ASTM D2663-95a(2006)

(Test Method)Standard Test Methods for Carbon Black-Dispersion in Rubber

Standard Test Methods for Carbon Black-Dispersion in Rubber

SCOPE

1.1 These test methods determine the degree of dispersion of carbon black in rubber. Three test methods are described as follows: SectionsTest Method A-Visual InspectionTest Method B-Agglomerate CountTest Method C-Microroughness Measurement

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2663–95a (Reapproved 2006)

Standard Test Methods for

1

Carbon Black—Dispersion in Rubber

This standard is issued under the fixed designation D2663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4

1. Scope Carbon Black Dispersion Standards

5

Carbon Black Dispersion Chart

1.1 These test methods determine the degree of dispersion

of carbon black in rubber. Three test methods are described as

TEST METHOD A—VISUAL INSPECTION

follows:

Sections 3. Scope

Test Method A—Visual Inspection 3-11

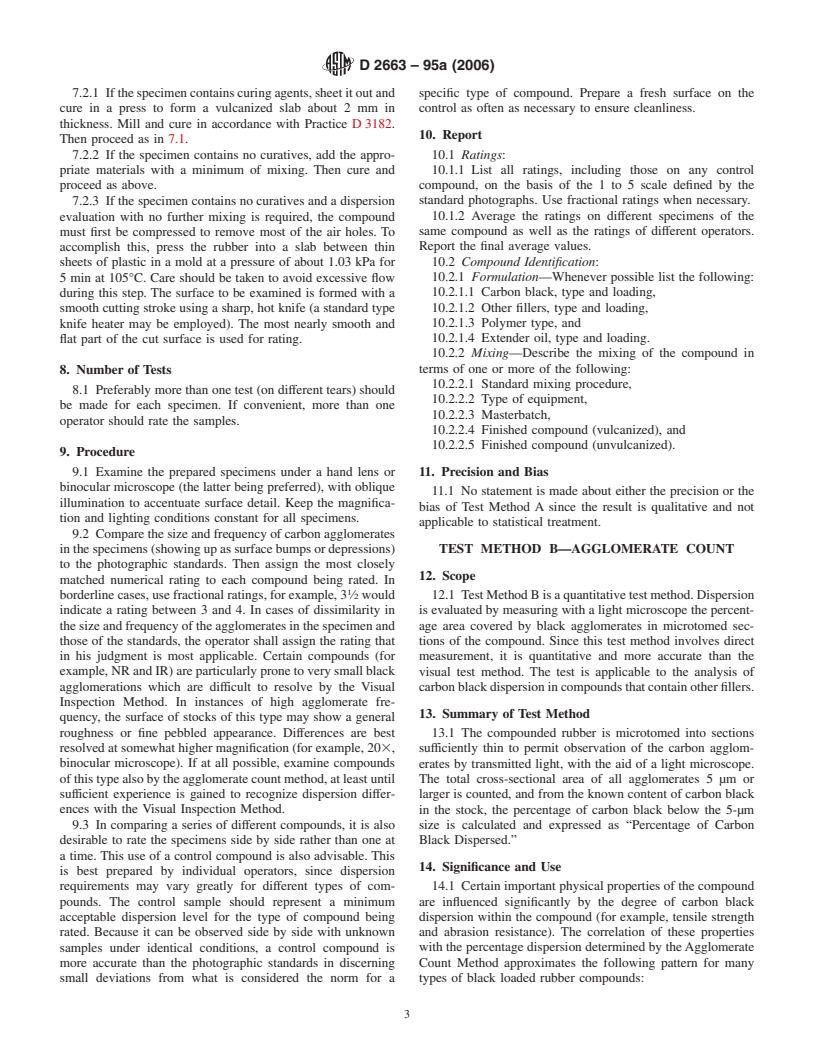

3.1 Test Method A is a qualitative visual test method.

Test Method B—Agglomerate Count 12-23

Test Method C—Microroughness Measurement 24-34 Ratings are made against a set of standard photographs (Fig.

4

1), andtheresultsareexpressedonanumericalscale.Thistest

1.2 The values stated in SI units are to be regarded as

methodcannotbeusedforcompoundsthatcontainfillersother

standard. No other units of measurement are included in this

than carbon black.

standard.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 The compound rubber is torn or cut to expose a fresh

responsibility of the user of this standard to establish appro-

surface for examination by the eye, aided preferably by a hand

priate safety and health practices and determine the applica-

lens or a low-power binocular microscope. The dispersion

bility of regulatory limitations prior to use.

level of the carbon black is compared against a series of five

2. Referenced Documents photographic standards and then rated numerically from 1

2 (very low) to 5 (high) (see Fig. 1).

2.1 ASTM Standards:

D1765 Classification System for Carbon Blacks Used in

5. Significance and Use

Rubber Products

5.1 Visual dispersion ratings correlate with certain impor-

D3051 Recommended Practice for Carbon Black—Stating

tant physical properties of the compound. A rating of 5

3

the Precision of ASTM Test Methods

indicates a state of dispersion developing near maximum

D3182 Practice for Rubber—Materials, Equipment, and

properties, while a rating of 1 would indicate a state of

Procedures for Mixing Standard Compounds and Prepar-

dispersion developing considerably depressed properties. Nor-

ing Standard Vulcanized Sheets

mally, the visual dispersion ratings indicate the following

D 3396 Recommended Practice for Carbon Black—

3 levels of compound quality:

Measuring the Precision of ASTM Test Methods

Visual Dispersion Rating Classification

D4483 Practice for Evaluating Precision for Test Method

Standards in the Rubber and Carbon Black Manufacturing

4to5 High

Industries 3 to 4 Intermediate

2to3 Low

2.2 ASTM Adjuncts:

1 to 2 Very low

6. Apparatus

6.1 Sharp Knife or Razor Blade.

6.2 Hand Lens (103)orbinocularmicroscope(10to203).

1

These test methods are under the jurisdiction of ASTM Committee D24 on

6.3 Illuminator, microscopical-type.

Carbon Black and are the direct responsibility of Subcommittee D24.71 on Carbon

Black Testing in Rubber. 6.4 Knife Heater.

Current edition approved July 15, 2006. Published August 2006. Originally

e1

approvedin1967.Lastpreviouseditionapprovedin2000asD2663–95a(2000) .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from ASTM International Headquarters. Order Adjunct No.

Standards volume information, refer to the standard’s Document Summary page on ADJD266302. Original adjunct produced in 1967.

5

the ASTM website. Available from ASTM International Headquarters. Order Adjunct No.

3

Withdrawn. ADJD266301. Original adjunct produced in 1967.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2663–95a (2006)

FIG. 1 Carbon Black Dispersion Standards—Visual Analysis of Torn Vulcanizates

6.5 Series of Photographic Standards, rating 1 to 5. These 7. Test Specimen

standards give the following percent dispersion ratings by the

7.1 Vulcanized Compounds—Use a slab of rubber about

Agglomerate Count Method:

2mm in thickness. Tear it so that a fresh surface is exposed.

Visual Rating Black Dispersed, %

The tear may be initiated by a small cut. The most nearly flat

170

280 part of the tear is used for rating.

391

7.2 Unvulcanized Compounds—Unvulcanized rubber may

496

599

be examined as follows:

2

---------------------- Page: 2 ----------------------

D2663–95a (2006)

7.2.1 Ifthespecimencontainscuringagents,sheetitoutand specific type of compound. Prepare

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.