ASTM G30-97

(Practice)Standard Practice for Making and Using U-Bend Stress-Corrosion Test Specimens

Standard Practice for Making and Using U-Bend Stress-Corrosion Test Specimens

SCOPE

1.1 This practice describes procedures for making and using U-bend specimens for the evaluation of stress-corrosion cracking in metals. The U-bend specimen is generally a rectangular strip which is bent 180° around a predetermined radius and maintained in this constant strain condition during the stress-corrosion test. Bends slightly less than or greater than 180° are sometimes used. Typical U-bend configurations showing several different methods of maintaining the applied stress are shown in Fig. 1.

1.2 U-bend specimens usually contain both elastic and plastic strain. In some cases (for example, very thin sheet or small diameter wire) it is possible to form a U-bend and produce only elastic strain. However, bent-beam (Practice G39 or direct tension (Practice G49)) specimens are normally used to study stress-corrosion cracking of strip or sheet under elastic strain only.

1.3 This practice is concerned only with the test specimen and not the environmental aspects of stress-corrosion testing which are discussed elsewhere (1), in Practices G35, G36, G37, G41, and G44, and Test Method G103.

1.4 The values stated in SI units are to be regarded as standard. The inch-pound units in parentheses are provided for information.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety hazard information see Section 9.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: G 30 – 97

Standard Practice for

Making and Using U-Bend Stress-Corrosion Test

Specimens

This standard is issued under the fixed designation G 30; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G 15 Terminology Relating to Corrosion and Corrosion

Testing

1.1 This practice describes procedures for making and using

G 35 Practice for Determining the Susceptibility of Stain-

U-bend specimens for the evaluation of stress-corrosion crack-

less Steels and Related Nickel-Chromium-Iron Alloys to

ing in metals. The U-bend specimen is generally a rectangular

Stress Corrosion Cracking in Polythionic Acids

strip which is bent 180° around a predetermined radius and

G 36 Practice for Evaluating Stress-Corrosion Cracking

maintained in this constant strain condition during the stress-

Resistance of Metals and Alloys in a Boiling Magnesium

corrosion test. Bends slightly less than or greater than 180° are

Chloride Solution

sometimes used. Typical U-bend configurations showing sev-

G 37 Practice for Use of Mattsson’s Solution of pH 7.2 to

eral different methods of maintaining the applied stress are

Evaluate the Stress-Corrosion Cracking Susceptibility of

shown in Fig. 1.

Copper-Zinc Alloys

1.2 U-bend specimens usually contain both elastic and

G 39 Practice for Preparation and Use of Bent-Beam Stress-

plastic strain. In some cases (for example, very thin sheet or

Corrosion Specimens

small diameter wire) it is possible to form a U-bend and

G 41 Practice for Determining Cracking Susceptibility of

produce only elastic strain. However, bent-beam (Practice G 39

Metals Exposed Under Stress to a Hot Salt Environment

or direct tension (Practice G 49)) specimens are normally used

G 44 Practice for Evaluating Stress Corrosion Cracking

to study stress-corrosion cracking of strip or sheet under elastic

Resistance of Metals and Alloys by Alternate Immersion in

strain only.

3.5 % Sodium Chloride Solution

1.3 This practice is concerned only with the test specimen

G 49 Practice for Preparation and Use of Direct Tension

and not the environmental aspects of stress-corrosion testing

Stress-Corrosion Test Specimens

which are discussed elsewhere (1), in Practices G 35, G 36,

G 103 Practice for Performing a Stress-Corrosion Cracking

G 37, G 41, G 44, G 103 and Test Method G 123.

Test of Low Copper Containing Al-Zn-Mg Alloys in

1.4 The values stated in SI units are to be regarded as

Boiling 6 % Sodium Chloride Solution

standard. The inch-pound units in parentheses are provided for

G 123 Test Method for Evaluating Stress-Corrosion Crack-

information.

ing of Stainless Alloys with Different Nickel Content in a

1.5 This standard does not purport to address all of the

Boiling Acidified Sodium Chloride Solution

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 For definitions of corrosion-related terms used in this

bility of regulatory limitations prior to use. (For more specific

practice see Terminology G 15.

safety hazard information see Section 10.)

4. Summary of Practice

2. Referenced Documents

4.1 This practice involves the stressing of a specimen bent

2.1 ASTM Standards:

3 to a U shape. The applied strain is estimated from the bend

E 3 Methods of Preparation of Metallographic Specimens

conditions. The stressed specimens are then exposed to the test

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

3 environment and the time required for cracks to develop is

rosion Test Specimens

determined. This cracking time is used as an estimate of the

stress corrosion resistance of the material in the test environ-

ment.

This practice is under the jurisdiction of ASTM Committee G-1 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.06on Stress-

Corrosion Cracking and Corrosion Fatigue. 5. Significance and Use

Current edition approved April 10, 1997. Published February 1998. Originally

5.1 The U-bend specimen may be used for any metal alloy

published as G 30 – 72. Last previous edition G 30 – 94.

The boldface numbers in parentheses refer to the list of references at the end of

this practice.

3 4

Annual Book of ASTM Standards, Vol 03.01. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G30

FIG. 1 Typical Stressed U-bends

sufficiently ductile to be formed into the U-shape without tested; however, the bulk sampling of mill products is outside

mechanically cracking. The specimen is most easily made from the scope of this standard.

strip or sheet but can be machined from plate, bar, castings, or 7.2 In performing tests to simulate a service condition it is

weldments; wire specimens may be used also. essential that the thickness of the test specimen, its orientation

5.2 Since the U-bend usually contains large amounts of with respect to the direction of metal working and the surface

elastic and plastic strain, it provides one of the most severe finish, etc., be relevant to the anticipated application.

tests available for smooth (as opposed to notched or pre-

8. Test Specimen

cracked) stress-corrosion test specimens. The stress conditions

8.1 Specimen Orientation—When specimens are cut from

are not usually known and a wide range of stresses exist in a

sheet or plate and in some cases strip or bar, it is possible to cut

single stressed specimen. The specimen is therefore unsuitable

them transverse or longitudinal to the direction of rolling. In

for studying the effects of different applied stresses on stress-

many cases the stress-corrosion cracking resistance in these

corrosion cracking or for studying variables which have only a

two directions is quite different so it is important to define the

minor effect on cracking. The advantage of the U-bend

orientation of the test specimen.

specimen is that it is simple and economical to make and use.

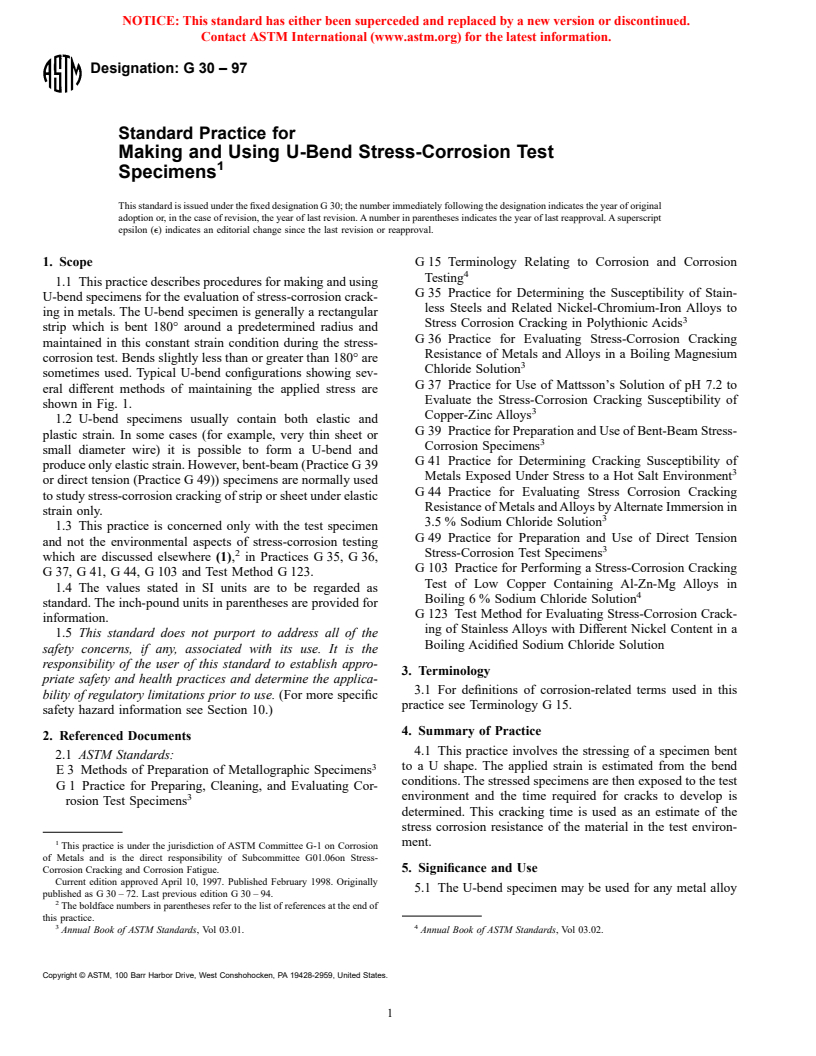

8.2 Specimen Dimensions—Fig. 2 shows a typical test

It is most useful for detecting large differences between the

specimen and lists, by way of example, several dimension

stress-corrosion cracking resistance of (a) different metals in

combinations that have been used successfully to test a wide

the same environment, (b) one metal in different metallurgical

range of materials. Other dimensional characteristics may be

conditions in the same environment, or (c) one metal in several

used as necessary. For example, some special types of U-bend

environments.

configuration have been used for simulating exposure condi-

6. Hazards

tions encountered in high temperature water environments

relative to the nuclear power industry. These include double

6.1 U-bends made from high strength material may be

U-bend (2) and split tube U-bend (or reverse U-bend) (3)

susceptible to high rates of crack propagation and a specimen

specimens.

containing more than one crack may splinter into two or more

8.2.1 Whether or not the specimen contains holes is depen-

pieces. Due to the highly stressed condition in a U-bend

dent upon the method of maintaining the applied stress (see

specimen, these pieces may leave the specimen at high velocity

Fig. 1).

and can be dangerous.

8.2.2 The length (L) and width (W) of the specimen are

7. Sampling

determined by the amount and form of the material available,

7.1 Specimens shall be taken from a location in the bulk the stressing method used, and the size of the test environment

sample so that they are representative of the material to be container.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G30

Examples of Typical Dimensions (SI Units)

Example L, mm M, mm W, mm T, mm D, mm X, mm Y, mm R, mm a, rad

a 80 50 20 2.5 10 32 14 5 1.57

b 100 90 9 3.0 7 25 38 16 1.57

c 120 90 20 1.5 8 35 35 16 1.57

d 130 100 15 3.0 6 45 32 13 1.57

e 150 140 15 0.8 3 61 20 9 1.57

f 310 250 25 13.0 13 105 90 32 1.57

g 510 460 25 6.5 13 136 165 76 1.57

h 102 83 19 3.2 9.6 40 16 4.8 1.57

FIG. 2 Typical U-Bend Specimen Dimensions (Examples only, not for specification.)

8.2.3 The thickness (T) is usually dependent upon the form dissolution, care must be taken to ensure that the solution used

of the material, its strength and ductility, and the means does not induce hydrogen embrittlement, selectively attack

available to perform the bending. For example, it is difficult to constituents in the metal, or leave undesirable residues on the

manually form U-bends of thickness greater than approxi- surface.

mately 3 mm (0.125 in.) if the yield strength exceeds about 8.3.5 It may be desirable to test a surface (for example, cold

1400 MPa (200 ksi). rolled or cold rolled, annealed, and pickled) without surface

8.2.4 For comparison purposes, it is desirable to keep the metal removal. In such cases the edges of the specimen should

specimen dimensions, especially the ratio of thickness to bend be milled. Sheared edges should be avoided in all cases.

radius, constant. This produces approximately the same maxi- 8.3.6 The final stage of surface preparation is degreasing.

mum strain in the materials being compared (see 9.3). How- Depending upon the method of stressing, this may be done

ever, it does not necessarily provide tests of equal severity if before or after stressing.

the mechanical properties of the materials being compared are 8.4 Identification of the specimen is best achieved by

widely different. stamping or scribing near one of the ends of the test specimen,

8.2.5 When wire is to be evaluated, the specimen is simply well away from the area to be stressed. Alternatively, nonme-

a wire of a length suitable for the restraining jig. It may be tallic tags may be attached to the bolt or fixture used to

desirable to loop the wire rather than use just a simple U-shape maintain the specimen in a stressed condition during the test.

(4).

9. Stress Considerations

8.3 Surface Finish:

8.3.1 Any necessary heat treatment should be performed 9.1 The stress of principal interest in the U-bend specimen

before the final surface preparation. is circumferential. It is nonuniform because (a) there is a stress

gradient through the thickness varying from a maximum

8.3.2 Surface preparation is generally a mechanical process

but in some cases it may be more convenient and acceptable to tension on the outer surface to a maximum compression on the

inner surface, (b) the stress varies from zero at the ends of the

chemically finish (see 8.3.4).

8.3.3 Grinding or machining should be done in stages so specimen to a maximum at the center of the bend, and (c) the

that the final cut leaves the surface with a finish of 0.76 μm (30 stress may vary across the width of the bend. The stress

μin.) or better. Care must be taken to avoid excessive heating distribution has been studied (5).

during preparation because this may induce undesirable re- 9.2 When a U-bend specimen is stressed, the material in the

sidual stresses and in some cases cause metallurgical or outer fibers of the bend is strained into the plastic portion of the

chemical changes, or both, at the surface. The edges of the true stress-true strain curve; for example, into Section AB in

specimen should receive the same finish as the faces. Fig. 3(a). Fig. 3(b–e) show several stress-strain relationships

8.3.4 When the final surface preparation involves chemical that can exist in the outer fibers of the U-bend test specimen;

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G30

FIG. 3 True Stress-True Strain Relationships for Stressed U-Bends

the actual relationship obtained will depend upon the method of stressing (see Section 10). For the conditions shown in Fig.

FIG. 4 Methods of Stressing U-Bend Specimens—Single-Stage Stressing

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G30

3(d), a quantitative measure of the maximum test stress can be U-bend legs to spring back slightly at the end of the stressing

made (6). sequence.

9.3 The total strain (e) on the outside of the bend can be

10.3 Two-stage stressing involves first forming the approxi-

closely approximated to the equation:

mate U-shape, then allowing the elastic strain to relax com-

e5 T/2R when T ,, R pletely before the second stage of applying the test stress. A

typical sequence of operations is shown in Fig. 5. The type of

where:

equipment shown in Fig. 4(a and b) can also be used to

T 5 specimen thickness, and

preform the U-shape. The test strain applied may be a

R 5 radius of bend curvature.

percentage of the tensile elastic strain that occurred during

preforming (Fig. 3(d)) or may involve additional plastic strain

10. Stressing the Specimen

(Fig. 3(e)).

10.1 Stressing is usually achieved by either a one- or a

10.4 The slope, MN, of the curve shown in Fig. 3(d) is steep

two-stage operation.

(equal to Young’s modulus). Therefore, it is often difficult to

10.2 Single-stage stressing is accomplished by bending the

reproducibly apply a constant percentage of the total elastic

specimen into shape and maintaining it in that shape without

prestrain and there is a danger of leaving the specimen surface

allowing relaxation of the tensile elastic strain. Typical stress-

under compressive stress. For this reason and also because it

ing sequences are shown in Fig. 4. The method shown in Fig.

results in a more severe test (that is, higher applied stress), it is

4(a) may be performed in a tension testing machine and is

recommended that the stress conditions shown in Fig. 3(bore)

often the most suitable method for stressing U-bends that are

be achieved. Hence, the final applied strain prior to testing

difficult to form manually due to large thickness or high-

consists of plastic and elastic strain. To achieve the conditions

strength material or both. The techniques shown in Fig. 4(b and

shown in Fig. 3(b and e), it is necessary (a) to a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.