ASTM E1491-06(2019)

(Test Method)Standard Test Method for Minimum Autoignition Temperature of Dust Clouds

Standard Test Method for Minimum Autoignition Temperature of Dust Clouds

SIGNIFICANCE AND USE

5.1 This test method provides a procedure for performing laboratory tests to determine the minimum autoignition temperature (MAIT) of a dust cloud.

5.2 The test data developed from this test method can be used to limit the temperature to which a dust cloud is exposed so as to prevent ignition of the cloud. Because of the short duration of the test, the data obtained are most applicable to industrial equipment where dust is present as a cloud for a short time. Because of the small scale of the test and the possible variation of the MAIT value with scale, the data obtained by this test method may not be directly applicable to all industrial conditions.

5.3 The MAIT data can also be used in conjunction with minimum spark ignition data to evaluate the hazards of grinding and impact sparks in the presence of dust clouds (1 and 2).3

5.4 The test values obtained are specific to the sample tested, the method used, and the test equipment utilized. The test values are not to be considered intrinsic material constants, but may be used as a relative measure of the temperature at which a dust cloud self ignites.

5.5 The test data are for cloud ignition. Dust in the form of a layer may ignite at significantly lower temperatures than the same dust in the form of a cloud (3). For liquid chemicals, see Test Method E659.

SCOPE

1.1 This test method covers the minimum temperature at which a given dust cloud will autoignite when exposed to air heated in a furnace at local atmospheric pressure.

1.2 Data obtained from this test method provide a relative measure of dust cloud autoignition temperatures.

1.3 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1491 − 06 (Reapproved 2019)

Standard Test Method for

Minimum Autoignition Temperature of Dust Clouds

This standard is issued under the fixed designation E1491; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method covers the determination of the minimum temperature at which a dust cloud will

autoignite.The dust cloud is exposed to air heated to various temperatures in a furnace. Ignition of the

cloud is indicated by visual observation of the flame. The chemical nature of the dust as well as its

concentration, particle size, moisture, and surface area affects the results.

1. Scope 2. Referenced Documents

1.1 This test method covers the minimum temperature at 2.1 ASTM Standards:

which a given dust cloud will autoignite when exposed to air D3173 Test Method for Moisture in the Analysis Sample of

heated in a furnace at local atmospheric pressure. Coal and Coke

D3175 Test Method for Volatile Matter in the Analysis

1.2 Data obtained from this test method provide a relative

Sample of Coal and Coke

measure of dust cloud autoignition temperatures.

E659 Test Method for Autoignition Temperature of Chemi-

1.3 Thistestmethodshouldbeusedtomeasureanddescribe

cals

the properties of materials, products, or assemblies in response

E1226 Test Method for Explosibility of Dust Clouds

to heat and flame under controlled laboratory conditions and

shouldnotbeusedtodescribeorappraisethefirehazardorfire

3. Terminology

risk of materials, products, or assemblies under actual fire

3.1 Definitions of Terms Specific to This Standard:

conditions.However,resultsofthistestmethodmaybeusedas

3.1.1 dust concentration, n—the mass of dust divided by the

elements of a fire risk assessment which takes into account all

internal volume of the test chamber.

of the factors which are pertinent to an assessment of the fire

3.1.2 minimum autoignition temperature (MAIT), n—the

hazard of a particular end use.

minimum temperature at which a dust cloud will self ignite

1.4 The values stated in SI units are to be regarded as

under the specified conditions of test.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.5 This standard does not purport to address all of the

4.1 The temperature of the furnace or oven is set at a

safety concerns, if any, associated with its use. It is the

predetermined value.

responsibility of the user of this standard to establish appro-

4.2 Dust is blown into the heated furnace, which is at

priate safety, health, and environmental practices and deter-

ambient pressure.

mine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accor-

4.3 Ignitionisdeterminedbyvisualobservationoftheflame

dance with internationally recognized principles on standard-

exiting the furnace.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Significance and Use

mendations issued by the World Trade Organization Technical

5.1 This test method provides a procedure for performing

Barriers to Trade (TBT) Committee.

laboratory tests to determine the minimum autoignition tem-

perature (MAIT) of a dust cloud.

This test method is under the jurisdiction ofASTM Committee E27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.05 on

Explosibility and Ignitability of Dust Clouds. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 15, 2019. Published March 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2012 as E1491 – 06 (2012). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E1491-06R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1491 − 06 (2019)

5.2 The test data developed from this test method can be 8. Hazards

used to limit the temperature to which a dust cloud is exposed

8.1 Safety Precautions:

so as to prevent ignition of the cloud. Because of the short

8.1.1 Prior to handling a dust, its toxicity and the toxicity of

duration of the test, the data obtained are most applicable to

its combustion products must be considered. This information

industrialequipmentwheredustispresentasacloudforashort

can usually be obtained from the manufacturer. Consideration

time. Because of the small scale of the test and the possible

will have to be given to ventilation, use of hoods, personal

variation of the MAIT value with scale, the data obtained by

protective gear, and procedures.

this test method may not be directly applicable to all industrial

8.1.2 Explosive, highly reactive, or easily decomposed ma-

conditions.

terials should not be tested unless they have been characterized

5.3 The MAIT data can also be used in conjunction with by prior testing. Procedures such as the use of barricades,

minimum spark ignition data to evaluate the hazards of hoods, and personal protective equipment should be used as

grinding and impact sparks in the presence of dust clouds (1 judgment indicates.

and 2). 8.1.3 Electrical systems must be grounded.

5.4 The test values obtained are specific to the sample

9. Sampling

tested, the method used, and the test equipment utilized. The

9.1 It is not practical to specify a single method of sampling

test values are not to be considered intrinsic material constants,

dust for test purposes because the character of the material and

but may be used as a relative measure of the temperature at

its available form affect selection of the sampling procedure.

which a dust cloud self ignites.

Generally accepted sampling procedures should be used as

5.5 The test data are for cloud ignition. Dust in the form of

described in STP 447A.

a layer may ignite at significantly lower temperatures than the

9.2 Tests may be run on an as-received sample. However,

same dust in the form of a cloud (3). For liquid chemicals, see

due to the possible accumulation of fines at some location in a

Test Method E659.

processingsystem,itisrecommendedthatthetestsamplebeat

6. Interferences

least 95 % minus 200 mesh (75 µm).

6.1 Unburneddustfromaprevioustestmayaffectresults.If

9.3 To achieve this particle fineness (95 % minus 200

there is a question, the furnace should be heated to its

mesh), grind, pulverize, or sieve the sample.

maximum temperature to clean it before future tests are made.

NOTE 1—The operator should consider the thermal stability and the

6.2 The material of construction of this test method may

friction and impact sensitivity of the dust during any grinding or

pulverizing. In sieving the material, the operator must verify that there is

have catalytic effects on the ignition and should be considered

no selective separation of components in a dust that is not a pure

during testing.

substance.

NOTE 2—It may be desirable in some cases to conduct dust autoignition

7. Apparatus

tests on a material as sampled from a process because dust streams may

7.1 Theequipmentconsistsofaheatedchamberclosedwith

contain a wide range of particle sizes or have a well-defined specific

moisture content, materials consisting of a mixture of chemicals may be

a frangible diaphragm, or flap vent, or a hole open to the

selectively separated on sieves, and certain fibrous materials may not pass

atmosphere.

through a relatively coarse screen. When a material is tested in the

7.2 The chamber is insulated and provided with a thermo- as-received state, it should be recognized that the test results may not

represent the lowest cloud autoignition temperature possible.Any process

statically controlled electric heater. A thermocouple measures

change resulting in a higher fraction of fines than normal or drier product

the set temperature of the chamber.

than normal may decrease the autoignition temperature.

7.3 Adust dispersion system generates a fairly uniform dust

9.4 The moisture content of the test sample should not

cloud within the chamber. There should be a minimal amount

exceed 10 % in order to avoid noticeable influence on test

of dust remaining in the disperser after the test.

results of a given dust.

7.4 Athermocouple(1milor25µm)andarecordingsystem

NOTE 3—There is no single method for determining the moisture

having a fast enough response may be used to measure the

content or for drying a sample. ASTM lists many methods for moisture

temperature rise during ignition of the dust cloud in the

determination in the Annual Book of ASTM Standards. Sample drying is

equally complex due to the presence of volatiles, lack of or varying

chamber.

porosity (see Test Methods D3173 and D3175), and sensitivity of the

7.5 Examplesofchambersandspecificproceduresthathave

sample to heat. Therefore, each must be dried in a manner that will not

been found suitable are listed in chronological order in

modify or destroy the integrity of the sample. Hygroscopic materials must

be desiccated.

Appendix X1 – Appendix X4.

10. Calibration and Standardization

10.1 Any new test vessel design other than those listed in

the appendixes must be standardized using dust samples whose

MAIT values are known. A minimum of three dust samples

The boldface numbers in parentheses refer to the list of references at the end of

this test method. STP 447A is available from ASTM Headquarters.

E1491 − 06 (2019)

over a wide range of MAIT values is required. For tempera- 11.4 Place a weighed amount of dust in the disperser. The

tures below 600°C, the MAIT value for each dust measured in recommended initial test concentration for most dusts is from

a furnace must agree to within 660°C of the average MAIT 300to1000g/m .IfdatafromTestMethodE1226existforthe

value for that dust as measured in the four furnaces in dust,theinitialtestcouldbemadeattheconcentrationatwhich

Appendix X1 – Appendix X4. the maximum pressure, P , and the maximum normalized

max

rate of pressure increase, K , were found.

st

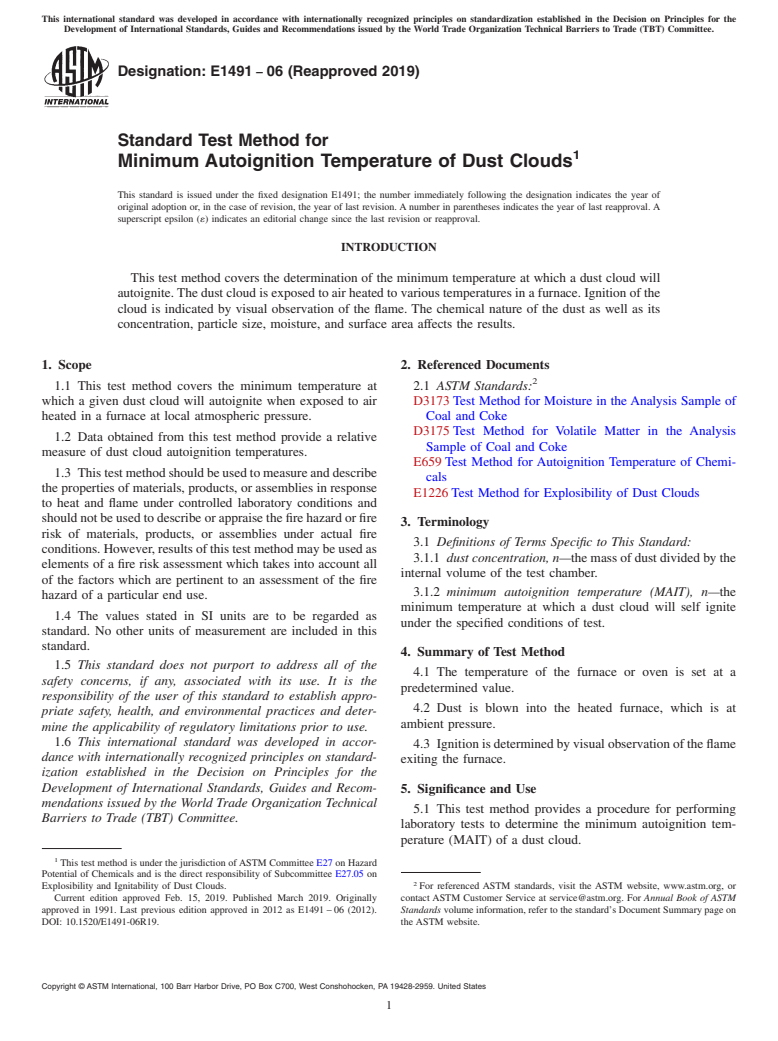

10.2 Representative MAIT data for six dusts are listed in

degrees Celsius in Table 1. These data are only intended to 11.5 Disperse the dust and observe whether or not flame

indicatethevariabilityamongfurnaces.Theanthracitecoalhas exits the furnace.

;85 % minus 200 mesh and a mass median diameter of ;40

NOTE 5—It is useful to darken the room to make it easier to observe the

µm. The anthraquinone (C H O ) has ;73 % minus 200

14 8 2

flame. Some flames, such as the blue flame of sulfur, are difficult to see.

mesh and a mass median diameter of ;56 µm.The Pocahontas

11.6 If no ignition occurs, increase the temperature 50 to

(Poc.) seam bituminous coal has ;70 % minus 200 mesh, a

100°C and test the dust again at the same concentration.

mass median diameter of ;56 µm, and 18 % volatility. The

11.7 After ignition has been achieved, lower the test tem-

Pittsburgh (Pgh.) seam bituminous coal has ;80 % minus 200

perature in 25°C increments to determine the lowest tempera-

mesh, a mass median diameter of ;45 µm, and 36 % volatility.

ture at which ignition occurs and the highest temperature at

The lycopodium is the reticulate form, Lycopodium clavatum.

which ignition does not occur for this dust concentration.

Itisanaturalplantsporehavinganarrowsizedistributionwith

Ignition is defined as flame exiting from the chamber.

100 % minus 200 mesh and mass median diameter of ;28 µm.

The sulfur has ;81 % minus 200 mesh and a mass median

11.8 At the highest temperature at which ignition is not

diameter of ;38 µm.

observed, vary the dust concentration. If the dust ignites at any

10.2.1 These data are from the four furnaces listed in the

concentration at this temperature, lower the test temperature

appendixes—the 0.27-L Godbert-Greenwald (G-G) Furnace,

and continue the testing. At least five tests over a range of

the 0.35-L BAM Oven, the 1.2-L Bureau of Mines Furnace,

concentrations must be run at the highest temperature at which

and the 6.8-L Bureau of Mines Furnace. The BAM oven is

ignition is not observed.

limited to a maximum test temperature of 600°C. The G-G

11.9 At the temperature at which ignition is observed, vary

Furnace generally yields somewhat higher MAIT data than the

the dust concentration to determine the range over which

other three. The greatest deviation in MAIT values occurs at

ignition occurs. In order to assure the repeatability of the data,

the highest temperatures, as shown by the anthracite coal data

observe at least three ignitions over a range of concentrations

in the table. However, the lower MAIT values (where agree-

at the lowest temperature at which ignition occurs.

ment is better) are of greater practical importance.

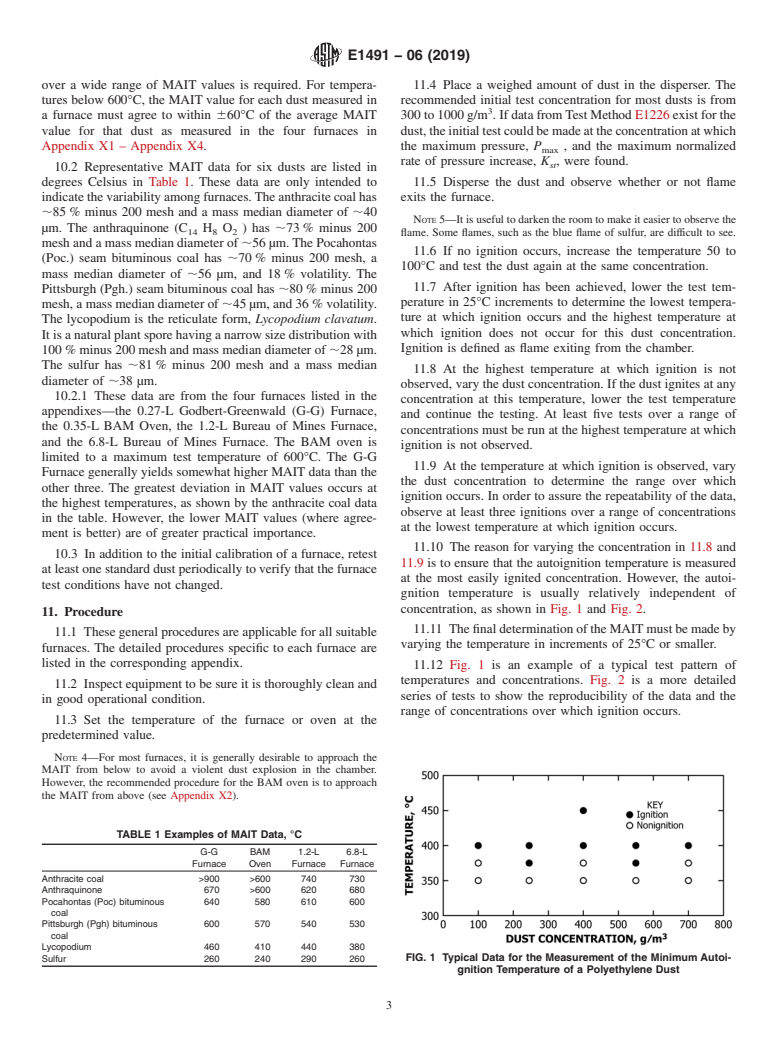

11.10 The reason for varying the concentration in 11.8 and

10.3 In addition to the initial calibration of a furnace, retest

11.9 is to ensure that the autoignition temperature is measured

at least one standard dust periodically to verify that the furnace

at the most easily ignited concentration. However, the autoi-

test conditions have not changed.

gnition temperature is usually relatively independent of

concentration, as shown in Fig. 1 and Fig. 2.

11. Procedure

11.11 ThefinaldeterminationoftheMAITmustbemadeby

11.1 These general procedures are applicable for all suitable

varying the temperature in increments of 25°C or smaller.

furnaces. The detailed procedures specific to each furnace are

listed in the corresponding appendix.

11.12 Fig. 1 is an example of a typical test pattern of

temperatures and concentrations. Fig. 2 is a more detailed

11.2 Inspect equipment to be sure it is thoroughly clean and

series of tests to show the reproducibility of the data and the

in good operational condition.

range of concentrations over which ignition occurs.

11.3 Set the temperature of the furnace or oven at the

predetermined value.

NOTE 4—For most furnaces, it is generally desirable to approach the

MAIT from below to avoid a violent dust explosion in the chamber.

However, the recommended procedure for the BAM oven is to approach

the MAIT from above (see Appendix X2).

TABLE 1 Examples of MAIT Data, °C

G-G BAM 1.2-L 6.8-L

Furnace Oven Furnace Furnace

Anthracite coal >900 >600 740 730

Anthraquinone 670 >600 620 680

Pocahontas (Poc) bituminous 640 580 610 600

coal

Pittsburgh (Pgh) bituminous 600

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.