ASTM C927-80(2014)

(Test Method)Standard Test Method for Lead and Cadmium Extracted from the Lip and Rim Area of Glass Tumblers Externally Decorated with Ceramic Glass Enamels

Standard Test Method for Lead and Cadmium Extracted from the Lip and Rim Area of Glass Tumblers Externally Decorated with Ceramic Glass Enamels

SIGNIFICANCE AND USE

5.1 The heavy metals, lead and cadmium, are known to cause serious health effects in man if consumed in excess. It is, therefore, important to measure the amount that may be extracted from an area of the glass drinking vessel in contact with the lip. Even though the amount of lead and cadmium extracted by this test method is in no way representative of the amount of the metals extracted by actual lip contact, the relative magnitude of metals extracted from one test specimen in relation to another test specimen provides an effective tool for discrimination.

SCOPE

1.1 This test method covers the determination of lead and cadmium extracted by acetic acid from the lip and rim area of glassware used for drinking and which is exteriorly decorated with ceramic glass enamels. The procedure of extraction may be expected to accelerate the release of lead and cadmium from the decorated area and to serve, therefore, as a severe test that is unlikely to be matched under the actual conditions of usage of such glassware. This test method is specific for lead and cadmium. Note 1—For additional information see Test Method C738.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C927 − 80 (Reapproved 2014)

Standard Test Method for

Lead and Cadmium Extracted from the Lip and Rim Area of

Glass Tumblers Externally Decorated with Ceramic Glass

Enamels

This standard is issued under the fixed designation C927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 ceramic glass decorations—ceramic glass enamels

fused to glassware at temperatures above 425°C (800°F) to

1.1 This test method covers the determination of lead and

produce a decoration.

cadmium extracted by acetic acid from the lip and rim area of

3.1.2 ceramic glass enamels (also ceramic enamels or glass

glassware used for drinking and which is exteriorly decorated

enamels)—predominately colored, silicate glass fluxes used to

with ceramic glass enamels. The procedure of extraction may

decorate glassware.

beexpectedtoacceleratethereleaseofleadandcadmiumfrom

the decorated area and to serve, therefore, as a severe test that

3.1.3 lip and rim area—that part of a drinking vessel which

is unlikely to be matched under the actual conditions of usage

extends 20 mm below the rim on the outside of the specimen.

of such glassware. This test method is specific for lead and

cadmium.

4. Summary of Test Method

NOTE 1—For additional information see Test Method C738. 4.1 Lead and cadmium are extracted from the lip and rim

area of the article under test by leaching with a 4 % acetic acid

1.2 The values stated in SI units are to be regarded as

solution at 20 to 24°C (68 to 75°F) for 24 h and are measured

standard. No other units of measurement are included in this

by atomic absorption spectrophotometry using specific hollow

standard.

cathode or electrodeless discharge lamps for lead and cadmium

1.3 This standard may involve hazardous materials,

respectively. Results are reported as micrograms per millilitre

operations, and equipment. This standard does not purport to

(ppm) extracted relative to the internal volume of the glass

address all of the safety concerns associated with its use. It is

article.

the responsibility of the user of this standard to establish

appropriate safety and health practices and determine the

5. Significance and Use

applicability of regulatory limitations prior to use.

5.1 The heavy metals, lead and cadmium, are known to

2. Referenced Documents cause serious health effects in man if consumed in excess. It is,

therefore, important to measure the amount that may be

2.1 ASTM Standards:

extracted from an area of the glass drinking vessel in contact

C738 Test Method for Lead and Cadmium Extracted from

with the lip. Even though the amount of lead and cadmium

Glazed Ceramic Surfaces

extracted by this test method is in no way representative of the

amount of the metals extracted by actual lip contact, the

3. Terminology

relative magnitude of metals extracted from one test specimen

3.1 Definitions:

in relation to another test specimen provides an effective tool

for discrimination.

This test method is under the jurisdiction of ASTM Committee C14 on Glass

and Glass Products and is the direct responsibility of Subcommittee C14.10 on 6. Interferences

Glass Decoration. It was developed jointly byASTM Committee C-14 and C-21 on

6.1 Since specific hollow cathode lamps or electrodeless

Ceramic Whitewares and Related Products, the Society of Glass Decorators A-20

Subcommittee on Ceramic Enameled Decorated Glass Tumblers, and an Inter- discharge lamps for lead and cadmium are used, there are no

agency Task Force consisting of FDA, EPA, and CPSC of the U.S. Government.

interferences.

Current edition approved May 1, 2014. Published May 2014. Originally

approvedin1980.Lastpreviouseditionapprovedin2009asC927-80(2009).DOI:

7. Apparatus

10.1520/C0927-80R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 Atomic Absorption Spectrophotometer (AAS), equipped

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

with a 102-mm single slot or Boling burner head and digital

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. concentration readout attachment (DCR) if available. This

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

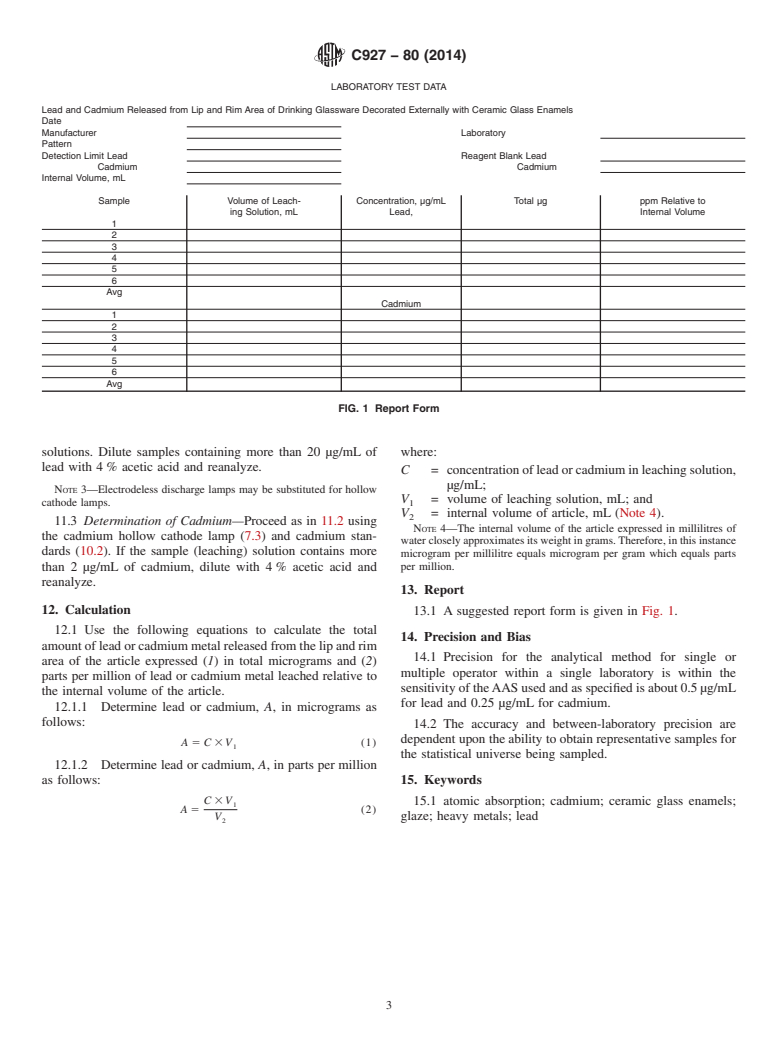

C927 − 80 (2014)

instrument should have a sensitivity of about 0.5 µg/mLof lead 9. Sampling

for 1 % absorption and a sensitivity of about 0.025 µg/mL of

9.1 Continuous Process—Since the amount of metal re-

cadmium for 1 % absorption. Use the operating conditions as

leased from a decoration can be affected by the firing

specified in the instrument manufacturer’s analytical methods

conditions, which may not be uniform across the width of the

manual.

lehr, a minimum of six samples should be taken representing

7.2 Hollow Cathode or Electrodeless Discharge Lead

both sides and the center of the lehr.

Lamp, set at 283.3 nm.

9.2 Load or Pile—A minimum of six samples should be

7.3 Hollow Cathode or Electrodeless Discharge Cadmium

randomly selected from throughout the load.

Lamp, set at 228.8 nm.

10. Preparation of Standards

7.4 Glassware of chemically resistant borosilicate glass for

use in preparing and storing reagents and solutions, and for use

10.1 Lead Standard Working Solutions—Dilute lead nitrate

as test specimen containers.

solution(8.7)withaceticacid(8.3)toobtainworkingstandards

having final lead concentrations of 0, 5, 10, 15, and 20 µg/mL.

7.5 Detection limits of lead and cadmium shall be deter-

mined and reported for individual instruments. In this test

10.2 Cadmium Standard Working Solutions—Dilute cad-

method, the detection limit shall be defined as twice the mean

mium stock solution (8.4) with acetic acid (8.3) to obtain

noise level at 0 µg/mL. Representative detection limits would

working standards having final cadmium concentrations of 0.0,

be approximately 0.01 to 0.03 µg/mL for lead and 0.0005 to

0.3, 0.5, 1, 1.5, and 2.0 µg/mL.

0.0010 µg/mL for cadmium.

10.3 Fresh working solutions should be prepared daily.

8. Reagents

11. Procedure

8.1 Purity of Reagents—Reagent grade chemicals shall be

11.1 Preparation of Sample—Take six identical units and

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit- cleanse each with a detergent rinse. Then rinse with tap water

followed by distilled water followed by air drying. Mark each

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be unit 7 mm below the rim. Record the internal volume of each

article in millilitres by filling from a graduated cylinder to

used provided it is first ascertained that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.