ASTM F2458-05(2015)

(Test Method)Standard Test Method for Wound Closure Strength of Tissue Adhesives and Sealants

Standard Test Method for Wound Closure Strength of Tissue Adhesives and Sealants

SIGNIFICANCE AND USE

4.1 Materials and devices that function at least in part by adhering to living tissues are finding increasing use in surgical procedures either as adjuncts to sutures and staples, or as frank replacements for those devices in a wide variety of medical procedures. While the nature and magnitude of the forces involved varies greatly with indication and with patient specific circumstances, all uses involve to some extent the ability of the material to resist imposed mechanical forces. Therefore, the mechanical properties of the materials, and in particular the adhesive properties, are important parameters in evaluating their fitness for use. In addition, the mechanical properties of a given adhesive composition can provide a useful means of determining product consistency for quality control or as a means for determining the effects of various surface treatments on the substrate prior to use of the device.

4.2 The complexity and variety of individual applications for tissue adhesive devices, even within a single indicated use (surgical procedure, which itself may vary depending on physical site and clinical intention) is such that the results of a single tensile strength test is not suitable for determining allowable design stresses without thorough analysis and understanding of the application, adhesive behaviors, and clinical indications.

4.3 This test method may be used for comparing adhesives or bonding processes for susceptibility to fatigue, mode of failure, and environmental changes, but such comparisons must be made with great caution since different adhesives may respond differently to varying conditions.

4.4 A correlation of the test method results with actual adhesive performance in live human tissue has not been established.

SCOPE

1.1 This test method covers a means for comparison of wound closure strength of tissue adhesives used to help secure the apposition of soft tissue. With the appropriate choice of substrate, it may also be used for purposes of quality control in the manufacture of medical devices used as tissue adhesives.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2458 − 05 (Reapproved 2015)

Standard Test Method for

Wound Closure Strength of Tissue Adhesives and Sealants

This standard is issued under the fixed designation F2458; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 tissue sealant—a surface coating with adequate adhe-

sive strength to prevent leakage of body fluids.

1.1 This test method covers a means for comparison of

3.2.3 cohesive strength—internal strength of the adhesive.

wound closure strength of tissue adhesives used to help secure

the apposition of soft tissue. With the appropriate choice of

3.2.4 adhesive strength—the strength of the tissue adhesive/

substrate,itmayalsobeusedforpurposesofqualitycontrolin

substrate interface.

the manufacture of medical devices used as tissue adhesives.

3.2.5 cohesivefailure—failureoftheinternaladhesivebond.

1.2 The values stated in SI units are to be regarded as

3.2.6 adhesive failure—failure of the adhesive/substrate

standard. No other units of measurement are included in this

bond.

standard.

3.2.7 substrate failure—failure of the tissue substrate.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Materials and devices that function at least in part by

priate safety and health practices and determine the applica-

adhering to living tissues are finding increasing use in surgical

bility of regulatory limitations prior to use.

procedureseitherasadjunctstosuturesandstaples,orasfrank

replacements for those devices in a wide variety of medical

2. Referenced Documents

procedures. While the nature and magnitude of the forces

involvedvariesgreatlywithindicationandwithpatientspecific

2.1 ASTM Standards:

D907Terminology of Adhesives circumstances,allusesinvolvetosomeextenttheabilityofthe

material to resist imposed mechanical forces. Therefore, the

E4Practices for Force Verification of Testing Machines

mechanical properties of the materials, and in particular the

2.2 Other Document:

adhesive properties, are important parameters in evaluating

American Association of Tissue Banking,Standards for

3 their fitness for use. In addition, the mechanical properties of a

Tissue Banking

given adhesive composition can provide a useful means of

determining product consistency for quality control or as a

3. Terminology

meansfordeterminingtheeffectsofvarioussurfacetreatments

3.1 Many terms in this test method are defined inTerminol-

on the substrate prior to use of the device.

ogy D907.

4.2 The complexity and variety of individual applications

3.2 Definitions:

for tissue adhesive devices, even within a single indicated use

3.2.1 tissue adhesive—any material used as a medical de-

(surgical procedure, which itself may vary depending on

vice to help secure the apposition of two wound edges or

physical site and clinical intention) is such that the results of a

opposed soft tissues.

single tensile strength test is not suitable for determining

allowabledesignstresseswithoutthoroughanalysisandunder-

standing of the application, adhesive behaviors, and clinical

indications.

ThistestmethodisunderthejurisdictionofASTMCommitteeF04onMedical

andSurgicalMaterialsandDevicesandisthedirectresponsibilityofSubcommittee

4.3 This test method may be used for comparing adhesives

F04.15 on Material Test Methods.

or bonding processes for susceptibility to fatigue, mode of

CurrenteditionapprovedMay1,2015.PublishedJuly2015.Originallyapproved

in 2005. Last previous edition approved in 2010 as F2458-05 (2010). DOI:

failure,andenvironmentalchanges,butsuchcomparisonsmust

10.1520/F2458-05R15.

be made with great caution since different adhesives may

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

respond differently to varying conditions.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4.4 A correlation of the test method results with actual

the ASTM website.

adhesive performance in live human tissue has not been

Available from American Association of Tissue Banks (AATB), 1320 Old

Chain Bridge Rd., Suite 450, McLean, VA 22101. established.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2458 − 05 (2015)

5. Apparatus 6.2 For Application Specific Testing—The grips of the test

machine must be able to hold the tissue without having the

5.1 Testing Machine—A testing machine of the constant-

tissue slip or be crushed by the grips. Some tissue (liver, lung)

rate-of-crosshead-movement type and comprising essentially

may not be suitable for this test.

the following:

6.2.1 The strength of any adhesive is highly dependent on

5.1.1 Fixed Member—A fixed or essentially stationary

the test substrate or adherend. For a specific application, the

member carrying one grip.

preferred substrate is freshly harvested tissue from the target

5.1.2 Movable Member—A movable member carrying a

organ of a domestic food animal. Tissue from bovine, porcine,

second grip.

orovineoriginispreferredduetowideavailabilityandthefact

5.1.3 Grips—Grips for holding the test specimen between

that relatively large samples of tissue can be harvested from a

the fixed member and the movable member of the testing

single source. Ideally, the tissue should be used within 24 h of

machine can be either the fixed or self-aligning type. Gripping

harvestandshouldbekeptbetween5and10°Cpriortotesting

pressure should be adjustable to prevent damage to the

if it cannot be used immediately after harvesting. Storage and

substrate and the use of sandpaper or plastic scrubbing pads

handling of tissue samples should be carried out according to

between the gripping surfaces and the substrate is recom-

the guidelines set forth in Standards forTissue Banking by the

mended to help prevent slippage.

AmericanAssociation of Tissue Banks. The specimens should

5.1.3.1 Fixed grips are rigidly attached to the fixed and

be brought to the test temperature or other prescribed tempera-

movable members of the testing machine. When this type of

ture (such as body temperature) prior to application of the

gripisused,extremecareshouldbetakentoensurethatthetest

adhesive.

specimen is inserted and clamped so that the long axis of the

6.2.2 Fixed tissue should not be used since it has been

test specimen coincides with the direction of pull through the

demonstrated that fixatives cause large alterations in the

centerline of the grip assembly.

mechanical properties of the tissue and it is probable that the

5.1.3.2 Self-aligning grips are attached to the fixed and

adhesive strength would be affected as well.

movablemembersofthetestingmachineinsuchamannerthat

6.2.3 If the target organ is of a size or geometry that does

they will move freely into alignment as soon as any load is

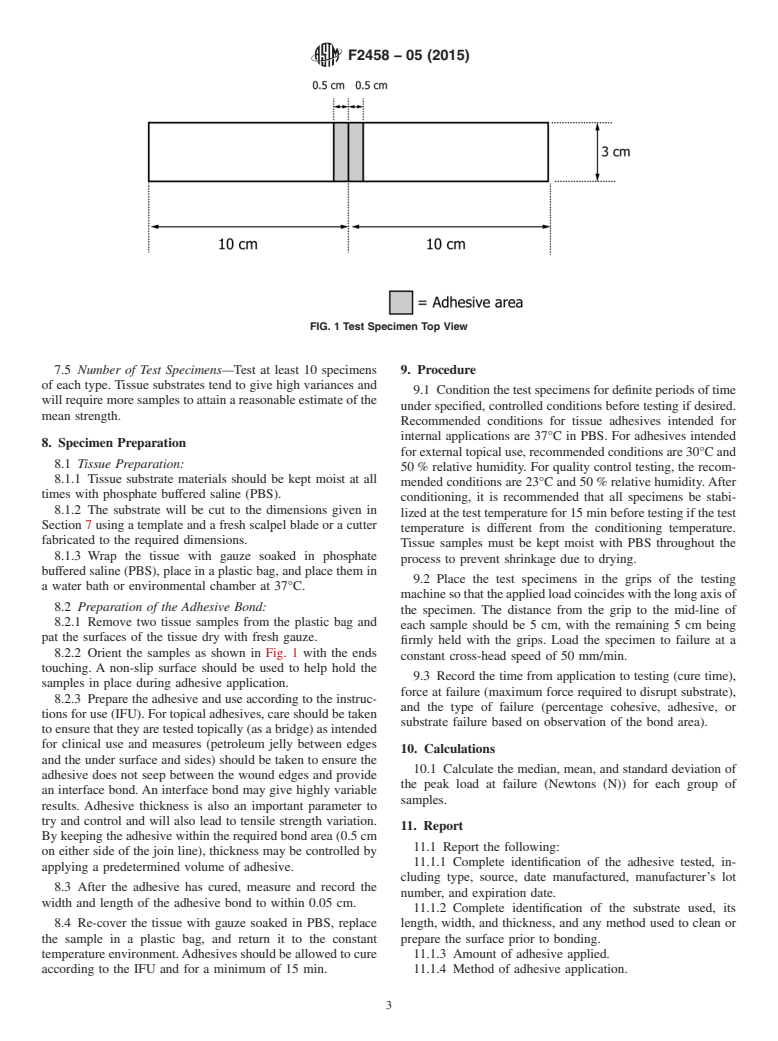

notallowfabricationoftestsamplesasshowninFig.1,atissue

applied so that the long axis of the test specimen will coincide

ofsimilaroriginbutlargersizeshouldbeused.Forexample,if

with the direction of the applied pull through the center line of

the intended indication is for anastomosis of small blood

the grip assembly. The specimens should be aligned as per-

vessels, a larger vessel should be substituted.

fectly as possible with the direction of pull so that no rotary

6.2.4 The thickness of the tissue sample should not exceed

motion that may induce slippage or damage to the sample will

5 mm.

occur in the grips; there is a limit to the amount of misalign-

ment self-aligning grips will accommodate. 6.3 For Quality Control Testing:

5.1.4 Drive Mechanism—A drive mechanism for imparting 6.3.1 For testing that is undertaken as part of a quality

to the movable member a uniform, controlled velocity with control process in the manufacturing of a tissue adhesive

respect to the stationary member, with this velocity to be device, the use of freshly harvested tissue is highly inconve-

regulated as specified in 8.3.

nient and may also lead to unacceptable variation in the test

5.1.5 Load Indicator—A suitable load-indicating mecha- results, especially if the failure occurs in the adherend (sub-

nism capable of showing the total tensile load carried by the

strate failure). Since the purpose of quality control testing is to

testspecimenwhenheldbythegrips.Thismechanismshallbe demonstrate consistency in the device, substitution of a model

essentially free of inertia lag at the specified rate of testing and

substrate is preferred so long as it is demonstrated that the

shall indicate the load with an accuracy of 61% of the adhesive bonds to the adherend. If the test is intended to

indicated value, or better. The accuracy of the testing machine

generate data on the cohesive strength of the device, any

shall be verified in accordance with Practices E4. metallic or polymeric material is acceptable so long as it has

beendemonstratedthattheadhesivebondstotheadherendand

5.2 Temperature-controlling Equipment—Capable of main-

that failure is substantially cohesive (>90% by area) and not

taining the test temperature to 62°C. If ambient laboratory

adhesive. For adhesive quality control testing, it is recom-

conditions are employed, the same degree of control is re-

mended that test results for any substrate of non-biological or

quired.

fixed tissue origin be correlated to testing previously done on

fresh tissue substrates prior to acceptance of the procedure.

6. Test Substrate

6.1 For Comparative Testing—Either fresh or frozen split

7. Test Specimen

thickness porcine skin graft may be used.

7.1 The wound strength test specimen is shown in Fig. 1.

6.1.1 Frozen split thickness porcine skin that has been

Two substrate samples are required for each test specimen.

aseptically prepared is available commercially and is preferred

due to ease of use and the potential for more consistent

7.2 Atemplate of the correct dimensions should be used.A

properties.It

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.