ASTM D4628-05(2011)e1

(Test Method)Standard Test Method for Analysis of Barium, Calcium, Magnesium, and Zinc in Unused Lubricating Oils by Atomic Absorption Spectrometry

Standard Test Method for Analysis of Barium, Calcium, Magnesium, and Zinc in Unused Lubricating Oils by Atomic Absorption Spectrometry

SIGNIFICANCE AND USE

Some oils are formulated with metal-containing additives that act as detergents, antioxidants, antiwear agents, etc. Some of these additives contain one or more of these metals: barium, calcium, zinc, and magnesium. This test method provides a means of determining the concentration of these metals that gives an indication of the additive content in these oils.

SCOPE

1.1 This test method is applicable for the determination of mass percent barium from 0.005 to 1.0 %, calcium and magnesium from 0.002 to 0.3 %, and zinc from 0.002 to 0.2 % in lubricating oils.

1.2 Higher concentrations can be determined by appropriate dilution. Lower concentrations of metals such as barium, calcium, magnesium, and zinc at about 10 ppm level can also be determined by this test method. Use of this test method for the determination at these lower concentrations should be by agreement between the buyer and the seller.

1.3 Lubricating oils that contain viscosity index improvers may give low results when calibrations are performed using standards that do not contain viscosity index improvers.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 3.1, 6.3, and 8.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4628 − 05(Reapproved 2011)

Standard Test Method for

Analysis of Barium, Calcium, Magnesium, and Zinc in

Unused Lubricating Oils by Atomic Absorption

Spectrometry

This standard is issued under the fixed designation D4628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Updated units statement and added research report number editorially in August 2011.

1. Scope and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

1.1 This test method is applicable for the determination of

mass percent barium from 0.005 to 1.0 %, calcium and

3. Summary of Test Method

magnesium from 0.002 to 0.3 %, and zinc from 0.002 to 0.2 %

3.1 A sample is weighed and base oil is added to 0.25 6

in lubricating oils.

0.01-g total mass. Fifty millilitres of a kerosine solution,

1.2 Higher concentrations can be determined by appropriate

containing potassium as an ionization suppressant, are added,

dilution. Lower concentrations of metals such as barium,

and the sample and oil are dissolved. (Warning—Hazardous.

calcium, magnesium, and zinc at about 10 ppm level can also

Potentially toxic and explosive.) Standards are similarly

be determined by this test method. Use of this test method for

prepared,alwaysaddingoilifnecessarytoyieldatotalmassof

the determination at these lower concentrations should be by

0.25 g. These solutions are burned in the flame of an atomic

agreement between the buyer and the seller.

absorption spectrophotometer. An acetylene/nitrous oxide

1.3 Lubricating oils that contain viscosity index improvers flame is used. (Warning—Combustible. Vapor harmful.)

may give low results when calibrations are performed using

4. Significance and Use

standards that do not contain viscosity index improvers.

4.1 Some oils are formulated with metal-containing addi-

1.4 The values stated in SI units are to be regarded as

tives that act as detergents, antioxidants, antiwear agents, etc.

standard. No other units of measurement are included in this

Some of these additives contain one or more of these metals:

standard.

barium, calcium, zinc, and magnesium. This test method

1.5 This standard does not purport to address all of the

provides a means of determining the concentration of these

safety concerns, if any, associated with its use. It is the

metals that gives an indication of the additive content in these

responsibility of the user of this standard to establish appro-

oils.

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use. Specific warning

statements are given in 3.1, 6.3, and 8.1.

5.1 Atomic Absorption Spectrophotometer.

5.2 Analytical Balance.

2. Referenced Documents

5.3 AutomaticMeasuringPipetorVolumetricClassAPipet,

2.1 ASTM Standards:

50-mL capacity.

D6299 Practice for Applying Statistical Quality Assurance

5.4 Bottles with Screw Caps, 60 mL.

This test method is under the jurisdiction of ASTM Committee D02 on NOTE 1—Suitable volumetric flasks or plastic bottles may be substi-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

tuted.

D02.03 on Elemental Analysis.

5.5 Shaker, Mechanical Stirrer, or Ultrasonic Bath, capable

Current edition approved May 1, 2011. Published August 2011. Originally

approved in 1986. Last previous edition approved in 2005 as D4628–05. DOI: of handling 60-mL bottles.

10.1520/D4628-05R11E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Reagents

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Base Oil, metal-free, with a viscosity of about 4 cSt at

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 100°C. A100 neutral oil which provides good solvency for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D4628 − 05 (2011)

FIG. 1 Plot Graphs for Barium and Calcium

standards and additive concentrate is satisfactory. Highly range of the particular instrument being used, but as a guide

paraffinic oils should be avoided. one cooperator used 0.4 % barium, 0.03 % calcium, 0.03 %

magnesium, and 0.06 % zinc. The stock standard blend should

6.2 2-EthylHexanoicAcid,whichhasbeendeterminedtobe

be heated and stirred to ensure a homogeneous solution.

free of interfering metals.

NOTE 5—In addition to the calibration standards identified in 6.4,

6.3 Kerosine, Metal-Free—See Notes 2-4.(Warning—

single-elementormultielementcalibrationstandardsmayalsobeprepared

Combustible.Vapor harmful.) Distillation range from 170°C to

from materials similar to the samples being analyzed, provided the

280°C at 100 kPa (1 atm). When the kerosine solvent is

calibration standards to be used have previously been characterized by

contaminated,itmaybepurifiedmetal-freebyrunningthrough

independent, primary (for example, gravimetric or volumetric), and

attapulgus clay. analytical techniques to establish the elemental concentration mass

percent levels.

NOTE 2—Solvents other than kerosine, such as xylene MEK and so

6.5 Potassium Ionization Suppressant Solution—containing

forth, may be used in this test method, however, the precision data quoted

in Section 16 was obtained using kerosine.

an oil-soluble potassium compound in kerosine at 2.0 6 0.1 g

NOTE 3—Metal-free kerosine can be obtained from most laboratory

potassium/litre of solution.

supply houses, but should be tested for metal content before using.

NOTE 4—Satisfactory results have been obtained in this test method by

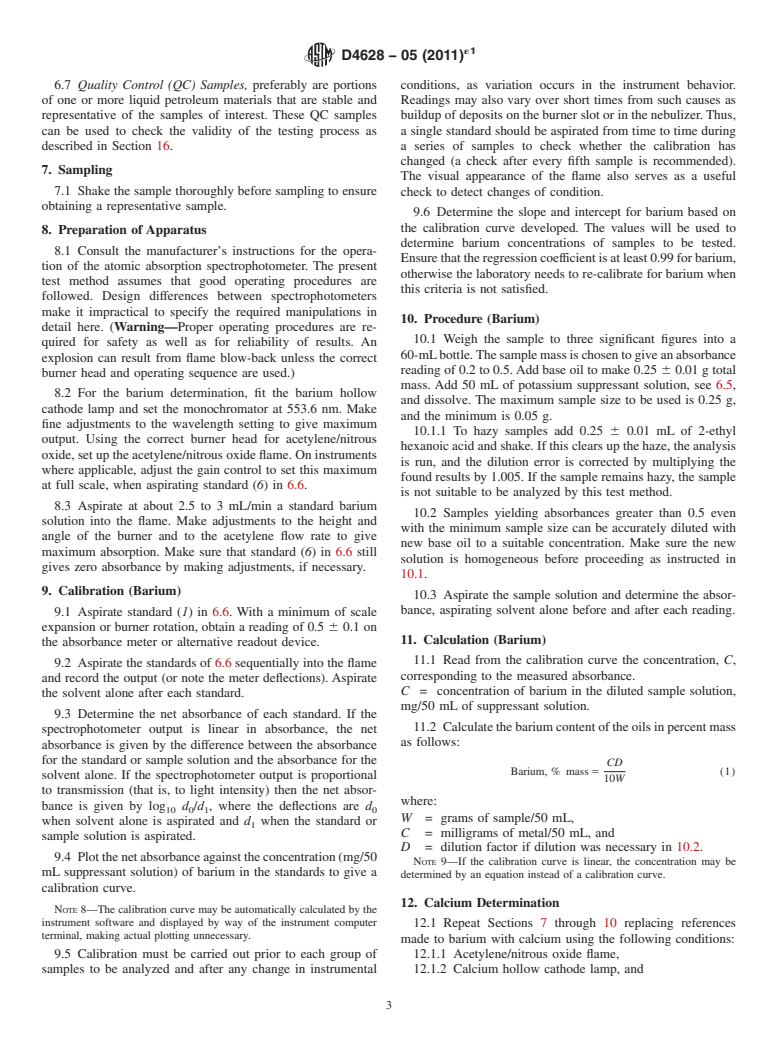

NOTE 6—The actual potassium concentration needed varies with the

using Baker “kerosine” (deodorized) which has typical initial and end

source of potassium and perhaps the instrumental conditions as well. To

boiling points of 191°C and 240°C, respectively, and a typical composi-

determine the needed concentration, atomize solutions containing 0, 500,

tion of 96.7 volume % saturates, 0.1 volume % olefins, and a maximum

1000, 1500, 2000, 2500, and 3000 ppm potassium with 25 ppm barium

of 3.2 volume % aromatics. If the kerosine used by an operator deviates

and5ppmcalciumineach.Plotgraphsofbariumandcalciumabsorbance

appreciably from this composition, there may be significant error.

versus potassium concentration as shown in Fig. 1. The minimum

concentration of potassium needed is that above the knee for both the

6.4 Oil-Soluble Metal Compounds , stock standard blend

barium and calcium curves.

inbaseoil.A0.25 60.01-gportionofthisstockstandardblend

6.6 Working Standards—Freshly prepared by weighing into

diluted with 50 mL of the potassium ionization suppressant

six60-mLbottles(1)0.25,(2)0.20,(3)0.15,(4)0.10,(5)0.05,

solution (see 6.5) shall yield a reading of 0.5 6 0.1 absorbance

units for each of the elements barium, calcium, magnesium, and(6)0gofstockstandardblend(see6.4)tothreesignificant

figures and add 0.0, 0.05, 0.10, 0.15, 0.20, and 0.25 6 0.01 g

and zinc using a minimum of scale expansion or burner

rotation. The concentrations of the metal should be blended of base oil, respectively. Add 50 mL of potassium ionization

suppressantsolution(see6.5)toeachbottleandshakeorstirto

accurately to three significant figures. The actual concentra-

tions should be chosen to conform to the optimum working dissolve.

NOTE 7—Many modern AAS instruments can store up to 3 or 4

calibration standards in memory. In such cases, follow the manufacturer’s

Oil soluble metal compounds found satisfactory for this test method are

available from National Institute of Standards and Technology, Office of Standard instructions, ensuring that the unknown sample’s absorbance is in the

Reference Materials, Washington, DC 20234. linear part of the calibration range used.

´1

D4628 − 05 (2011)

6.7 Quality Control (QC) Samples, preferably are portions conditions, as variation occurs in the instrument behavior.

of one or more liquid petroleum materials that are stable and Readings may also vary over short times from such causes as

representative of the samples of interest. These QC samples buildup of deposits on the burner slot or in the nebulizer.Thus,

can be used to check the validity of the testing process as a single standard should be aspirated from time to time during

described in Section 16. a series of samples to check whether the calibration has

changed (a check after every fifth sample is recommended).

7. Sampling

The visual appearance of the flame also serves as a useful

7.1 Shake the sample thoroughly before sampling to ensure

check to detect changes of condition.

obtaining a representative sample.

9.6 Determine the slope and intercept for barium based on

the calibration curve developed. The values will be used to

8. Preparation of Apparatus

determine barium concentrations of samples to be tested.

8.1 Consult the manufacturer’s instructions for the opera-

Ensurethattheregressioncoefficientisatleast0.99forbarium,

tion of the atomic absorption spectrophotometer. The present

otherwise the laboratory needs to re-calibrate for barium when

test method assumes that good operating procedures are

this criteria is not satisfied.

followed. Design differences between spectrophotometers

make it impractical to specify the required manipulations in

10. Procedure (Barium)

detail here. (Warning—Proper operating procedures are re-

10.1 Weigh the sample to three significant figures into a

quired for safety as well as for reliability of results. An

60-mLbottle.Thesamplemassischosentogiveanabsorbance

explosion can result from flame blow-back unless the correct

reading of 0.2 to 0.5.Add base oil to make 0.25 6 0.01 g total

burner head and operating sequence are used.)

mass. Add 50 mL of potassium suppressant solution, see 6.5,

8.2 For the barium determination, fit the barium hollow

and dissolve. The maximum sample size to be used is 0.25 g,

cathode lamp and set the monochromator at 553.6 nm. Make

and the minimum is 0.05 g.

fine adjustments to the wavelength setting to give maximum

10.1.1 To hazy samples add 0.25 6 0.01 mL of 2-ethyl

output. Using the correct burner head for acetylene/nitrous

hexanoic acid and shake. If this clears up the haze, the analysis

oxide, set up the acetylene/nitrous oxide flame. On instruments

is run, and the dilution error is corrected by multiplying the

where applicable, adjust the gain control to set this maximum

found results by 1.005. If the sample remains hazy, the sample

at full scale, when aspirating standard (6)in 6.6.

is not suitable to be analyzed by this test method.

8.3 Aspirate at about 2.5 to 3 mL/min a standard barium

10.2 Samples yielding absorbances greater than 0.5 even

solution into the flame. Make adjustments to the height and

with the minimum sample size can be accurately diluted with

angle of the burner and to the acetylene flow rate to give

new base oil to a suitable concentration. Make sure the new

maximum absorption. Make sure that standard (6)in 6.6 still

solution is homogeneous before proceeding as instructed in

gives zero absorbance by making adjustments, if necessary.

10.1.

9. Calibration (Barium)

10.3 Aspirate the sample solution and determine the absor-

bance, aspirating solvent alone before and after each reading.

9.1 Aspirate standard (1)in 6.6. With a minimum of scale

expansion or burner rotation, obtain a reading of 0.5 6 0.1 on

11. Calculation (Barium)

the absorbance meter or alternative readout device.

11.1 Read from the calibration curve the concentration, C,

9.2 Aspirate the standards of 6.6 sequentially into the flame

corresponding to the measured absorbance.

and record the output (or note the meter deflections). Aspirate

C = concentration of barium in the diluted sample solution,

the solvent alone after each standard.

mg/50 mL of suppressant solution.

9.3 Determine the net absorbance of each standard. If the

11.2 Calculatethebariumcontentoftheoilsinpercentmass

spectrophotometer output is linear in absorbance, the net

as follows:

absorbance is given by the difference between the absorbance

for the standard or sample solution and the absorbance for the

CD

Barium, % mass 5 (1)

solvent alone. If the spectrophotometer output is proportional

10W

to transmission (that is, to light intensity) then the net absor-

where:

bance is given by log d /d , where the deflections are d

10 0 1 0

W = grams of sample/50 mL,

when solvent alone is aspirated and d when the standard or

C = milligrams of metal/50 mL, and

sample solution is aspirated.

D = dilution factor if dilution was necessary in 10.2.

9.4 Plotthenetabsorbanceagainsttheconcentration(mg/50

NOTE 9—If the calibration curve is linear, the concentration may be

mL suppressant solution) of barium in the standards to give a

determined by an equation instead of a calibration curve.

calibration curve.

12. Calcium Determination

NOTE 8—The calibration curve may be automatically calculated by the

instrument software and displayed by way of the instrument computer

12.1 Repeat Sections 7 through 10 replacing references

terminal, making actual plotting unnecessary.

made to barium with calcium using the following conditions:

9.5 Calibration must be carried out prior to each group of 12.1.1 Acetylene/nitrous oxide flame,

samples to be analyzed and after any change in instrumental 12.1.2 Calcium hollow cathode lamp, and

´1

D4628 − 05 (2011)

TABLE 1 Repeatability

12.1.3 Analytical line 422.7 nm.

Element Range, Repeatability

Mass %

13. Magnesium Determination

Barium 0.005–1.0 0.0478x ⁄3

13.1 Repeat Sections 7 through 10 replacing references Calcium 0.002–0.3 0.0227x ⁄3

Magnesium 0.002–0.3 0.0168x ⁄3

made to barium with magnesium using the following condi-

Zinc 0.002–0.2 0.0247X ⁄3

tions:

Calcium 1.7 0.032

13.1.1 Acetylene/nitrous oxide flame, Zinc 1.0 0.025

13.1.2 Magnesium hollow cathode lamp, and

13.1.3 Analytical line 285.2 nm.

17. Precision and Bias

17.1 The precision of this test method as determined by

14. Zinc Determination

statistical examination of interlaboratory results is as follows:

14.1 Repeat Sections 7 through 10 replacing references

17.1.1 Repeatability—The difference between the two test

made to barium with zinc using the following conditions:

results, obtained by the same operator with the same apparatus

14.1.1 Acetylene/nitrous oxide flame, under constant operating conditions on identical test material,

would, in the long run, in the normal and corr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.