ASTM E2019-03(2007)

(Test Method)Standard Test Method for Minimum Ignition Energy of a Dust Cloud in Air

Standard Test Method for Minimum Ignition Energy of a Dust Cloud in Air

SIGNIFICANCE AND USE

This test method provides a procedure for performing laboratory tests to determine the minimum ignition energy of a dust cloud.

Note 1—For gases and vapors, see Test Method E 582.

The data developed by this test method may be used to assess the spark ignitibility of a dust cloud. Additional guidance on the significance of minimum ignition energy is in X1.1.

The values obtained are specific to the sample tested, the method used and the test equipment used. The values are not to be considered intrinsic material constants.

The MIE of a dust as determined using this procedure can be compared with the MIE's of reference dusts (using the same procedure) to obtain the relative sensitivity of the dust to spark ignition. An understanding of the relative sensitivity to spark ignition can be used to minimize the probability of explosions due to spark ignition.SCOPE

1.1 This test method determines the minimum ignition energy of a dust cloud in air by a high voltage spark.

1.2 The Minimum Ignition Energy (MIE) of a dust-cloud is primarily used to assess the likelihood of ignition during processing and handling. The likelihood of ignition is used to evaluate the need for precautions such as explosion prevention systems. The MIE is determined as the electrical energy stored in a capacitor which, when released as a high voltage spark, is just sufficient to ignite the dust cloud at its most easily ignitable concentration in air. The laboratory test method described in this standard does not optimize all test variables that affect MIE. Smaller MIE values might be determined by increasing the number of repetitions or optimizing the spark discharge circuit for each dust tested.

1.3 In this test method, the test equipment is calibrated using a series of reference dusts whose MIE values lie within established limits. Once the test equipment is calibrated, the relative ignition sensitivity of other dusts can be found by comparing their MIE values with those of the reference dusts or with dusts whose ignition sensitivities are known from experience. X1.1 of this test method includes guidance on the significance of minimum ignition energy with respect to electrostatic discharges.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 8

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2019 − 03 (Reapproved2007)

Standard Test Method for

Minimum Ignition Energy of a Dust Cloud in Air

This standard is issued under the fixed designation E2019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3173Test Method for Moisture in theAnalysis Sample of

Coal and Coke

1.1 This test method determines the minimum ignition

D3175Test Method for Volatile Matter in the Analysis

energy of a dust cloud in air by a high voltage spark.

Sample of Coal and Coke

1.2 The Minimum Ignition Energy (MIE) of a dust-cloud is

E582 Test Method for Minimum Ignition Energy and

primarily used to assess the likelihood of ignition during

Quenching Distance in Gaseous Mixtures

processing and handling. The likelihood of ignition is used to

E789Test Method for Dust Explosions in a 1.2-Litre Closed

evaluate the need for precautions such as explosion prevention

Cylindrical Vessel (Withdrawn 2007)

systems.The MIE is determined as the electrical energy stored

E1226Test Method for Explosibility of Dust Clouds

in a capacitor which, when released as a high voltage spark, is

E1445Terminology Relating to Hazard Potential of Chemi-

justsufficienttoignitethedustcloudatitsmosteasilyignitable

cals

concentration in air. The laboratory test method described in

2.2 IEC Standards:

this standard does not optimize all test variables that affect

1241-2-3, 1994ElectricalApparatus for Use in the Presence

MIE. Smaller MIE values might be determined by increasing

of Combustible Dusts, Part 2: Test Method, Section 3:

the number of repetitions or optimizing the spark discharge

Method for Determining Minimum Ignition Energy of

circuit for each dust tested.

Dust-Air Mixtures

1.3 Inthistestmethod,thetestequipmentiscalibratedusing

3. Terminology

a series of reference dusts whose MIE values lie within

3.1 Definitions of Terms Specific to This Standard:

established limits. Once the test equipment is calibrated, the

3.1.1 (See also Terminology E1445):

relative ignition sensitivity of other dusts can be found by

3.1.2 spark discharge, n—transient discrete electric

comparing their MIE values with those of the reference dusts

discharge, which takes place between two conductors, which

or with dusts whose ignition sensitivities are known from

are at different potentials. The discharge bridges the gap

experience. X1.1 of this test method includes guidance on the

significance of minimum ignition energy with respect to between the conductors in the form of a single ionization

channel.

electrostatic discharges.

1.4 This standard does not purport to address all of the 3.1.3 minimum ignition energy (MIE), n—electrical energy

discharged from a capacitor, which is just sufficient to effect

safety concerns, if any, associated with its use. It is the

ignition of the most easily ignitable concentration of fuel in air

responsibility of the user of this standard to establish appro-

under the specific test conditions.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

3.1.4 ignition delay time, n—the time between the onset of

tionary statements are given in Section 8.

dispersion of the dust sample into a cloud and the activation of

the ignition source.

2. Referenced Documents

2 4. Summary of Test Method

2.1 ASTM Standards:

4.1 A dust cloud is formed in a laboratory chamber by an

introduction of the material with air.

This test method is under the jurisdiction ofASTM Committee E27 on Hazard

4.2 Ignition trials of this dust-air mixture are then

Potential of Chemicalsand is the direct responsibility of Subcommittee E27.05 on

Explosibility and Ignitability of Dust Clouds. attempted, after a specific ignition delay time, by a spark

Current edition approved Oct. 1, 2007. Published January 2008. Originally

discharge from a charged capacitor.

approved in 1999. Last previous edition approved in 2003 as E2019–03. DOI:

10.1520/E2019-03R07.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from International Electrotechnical Commission (IEC), 3 rue de

the ASTM website. Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2019 − 03 (2007)

4.3 The stored energy discharged into the spark and the 7.2.2 Electrode Diameter and Shape, 2 6 1 mm. For

occurrence or nonoccurrence of flame are recorded. circuits in which high voltage is maintained across the spark

gap prior to spark breakdown, a significant fraction of the

4.4 The minimum ignition energy is sought by varying the

energy stored in the capacitor may drain away as corona

dust concentration, the spark discharge energy and optionally

discharges from sharp electrode tips prior to the spark dis-

the ignition delay time.

charge. This is increasingly important at low stored energies.

4.5 Ignition is determined by visual observation of a flame

Electrodes with rounded tips can be used to reduce corona

propagation away from the spark gap.

effects that can occur with pointed electrodes, which may give

incorrectvaluesofsparkenergy.Ifpointedelectrodesareused,

5. Significance and Use

corona effects should be considered carefully.

5.1 This test method provides a procedure for performing

7.2.3 Electrode Gap—the optimum spacing is typically of

laboratory tests to determine the minimum ignition energy of a

the order of 6 mm. For certain materials at low ignition energy

dust cloud.

values, however, the gap spacing may need to be reduced in

ordertoinitiatethespark.Underthesecircumstances,thespark

NOTE 1—For gases and vapors, see Test Method E582.

gapcanbereducedandthetestscarriedoutwiththelargestgap

5.2 The data developed by this test method may be used to

possible, but the gap should not be less than 2 mm.

assess the spark ignitibility of a dust cloud. Additional guid-

ance on the significance of minimum ignition energy is in

NOTE 2—The capacitance of the electrodes and associated high voltage

cables between the storage capacitor and the electrodes should be as low

X1.1.

as possible. It should be noted that cable capacitance may be of the order

5.3 Thevaluesobtainedarespecifictothesampletested,the

40pF/m depending on its construction, which represents significant

methodusedandthetestequipmentused.Thevaluesarenotto

additional stored energy at low storage capacitance and high voltage. The

stray capacitance of these components must be measured to determine if

be considered intrinsic material constants.

it needs to be taken into account when calculating the stored circuit

5.4 The MIE of a dust as determined using this procedure

energy.

can be compared with the MIE’s of reference dusts (using the

NOTE3—Insulationresistancebetweenelectrodesshouldbesufficiently

same procedure) to obtain the relative sensitivity of the dust to high to prevent leakage currents prior to discharge. Typically, a minimum

resistance between the electrodes of 10 Ω is required for a minimum

spark ignition. An understanding of the relative sensitivity to

ignitionenergyof1mJ,and10 Ωforaminimumignitionenergyof100

spark ignition can be used to minimize the probability of

mJ. Insulation resistance may decrease over time due to contamination of

explosions due to spark ignition.

thesurfacewithcarbonandothermaterials.Theresistancemaybedirectly

measured across the electrodes.Alternatively, a decrease may be inferred

6. Interferences

by the inability to hold constant voltage on the isolated storage capacitor

for the timescale of a test.

6.1 Dust residue from previous tests may affect results. The

NOTE 4—Almost all electrostatic discharges in plant installations are

chamber must be cleaned before a new product is tested.

capacitive with negligible inductance. It has been found that for equal

stored energies many dusts can be ignited more easily when a resistor or

6.2 Problems may arise due to electrical shortcircuits when

an inductance is placed in the discharge circuit to create longer duration

using conductive materials.

sparks. Ideally, the MIE should correspond to circuits whose discharge

duration has been optimized for the dust in question using, for example,

7. Apparatus

an inductance.

7.1 Test Apparatus—Although a number of different test

8. Safety Precautions

apparatuses are used in practice, they all have the following

components in common:Atest chamber, spark electrodes, and

8.1 Prior to handling a test material, the toxicity of the

a spark generation circuit. Various configurations of the spark

sample and its combustion products must be considered. This

generation circuits are provided in the Appendix X1. The

information is generally obtained from the manufacturer or

purpose of the test chamber is to produce a uniform, nontur-

supplier. Appropriate safety precautions must be taken if the

bulent and known density dust cloud in air at the time of

materialhastoxicorirritatingcharacteristics.MIE-testsshould

ignition.TheclearplasticorglassHartmanntube,typically0.5

be conducted in a ventilated hood or other area having

or 1.2 L and the 20-L sphere apparatus have been found

adequate ventilation.

suitable for this test method. These vessels are described in

8.2 Before initiating a test, check and secure the apparatus,

Refs (1-3, 10) and Test Methods E789 and E1226. These and

fittings and gaskets to prevent leakage.

other suitable chambers can be used provided that the calibra-

tion requirements in 10.1 are met.

8.3 All enclosures containing electrical equipment must be

7.2 Spark Generation Circuit—The Appendix describes connected to a common ground.

some suitable forms of circuits, all of which shall have the

8.4 The test method should not be used with recognized

following characteristics:

explosives, such as gunpowder or dynamite; pyrophoric sub-

7.2.1 Electrode Material, such as tungsten, stainless steel,

stances; or, substances or mixtures of substances, which may

brass, or graphite.

under some circumstances behave in a similar manner without

considering the special hazards. Where any doubt exists about

the existence of a hazard due to explosive properties, expert

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this standard. advice should be sought.

E2019 − 03 (2007)

when coarser bulk powder is handled. Therefore, it is recom-

mended that the test sample be at least 95% minus 200 mesh

(75µm).Ingeneral,thesampletestedshouldbeatleastasfine

as the dust at the location being considered, which, in some

cases, may require testing of sub-325 mesh or even finer dust.

9.3 To achieve this particle fineness (≥ 95% minus 200

mesh) the sample may be ground or pulverized, or it may be

sieved.

NOTE 5—The operator should consider the thermal stability of the dust

during grinding or pulverizing.

NOTE6—Insomecases,itmaybedesirabletoconductdustdeflagration

tests on material as sampled from a process because process dust streams

may contain a wide range of particle sizes or have a well-defined specific

moisture content. When a material is tested in the as-received state, it

should be recognized that the test results may not represent the most

severe ignition hazards possible.Any process change resulting in a higher

fraction of fines or drier product may result in a lower MIE for the

product.

NOTE 7—The possible reduction of the particle size due to attrition by

the dust dispersion system of the test apparatus should be considered.

NOTE 8—In sieving the material, the operator must verify that there is

no selective separation of components in a dust that is not a pure

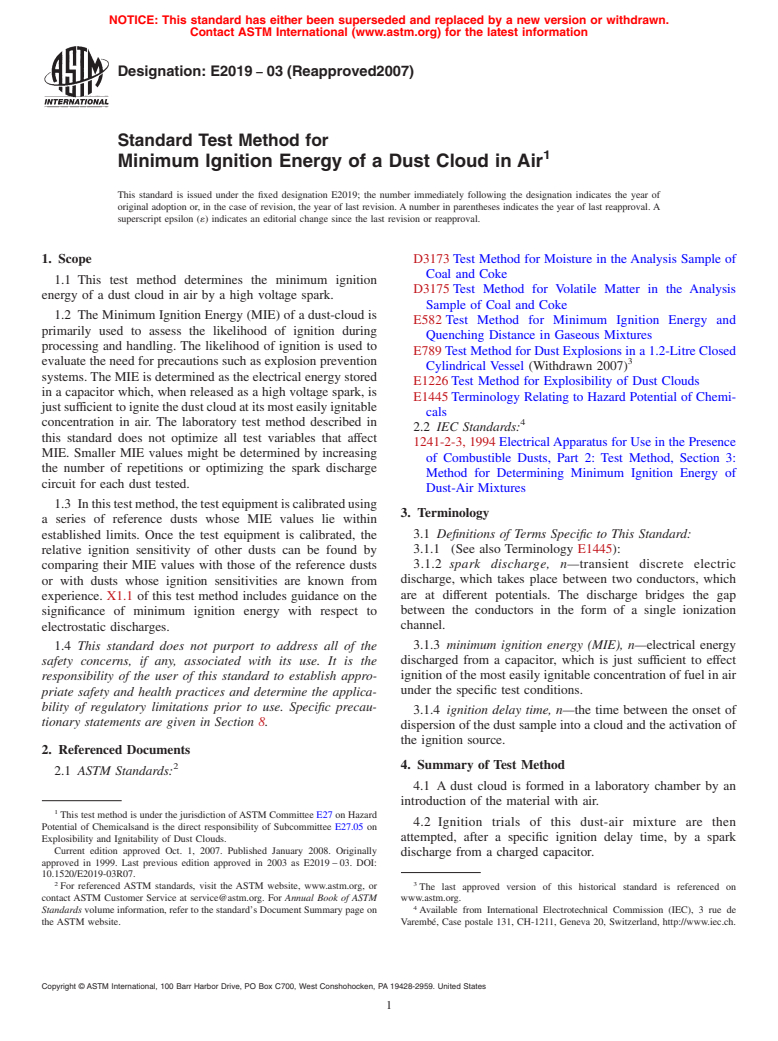

FIG. 1 Correlation of Median Particle Size and MIE (5)

substance. Materials consisting of a mixture of chemicals may be

separated selectively on sieves and certain fibrous materials, which may

not pass through a relatively coarse screen may produce dust deflagra-

tions.

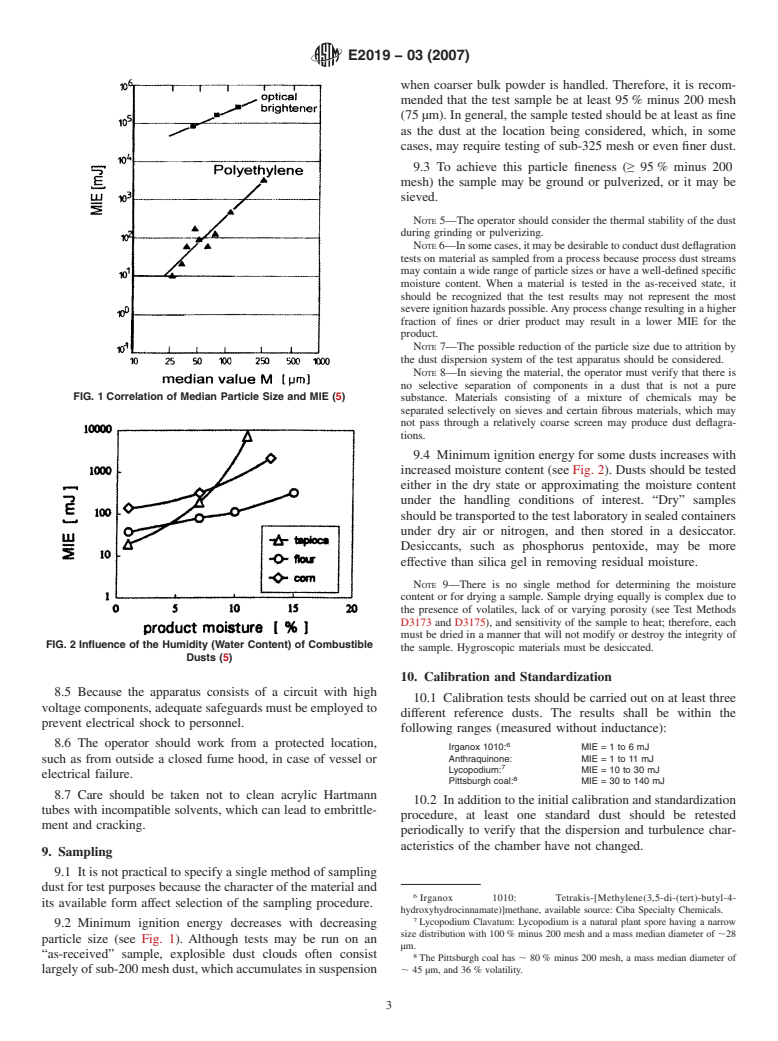

9.4 Minimum ignition energy for some dusts increases with

increased moisture content (see Fig. 2). Dusts should be tested

either in the dry state or approximating the moisture content

under the handling conditions of interest. “Dry” samples

shouldbetransportedtothetestlaboratoryinsealedcontainers

under dry air or nitrogen, and then stored in a desiccator.

Desiccants, such as phosphorus pentoxide, may be more

effective than silica gel in removing residual moisture.

NOTE 9—There is no single method for determining the moisture

content or for drying a sample. Sample drying equally is complex due to

the presence of volatiles, lack of or varying porosity (see Test Methods

D3173 and D3175), and sensitivity of the sample to heat; therefore, each

must be dried in a manner that will not modify or destroy the integrity of

FIG. 2 Influence of the Humidity (Water Content) of Combustible

the sample. Hygroscopic materials must be desiccated.

Dusts (5)

10. Calibration and Standardization

8.5 Because the apparatus consists of a circuit with high

10.1 Calibration tests should be carried out on at least three

voltagecomponents,adequatesafeguardsmustbeemployedto

different reference dusts. The results shall be within the

prevent electrical shock to personnel.

following ranges (measured without inductance):

8.6 The operator should work from a protected location,

Irganox 1010: MIE=1to6mJ

Anthraquinone: MIE=1to11mJ

such as from outside a closed fume hood, in case of vessel or

Lycopodium: MIE=10to30mJ

electrical failure.

Pittsburgh coal: MIE = 30 to 140 mJ

8.7 Care should be taken not to clean acrylic Hartmann

10.2 Inadditiontotheinitialcalibrationandstandardization

tubes with incompatible solvents, which can lead to embrittle-

procedure, at least one standard dust should be retested

ment and cracking.

periodically to verify that the dispersion and turbulence char-

acteristics of the chamber have not changed.

9. Sampling

9.1 Itisnotpracticaltospecifyasinglemethodofsampling

dust for test purposes because the character of the material and

Irganox 1010: Tetrakis-[Methylene(3,5-di-(tert)-butyl-4-

its available form affect selection of the sampling procedure.

hydroxyhydrocinnamate)]methane, available source: Ciba Specialty Chemicals.

Lycopodium Clavatum: Lycopodium is a natural plant spore having a narrow

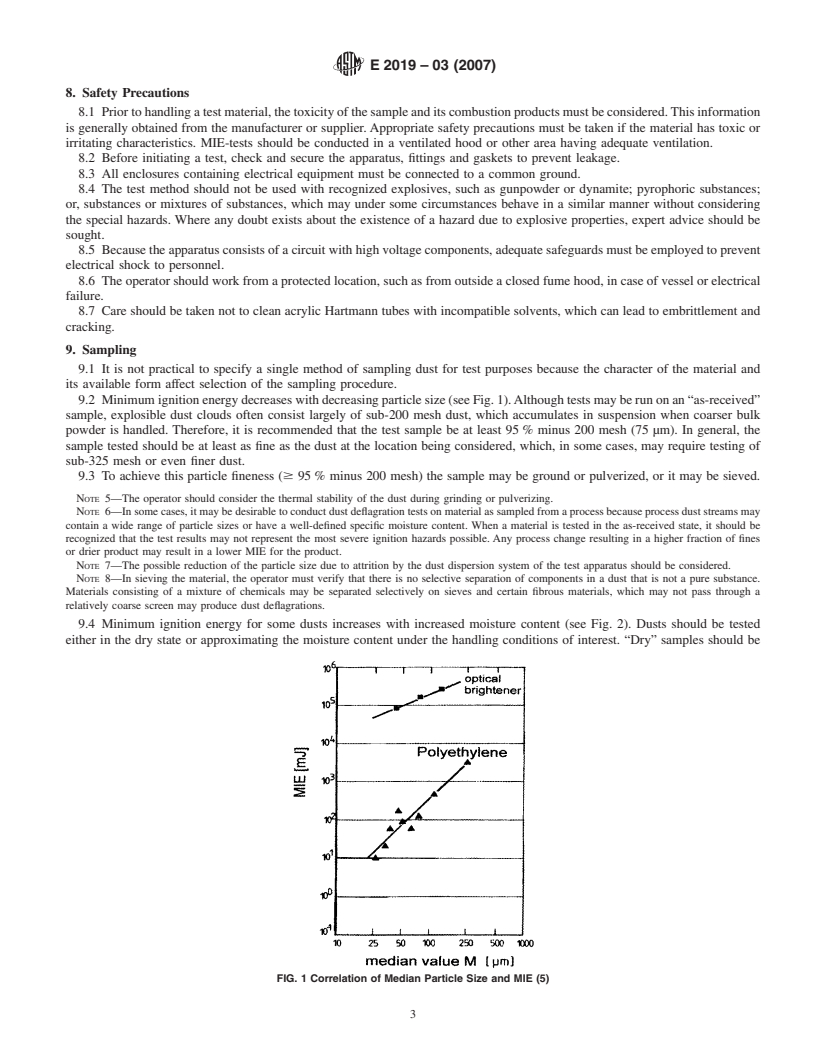

9.2 Minimum ignition energy decreases with decreasing

size dis

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:E2019–02 Designation: E 2019 – 03 (Reapproved 2007)

Standard Test Method for

Minimum Ignition Energy of a Dust Cloud in Air

This standard is issued under the fixed designation E2019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Paragraph 9.2 was corrected editorially July 2003.

1. Scope

1.1 This test method determines the minimum ignition energy of a dust cloud in air by a high voltage spark. .

1.2 TheMinimumIgnitionEnergy(MIE)ofadust-cloudisprimarilyusedtoassessthelikelihoodofignitionduringprocessing

and handling. The likelihood of ignition is used to evaluate the need for precautions such as explosion prevention systems. The

MIE is determined as the electrical energy stored in a capacitor which, when released as a high voltage spark, is just sufficient to

ignite the dust cloud at its most easily ignitable concentration in air. The laboratory test method described in this standard does

not optimize all test variables that affect MIE. Smaller MIE values might be determined by increasing the number of repetitions

or optimizing the spark discharge circuit for each dust tested.

1.3 Inthistestmethod,thetestequipmentiscalibratedusingaseriesofreferencedustswhoseMIEvaluesliewithinestablished

limits. Once the test equipment is calibrated, the relative ignition sensitivity of other dusts can be found by comparing their MIE

values with those of the reference dusts or or with dusts whose ignition sensitivities are known from experience. X1.1 of this test

method includes guidance on the significance of minimum ignition energy with respect to electrostatic dishcharges.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in 8

2. Referenced Documents

2.1 ASTM Standards:

D3173 Test Method for Moisture in the Analysis Sample of Coal and Coke

D3175 Test Method for Volatile Matter in the Analysis Sample of Coal and Coke

E582 Test Method for Minimum Ignition Energy and Quenching Distance in Gaseous Mixtures

E789 Test Method for Dust Explosions in a 1.2 Liter 1.2-Litre Closed Cylindrical Vessel

E1226 Test Method for Pressure and Rate of Pressure Rise for Combustible Dusts

E1445 Terminology Relating to HazardousHazard Potential of Chemicals

2.2 IEC Standards:

1241-2-3, 1994 ElectricalApparatus for Use in the Presence of Combustible Dusts, Part 2:Test Method, Section 3: Method for

Determining Minimum Ignition Energy of Dust-Air Mixtures

3. Terminology

3.1 Definitions of Terms Specific to This Standard: (See also Terminology E1445):

3.1.1 spark discharge, n—transientdiscreteelectricdischarge,whichtakesplacebetweentwoconductors,whichareatdifferent

potentials. The discharge bridges the gap between the conductors in the form of a single ionization channel.

3.1.2 minimum ignition energy (MIE), n—electricalenergydischargedfromacapacitor,whichisjustsufficienttoeffectignition

of the most easily ignitable mixtureconcentration of a given fuel-mixturefuel in air under the specific test conditions.

3.1.3 ignition delay time, n—the time between the onset of dispersion of the dust sample into a cloud and the activation of the

ignition source.

This test method is under the jurisdiction of ASTM Committee E27 on Hazard Potential of Chemicals and is the direct responsibility of Subcommittee E27.05 on

Explosibility and Ignitability of Dust Clouds.

Current edition approved June 10, 2002. Published September 2002. Originally published as E2019–99. Last previous edition E2019–99.

Current edition approved Oct. 1, 2007. Published January 2008. Originally approved in 1999. Last previous edition approved in 2003 as E2019–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards,

Vol 05.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 14.02.

Available from IEC Case Postale 56, CH-1211 Geneva, 20, Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 2019 – 03 (2007)

4. Summary of Test Method

4.1 A dust cloud is formed in a laboratory chamber by an introduction of the material with air.

4.2 Ignition trials of this dust-air mixture are then attempted, after a specific ignition delay time, by a spark discharge from a

charged capacitor.

4.3 The stored energy discharged into the spark and the occurrence or nonoccurrence of flame are recorded.

4.4 The minimum ignition energy is sought by varying the dust concentration, the spark discharge energy and optionally the

ignition delay time.

4.5 Ignition is determined by visual observation of a flame propagation away from the spark gap.

5. Significance and Use

5.1 This test method provides a procedure for performing laboratory tests to determine the minimum ignition energy of a dust

cloud.

NOTE 1—For gases and vapors, see Test Method E582.

5.2 The data developed by this test method may be used to assess the spark ignitibility of a dust cloud.Additional guidance on

the significance of minimum ignition energy is in X1.1.

5.3 The values obtained are specific to the sample tested, the method used and the test equipment used. The values are not to

be considered intrinsic material constants.

5.4 The MIE of a dust as determined using this procedure can be compared with the MIE’s of reference dusts (using the same

procedure) to obtain the relative sensitivity of the dust to spark ignition. An understanding of the relative sensitivity to spark

ignition can be used to minimize the probability of explosions due to spark ignition.

6. Interferences

6.1 Dust residue from previous tests may affect results. The chamber must be cleaned before a new product is tested.

6.2 Problems may arise due to electrical shortcircuits when using conductive materials.

7. Apparatus

7.1 Test Apparatus— Although a number of different test apparatuses are used in practice, they all have the following

components in common: A test chamber, spark electrodes, and a spark generation circuit. Various configurations of the spark

generation circuits are provided in theAppendix X1. The purpose of the test chamber is to produce a uniform, nonturbulent and

known density dust cloud in air at the time of ignition. The clear plastic or glass Hartmann tube, typically 0.5 or 1.2 L and the

20-L sphere apparatus have been found suitable for this test method. These vessels are described in Refs (1-3, 10) and Test

Methods E789 and E1226. These and other suitable chambers can be used provided that the calibration requirements in 10.1 are

met.

7.2 Spark Generation Circuit—TheAppendix describes some suitable forms of circuits, all of which shall have the following

characteristics:

7.2.1 Electrode Material, such as tungsten, stainless steel, brass, or graphite.

7.2.2 Electrode Diameter and Shape,2 6 1 mm. For circuits in which high voltage is maintained across the spark gap prior

to spark breakdown, a significant fraction of the energy stored in the capacitor may drain away as corona discharges from sharp

electrode tips prior to the spark discharge. This is increasingly important at low stored energies. Electrodes with rounded tips can

beusedtoreducecoronaeffectsthatcanoccurwithpointedelectrodes,whichmaygiveincorrectvaluesofsparkenergy.Ifpointed

electrodes are used, corona effects should be considered carefully.

7.2.3 Electrode Gap— the optimum spacing is typically of the order of 6 mm. For certain materials at low ignition energy

values, however, the gap spacing may need to be reduced in order to initiate the spark. Under these circumstances, the spark gap

can be reduced and the tests carried out with the largest gap possible, but the gap should not be less than 2 mm.

NOTE 2—The capacitance of the electrodes and associated high voltage cables between the storage capacitor and the electrodes should be as low as

possible. It should be noted that cable capacitance may be of the order 40pF/m depending on its construction, which represents significant additional

stored energy at low storage capacitance and high voltage. The stray capacitance of these components must be measured to determine if it needs to be

taken into account when calculating the stored circuit energy.

NOTE 3—Insulation resistance between electrodes should be sufficiently high to prevent leakage currents prior to discharge. Typically, a minimum

12 10

resistance between the electrodes of 10 V is required for a minimum ignition energy of 1 mJ, and 10 V for a minimum ignition energy of 100 mJ.

Insulationresistancemaydecreaseovertimeduetocontaminationofthesurfacewithcarbonandothermaterials.Theresistancemaybedirectlymeasured

acrosstheelectrodes.Alternatively,adecreasemaybeinferredbytheinabilitytoholdconstantvoltageontheisolatedstoragecapacitorforthetimescale

of a test.

NOTE 4—Almost all electrostatic discharges in plant installations are capacitive with negligible inductance. It has been found that for equal stored

energiesmanydustscanbeignitedmoreeasilywhenaresistororaninductanceisplacedinthedischargecircuittocreatelongerdurationsparks.Ideally,

the MIE should correspond to circuits whose discharge duration has been optimized for the dust in question using, for example, an inductance.

Available from IEC Case Postale 56, CH-1211 Geneva, 20, Switzerland.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

E 2019 – 03 (2007)

8. Safety Precautions

8.1 Priortohandlingatestmaterial,thetoxicityofthesampleanditscombustionproductsmustbeconsidered.Thisinformation

is generally obtained from the manufacturer or supplier.Appropriate safety precautions must be taken if the material has toxic or

irritating characteristics. MIE-tests should be conducted in a ventilated hood or other area having adequate ventilation.

8.2 Before initiating a test, check and secure the apparatus, fittings and gaskets to prevent leakage.

8.3 All enclosures containing electrical equipment must be connected to a common ground.

8.4 The test method should not be used with recognized explosives, such as gunpowder or dynamite; pyrophoric substances;

or, substances or mixtures of substances, which may under some circumstances behave in a similar manner without considering

the special hazards. Where any doubt exists about the existence of a hazard due to explosive properties, expert advice should be

sought.

8.5 Becausetheapparatusconsistsofacircuitwithhighvoltagecomponents,adequatesafeguardsmustbeemployedtoprevent

electrical shock to personnel.

8.6 Theoperatorshouldworkfromaprotectedlocation,suchasfromoutsideaclosedfumehood,incaseofvesselorelectrical

failure.

8.7 Care should be taken not to clean acrylic Hartmann tubes with incompatible solvents, which can lead to embrittlement and

cracking.

9. Sampling

9.1 It is not practical to specify a single method of sampling dust for test purposes because the character of the material and

its available form affect selection of the sampling procedure.

9.2 Minimumignitionenergydecreaseswithdecreasingparticlesize(seeFig.1).Althoughtestsmayberunonan“as-received”

sample, explosible dust clouds often consist largely of sub-200 mesh dust, which accumulates in suspension when coarser bulk

powder is handled. Therefore, it is recommended that the test sample be at least 95% minus 200 mesh (75 µm). In general, the

sample tested should be at least as fine as the dust at the location being considered, which, in some cases, may require testing of

sub-325 mesh or even finer dust.

9.3 To achieve this particle fineness ($ 95% minus 200 mesh) the sample may be ground or pulverized, or it may be sieved.

NOTE 5—The operator should consider the thermal stability of the dust during grinding or pulverizing.

NOTE 6—Insomecases,itmaybedesirabletoconductdustdeflagrationtestsonmaterialassampledfromaprocessbecauseprocessduststreamsmay

contain a wide range of particle sizes or have a well-defined specific moisture content. When a material is tested in the as-received state, it should be

recognized that the test results may not represent the most severe ignition hazards possible. Any process change resulting in a higher fraction of fines

or drier product may result in a lower MIE for the product.

NOTE 7—The possible reduction of the particle size due to attrition by the dust dispersion system of the test apparatus should be considered.

NOTE 8—In sieving the material, the operator must verify that there is no selective separation of components in a dust that is not a pure substance.

Materials consisting of a mixture of chemicals may be separated selectively on sieves and certain fibrous materials, which may not pass through a

relatively coarse screen may produce dust deflagrations.

9.4 Minimum ignition energy for some dusts increases with increased moisture content (see Fig. 2). Dusts should be tested

either in the dry state or approximating the moisture content under the handling conditions of interest. “Dry” samples should be

FIG. 1 Correlation of Median Particle Size and MIE (5)

E 2019 – 03 (2007)

FIG. 2 Influence of the Humidity (Water Content) of Combustible

Dusts (5)

transported to the test laboratory in sealed containers under dry air or nitrogen, and then stored in a desiccator. Desiccants, such

as phosphorus pentoxide, may be more effective than silica gel in removing residual moisture.

NOTE 9—Thereisnosinglemethodfordeterminingthemoisturecontentorfordryingasample.Sampledryingequallyiscomplexduetothepresence

of volatiles, lack of or varying porosity (see Test Methods D3173 and D3175), and sensitivity of the sample to heat; therefore, each must be dried in

a manner that will not modify or destroy the integrity of the sample. Hygroscopic materials must be desiccated.

10. Calibration and Standardization

10.1 Calibration tests should be carried out on at least three different reference dusts. The results shall be within the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.