ASTM E2021-15(2023)

(Test Method)Standard Test Method for Hot-Surface Ignition Temperature of Dust Layers

Standard Test Method for Hot-Surface Ignition Temperature of Dust Layers

SIGNIFICANCE AND USE

5.1 This test method is applicable to dusts and powders, and provides a procedure for performing laboratory tests to evaluate hot-surface ignition temperatures of dust layers.

5.2 The test data can be of value in determining safe operating conditions in industrial plants, mines, manufacturing processes, and locations of material usage and storage.

5.3 Due to variation of ignition temperature with layer thickness, the test data at one thickness may not be applicable to all industrial situations (see Appendix X1). Tests at various layer thicknesses may provide a means for extrapolation to thicker layers, as listed in the following for pulverized Pittsburgh bituminous coal dust (2). Mathematical modeling of layer ignition at various layer thicknesses is described in Ref. (3).

Layer Thickness, mm

Hot-Surface Ignition Temperature, °C

6.4

300

9.4

260

12.7

240

25.4

210

5.4 This hot plate test method allows for loss of heat from the top surface of the dust layer, and therefore generally gives a higher ignition temperature for a material than Test Method E771, which is a more adiabatic system.

5.5 This test method for dust layers generally will give a lower ignition temperature than Test Method E1491, which is for dust clouds. The layer ignition temperature is determined while monitoring for periods of minutes to hours, while the dust cloud is only exposed to the furnace for a period of seconds.

Note 1: Much of the literature data for layer ignition is actually from a basket in a heated furnace (4), known as the modified Godbert-Greenwald furnace test. Other data are from nonstandardized hot plates (5-9).

5.6 Additional information on the significance and use of this test method may be found in Ref. (10).

SCOPE

1.1 This test method covers a laboratory procedure to determine the hot-surface ignition temperature of dust layers, that is, measuring the minimum temperature at which a dust layer will self-heat. The test consists of a dust layer heated on a hot plate.2,3

1.2 Data obtained from this test method provide a relative measure of the hot-surface ignition temperature of a dust layer.

1.3 This test method should be used to measure and describe the properties of materials in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire hazard risk of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard risk of a particular end use product.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2021 − 15 (Reapproved 2023)

Standard Test Method for

Hot-Surface Ignition Temperature of Dust Layers

This standard is issued under the fixed designation E2021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers a laboratory procedure to 2.1 ASTM Standards:

determine the hot-surface ignition temperature of dust layers, E771 Test Method for Spontaneous Heating Tendency of

Materials (Withdrawn 2001)

that is, measuring the minimum temperature at which a dust

layer will self-heat. The test consists of a dust layer heated on E1445 Terminology Relating to Hazard Potential of Chemi-

2,3

cals

a hot plate.

E1491 Test Method for Minimum Autoignition Temperature

1.2 Data obtained from this test method provide a relative

of Dust Clouds

measure of the hot-surface ignition temperature of a dust layer.

2.2 IEC Standard:

1.3 This test method should be used to measure and describe

IEC 1241-2-1 Electrical Apparatus for Use in the Presence

the properties of materials in response to heat and flame under

of Combustible Dust; Part 2: Test Methods—Section 1:

controlled laboratory conditions and should not be used to

Methods for Determining the Minimum Ignition Tempera-

describe or appraise the fire hazard or fire hazard risk of

tures of Dusts, Method A

materials, products, or assemblies under actual fire conditions.

However, results of this test method may be used as elements

3. Terminology

of a fire risk assessment that takes into account all of the factors

3.1 Definitions—For definitions of other terms used in this

that are pertinent to an assessment of the fire hazard risk of a

standard, see Terminology E1445.

particular end use product.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as

3.2.1 hot-surface ignition temperature of a dust layer,

standard. No other units of measurement are included in this

n—lowest set temperature of the hot plate that causes ignition

standard.

of the dust layer.

1.5 This standard does not purport to address all of the

3.2.2 ignition of a dust layer, n—initiation of self-heating or

safety concerns, if any, associated with its use. It is the

combustion in a material under test.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.2.3 ignition time, n—time between the start of heating and

the point at which the maximum temperature or flaming

mine the applicability of regulatory limitations prior to use.

Specific precautionary statements are given in Section 8. combustion is reached.

1.6 This international standard was developed in accor-

3.2.4 temperature rise, ΔT, n—the difference between T

max

dance with internationally recognized principles on standard-

and the initial set temperature of the hot plate.

ization established in the Decision on Principles for the

3.2.5 T , n—maximum temperature measured during test.

max

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Summary of Test Method

Barriers to Trade (TBT) Committee.

4.1 The test material is placed within a metal ring on top of

a hot plate, that is at a preset constant temperature.

This test method is under the jurisdiction of ASTM Committee E27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

the Flammability and Ignitability of Chemicals. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2023. Published May 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2015 as E2021 – 15. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2021-15R23 the ASTM website.

2 5

This test method is based on recommendations of the National Materials The last approved version of this historical standard is referenced on

Advisory Board of the National Academy of Sciences (1). www.astm.org.

3 6

The boldface numbers in parentheses refer to the list of references at the end of Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

this standard. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2021 − 15 (2023)

NOTE 1—Much of the literature data for layer ignition is actually from

4.2 The sample temperature is monitored to determine

a basket in a heated furnace (4), known as the modified Godbert-

temperature rise due to oxidative reactions or decomposition

Greenwald furnace test. Other data are from nonstandardized hot plates

reactions, or both.

(5-9).

4.3 Ignition is considered to have taken place when either of

5.6 Additional information on the significance and use of

the following occurs:

this test method may be found in Ref. (10).

4.3.1 Temperature in the dust layer at position of thermo-

couple rises at least 50 °C above the hot plate temperature, or

6. Limitations and Interferences

4.3.2 Visible evidence of combustion is apparent, such as

6.1 This test method should not be used with materials

red glow or flame.

having explosive or highly reactive properties.

4.4 Hot plate surface temperature is varied from test to test,

6.2 If the metal (for example, aluminum) plate or ring reacts

as necessary, until the hot-surface ignition temperature is

with the test material, choose another type of metal that does

determined.

not react.

5. Significance and Use

7. Apparatus

5.1 This test method is applicable to dusts and powders, and

provides a procedure for performing laboratory tests to evalu-

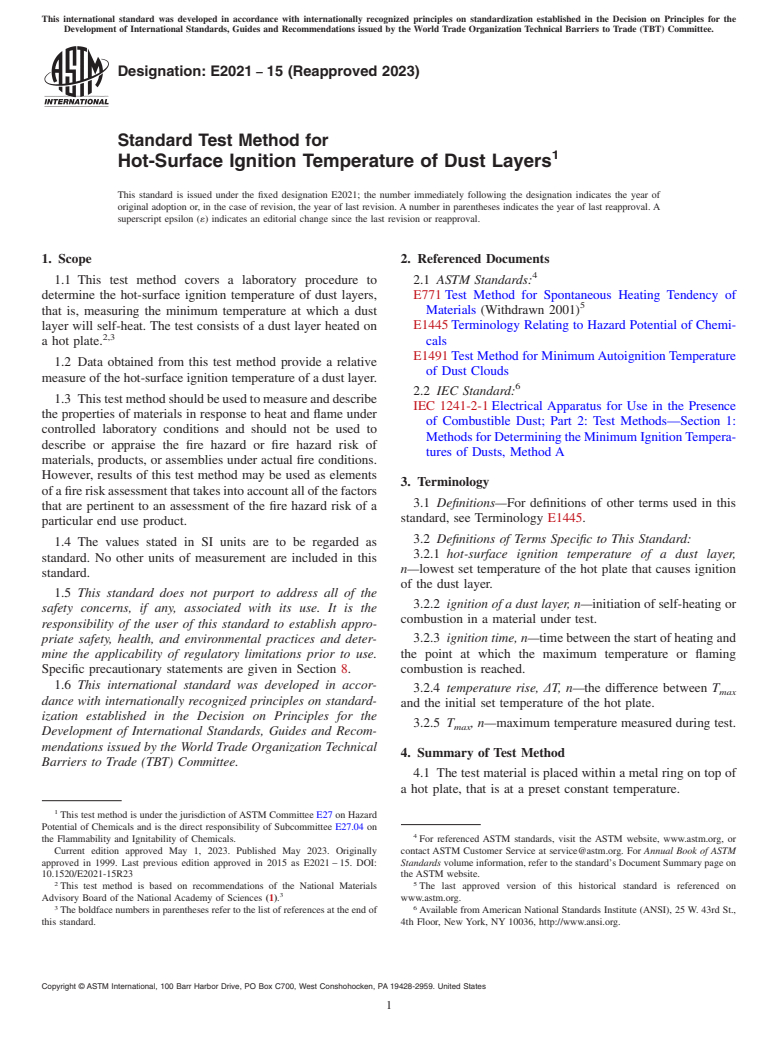

7.1 The complete apparatus, shown in Fig. 1, consists of a

ate hot-surface ignition temperatures of dust layers.

circular metal (for example, aluminum) plate centrally posi-

tioned on top of a hot plate. The dust layer is confined within

5.2 The test data can be of value in determining safe

a metal ring on top of the metal plate. An example of an

operating conditions in industrial plants, mines, manufacturing

apparatus that has been found suitable is given in Appendix

processes, and locations of material usage and storage.

X2.

5.3 Due to variation of ignition temperature with layer

7.1.1 Heated Surface, consisting of a metal plate of approxi-

thickness, the test data at one thickness may not be applicable

mately 200 mm diameter and at least 20 mm thick. This plate

to all industrial situations (see Appendix X1). Tests at various

is centrally placed on top of a commercial hotplate. A thermo-

layer thicknesses may provide a means for extrapolation to

couple is mounted radially in the metal plate, with its junction

thicker layers, as listed in the following for pulverized Pitts-

in contact with the plate within 1.0 mm 6 0.5 mm of the upper

burgh bituminous coal dust (2). Mathematical modeling of

surface. This thermocouple is connected to a temperature

layer ignition at various layer thicknesses is described in Ref.

controller. The plate and its thermocouple-controller assembly,

(3).

in conjunction with the commercial hotplate, should satisfy the

Layer Thickness, mm Hot-Surface Ignition Temperature, °C

following requirements:

6.4 300

7.1.1.1 The plate should be capable of attaining a maximum

9.4 260

12.7 240

temperature of 450 °C without a dust layer in position,

25.4 210

7.1.1.2 The temperature controller must be capable of main-

5.4 This hot plate test method allows for loss of heat from

taining the temperature of the plate constant to within 65 °C

the top surface of the dust layer, and therefore generally gives

throughout the time period of the test,

a higher ignition temperature for a material than Test Method

7.1.1.3 When the temperature of the plate has reached a

E771, which is a more adiabatic system.

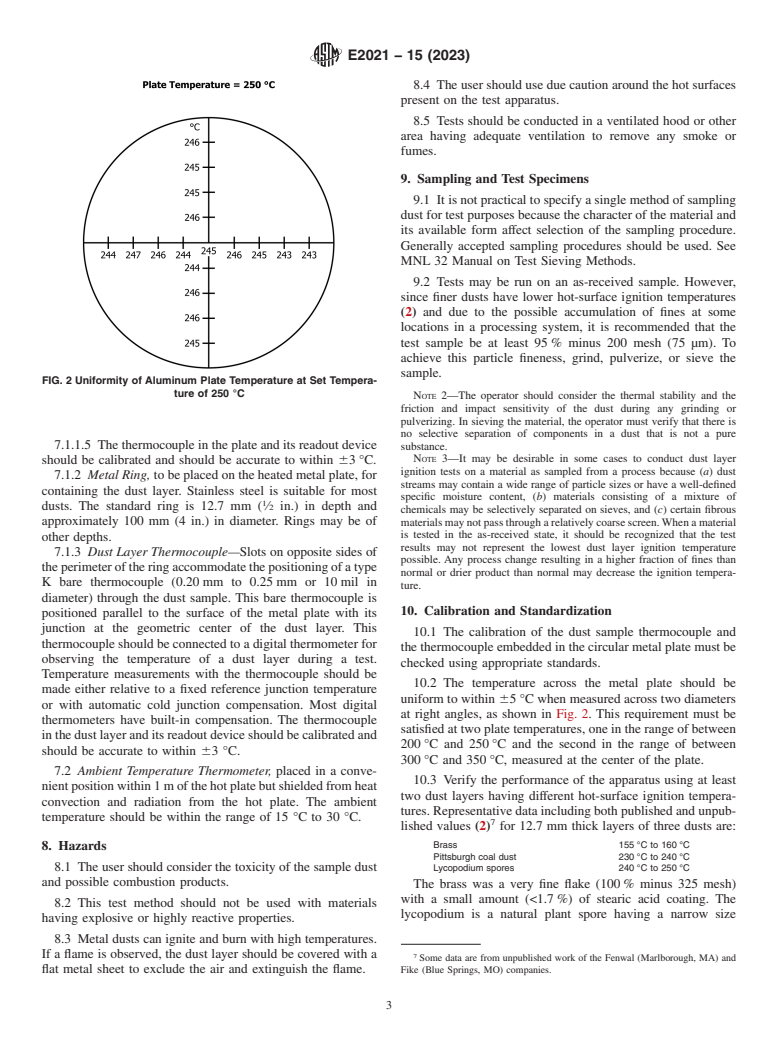

constant value, the temperature across the plate should be

uniform to within 65 °C, as shown in Fig. 2,

5.5 This test method for dust layers generally will give a

lower ignition temperature than Test Method E1491, which is 7.1.1.4 The temperature control should be such that the

for dust clouds. The layer ignition temperature is determined recorded plate temperature will not change by more than

while monitoring for periods of minutes to hours, while the 65 °C during the placing of the dust layer and will be restored

dust cloud is only exposed to the furnace for a period of to within 2 °C of the previous value within 5 min of placing the

seconds. dust layer, and

FIG. 1 Schematic of Hotplate Layer Ignition Apparatus

E2021 − 15 (2023)

8.4 The user should use due caution around the hot surfaces

present on the test apparatus.

8.5 Tests should be conducted in a ventilated hood or other

area having adequate ventilation to remove any smoke or

fumes.

9. Sampling and Test Specimens

9.1 It is not practical to specify a single method of sampling

dust for test purposes because the character of the material and

its available form affect selection of the sampling procedure.

Generally accepted sampling procedures should be used. See

MNL 32 Manual on Test Sieving Methods.

9.2 Tests may be run on an as-received sample. However,

since finer dusts have lower hot-surface ignition temperatures

(2) and due to the possible accumulation of fines at some

locations in a processing system, it is recommended that the

test sample be at least 95 % minus 200 mesh (75 μm). To

achieve this particle fineness, grind, pulverize, or sieve the

sample.

FIG. 2 Uniformity of Aluminum Plate Temperature at Set Tempera-

ture of 250 °C

NOTE 2—The operator should consider the thermal stability and the

friction and impact sensitivity of the dust during any grinding or

pulverizing. In sieving the material, the operator must verify that there is

no selective separation of components in a dust that is not a pure

7.1.1.5 The thermocouple in the plate and its readout device substance.

NOTE 3—It may be desirable in some cases to conduct dust layer

should be calibrated and should be accurate to within 63 °C.

ignition tests on a material as sampled from a process because (a) dust

7.1.2 Metal Ring, to be placed on the heated metal plate, for

streams may contain a wide range of particle sizes or have a well-defined

containing the dust layer. Stainless steel is suitable for most

specific moisture content, (b) materials consisting of a mixture of

dusts. The standard ring is 12.7 mm ( ⁄2 in.) in depth and

chemicals may be selectively separated on sieves, and (c) certain fibrous

approximately 100 mm (4 in.) in diameter. Rings may be of materials may not pass through a relatively coarse screen. When a material

is tested in the as-received state, it should be recognized that the test

other depths.

results may not represent the lowest dust layer ignition temperature

7.1.3 Dust Layer Thermocouple—Slots on opposite sides of

possible. Any process change resulting in a higher fraction of fines than

the perimeter of the ring accommodate the positioning of a type

normal or drier product than normal may decrease the ignition tempera-

K bare thermocouple (0.20 mm to 0.25 mm or 10 mil in

ture.

diameter) through the dust sample. This bare thermocouple is

10. Calibration and Standardization

positioned parallel to the surface of the metal plate with its

junction at the geometric center of the dust layer. This

10.1 The calibration of the dust sample thermocouple and

thermocouple should be connected to a digital thermometer for

the thermocouple embedded in the circular metal plate must be

observing the temperature of a dust layer during a test.

checked using appropriate standards.

Temperature measurements with the thermocouple should be

10.2 The temperature across the metal plate should be

made either relative to a fixed reference junction temperature

uniform to within 65 °C when measured across two diameters

or with automatic cold junction compensation. Most digital

at right angles, as shown in Fig. 2. This requirement must be

thermometers have built-in compensation. The thermocouple

satisfied at two plate temperatures, one in the range of between

in the dust layer and its readout device should be calibrated and

200 °C and 250 °C and the second in the range of between

should be accurate to within 63 °C.

300 °C and 350 °C, measured at the center of the plate.

7.2 Ambient Temperature Thermometer, placed in a conve-

10.3 Verify the performance of the apparatus using at least

nient position within 1 m of the hot plate but shielded from heat

two dust layers having different hot-surface ignition tempera-

convection and radiation from the hot plate. The ambient

tures. Representative data including both published and unpub-

temperature should be within the range of 15 °C to 30 °C.

lished values (2) for 12.7 mm thick layers of three dusts are:

Brass 155 °C to 160 °C

8. Hazards

Pittsburgh coal dust 230 °C to 240 °C

8.1 The user should consider the toxicity of the sample dust Lycopodium spores 240 °C to 250 °C

and possible combustion products.

The brass was a very fine flake (100 % minus 325 mesh)

with a small amount (<1.7 %) of stearic acid coating. The

8.2 This test method should not be used with materials

lycopodium is a natural plant spore having a narrow size

having explosive or highly reactive properties.

8.3 Metal dusts can ignite and burn with high temperatures.

If a flame is observed, the dust layer should be covered with a

Some data are from unpublished work of the Fenwal (Marlborough, MA) and

flat metal sheet to exclude the air and extinguish the flame. Fike (Blue Springs, MO) companies.

E2021 − 15 (2023)

distribution with 100 % minus 200 mesh and mass median 11.2.3 Continuously monitor the temperatures of the hot

diameter of ;28 μm. This is the reticulate form Lycopodium plate and of the dust layer as a function of time to the end of

clavatum. The Pittsburgh seam bituminous coal has ;80 %

the test. A typical test period is two hours. Continue the test if

minus 200 mesh, a mass median diameter of ;45 μm, and any self-heating is evident. Self-heating may be indicated by

36 % volatility. Additional data that can be used for calibration

localized heavy smoke, or increasing temperature. Terminate

are thos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.