ASTM A356/A356M-04

(Specification)Standard Specification for Steel Castings, Carbon, Low Alloy, and Stainless Steel, Heavy-Walled for Steam Turbines

Standard Specification for Steel Castings, Carbon, Low Alloy, and Stainless Steel, Heavy-Walled for Steam Turbines

SCOPE

1.1 This specification covers one grade of martensitic stainless steel and several grades of ferritic steel castings for cylinders (shells), valve chests, throttle valves, and other heavy-walled castings for steam turbine applications.

1.2 Optional supplementary requirements (S1 through S5) shall apply as selected by and specified by the purchaser.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 356/A 356M – 04

Standard Specification for

Steel Castings, Carbon, Low Alloy, and Stainless Steel,

1

Heavy-Walled for Steam Turbines

This standard is issued under the fixed designationA356/A356M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* [51 mm] in Thickness

E 709 Guide for Magnetic Particle Examination

1.1 This specification covers one grade of martensitic stain-

2.2 Manufacturers’ Standardization Society of the Valve

less steel and several grades of ferritic steel castings for

4

and Fitting Industry Standard:

cylinders (shells), valve chests, throttle valves, and other

SP-55 Quality Standard for Steel Castings for Valves,

heavy-walled castings for steam turbine applications.

Flanges, and Fittings and Other Piping Components (Vi-

1.2 Optional supplementary requirements (S1 through S5)

sual Method)

shall apply as selected by and specified by the purchaser.

1.3 The values stated in either inch-pound units or SI units

3. Classification

are to be regarded separately as standard. Within the text, the

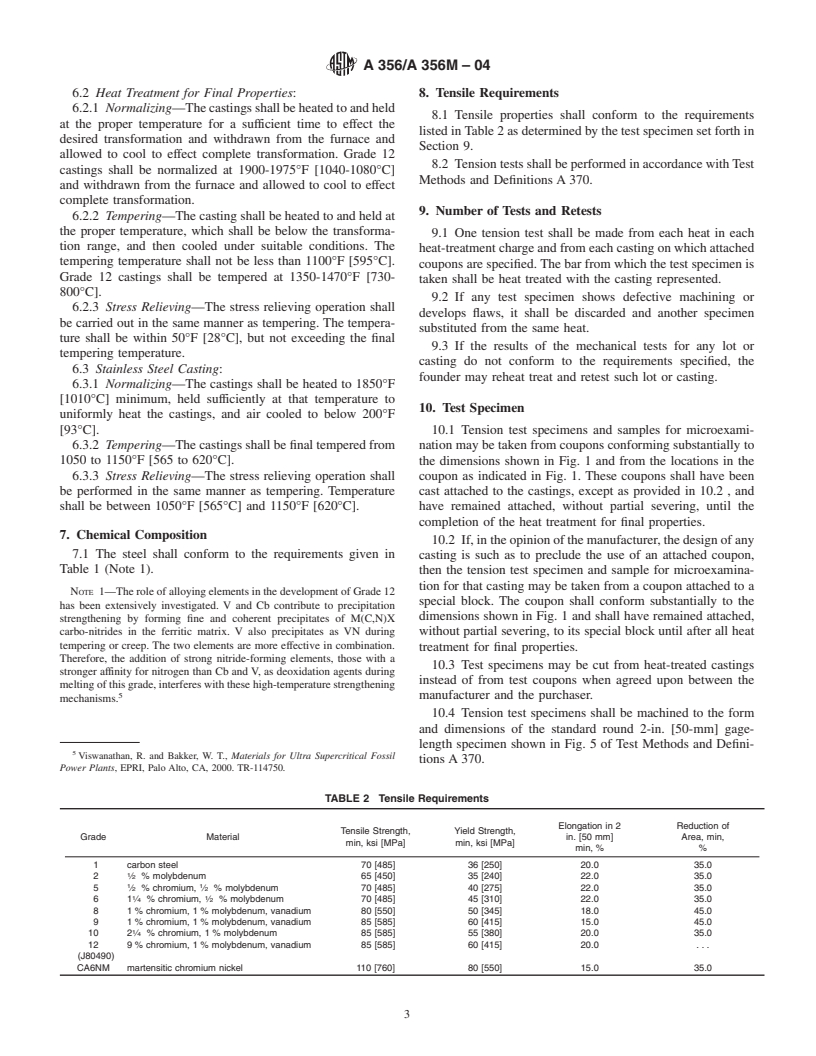

3.1 The castings are furnished in the grades shown in Table

SI units are shown in brackets. The values stated in each

1.

system are not exact equivalents; therefore, each system must

be used independently of the other. Combining values from the

4. Ordering Information

two systems may result in nonconformance with the specifi-

4.1 Orders for material to this specification should include

cation.

the following information:

4.1.1 A description of the casting by pattern number or

2. Referenced Documents

2

drawing (dimensional tolerances shall be included on the

2.1 ASTM Standards:

casting drawing),

A 370 Test Methods and Definitions for MechanicalTesting

4.1.2 Grade of steel,

of Steel Products

4.1.3 Options in the specification, and

A 488/A 488M Practice for Steel Castings, Welding, Quali-

4.1.4 The supplementary requirements desired, including

fications of Procedures and Personnel

the standards of acceptance.

E 94 Guide for Radiographic Examination

E 125 Reference Photographs for Magnetic Particle Indica-

5. Melting Process

tions on Ferrous Castings

5.1 The steel shall be made by the open-hearth or electric-

E 142 Method for Controlling Quality of Radiographic

furnace process.

3

Testing

5.2 Deoxidation Practice:

E 165 Test Method for Liquid Penetrant Examination

5.2.1 Deoxidation of the carbon and low-alloy steel grades

E 186 Reference Radiographs for Heavy-Walled (2 to 4

shall be by manganese and silicon. Furnace or ladle deoxida-

1

⁄2-in. [51 to 114-mm]) Steel Castings

tion with other agents is permissible with the approval of the

1

E 280 Reference Radiographs for Heavy-Walled (4 ⁄2 to

purchaser.

12-in. [114 to 305-mm]) Steel Castings

5.2.2 The purchaser may specify that no aluminum be

E 446 Reference Radiographs for Steel Castings Up to 2 in.

added.

5.2.3 Vacuum deoxidation is acceptable. The specific

method shall be subject to approval by the purchaser.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee 6. Heat Treatment

A01.18 on Castings.

6.1 Preliminary Heat Treatment—The castings may receive

Current edition approved Oct. 1, 2004. Published October 2004. Originally

such preliminary heat treatment as the founder may elect to

approved in 1952. Last previous edition approved in 2003 as A 356/A 356M – 98

(2003).

employ.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

3

Withdrawn. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 356/A 356M – 04

2

TABLE 1 Chemical Requirements

Composition, %

Grade Material Phosphorus,

Carbon Manganese Silicon Sulfur, max Molybdenum Chromium Nickel Vanadium Columbium Nitrogen Aluminum

max

A A

1 carbon steel 0.35 max 0.70 max 0.60max 0.035 0.030 . . . . . . .

A A

1

2 ⁄2 % molybdenum 0.25 max 0.70 max 0.60 max 0.035 0.030 0.45-0.65 . . . . . . . . . . . . . . . . . .

A A

1 1

5 ⁄2 % chromium, ⁄2 % 0.25 max 0.70 max 0.60 max 0.035 0.030 0.40-0.60 0.40-0.70 . . . . . . . . . . . . . . .

molybdenum

1 1

61 ⁄4 % chromium, ⁄2 %

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.