ASTM E251-20

(Test Method)Standard Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gages

Standard Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gages

SIGNIFICANCE AND USE

4.1 Strain gages are the most widely used devices for the determination of materials, properties and for analyzing stresses in structures. However, performance parameters of strain gages are affected by both the materials from which they are made and their geometric design. These test methods detail the minimum information that must accompany strain gages if they are to be used with acceptable accuracy of measurement.

4.2 Most performance parameters of strain gages require mechanical testing that is destructive. Since test gages cannot be used again, it is necessary to treat data statistically and then apply values to the remaining population from the same lot or batch. Failure to acknowledge the resulting uncertainties can have serious repercussions. Resistance measurement is non-destructive and can be made for each gage.

4.3 Properly designed and manufactured strain gages, whose properties have been accurately determined and with appropriate uncertainties applied, represent powerful measurement tools. They can determine small dimensional changes in structures with excellent accuracy, far beyond that of other known devices. It is important to recognize, however, that individual strain gages cannot be calibrated. If calibration and traceability to a standard are required, strain gages should not be employed.

4.4 To be used, strain gages must be bonded to a structure. Good results depend heavily on the materials used to clean the bonding surface, to bond the gage, and to provide a protective coating. Skill of the installer is another major factor in success. Finally, instrumentation systems must be carefully designed to assure that they do not unduly degrade the performance of the gages. In many cases, it is impossible to achieve this goal. If so, allowance must be made when considering accuracy of data. Test conditions can, in some instances, be so severe that error signals from strain gage systems far exceed those from the structural deformations to be mea...

SCOPE

1.1 The purpose of these test methods are to provide uniform test methods for the determination of strain gage performance characteristics. Suggested testing equipment designs are included.

1.2 Test Methods E251 describes methods and procedures for determining five strain gage parameters:

Section

Part I—General Requirements

7

Part II—Resistance at a Reference Temperature

8

Part III—Gage Factor at a Reference Temperature

9

Part IV—Temperature Coefficient of Gage Factor

10

Part V—Transverse Sensitivity

11

Part VI—Thermal Output

12

1.3 Strain gages are very sensitive devices with essentially infinite resolution. Their response to strain, however, is low and great care must be exercised in their use. The performance characteristics identified by these test methods must be known to an acceptable accuracy to obtain meaningful results in field applications.

1.3.1 Strain gage resistance is used to balance instrumentation circuits and to provide a reference value for measurements since all data are related to a change in the gage resistance from a known reference value.

1.3.2 Gage factor is the transfer function of a strain gage. It relates resistance change in the gage and strain to which it is subjected. Accuracy of strain gage data can be no better than the precision of the gage factor.

1.3.3 Changes in gage factor as temperature varies also affect accuracy although to a much lesser degree since variations are usually small.

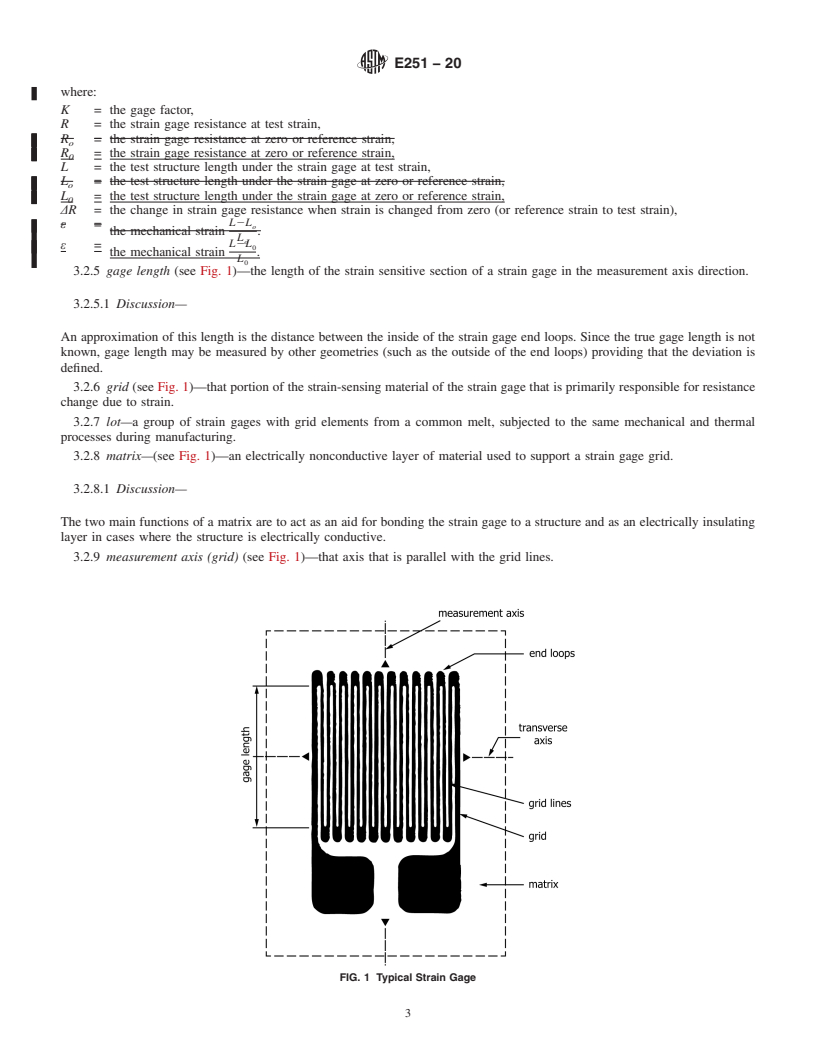

1.3.4 Transverse sensitivity is a measure of the strain gage's response to strains perpendicular to its measurement axis. Although transverse sensitivity is usually much less than 10 % of the gage factor, large errors can occur if the value is not known with reasonable precision.

1.3.5 Thermal output is the response of a strain gage to temperature changes. Thermal output is an additive (not multiplicative) error. Therefore, it can...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E251 − 20

Standard Test Methods for

Performance Characteristics of Metallic Bonded Resistance

1

Strain Gages

This standard is issued under the fixed designation E251; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

The Organization of International Legal Metrology is a treaty organization with approximately 75

member nations. In 1984, OIML issued International Recommendation No. 62, “Performance

Characteristics of Metallic Resistance Strain Gages.” Test Methods E251 has been modified and

expanded to be the United States ofAmerica’s compliant test specification. Throughout this standard

the terms “strain gage” and “gage” are to be understood to represent the longer, but more accurate,

“metallic bonded resistance strain gages.”

1. Scope subjected. Accuracy of strain gage data can be no better than

the precision of the gage factor.

1.1 The purpose of these test methods are to provide

1.3.3 Changes in gage factor as temperature varies also

uniform test methods for the determination of strain gage

affect accuracy although to a much lesser degree since varia-

performance characteristics. Suggested testing equipment de-

signs are included. tions are usually small.

1.3.4 Transversesensitivityisameasureofthestraingage’s

1.2 Test Methods E251 describes methods and procedures

response to strains perpendicular to its measurement axis.

for determining five strain gage parameters:

Although transverse sensitivity is usually much less than 10%

Section

Part I—General Requirements 7 of the gage factor, large errors can occur if the value is not

Part II—Resistance at a Reference Temperature 8

known with reasonable precision.

Part III—Gage Factor at a Reference Temperature 9

1.3.5 Thermal output is the response of a strain gage to

Part IV—Temperature Coefficient of Gage Factor 10

Part V—Transverse Sensitivity 11

temperature changes. Thermal output is an additive (not

Part VI—Thermal Output 12

multiplicative) error. Therefore, it can often be much larger

1.3 Strain gages are very sensitive devices with essentially

than the gage output from structural loading. To correct for

infinite resolution. Their response to strain, however, is low

these effects, thermal output must be determined from gages

and great care must be exercised in their use.The performance

bonded to specimens of the same material on which the tests

characteristics identified by these test methods must be known

are to run, often to the test structure itself.

to an acceptable accuracy to obtain meaningful results in field

1.4 Bonded resistance strain gages differ from extensom-

applications.

eters in that they measure average unit elongation (∆L/L) over

1.3.1 Strain gage resistance is used to balance instrumenta-

tioncircuitsandtoprovideareferencevalueformeasurements a nominal gage length rather than total elongation between

definite gauge points. Practice E83 is not applicable to these

sincealldataarerelatedtoachangeinthegageresistancefrom

a known reference value. gages.

1.3.2 Gage factor is the transfer function of a strain gage. It

1.5 These test methods do not apply to transducers, such as

relates resistance change in the gage and strain to which it is

load cells and extensometers, that use bonded resistance strain

gages as sensing elements.

1

1.6 Strain gages are part of a complex system that includes

These test methods are under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and are the direct responsibility of Subcommittee E28.01 on

structure, adhesive, gage, lead wires, instrumentation, and

Calibration of Mechanical Testing Machines and Apparatus.

(often) environmental protection. As a result, many things

Current edition approved May 1, 2020. Published August 2020. Originally

affect the performance of strain gages, including user tech-

approved in 1964. Last previous edition approved in 2014 as E251–92 (2014).

DOI: 10.1520/E0251-92R14. nique.Afurthercomplicationisthatstraingagesonceinstalled

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E251 − 20

normally cannot be reinstalled in another location. Therefore, R 2 R ∆R

0

gage characteristics can be stated only on a statistical basis. R R

0 0

K 5 5 (1)

L 2 L ε

0

1.7 This standard does not purport to address all of the

L

0

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

where:

priate

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E251 − 92 (Reapproved 2014) E251 − 20

Standard Test Methods for

Performance Characteristics of Metallic Bonded Resistance

1

Strain Gages

This standard is issued under the fixed designation E251; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

The Organization of International Legal Metrology is a treaty organization with approximately 75

member nations. In 1984, OIML issued International Recommendation No. 62, “Performance

Characteristics of Metallic Resistance Strain Gages.” Test Methods E251 has been modified and

expanded to be the United States of America’s compliant test specification. Throughout this standard

the terms “strain gage” and “gage” are to be understood to represent the longer, but more accurate,

“metallic bonded resistance strain gages.”

1. Scope

1.1 The purpose of these test methods are to provide uniform test methods for the determination of strain gage performance

characteristics. Suggested testing equipment designs are included.

1.2 Test Methods E251 describes methods and procedures for determining five strain gage parameters:

Section

Part I—General Requirements 7

Part II—Resistance at a Reference Temperature 8

Part III—Gage Factor at a Reference Temperature 9

Part IV—Temperature Coefficient of Gage Factor 10

Part V—Transverse Sensitivity 11

Part VI—Thermal Output 12

1.3 Strain gages are very sensitive devices with essentially infinite resolution. Their response to strain, however, is low and great

care must be exercised in their use. The performance characteristics identified by these test methods must be known to an

acceptable accuracy to obtain meaningful results in field applications.

1.3.1 Strain gage resistance is used to balance instrumentation circuits and to provide a reference value for measurements since

all data are related to a change in the gage resistance from a known reference value.

1.3.2 Gage factor is the transfer function of a strain gage. It relates resistance change in the gage and strain to which it is

subjected. Accuracy of strain gage data can be no better than the precision of the gage factor.

1.3.3 Changes in gage factor as temperature varies also affect accuracy although to a much lesser degree since variations are

usually small.

1.3.4 Transverse sensitivity is a measure of the strain gage’s response to strains perpendicular to its measurement axis. Although

transverse sensitivity is usually much less than 10 % of the gage factor, large errors can occur if the value is not known with

reasonable precision.

1.3.5 Thermal output is the response of a strain gage to temperature changes. Thermal output is an additive (not multiplicative)

error. Therefore, it can often be much larger than the gage output from structural loading. To correct for these effects, thermal

output must be determined from gages bonded to specimens of the same material on which the tests are to run, often to the test

structure itself.

1.4 Bonded resistance strain gages differ from extensometers in that they measure average unit elongation (ΔL/L) over a

nominal gage length rather than total elongation between definite gauge points. Practice E83 is not applicable to these gages.

1

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and are the direct responsibility of Subcommittee E28.01 on Calibration

of Mechanical Testing Machines and Apparatus.

Current edition approved April 15, 2014May 1, 2020. Published August 2014August 2020. Originally approved in 1964. Last previous edition approved in 20092014 as

E251 – 92 (2009).(2014). DOI: 10.1520/E0251-92R14.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E251 − 20

1.5 These test methods do not apply to transducers, such as load cells and extensometers, that use bonded resistance strain gages

as sensing elements.

1.6 strainStrain gages are part of a complex system that includes structure, adhesive, gage, lead wires, instrumentation, and

(often) environmental protection. As a result, many things affect the performance of strain gages, including user technique. A

further complication is that strain g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.