ASTM F1586/F1586M-13

(Specification)Standard Specification for Wrought Nitrogen Strengthened 21Chromium-10Nickel-3Manganese-2.5Molybdenum Stainless Steel Alloy Bar for Surgical Implants (UNS S31675)

Standard Specification for Wrought Nitrogen Strengthened 21Chromium-10Nickel-3Manganese-2.5Molybdenum Stainless Steel Alloy Bar for Surgical Implants (UNS S31675)

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought nitrogen strengthened 21chromium—10nickel—3manganese—2.5molybdenum stainless steel alloy bar for surgical implants.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1586/F1586M −13

StandardSpecification for

Wrought Nitrogen Strengthened 21Chromium—10Nickel—

3Manganese—2.5Molybdenum Stainless Steel Alloy Bar for

1

Surgical Implants (UNS S31675)

ThisstandardisissuedunderthefixeddesignationF1586/F1586M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Implants (UNS S31673)

F746Test Method for Pitting or Crevice Corrosion of

1.1 This specification covers the chemical, mechanical, and

Metallic Surgical Implant Materials

metallurgical requirements for wrought nitrogen strengthened

3

2.2 Aerospace Material Specifications:

21chromium—10nickel—3manganese—2.5molybdenum

AMS 2248Chemical CheckAnalysis Limits, Corrosion and

stainless steel alloy bar for surgical implants.

Heat Resistant Steels and Alloys, Maraging and Other

1.2 The values stated in either inch-pound units or SI units

Highly-Alloyed Steels, and Iron Alloys

4

are to be regarded separately as standard. The values stated in

2.3 ISO Standard:

each system may not be exact equivalents; therefore, each

ISO 6892Metallic Materials Tensile Testing at Ambient

system shall be used independently of the other. Combining

Temperature

values from the two systems may result in non-conformance

ISO 9001Quality Management System—Requirements

with the standard.

2.4 Quality Standard:

SI 10™American National Standard for Use of the Interna-

2. Referenced Documents

tional System of Units (SI): The Modern Metric System

2

5

2.1 ASTM Standards:

2.5 Quality Standard:

A262Practices for Detecting Susceptibility to Intergranular

ASQ C1Specification of General Requirements for a Qual-

Attack in Austenitic Stainless Steels

ity Program

A484/A484MSpecification for General Requirements for

3. Terminology

Stainless Steel Bars, Billets, and Forgings

A751Test Methods, Practices, and Terminology for Chemi-

3.1 Definitions of Terms Specific to This Standard:

cal Analysis of Steel Products

3.1.1 lot, n—the total number of mill products produced

E8Test Methods for Tension Testing of Metallic Materials

from the same melt heat under the same conditions at essen-

E10Test Method for Brinell Hardness of Metallic Materials

tially the same time.

E18Test Methods for Rockwell Hardness of Metallic Ma-

4. General Requirements for Delivery

terials

E29Practice for Using Significant Digits in Test Data to

4.1 In addition to the requirements of this specification, all

Determine Conformance with Specifications

requirements of the current edition of Specification A484/

E45Test Methods for Determining the Inclusion Content of

A484M shall apply.

Steel

4.2 In cases in which a conflict exists between this specifi-

E112Test Methods for Determining Average Grain Size

cation and the standards listed in Section 2, this specification

F138Specification for Wrought 18Chromium-14Nickel-

shall take precedence.

2.5MolybdenumStainlessSteelBarandWireforSurgical

5. Ordering Information

1

5.1 Inquiriesandordersformaterialunderthisspecification

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devicesis under the direct responsibility of

shall include the following information:

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved June 1, 2013. Published August 2013. Originally

3

approved in 1995. Last previous edition approved in 2008 as F1586–08. DOI: Available from Society of Automotive Engineers (SAE), 400 Commonwealth

10.1520/F1586-13. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Standardsvolume information,referto thestandard’sDocumentSummary page on Available fromAmerican Society for Quality (ASQ), 600 N. PlankintonAve.,

the ASTM website. Milwaukee, WI 53203, http://www.asq.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1586/F1586M−13

5.1.1 Quantity, 7.2.2 Product analysis tolerances do not broaden the speci-

5.1.2 ASTM designation and date of issue, fied heat analysis requirements but cover variations between

5.1.3 Mechanical properties (if applicable, for special laboratories in the measurement of chemical content. Product

conditions), analysis limits shall be as specified in Table 2.

5.1.4 Form,

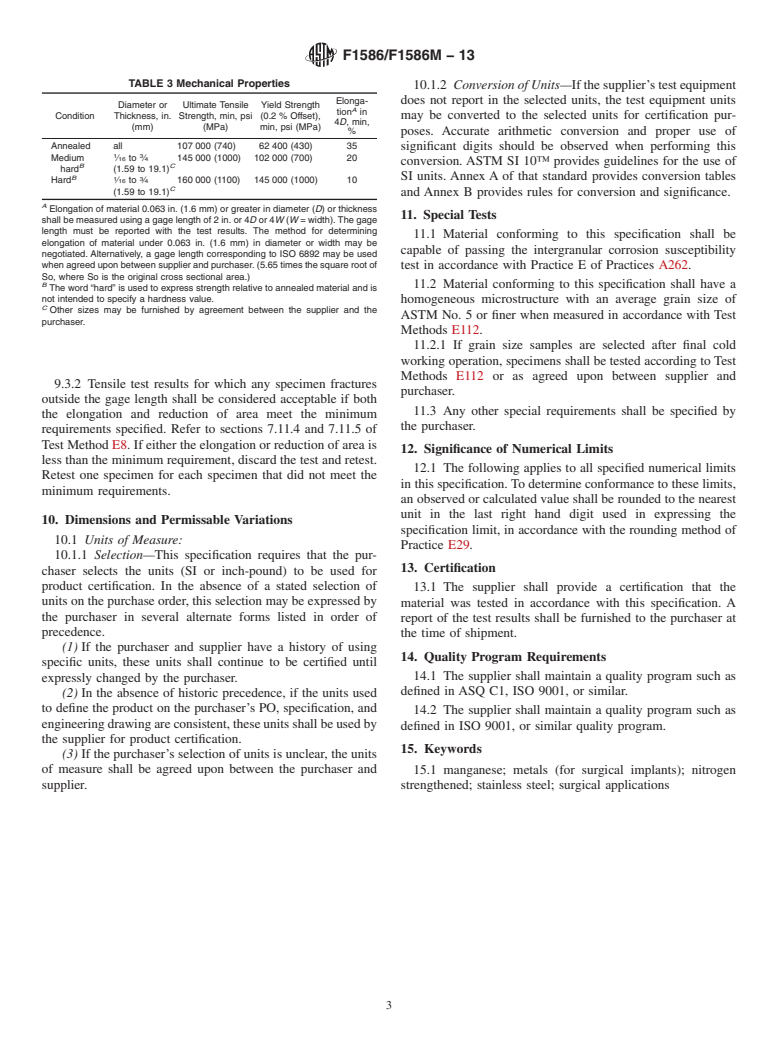

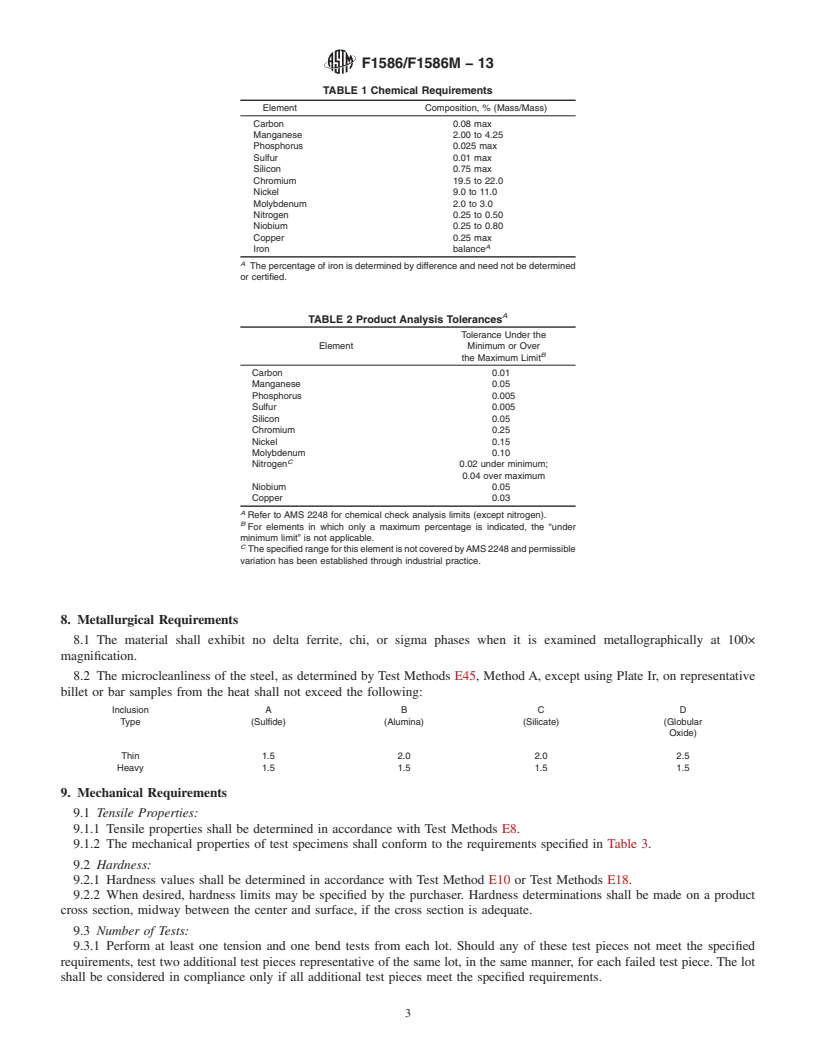

8. Metallurgical Requirements

5.1.5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1586 − 08 F1586/F1586M − 13

Standard Specification for

Wrought Nitrogen Strengthened 21Chromium—10Nickel—

3Manganese—2.5Molybdenum Stainless Steel Alloy Bar for

1

Surgical Implants (UNS S31675)

This standard is issued under the fixed designation F1586;F1586/F1586M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought nitrogen strengthened

21chromium—10nickel—3manganese—2.5molybdenum stainless steel alloy bar for surgical implants.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values given in

parentheses are mathematical conversions to SI units that are provided for information only and are not considered stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E8 Test Methods for Tension Testing of Metallic Materials

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E45 Test Methods for Determining the Inclusion Content of Steel

E112 Test Methods for Determining Average Grain Size

F138 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Bar and Wire for Surgical Implants

(UNS S31673)

F746 Test Method for Pitting or Crevice Corrosion of Metallic Surgical Implant Materials

3

2.2 Aerospace Material Specifications:

AMS 2248 Chemical Check Analysis Limits, Corrosion and Heat Resistant Steels and Alloys, Maraging and Other

Highly-Alloyed Steels, and Iron Alloys

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devicesis under the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved May 1, 2008June 1, 2013. Published May 2008August 2013. Originally approved in 1995. Last previous edition approved in 20022008 as

F1586 – 02.F1586 – 08. DOI: 10.1520/F1586-08.10.1520/F1586-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1586/F1586M − 13

4

2.3 ASQC Standard:

ASQ C1 Specification of General Requirements for a Quality Program

4

2.3 ISO Standard:

ISO 6892 Metallic Materials Tensile Testing at Ambient Temperature

ISO 9001 Quality Management System—Requirements

2.4 Quality Standard:

SI 10™ American National Standard for Use of the International System of Units (SI): The Modern Metric System

5

2.5 Quality Standard:

ASQ C1 Specification of General Requirements for a Quality Program

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot, n—the total number of mill products produced from the same melt heat under the same conditions at essentially the

same time.

4. General Requirements for Delivery

4.1 In addition to the requirements of this specification, all requirements of the current edition of Specification A484/A484M

shall apply.

4.2 In cases in which a conflict exists between this specification and the standards listed in Section 2, this specification shall

take precedence.

5. Ordering Information

5.1 Inquiries and orders for material under this specification shall include the following information:

5.1.1 Quantity,

5.1.2 ASTM designation and d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.