ASTM E2931-13(2019)

(Test Method)Standard Test Method for Limiting Oxygen (Oxidant) Concentration of Combustible Dust Clouds

Standard Test Method for Limiting Oxygen (Oxidant) Concentration of Combustible Dust Clouds

SIGNIFICANCE AND USE

5.1 This test method provides a procedure for performing laboratory tests to evaluate relative deflagration parameters of dusts.

5.2 Knowledge of the limiting oxygen (oxidant) concentration is needed for safe operation of some chemical processes. This information may be needed in order to start up, shut down or operate a process while avoiding the creation of flammable dust-gas atmospheres therein, or to pneumatically transport materials safely. NFPA 69 provides guidance for the practical use of LOC data, including the appropriate safety margin to use.

5.3 Since the LOC as measured by this method may vary with the energy of the ignitor and the propagation criteria, the LOC should be considered a relative rather than absolute measurement.

5.4 If too weak an ignition source is used, the measured LOC would be higher than the “true” value and would not be sufficiently conservative. This is an ignitability limit rather than a flammability limit, and the test could be described as “underdriven.” Ideally, the ignition energy is increased until the measured LOC is independent of ignition energy (that is, the “true” value). However, at some point the ignition energy may become too strong for the size of the test chamber, and the system becomes “overdriven.” When the ignitor flame becomes too large relative to the chamber volume, a test could appear to result in an explosion, while it is actually just dust burning in the ignitor flame with no real propagation beyond the ignitor (1-3).5 This LOC value would be overly conservative.

5.5 The recommended ignition source for measuring the LOC of dusts in 20-L chambers is a 2500-J pyrotechnic ignitor.6 This ignitor contains 0.6 g of a powder mixture of 40 % zirconium, 30 % barium nitrate, and 30 % barium peroxide. Measuring the LOC at several ignition energies will provide information on the possible overdriving of the system to evaluate the effect of possible overdriving in a 20-L chamber, comparison tests may also be m...

SCOPE

1.1 This test method is designed to determine the limiting oxygen concentration of a combustible dust dispersed in a mixture of air with an inert/nonflammable gas in a near-spherical closed vessel of 20 L or greater volume.

1.2 Data obtained from this method provide a relative measure of the deflagration characteristics of dust clouds.

1.3 This test method should be used to measure and describe the properties of materials in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E2931 −13 (Reapproved 2019)

Standard Test Method for

Limiting Oxygen (Oxidant) Concentration of Combustible

Dust Clouds

This standard is issued under the fixed designation E2931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method is designed to determine the limiting 2.1 ASTM Standards:

oxygen concentration of a combustible dust dispersed in a D3173 Test Method for Moisture in the Analysis Sample of

mixture of air with an inert/nonflammable gas in a near- Coal and Coke

spherical closed vessel of 20 L or greater volume. D3175 Test Method for Volatile Matter in the Analysis

Sample of Coal and Coke

1.2 Data obtained from this method provide a relative

E691 Practice for Conducting an Interlaboratory Study to

measure of the deflagration characteristics of dust clouds.

Determine the Precision of a Test Method

1.3 Thistestmethodshouldbeusedtomeasureanddescribe

E177 Practice for Use of the Terms Precision and Bias in

the properties of materials in response to heat and flame under

ASTM Test Methods

controlled laboratory conditions and should not be used to

E1226 Test Method for Explosibility of Dust Clouds

describe or appraise the fire hazard or fire risk of materials,

E1515 Test Method for Minimum Explosible Concentration

products, or assemblies under actual fire conditions. However,

of Combustible Dusts

results of this test may be used as elements of a fire risk

E2079 Test Methods for Limiting Oxygen (Oxidant) Con-

assessment that takes into account all of the factors that are

centration in Gases and Vapors

pertinent to an assessment of the fire hazard of a particular end

2.2 NFPA Publications:

use.

NFPA 69 Standard on Explosion Prevention Systems

2.3 CEN/CENELEC Publications:

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this EN 14034–4 Determination of the Explosion Characteristics

standard. of Dust Clouds — Part 4: Determination of the Limiting

Oxygen Concentration LOC of Dust Clouds

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.1.1 (dP/dt) ,n—the maximum rate of pressure rise

ex

mine the applicability of regulatory limitations prior to use.

duringthecourseofadeflagrationtest.Therateofpressurerise

Specific precautionary statements are given in Section 8.

can be size-normalized by multiplying by the cube root of the

1.6 This international standard was developed in accor-

chamber volume, giving:

dance with internationally recognized principles on standard-

1⁄3

ization established in the Decision on Principles for the dP ⁄dt 3V

~ !

ex

Development of International Standards, Guides and Recom-

3.1.2 dust concentration, n—the mass of dust divided by the

mendations issued by the World Trade Organization Technical

internal volume of the test chamber.

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction ofASTM Committee E27 on Hazard Standards volume information, refer to the standard’s Document Summary page on

Potential of Chemicals and is the direct responsibility of Subcommittee E27.05 on the ASTM website.

Explosibility and Ignitability of Dust Clouds. Available from National Fire Protection Association (NFPA), 1 Batterymarch

Current edition approved Feb. 15, 2019. Published March 2019. Originally Park, Quincy, MA 02169-7471, http://www.nfpa.org.

approved in 2013. Last previous edition approved in 2013 as E2931 – 13. DOI: Available from European Committee for Standardization (CEN), Avenue

10.1520/E2931-13R19. Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2931−13 (2019)

3.1.3 limit of flammability, n—the boundary in composition This information may be needed in order to start up, shut down

space dividing flammable and nonflammable regions. or operate a process while avoiding the creation of flammable

dust-gas atmospheres therein, or to pneumatically transport

3.1.4 limiting oxygen (oxidant) concentration (LOC) of a

materials safely. NFPA 69 provides guidance for the practical

fuel-oxidant-inert system, n—the oxygen (oxidant) concentra-

use of LOC data, including the appropriate safety margin to

tion at the limit of flammability for the worst case (most

use.

flammable) fuel concentration.

3.1.4.1 Discussion—The limiting oxygen (oxidant) concen-

5.3 Since the LOC as measured by this method may vary

tration is sometimes also known as minimum oxygen (oxidant)

with the energy of the ignitor and the propagation criteria, the

Concentration or as Critical oxygen (oxidant) Concentration.

LOC should be considered a relative rather than absolute

measurement.

3.1.5 P ,n—the maximum explosion pressure (absolute)

ex,a

reached during the course of a single deflagration test.

5.4 If too weak an ignition source is used, the measured

LOC would be higher than the “true” value and would not be

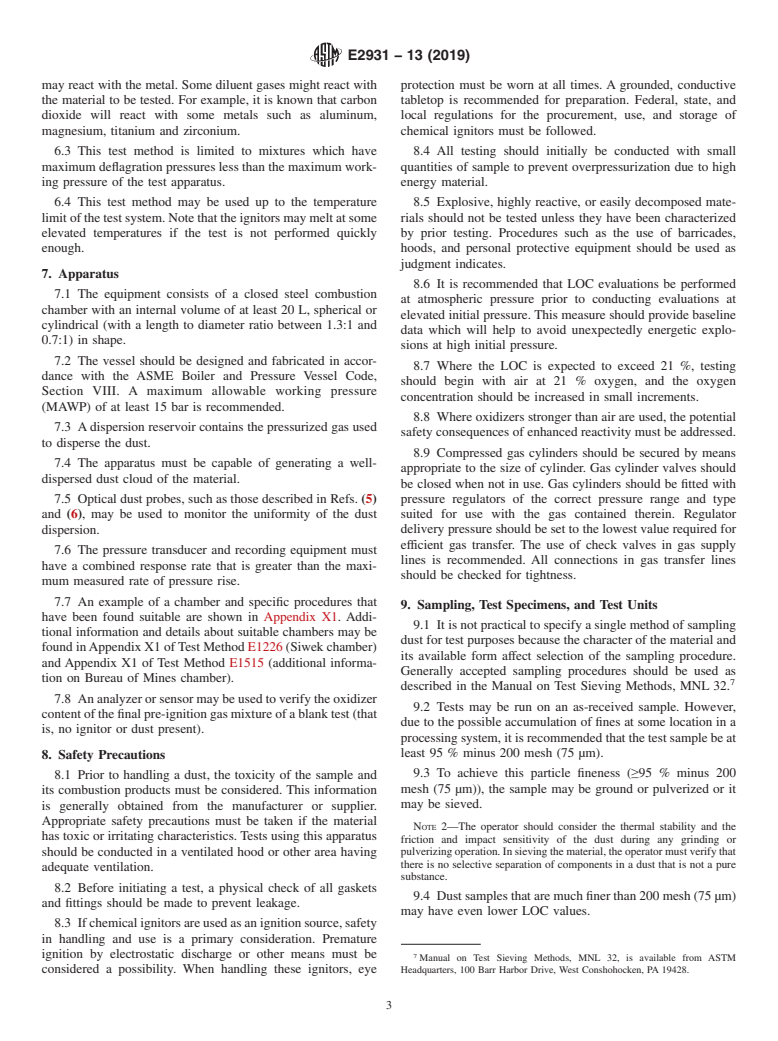

3.1.6 P ,n—the absolute pressure at the time the

ignition

sufficientlyconservative.Thisisanignitabilitylimitratherthan

ignitor is activated, see Fig. 1.

a flammability limit, and the test could be described as

3.1.7 ∆P ,n—thepressureriseinthechamberduetothe

ignitor

“underdriven.” Ideally, the ignition energy is increased until

ignitor by itself in air at atmospheric pressure.

the measured LOC is independent of ignition energy (that is,

3.1.8 pressure ratio (PR), n—defined as:

the “true” value). However, at some point the ignition energy

PR 5 ~P 2 ∆P !⁄P may become too strong for the size of the test chamber, and the

ex,a ignitor ignition

system becomes “overdriven.” When the ignitor flame be-

4. Summary of Test Method

comes too large relative to the chamber volume, a test could

4.1 Adust cloud is formed in a closed combustion chamber appear to result in an explosion, while it is actually just dust

burning in the ignitor flame with no real propagation beyond

by dispersion of the material with air and an inert gas (such as

nitrogen, carbon dioxide, argon, etc.). The test is normally the ignitor (1-3). This LOC value would be overly conserva-

tive.

made at atmospheric pressure and ambient temperature. Pro-

portions of the gaseous components (oxygen and inert gas) are

5.5 The recommended ignition source for measuring the

determined by a suitable means.

LOC of dusts in 20-L chambers is a 2500-J pyrotechnic

4.2 Ignition of the mixture is attempted after a specified ignitor. This ignitor contains 0.6 g of a powder mixture of

40 % zirconium, 30 % barium nitrate, and 30 % barium

delay time, and flammability is determined from the pressure

rise produced. Fuel, oxygen (oxidant), and inert gas propor- peroxide. Measuring the LOC at several ignition energies will

provide information on the possible overdriving of the system

tions are varied between trials until the following are deter-

mined: to evaluate the effect of possible overdriving in a 20-L

chamber, comparison tests may also be made in a larger

4.2.1 L—The lowest oxygen (oxidant) concentration for

which flame propagation is possible for at least one dust chamber such as a 1-m chamber (1-3).

concentration (typically the “worst case” or most flammable

5.6 The values obtained by this testing technique are spe-

fuel concentration range), and

cific to the sample tested (particularly the particle size distri-

4.2.2 H—The highest oxygen (oxidant) concentration for

bution) and the method used and are not to be considered

which flame propagation is not possible for the same “worst

intrinsic material constants.

case” fuel concentration range.

NOTE 1—Much of the previously published LOC data (4). were

obtained using a spark ignition source in a 1.2-L Hartmann chamber and

5. Significance and Use

may not be sufficiently conservative. The European method of LOC

5.1 This test method provides a procedure for performing determination EN 14034–4 uses two 1000-J pyrotechnic igniters in the

20-L chamber.

laboratory tests to evaluate relative deflagration parameters of

dusts.

6. Interferences/Limitations

5.2 Knowledge of the limiting oxygen (oxidant) concentra-

6.1 Unburned dust or combustion products remaining in the

tion is needed for safe operation of some chemical processes.

chamber or disperser from a previous test may affect results.

The chamber and disperser should both be cleaned thoroughly

before each test is made.

6.2 Carbon dioxide should not be used as the diluent gas

when determining the LOC for most metal dusts because it

The boldface numbers in parentheses refer to a list of references at the end of

this standard.

The sole source of supply of the pyrotechnic ignitors known to the committee

at this time is Cesana Corp., P.O. Box 182,Verona, NY13478, or Fr. Sobbe, GmbH,

Beylingstrasse 59, Postfach 140128, D-4600 Dortmund-Derne, Germany. If you are

aware of alternative suppliers, please provide this information to ASTM Interna-

FIG. 1Typical Data for a Weak Dust Deflagration in a tional Headquarters.Your comments will receive careful consideration at a meeting

20-L Chamber of the responsible technical committee, which you may attend.

E2931−13 (2019)

may react with the metal. Some diluent gases might react with protection must be worn at all times. A grounded, conductive

the material to be tested. For example, it is known that carbon tabletop is recommended for preparation. Federal, state, and

dioxide will react with some metals such as aluminum, local regulations for the procurement, use, and storage of

magnesium, titanium and zirconium. chemical ignitors must be followed.

6.3 This test method is limited to mixtures which have 8.4 All testing should initially be conducted with small

maximum deflagration pressures less than the maximum work- quantities of sample to prevent overpressurization due to high

ing pressure of the test apparatus. energy material.

6.4 This test method may be used up to the temperature 8.5 Explosive, highly reactive, or easily decomposed mate-

limitofthetestsystem.Notethattheignitorsmaymeltatsome rials should not be tested unless they have been characterized

elevated temperatures if the test is not performed quickly by prior testing. Procedures such as the use of barricades,

enough. hoods, and personal protective equipment should be used as

judgment indicates.

7. Apparatus

8.6 It is recommended that LOC evaluations be performed

7.1 The equipment consists of a closed steel combustion

at atmospheric pressure prior to conducting evaluations at

chamber with an internal volume of at least 20 L, spherical or

elevated initial pressure. This measure should provide baseline

cylindrical (with a length to diameter ratio between 1.3:1 and

data which will help to avoid unexpectedly energetic explo-

0.7:1) in shape.

sions at high initial pressure.

7.2 The vessel should be designed and fabricated in accor-

8.7 Where the LOC is expected to exceed 21 %, testing

dance with the ASME Boiler and Pressure Vessel Code,

should begin with air at 21 % oxygen, and the oxygen

Section VIII. A maximum allowable working pressure

concentration should be increased in small increments.

(MAWP) of at least 15 bar is recommended.

8.8 Where oxidizers stronger than air are used, the potential

7.3 Adispersion reservoir contains the pressurized gas used

safety consequences of enhanced reactivity must be addressed.

to disperse the dust.

8.9 Compressed gas cylinders should be secured by means

7.4 The apparatus must be capable of generating a well-

appropriate to the size of cylinder. Gas cylinder valves should

dispersed dust cloud of the material.

be closed when not in use. Gas cylinders should be fitted with

7.5 Optical dust probes, such as those described in Refs. (5) pressure regulators of the correct pressure range and type

and (6), may be used to monitor the uniformity of the dust suited for use with the gas contained therein. Regulator

dispersion. delivery pressure should be set to the lowest value required for

efficient gas transfer. The use of check valves in gas supply

7.6 The pressure transducer and recording equipment must

lines is recommended. All connections in gas transfer lines

have a combined response rate that is greater than the maxi-

should be checked for tightness.

mum measured rate of pressure rise.

7.7 An example of a chamber and specific procedures that

9. Sampling, Test Specimens, and Test Units

have been found suitable are shown in Appendix X1. Addi-

9.1 It is not practical to specify a single method of sampling

tional information and details about suitable chambers may be

dust for test purposes because the character of the material and

found inAppendix X1 ofTest Method E1226 (Siwek chamber)

its available form affect selection of the sampling procedure.

and Appendix X1 of Test Method E1515 (additional informa-

Generally accepted sampling procedures should be used as

tion on Bureau of Mines chamber).

described in the Manual on Test Sieving Methods, MNL 32.

7.8 Ananalyzerorsensormaybeusedtoverifytheoxidizer

9.2 Tests may be run on an as-received sample. However,

contentofthefinalpre-ignitiongasmixtureofablanktest(that

due to the possible accumulation of fines at some location in a

is, no ignitor or dust present).

processing system, it is recommended that the test sample be at

least 95 % minus 200 mesh (75 µm).

8. Safety Precautions

9.3 To achieve this particle fineness (≥95 % minus 200

8.1 Prior to handling a dust, the toxicity of the sample and

mesh (75 µm)), the sample may be ground or pulverized or it

its combustion products must be considered. This information

may be sieved.

is generally obtained from the manufacturer or supplier.

Appropriate safety precautions must be taken if the material

NOTE 2—The operator should consider the thermal stability and the

has toxic or irritating characteristics. Tests using this apparatus

friction and impact sensitivity of the dust during any grinding or

should be conducted in a ventilated hood or other area having pulver

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.