ASTM D1666-87(1999)

(Test Method)Standard Methods for Conducting Machining Tests of Wood and Wood-Base Materials

Standard Methods for Conducting Machining Tests of Wood and Wood-Base Materials

SCOPE

1.1 These methods cover procedures for planing, shaping, turning, mortising, boring, and sanding; all of which are common wood-working operations used in the manufacture of wood products. These tests apply, in different degrees, to two general classes of materials:

1.1.1 Wood in the form of lumber, and

1.1.2 Wood-base panel materials.

1.2 Because of the importance of planing, some of the variables that affect the results of this operation are explored with a view to determining optimum conditions. In most of the other tests, however, it is necessary to limit the work to one set of fairly typical commercial conditions in which all the different woods are treated alike.

1.3 Several factors enter into any complete appraisal of the machining properties of a given wood. Quality of finished surface is recommended as the basis for evaluation of machining properties. Rate of dulling of cutting tools and power consumed in cutting are also important considerations but are beyond the scope of these methods.

1.4 Although the methods presented include the results of progressive developments in the evaluation of machining properties, further improvements may be anticipated. For example, by present procedures quality of the finished surface is evaluated by visual inspection, but as new mechanical or physical techniques become available that will afford improved precision of evaluation, they should be employed.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. > Note 1-The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1666 – 87 (Reapproved 1999)

Standard Methods for

Conducting Machining Tests of Wood and Wood-Base

Materials

This standard is issued under the fixed designation D 1666; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

One of the significant characteristics of wood is the facility with which it can be machined and

fabricated. Different species, however, vary greatly in their behavior under cutting tools, so that some

systematic method is needed for determining their suitability for uses where the character of the

machined surface is of prime importance. Such uses include cabinetwork, millwork, and other

products where favorable machining properties are essential to good finish. For such products as

common boards, on the other hand, good machining properties are secondary, although still an asset.

The machining test procedures presented in these methods cover such common operations as

planing, shaping, turning, boring, mortising, and sanding. They are the result of many years of

extensive research and development and include practical methods for qualitatively evaluating and

interpreting the results. Because of their satisfactory use with a wide range of materials, it is believed

that the methods are equally applicable to species, hardwoods and softwoods, and to wood-base

materials, such as plywood, particleboard, and hardboard.

1. Scope 1.4 Although the methods presented include the results of

progressive developments in the evaluation of machining

1.1 These methods cover procedures for planing, shaping,

properties, further improvements may be anticipated. For

turning, mortising, boring, and sanding; all of which are

example, by present procedures quality of the finished surface

common wood-working operations used in the manufacture of

is evaluated by visual inspection, but as new mechanical or

wood products. These tests apply, in different degrees, to two

physical techniques become available that will afford improved

general classes of materials:

precision of evaluation, they should be employed.

1.1.1 Wood in the form of lumber, and

1.5 This standard does not purport to address all of the

1.1.2 Wood-base panel materials.

safety concerns, if any, associated with its use. It is the

1.2 Because of the importance of planing, some of the

responsibility of the user of this standard to establish appro-

variables that affect the results of this operation are explored

priate safety and health practices and determine the applica-

with a view to determining optimum conditions. In most of the

bility of regulatory limitations prior to use.

other tests, however, it is necessary to limit the work to one set

of fairly typical commercial conditions in which all the

NOTE 1—The values stated in inch-pound units are to be regarded as the

different woods are treated alike. standard. The metric equivalents of inch-pound units may be approximate.

1.3 Several factors enter into any complete appraisal of the

2. Definitions and Descriptions of Terms

machining properties of a given wood. Quality of finished

2.1 A number of special terms relating to wood and to

surface is recommended as the basis for evaluation of machin-

ing properties. Rate of dulling of cutting tools and power machining are used in describing the procedures for the various

machining studies. Definitions and descriptions of a number of

consumed in cutting are also important considerations but are

beyond the scope of these methods. the important terms used are presented in Appendix X1.

3. Significance and Use

These methods are under the jurisdiction of ASTM Committee D-7 on Wood

3.1 Machining tests are made to determine the working

are are the direct responsibility of Subcommittee D07.01 on Fundamental Test

qualities and characteristics of different species of wood and of

Methods and Properties.

different wood- and wood-base materials under a variety of

Current edition approved Dec. 31, 1987. Published February 1988. Originally

published as D 1666 – 59 T. Last previous edition D 1666 – 64 (1981)e . machine operations such as are encountered in commercial

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1666

manufacturing practice. The tests provide a systematic basis kinds of wood, the density, and the amount and kind of binder

for comparing the behavior of different species with respect to should be known and made part of the record. Particleboard

woodworking machine operations and of evaluating their and hardboard shall be typical of the product under consider-

potential suitability for certain uses where these properties are ation as they are manufactured and marketed. For the planing

of prime importance. and sanding tests, the particleboard and hardboard samples

should be procured in the unsurfaced condition, whenever

4. Apparatus

possible, so that these evaluations may be made on the same

part of the material that will be removed from the board in the

4.1 Machines—To yield data that can be duplicated for

normal use conditions where planing and sanding are done.

comparative purposes, all machines used in these tests shall be

6.4 Test samples of lumber shall be so selected as to exclude

modern commercial size machines of good make, in good

the small amount at each extreme that is not fairly typical of the

mechanical condition, and operated by fully qualified persons.

species under consideration in number of rings per inch

Numerous machines meet these requirements, and no attempt

(average ring width per millimetre).

is made to do more than describe the preferred type of machine

for each test in very general terms (Note 2). Complete

NOTE 5—Number of rings per inch is determined by visual count along

information on the machine used, the cutting tool, and the

a line perpendicular to the growth rings. Different samples of a given

operating conditions of each test shall be made part of the species often differ widely in this respect, and often the samples at both

extremes are not typical in their properties.

record.

NOTE 2—Where machines with all of these qualifications are not

7. Dimensions and Weight of Samples

available, machines that are inferior in some respects have limited uses,

7.1 Lumber samples shall be dried to a uniform moisture

such as for comparing the machining properties of species for local use

content of 6 percent before testing, or to such other moisture

under local conditions.

content as may be specified.

4.2 Sharpness of Knives and Cutters—Carbide-tipped

7.2 Samples must be large enough to yield the minimum

knives and cutters shall be the preferred type because of the

acceptable size (0.75 by 5 in. by 4 ft) (19 by 127 mm 3 1.2 m)

much longer sharpness life of that material. High-speed steel

when at the prescribed moisture content and surfaced smoothly

shall be second choice and carbon steel third. The cutting tool

on two sides. Where it is desired to make more planer cuts than

material used shall be made part of the record. Every precau-

are specified, lumber thicker than 1 in. (25 mm) may be used.

tion shall be taken to keep the sharpness uniformly good in all

7.3 Lumber test samples shall be so selected as to exclude

tests by resharpening when necessary.

the small amount at each extreme of weight that is not typical

NOTE 3—A practical measure of the deterioration of a machined lumber

of the species under consideration.

surface because of dulling of the cutting tool can be had by the use of two

NOTE 6—Different samples of a species sometimes vary in density by

check samples. They should come from the same board of some species

as much asa2to1 ratio. The properties exhibited by samples at either

that machines exceptionally well, such as mahogany. Both should be

extreme of density are not typical of the species as a whole.

machined with a freshly sharpened cutting tool at the outset. One will be

retained in that condition as a control, and the other, at intervals of1hor

7.4 Particleboard and hardboard test material shall be typi-

so as experience dictates, shall be machined with the regular test

cal in dimensions and weight of the products under consider-

specimens and compared with the control. When the machined surface

ation as they are manufactured and marketed.

deteriorates perceptibly, as indicated by this comparison, the cutting tool

should be resharpened.

8. Sampling

Similarly with particle board or hardboard, some well-known product

8.1 A total of 50 test samples of lumber is required for each

that has good machining properties may be used as a control material for

comparison. species tested (Note 7). Except in the few species where the

making of some quartered lumber is standard practice, the

5. Shipment and Protection of Samples

samples shall be commercial flat grain. The test material shall

5.1 All test material shall be properly protected in shipment

be selected by one fully qualified to identify the species, to

to ensure its delivery in satisfactory condition for the required

judge if it is fairly representative of the product being shipped

tests. On receipt, the material shall be carefully protected to

and if it meets the specifications. If only exploratory tests are

prevent deterioration pending the preparation for the tests.

to be made, a smaller number of samples may be selected.

NOTE 7—It is desirable that the samples represent numerous different

6. General Requirements of Samples

trees and logs. The material for tests should preferably be obtained in log

6.1 The tests shall be made on seasoned material.

form and then sawn to the desired size. When this is not possible it will

6.2 Lumber shall be clear (Note 4), sound, well- be necessary to select random samples from a lumber pile.

manufactured, and accurately identified as to species. It may be

8.2 For each type of particleboard tested, five samples (Note

either rough or dressed.

8) shall be selected, one from each of five different sheets. The

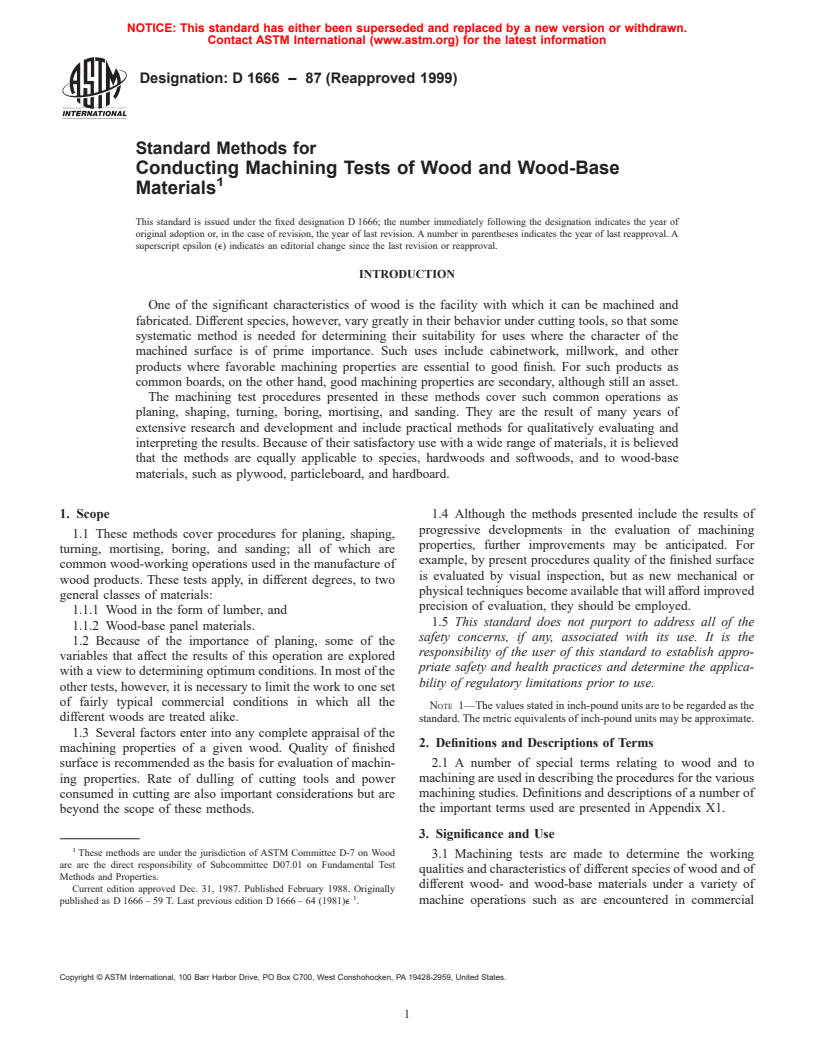

size of these samples (Fig. 1) shall be 2 by 4 ft (610 by 1220

NOTE 4—Clear means free from all defects, including knots, stain,

incipient decay, surface checks, end splits, compression wood, and tension mm), and the thickness in different products shall be as

wood.

manufactured (Note 9).

6.3 Particleboard and hardboard samples may be typical

NOTE 8—Particleboard and hardboard of any one process and mill are

commercial products or samples of new boards under devel-

much more uniform in their properties than different boards of a given

opment as the occasion requires. In either case the kind or species. For this reason, five samples selected as described in 8.2 are

D 1666

keeping in mind that the data will apply only to these specific conditions.

In any event, the material should be conditioned to a uniform moisture

content, and the actual moisture content determined and recorded.

9.1.4 Joint one edge and one side of the boards flat and

plane the other side to provide a final board thickness of 0.75

in. (19 mm).

9.1.5 Saw the boards into the specified smaller sizes for the

different tests as shown in Fig. 1. Each of the test specimens

shall bear the same number as the board from which it was cut;

take care to place the number where it will not be lost in the

machining process.

NOTE 11—The specimen for shaping, boring and mortising (Fig. 1)

must be accurately cut to size to ensure proper fit in the test jig. The

turning specimens also must be accurate since they have to fit special lathe

centers. The size of the planing specimen is less critical and, if necessary,

it may be 1 in. (25 mm) or so short of the specified 3 ft (910 mm) without

serious objection.

10. Preparation of Specimens from Particleboard and

Hardboard

10.1 Each different test has its own procedure as described

in Sections 18-23. The following steps in preparing the test

specimens apply to all tests with particleboard and hardboard:

10.1.1 Mark each 2 by 4-ft (610 by 1210 mm) board to

identify the source and the individual sample.

10.1.2 Condition the boards to the standard 6% EMC (see

9.1.3) or to such other moisture condition as may be specified.

METRIC EQUIVALENTS

10.1.3 Saw each of the original particleboard, and hard-

in. ⁄2 3 4 5 12 36 48

board samples into smaller sizes for the different tests as shown

cm 1.3 7.6 10.2 12.7 30.5 91 122

in Fig. 2.

FIG. 1 Diagram for Sawing Lumber Samples into Smaller

10.1.4 Each of the test specimens shall bear the same

Samples for Individual Tests

number as the board from which it was cut.

METHODS OF TESTING LUMBER

considered sufficient to give representative results.

NOTE 9—For sawing tests where power consumption is an important

factor, material thicker than 0.75 in. (19 mm) shall be reduced to that

11. Planing

thickness before test. For material thinner than 0.75 in., a sufficient

11.1 A moulder (Fig. 3) is the preferable machine for the

number of pieces shall be laminated together to provide the 0.75-in.

planing test because of its relatively wide range of feeds and

thickness.

speeds and because of the ease of changing heads. In the

8.3 For each type of hardboard tested, five samples shall be

absence of a moulder, a planer or planer-matcher may be used.

selected, one from each of five different sheets. The size of

In any case use only straight knives, and plane only one side of

these samples shall be 2 by 4 ft (610 by 1220 mm), and the

the test specimen at a time.

thickness shall be that of the hardboard as manufactured.

11.2 Steel knives shall be freshly ground at the outset and

jointed to a point where each knife shows a hairline land for the

9. Preparation of Test Specimens from Lumber

entire length of the blade. When the land or jointed portion of

9.1 Each different test has its own procedure as described in

the edge becomes as much as ⁄32 in. (0.80 mm) wide, as a

Sections 11-16. The following steps in preparing the test

result of repeated jointings, the knives shall be reground before

specimens apply to all tests with lumber:

continuing with the test.

9.1.1 Mark each board, nominal 1 by 5 in. by 4 ft (as by 127

11.3 All specimens used in this test (50 per species) shall be

mm by 1.2 m) to identify adequately the species source and

0.75 by 4 in. by 3 ft (19 by 102 by 910 mm).

individual sample.

11.4 The moisture content shall be 6% or such other value

9.1.2 Cut a 0.5-in. (13-mm) cross section from one end of

as may be specified.

each nominal 1 by 5 in. by 4 ft board for specific gravity

11.5 All cuts shall be ⁄16 in. (1.6 mm) deep.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.