (optional for negative pressure system),

neutralization.

and

NOTE 2—A Krypton 85 source, a Polonium 210 source, or a Corona

6.2.11 Optical particle counters.

Raabe, O., “The Dilution of Monodispersed Suspensions for Aerosolization,”

American Industrial Hygiene Association Journal, Vol 29, 1968, pp. 439-443.

4 6

Symposium on Gas and Liquid Filtration, ASTM STP 975, ASTM, Vol 11, Liu,B.Y.H.andPiu,D.Y.H.,“ElectricalNeutralizationofAerosols,” Aerosol

1986, pp. 141-164. Science, Vol 5, 1974, pp. 465-472.

F2299/F2299M − 03 (2010)

FIG. 1 Schematic of Test Method

electrical discharge, A-C source have been found satisfactory for this

Conduct material testing in a relative humidity range of 30 to

purpose.

50% and hold the relative humidity 65% during a given test.

7.4 Aerosol Dilution and Humidity Control—Prior to injec-

Complete the aerosol mixing a minimum of 8 duct diameters

tion or dispersion of the initial aerosol concentration into the

distance before the inlet sampling probe and the material

main test chamber, dry or dilute the aerosol with make-up

specimen.

airflow for the final test aerosol concentration as needed.

F2299/F2299M − 03 (2010)

FIG. 2 Atomizer

7.5.2 Introduce the latex aerosol a minimum of 10 duct

diametersupstreamofthematerialspecimenandatasufficient

distance to provide thorough mixing before the upstream

sampling probe.

7.6 Airflow Metering:

7.6.1 Use a positive pressure (compressed air) or a negative

pressure (exhaust fan or blower) system for the airflow to the

main test chamber. For the application of any of these

techniquesofairflowmeasurementandcalibration,refertothe

standardsandpracticesoftheAmericanSocietyofMechanical

Engineers.

7.6.2 Use a High Efficiency Particulate Aerosol (HEPA)

type filter (99.97% efficiency on 0.3 µm aerosol) upstream of

the systems airflow measurement. Size the HEPAtype filter to

provide adequate system collection of the exhausting test

aerosol.

FIG. 3 Collision Atomizer

7.7 Pressure Drop Measurement:

7.7.1 Use static pressure taps that are flush with the duct

walls at a distance of 1 duct diameter upstream and down-

7.5 Material Specimen Holder:

stream of the filter medium faces.

7.5.1 The material specimen holder and test section shall be

7.7.2 Withnofiltermediuminthesampleholder,thereshall

a continuous straight walled vessel, interrupted only by the

be no measurable pressure loss between the inlet-side and

filter medium sample throughout its length. The material

outlet-side pressure taps. Use a pressure-measuring instrument

specimen holder must provide an uninterrupted airflow, pas-

capable of being read to 60.025 cm of water gauge to make

sage without measurable peripheral air leakage. Use a 50 to

this determination.

150 mm [2 to 6 in.] cross-sectional diameter for the medium

7.8 Aerosol Sample Extraction and Transport—Use geo-

sample size. Choose the specimen size to ensure that the test

metrically and kinematically identical centerline probes to

specimen is representative of the overall material and provides

extractrepresentativeaerosolsfromtheinletandoutletsidesof

enough rigidity to be self-supporting.

the material specimen test section. Use probes that have a

NOTE 3—The recommended filter medium cross sections allow face

radiusofcurvature(R)of12cmor R/D(Diameter)>20:1and

velocities of 0.5 to 25 cm/s [approximately 1 to 50 ft/min] at flow rates of

3 3

present a cross-sectional area of less than 10% of the cross-

1 L/min to 1 m /min [approximately 0.035 to 35 ft /min] to be developed

in testing. sectional area of the test system ducting. Locate the upstream

F2299/F2299M − 03 (2010)

probe 8 duct diameters (minimum) downstream of the aerosol exceed the suggested coincidence limits for the single particle

injection point and 2 duct diameters ahead of the material counters, an inlet dilution at the optical particle counter of the

specimen. Locate the downstream probe 3 duct diameters aerosol is required. Achieve inlet dilution by passing some

downstream of the filter medium specimen. To minimize portion of the conditioned inlet aerosol through a HEPAgrade

aerosol sampling transport line losses due to settling, diffusion filter and remixing it with the sampled inlet aerosol to the light

andinertiafortheaerosolparticlesizerangeofthetestmethod, scattering particle counter.

use the following characteristics of the sampling.

7.9.3 Establish accurate dilution ratios in order to specify

the exact aerosol sample volume extracted from the inlet flow

7.8.1 Maintain the sampling line flow in the laminar flow

regime; that is, the Reynolds Number must be less than 1000. for aerosol particle counting. Recommended sampling times

are on the order of 10 to 60 s. If separate particle counters are

CalculatetheReynoldsNumberinaccordancewiththefollow-

ing formula: used for inlet and outlet aerosol concentrations, they must be

calibrated for the aerosol particle size and concentration

ρ VD

g 1

Re# 5 (1)

response needed within the test system.

µ

g

NOTE6—Theflowrateoftherespectiveopticalparticlecountermustbe

wher

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.