ASTM B819-00

(Specification)Standard Specification for Seamless Copper Tube for Medical Gas Systems

Standard Specification for Seamless Copper Tube for Medical Gas Systems

SCOPE

1.1 This specification establishes the requirements for two wall thickness schedules of specially cleaned, straight lengths of seamless copper tube, identified as Types K and L, suitable for medical gas systems. The tube shall be installed in conformance with the requirements of the National Fire Protection Association (NFPA) Standard 99, Gas and Vacuum Systems (NFPA) Standard 99C, Standard for Hypobaric Facilities (NFPA) Standard 99B, and Canadian Standards Association (CSA) Standard Z 305.1/Z 7396.1, Nonflammable Medical Gas Piping Systems.

Note 1--Types K and L tube are defined in Specification B88.

Note 2--Drawn temper tube is suitable for use with capillary (solder joint) fittings for brazing.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion of Section 12 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 819 – 00

Standard Specification for

Seamless Copper Tube for Medical Gas Systems

This standard is issued under the fixed designation B819; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B280 Specification for Seamless Copper Tube for Air

Conditioning and Refrigeration Field Service

1.1 This specification establishes the rquirements for two

B601 Practice for Temper Designations for Copper and

wall thickness schedules of specially cleaned, straight lengths

Copper Alloys—Wrought and Cast

of seamless copper tube, identified as Types K and L, suitable

B846 Terminology for Copper and Copper Alloys

for medical gas systems. The tube shall be installed in

E8 TestMethodsforTensionTestingofMetallicMaterials

conformance with the requirements of the National Fire

E18 Test Methods for Rockwell Hardness and Rockwell

Protection Association (NFPA) Standard99, Gas and Vacuum

Superficial Hardness of Metallic Materials

Systems(NFPA)Standard99C,StandardforHypobaricFacili-

E29 Practice for Using Significant Digits in Test Data to

ties (NFPA) Standard 99B, and Canadian Standards Associa-

Determine Conformance with Specifications

tion (CSA) Standard Z305.1/Z7396.1, Nonflammable Medi-

E53 Methods for Chemical Analysis of Copper

cal Gas Piping Systems.

E62 Test Methods for Chemical Analysis of Copper and

NOTE 1—Types K and L tube are defined in Specification B88. 6

Copper Alloys (Photometric Methods)

NOTE 2—Drawn temper tube is suitable for use with capillary (solder

E243 Practice for Electromagnetic (Eddy-Current) Exami-

joint) fittings for brazing.

nation of Copper and Copper-Alloy Tubes

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

E255 Practice for Sampling Copper and CopperAlloys for

as standard. The values given in parentheses are mathematical

Determination of Chemical Composition

conversions to SI units, which are provided for information

E527 Practice for Numbering Metals and Alloys (UNS)

only and are not considered standard.

2.3 Other Standards:

1.3 Thefollowingsafetyhazardcaveatpertainsonlytothe

National Fire Protection Association (NFPA) 99, Gas and

test method portion of Section 12 of this specification. This

Vacuum Systems (NFPA) 99C and Standard for Hy-

standard does not purport to address all of the safety concerns,

pobaric Facilities (NFPA) 99B

if any, associated with its use. It is the responsibility of the user

Compressed Gas Association (CGA) G-4.1, Cleaning

of this standard to establish appropriate safety and health

Equipment for Oxygen Service

practices and determine the applicability of regulatory limita-

Canadian Standards Association (CSA) Z305.1/Z7396.1,

tions prior to use.

Nonflammable Medical Gas Piping Systems

2. Referenced Documents

3. Terminology

2.1 The following documents in the current issue of the

3.1 For definitions of terms related to copper and copper

Book of Standards in effect on date of material purchase form

alloys, refer to Terminology B846.

a part of this specification to the extent referenced herein:

3.2 Definitions of Terms Specific to This Standard:

2.2 ASTM Standards:

3.2.1 lengths—straight pieces of the product.

B88 Specification for Seamless Copper Water Tube

3.2.2 standard—uniform lengths established as commercial

B251 Specification for General Requirements for Wrought

standards.

Seamless Copper and Copper-Alloy Tube

Annual Book of ASTM Standards, Vol 03.01.

1 5

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper Annual Book of ASTM Standards, Vol 14.02.

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe Annual Book of ASTM Standards, Vol 03.05.

and Tube. Annual Book of ASTM Standards, Vol 03.03.

Current edition approved Sept. 10, 2000. Published November 2000. Originally Annual Book of ASTM Standards, Vol 01.01.

published as B819–92. Last previous edition B819–95. Available from National Fire Protection Association, Batterymarch Park,

The UNS system for copper and copper alloys (see Practice E527) is a simple Quincy, MA 02269.

expansion of the former standard system accomplished by the addition of a prefix Available from Compressed Gas Association Inc., 1725 Jefferson Davis

“C”andasuffix“00”.Thesuffixcanbeusedtoaccommodatecompositionvariation Highway, Suite 1004, Arlington, VA 22202–4102.

of the base alloy. Available from Canadian StandardsAssociation, 178 Rexdale Blvd., Rexdale,

Annual Book of ASTM Standards, Vol 02.01. Ontario, Canada M9W 1R3.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 819

3.2.3 tube, copper water—aseamlesscoppertubeconform- 6. Chemical Composition

ing to the particular dimensions commercially known as

6.1 The material shall conform to the following chemical

CopperWaterTubeanddesignatedasTypesKandL(seeTable

requirements of Copper UNS No. C12200:

1).

Copper (incl silver), % 99.9 minimum

3.2.4 tube, seamless—a tube produced with a continuous

Phosphorous, % 0.015 to 0.040

periphery in all stages of the operations.

6.2 These specification limits do not preclude the presence

of other elements. Limits for unnamed elements may be

4. Ordering Information

establishedbyagreementbetweenthemanufacturerorsupplier

4.1 Ordersformaterialunderthisspecificationshallinclude

and the purchaser.

the following information:

4.1.1 Specification B819–00.

7. Temper

4.1.2 Nominal or standard size (Column 1 of Table 1) and

7.1 Seamless copper tube for medical gas systems shall be

whether Type K or L (Sections 3 and 10),

furnished in the H58 (Drawn General Purpose) temper, as

4.1.3 Temper (Sections 7 and 8),

defined in Practice B601.

4.1.4 Length (see 10.5),

4.1.5 Quantity (pieces) of each size and type,

4.2 The following options are available and should be

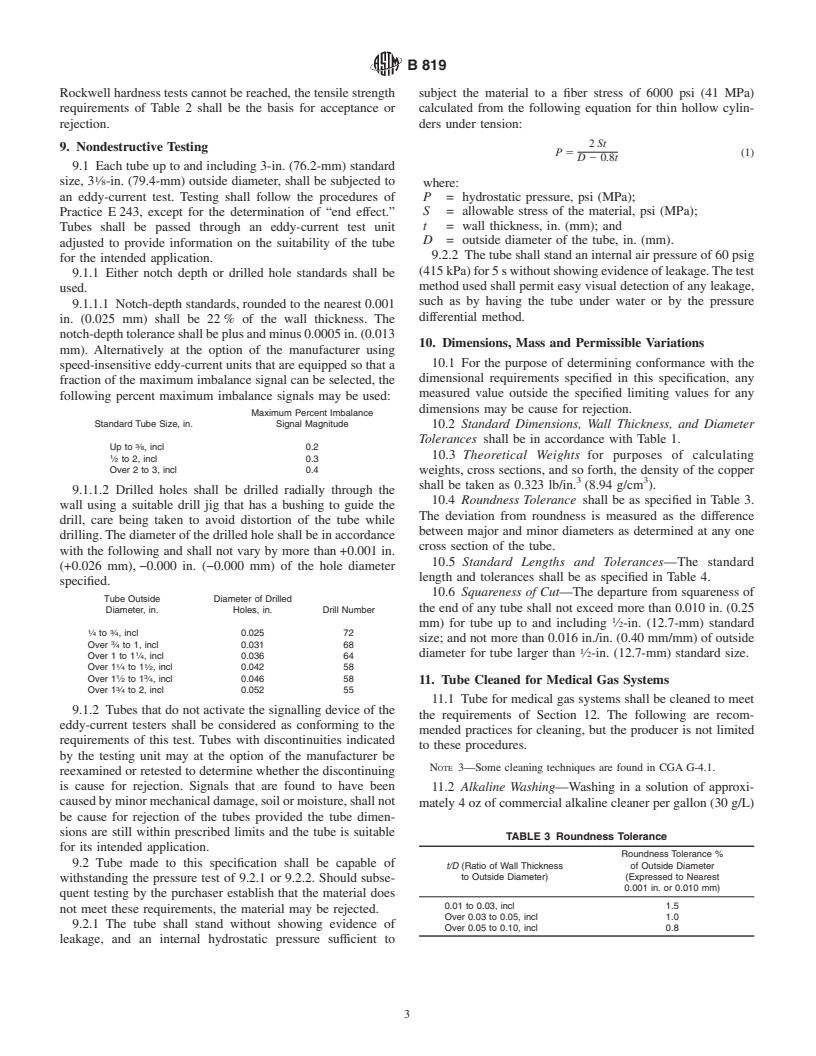

TABLE 2 Mechanical Properties

specified at the time of placing the order when required.

A

Temper Designation Rockwell Hardness Tensile Strength

4.2.1 Whethertensiontestdeterminationsarerequired(Sec-

Form

B C

Standard Former Scale Value min, ksi (MPa)

tion 8),

H58 drawn straight 30T 30 min 36 (250)

4.2.2 Whether the tube shall be charged with dry, oil-free general lengths

purpose

nitrogen during capping, closing, or plugging (see 11.8),

A

Rockwell hardness tests shall be made on the inside surfaces of the tube.

4.2.3 Certification, if required (see Section 20), and

When suitable equipment is not available for determining the specified Rockwell

4.2.4 Mill Test Report, if required, (see Section 21).

hardness, other Rockwell scales and values may be specified subject to between

4.2.5 Inaddition,whenmaterialispurchasedforagenciesof the purchaser and the supplier.

B

ksi = 1000 psi.

the U.S. Government, it shall conform to the Supplementary

C 6

MPa = pascal 3 10 .

Requirements as defined herein when specified in the contract

or purchase order.

5. Materials and Manufacture 8. Mechanical Properties

5.1 Material—The materials of manufacture shall be a cast 8.1 The tube shall conform to the mechanical property

billet of Copper Alloy UNS C12200 of such purity and requirements specified in Table 2 when tested in accordance

soundness as to be suitable for processing into the products with Test Methods E18 and E8, respectively. Tension test

prescribed herein. determinationsneednotbemadeexceptwhenindicatedbythe

5.2 Manufacture—The product shall be manufactured by purchaseratthetimeofplacingtheorder.Aconvenientmethod

such hot working necessary to convert the billet to a tubular ofindicatingthatthesetestsaretobemadeistostatethat“Test

shape and cold worked to the finished size. Procedure T” is required (see 4.2.1). Where agreement on the

TABLE 1 Dimensions, Mass, and Tolerances in Diameter and Wall Thickness for Nominal or Standard Copper Water Tube Sizes.

(All tolerances are plus and minus except as otherwise indicated)

Nominal Average

Wall Thickness and Tolerances, in.

or Outside Outside

A

Standard Diameter, Diameter Type K Type L Theoretical Mass, lb/ft (kg/m)

Size. in. (mm) Tolerances,

Wall Thickness Wall Tolerance Thickness Tolerance Type K Type L

in. in. (mm)

⁄4 0.375 (9.52) 0.001 (0.025) 0.035 (0.889) 0.0035 (0.089) 0.030 (0.762) 0.003 (0.076) 0.145 (0.216) 0.126 (0.187)

⁄8 0.500 (12.7) 0.001 (0.025) 0.049 (1.24) 0.005 (0.13) 0.035 (0.889) 0.004 (0.10) 0.269 (0.400) 0.198 (0.295)

⁄2 0.625 (15.9) 0.001 (0.025) 0.049 (1.24) 0.005 (0.13) 0.040 (1.02) 0.004 (0.10) 0.344 (0.512) 0.285 (0.424)

⁄8 0.750 (19.1) 0.001 (0.025) 0.049 (1.24) 0.005 (0.13) 0.042 (1.07) 0.004 (0.10) 0.418 (0.622) 0.362 (0.539)

⁄4 0.875 (22.3) 0.001 (0.025) 0.065 (1.65) 0.006 (0.15) 0.045 (1.14) 0.004 (0.10) 0.641 (0.954) 0.455 (0.677)

1 1.125 (28.6) 0.0015 (0.038) 0.065 (1.65) 0.006 (0.15) 0.050 (1.27) 0.005 (0.13) 0.839 (1.25) 0.655 (0.975)

1 ⁄4 1.375 (34.9) 0.0015 (0.038) 0.065 (1.65) 0.006 (0.15) 0.055 (1.40) 0.006 (0.15) 1.040 (1.55) 0.884 (1.32)

1 ⁄2 1.625 (41.3) 0.002 (0.051) 0.072 (1.83) 0.007 (0.18) 0.060 (1.52) 0.006 (0.15) 1.360 (2.02) 1.140 (1.70)

2 2.125 (54.0) 0.002 (0.051) 0.083 (2.11) 0.008 (0.20) 0.070 (1.78) 0.007 (0.18) 2.060 (3.07) 1.750 (2.60)

2 ⁄2 2.625 (66.7) 0.002 (0.051) 0.095 (2.41) 0.010 (0.25) 0.080 (2.03) 0.008 (0.20) 2.930 (4.36) 2.480 (3.69)

3 3.125 (79.4) 0.002 (0.510) 0.109 (2.77) 0.011 (0.28) 0.090 (2.29) 0.009 (0.23) 4.000 (5.95) 3.330 (4.96)

3 ⁄2 3.625 (92.1) 0.002 (0.051) 0.120 (3.05) 0.012 (0.30) 0.100 (2.54) 0.010 (0.25) 5.120 (7.62) 4.290 (6.38)

4 4.125 (105) 0.002 (0.051) 0.134 (3.40) 0.013 (0.33) 0.110 (2.79) 0.011 (0.28) 6.510 (9.69) 5.380 (8.01)

5 5.125 (130) 0.002 (0.051) 0.160 (4.06) 0.016 (0.41) 0.125 (3.18) 0.012 (0.30) 9.670 (14.4) 7.610 (11.3)

6 6.125 (156) 0.002 (0.051) 0.192 (4.88) 0.019 (0.48) 0.140 (3.56) 0.014 (0.36) 13.900 (20.7) 10.200 (15.2)

8 8.125 (206) +0.002 (0.051) 0.271 (6.88) 0.027 (0.69) 0.200 (5.08) 0.020 (0.51) 25.900 (38.5) 19.300 (28.7)

H

−0.006 (0.150)

A

The average outside diameter of a tube is the average of the maximum and minimum outside diameter, as determined at any one cross section of the tube.

B 819

Rockwellhardnesstestscannotbereached,thetensilestrength subject the material to a fiber stress of 6000 psi (41 MPa)

requirements of Table 2 shall be the basis for acceptance or calculated from the following equation for thin hollow cylin-

rejection. ders under tension:

2 St

9. Nondestructive Testing

P 5 (1)

D 20.8t

9.1 Each tube up to and including 3-in. (76.2-mm) standard

size, 3 ⁄8-in. (79.4-mm) outside diameter, shall be subjected to where:

an eddy-current test. Testing shall follow the procedures of P = hydrostatic pressure, psi (MPa);

Practice E243, except for the determination of “end effect.” S = allowable stress of the material, psi (MPa);

t = wall thickness, in. (mm); and

Tubes shall be passed through an eddy-current test unit

D = outside diameter of the tube, in. (mm).

adjusted to provide information on the suitability of the tube

9.2.2 Thetubeshallstandaninternalairpressureof60psig

for the intended application.

(415kPa)for5swithoutshowingevidenceofleakage.Thetest

9.1.1 Either notch depth or drilled hole standards shall be

method used shall permit easy visual detection of any leakage,

used.

such as by having the tube under water or by the pressure

9.1.1.1 Notch-depth standards, rounded to the nearest 0.001

differential method.

in. (0.025 mm) shall be 22% of the wall thickness. The

notch-depthtoleranceshallbeplusandminus0.0005in.(0.013

10. Dimensions, Mass and Permissible Variations

mm). Alternatively at the option of the manufacturer using

10.1 For the purpose of determining conformance with the

speed-insensitiveeddy-currentunitsthatareequippedsothata

dimensional requirements specified in this specification, any

fraction of the maximum imbalance signal can be selected, the

measured value outside the specified limiting values for any

following percent maximum imbalance signals may be used:

dimensions may be cause for rejection.

Maximum Percent Imbalance

Standard Tube Size, in. Signal Magnitude 10.2 Standard Dimensions, Wall Thickness, and Diameter

Tolerances shall be in accordance with Table 1.

Up to ⁄8, incl 0.2

10.3 Theoretical Weights for purposes of calculating

⁄2 to 2, incl 0.3

Over 2 to 3, incl 0.4

weights, cross sections, and so forth, the density of the copper

3 3

shall be taken as 0.323 lb/in. (8.94 g/cm ).

9.1.1.2 Drilled holes shall be drilled radially through the

10.4 Roundness Tolerance shall be as specified in Table 3.

wall using a suitable drill jig that has a bushing to guide the

The deviation from roundness is measured as the difference

drill, care being taken to avoid distortion of the tube while

between major and minor diameters as determined at any one

drilling.Thediameterofthedrilledholeshallbeinaccordance

cross section of the tube.

with the following and shall not vary by more than+0.001 in.

10.5 Standard Lengths and Tolerances—The standard

(+0.026 mm),−0.000 in. (−0.000 mm) of the hole diameter

length and tolerances shall be as specified in Table 4.

specified.

10.6 Squareness of Cut—The departure from squareness of

Tube Outside Diameter of Drilled

the end of any tube shall not exceed more than 0.010 in. (0.25

Diameter, in. Holes, in. Drill Number

mm) for tube up to and including ⁄2-in. (12.7-mm) standard

1 3

⁄4 to ⁄4, incl 0.025 72

size; and not more than 0.016 in./in. (0.40 mm/mm) of outside

Over ⁄4 to 1, incl 0.031 68

diameter for tube larger than ⁄2-in. (12.7-mm) standard size.

Over 1 to 1 ⁄4, incl 0.036 64

1 1

Over 1 ⁄4 to 1 ⁄2, incl 0.042 58

1 3

Over 1 ⁄2 to 1 ⁄4, incl 0.046 58

11. Tube Cleaned for Medical Gas Systems

Over 1 ⁄4 to 2, incl 0.052 55

11.1 Tube for medical gas systems shall be cleaned to meet

9.1.2 Tubes that do not activate the signalling device of the

the requirements of Section 12. The following are recom-

eddy-current testers shall be considered as conforming to the

mended practices for cleaning, but the producer is not limited

requirements of this test. Tubes with discontinuities indicated

to these procedures.

by the testing unit may at the option of the manufacturer be

NOTE 3—Some cleaning techniques are found in CGA G-4.1.

reexamined or retested to determine whether the discontinuing

is cause for rejection. Signals that are found to have been

11.2 Alkaline Washing—Washing in a solution of approxi-

causedbyminormechanicaldamage,soilormoisture,shallnot mately4ozofcommercialalkalinecleanerpergallon(30g/L)

be cause for rejection of the tubes provided the tube dimen-

sions are still within prescribed limits and the tube is suitable

TABLE 3 Round

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.