ASTM C1074-10

(Practice)Standard Practice for Estimating Concrete Strength by the Maturity Method

Standard Practice for Estimating Concrete Strength by the Maturity Method

SIGNIFICANCE AND USE

This practice can be used to estimate the in-place strength of concrete to allow the start of critical construction activities such as: (1) removal of formwork and reshoring; (2) post-tensioning of tendons; (3) termination of cold weather protection; and (4) opening of roadways to traffic.

This practice can be used to estimate strength of laboratory specimens cured under non-standard temperature conditions.

The major limitations of the maturity method are: (1) the concrete must be maintained in a condition that permits cement hydration; (2) the method does not take into account the effects of early-age concrete temperature on the long-term strength; and (3) the method needs to be supplemented by other indications of the potential strength of the concrete mixture.

The accuracy of the estimated strength depends, in part, on using the appropriate maturity function for the particular concrete mixture. Annex A1 provides a procedure for determining experimentally the best parameters (datum temperature or value of Q) for the maturity functions described in Section 6.

SCOPE

1.1 This practice provides a procedure for estimating concrete strength by means of the maturity method. The maturity index is expressed either in terms of the temperature-time factor or in terms of the equivalent age at a specified temperature.

1.2 This practice requires establishing the strength-maturity relationship of the concrete mixture in the laboratory and recording the temperature history of the concrete for which strength is to be estimated.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure. )

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1074–10

Standard Practice for

Estimating Concrete Strength

1

by the Maturity Method

This standard is issued under the fixed designation C1074; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Specimens)

1.1 This practice provides a procedure for estimating con-

C192/C192M Practice for Making and Curing Concrete

crete strength by means of the maturity method. The maturity

Test Specimens in the Laboratory

index is expressed either in terms of the temperature-time

C403/C403M Test Method for Time of Setting of Concrete

factor or in terms of the equivalent age at a specified tempera-

Mixtures by Penetration Resistance

ture.

C511 Specification for Mixing Rooms, Moist Cabinets,

1.2 This practice requires establishing the strength-maturity

Moist Rooms, and Water Storage Tanks Used in the

relationship of the concrete mixture in the laboratory and

Testing of Hydraulic Cements and Concretes

recording the temperature history of the concrete for which

C684 Test Method for Making, Accelerated Curing, and

strength is to be estimated.

Testing Concrete Compression Test Specimens

1.3 The values stated in SI units are to be regarded as

C803/C803M Test Method for Penetration Resistance of

standard. No other units of measurement are included in this

Hardened Concrete

standard.

C873/C873M Test Method for Compressive Strength of

1.4 This standard does not purport to address all of the

Concrete Cylinders Cast in Place in Cylindrical Molds

safety concerns, if any, associated with its use. It is the

C900 Test Method for Pullout Strength of Hardened Con-

responsibility of the user of this standard to establish appro-

crete

priate safety and health practices and determine the applica-

C918/C918M Test Method for Measuring Early-Age Com-

bility of regulatory limitations prior to use. (Warning—Fresh

pressive Strength and Projecting Later-Age Strength

hydraulic cementitious mixtures are caustic and may cause

2

chemical burns to skin and tissue upon prolonged exposure. )

3. Terminology

2. Referenced Documents 3.1 Definitions of Terms Specific to This Standard:

3

3.1.1 datum temperature—thetemperaturethatissubtracted

2.1 ASTM Standards:

from the measured concrete temperature for calculating the

C39/C39M Test Method for Compressive Strength of Cy-

temperature-time factor according to Eq 1.

lindrical Concrete Specimens

3.1.2 equivalent age—the number of days or hours at a

C78 Test Method for Flexural Strength of Concrete (Using

specified temperature required to produce a maturity equal to

Simple Beam with Third-Point Loading)

the maturity achieved by a curing period at temperatures

C109/C109M Test Method for Compressive Strength of

different from the specified temperature.

3.1.3 maturity—the extent of the development of a property

of a cementitious mixture.

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

3.1.3.1 Discussion—While the term is used usually to

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.64on

Nondestructive and In-Place Testing.

describe the extent of relative strength development, it can also

Current edition approved June 15, 2010. Published July 2010. Originally

be applied to the evolution of other properties that are

approved in 1987. Last previous edition approved in 2004 as C1074–04. DOI:

dependent on the chemical reactions that occur in a cementi-

10.1520/C1074-10.

2

tious mixture. At any age, maturity depends on the curing

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

Annual Book of ASTM Standards, Vol 04.02.

history.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.4 maturity function—a mathematical expression that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

uses the measured temperature history of a cementitious

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mixture during the curing period to calculate an index that is

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

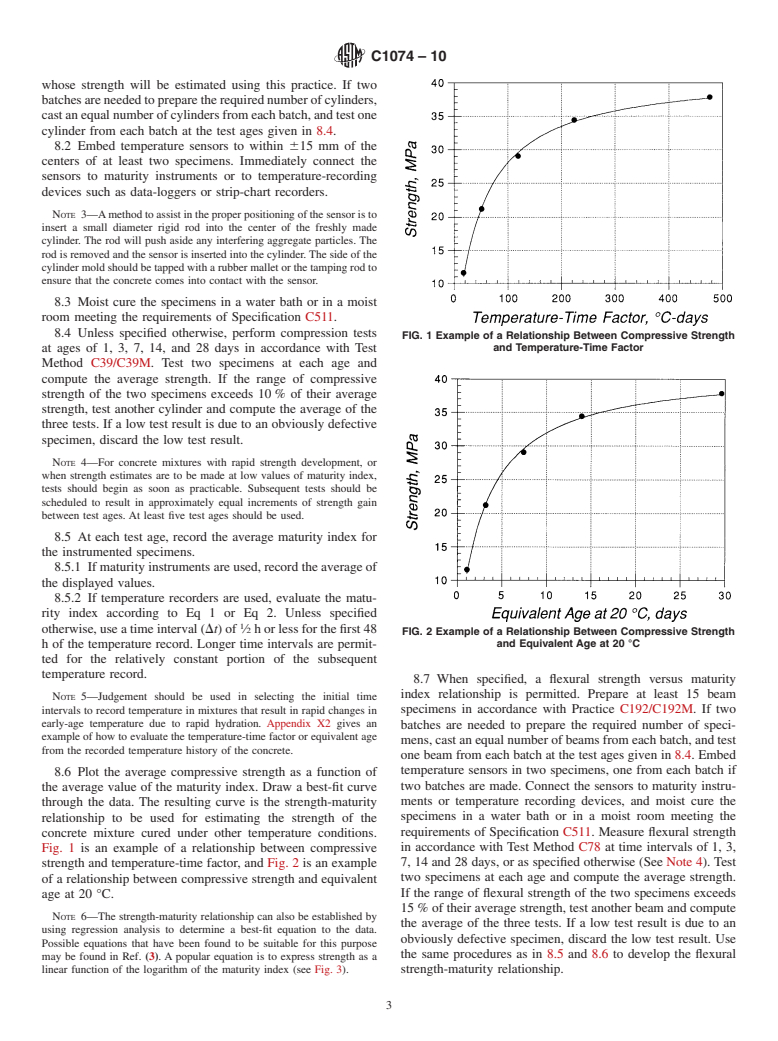

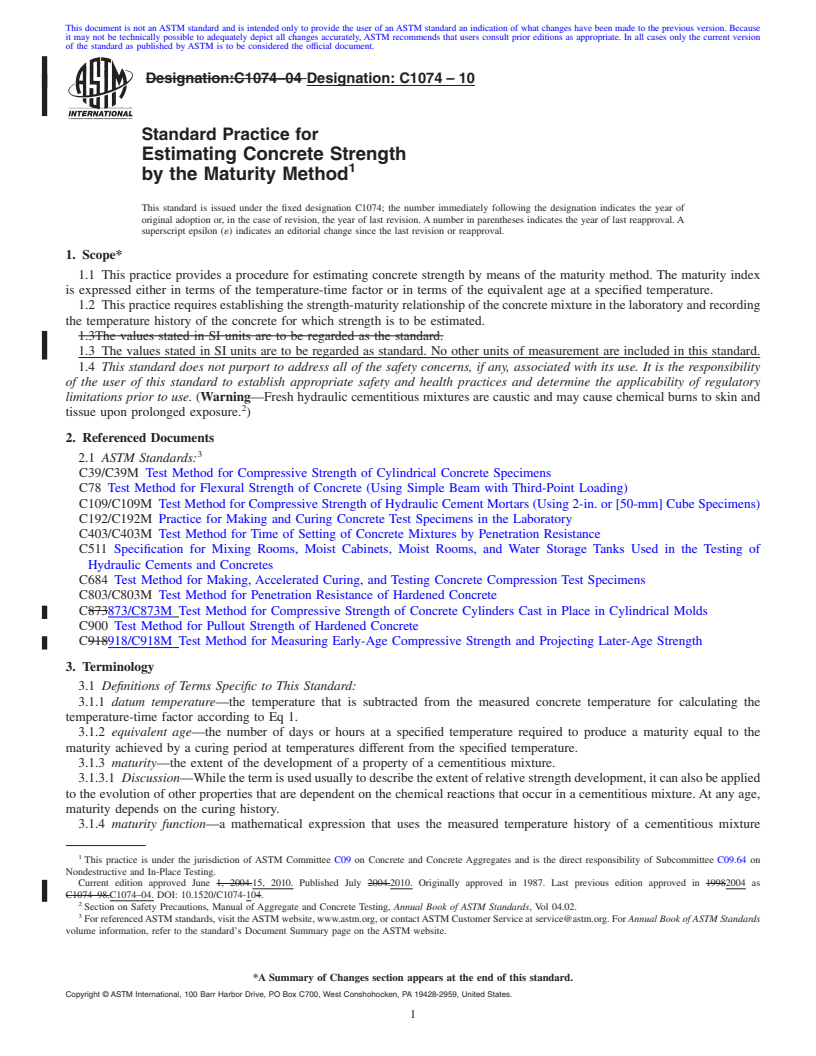

C1074–10

indicative of the maturity at the end of that period. Refer to 6. Maturity Functions

Appendix X1 for additional discussion of this term.

6.1 There are two alternative functions for computing the

3.1.5 maturity index—an indicator of maturity that is calcu-

maturity index from the measured temperat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1074–04 Designation:C1074–10

Standard Practice for

Estimating Concrete Strength

1

by the Maturity Method

This standard is issued under the fixed designation C1074; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice provides a procedure for estimating concrete strength by means of the maturity method. The maturity index

is expressed either in terms of the temperature-time factor or in terms of the equivalent age at a specified temperature.

1.2 This practice requires establishing the strength-maturity relationship of the concrete mixture in the laboratory and recording

the temperature history of the concrete for which strength is to be estimated.

1.3The values stated in SI units are to be regarded as the standard.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and

2

tissue upon prolonged exposure. )

2. Referenced Documents

3

2.1 ASTM Standards:

C39/C39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C78 Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C403/C403M Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C684 Test Method for Making, Accelerated Curing, and Testing Concrete Compression Test Specimens

C803/C803M Test Method for Penetration Resistance of Hardened Concrete

C873873/C873M Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds

C900 Test Method for Pullout Strength of Hardened Concrete

C918918/C918M Test Method for Measuring Early-Age Compressive Strength and Projecting Later-Age Strength

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 datum temperature—the temperature that is subtracted from the measured concrete temperature for calculating the

temperature-time factor according to Eq 1.

3.1.2 equivalent age—the number of days or hours at a specified temperature required to produce a maturity equal to the

maturity achieved by a curing period at temperatures different from the specified temperature.

3.1.3 maturity—the extent of the development of a property of a cementitious mixture.

3.1.3.1 Discussion—Whilethetermisusedusuallytodescribetheextentofrelativestrengthdevelopment,itcanalsobeapplied

to the evolution of other properties that are dependent on the chemical reactions that occur in a cementitious mixture.At any age,

maturity depends on the curing history.

3.1.4 maturity function—a mathematical expression that uses the measured temperature history of a cementitious mixture

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.64 on

Nondestructive and In-Place Testing.

Current edition approved June 1, 2004.15, 2010. Published July 2004.2010. Originally approved in 1987. Last previous edition approved in 19982004 as

C1074–98.C1074–04. DOI: 10.1520/C1074-104.

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, Vol 04.02.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.