ASTM D2687-95(2001)

(Practice)Standard Practices for Sampling Particulate Ion-Exchange Materials

Standard Practices for Sampling Particulate Ion-Exchange Materials

SIGNIFICANCE AND USE

This practice will be used most frequently to sample materials as received from the manufacturer in the original shipping container and prior to any resin-conditioning procedure. Since certain ion-exchange materials are supplied by the manufacturer in the dry or free-flowing state whereas others are supplied moist, it is necessary to employ two different sampling devices. Therefore, this practice is divided into Sampling Procedure—Dry or Free-Flowing Material, and Sampling Procedure—Moist Material.

Once the sample is obtained, it is necessary to protect the ion-exchange materials from changes. Samples should be placed in sealable, gasproof containers immediately.

SCOPE

DESIG: D 2687 95 (Reapproved 2001) ^TITLE: Standard Practices for Sampling Particulate Ion-Exchange Materials ^SCOPE:

1.1 These practices cover procedures for obtaining representative samples of ion-exchange materials. The following practices are included:SectionsPractice A-Sampling from a Single Package andMultiple Package Lots or Shipments 4 to 10Practice B-Sampling from Fixed Bed Ion-ExchangeEquipment Having Unrestricted Head Room 11 to 15Practice C-Sampling from Fixed Bed Ion-ExchangeEquipment Having Restricted Head Room 16 to 21

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2687 – 95 (Reapproved 2001)

Standard Practices for

Sampling Particulate Ion-Exchange Materials

This standard is issued under the fixed designation D 2687; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 These practices cover procedures for obtaining repre- 5.1 This practice will be used most frequently to sample

sentative samples of ion-exchange materials. The following materials as received from the manufacturer in the original

practices are included: shipping container and prior to any resin-conditioning proce-

dure. Since certain ion-exchange materials are supplied by the

Sections

PracticeA—Sampling from a Single Package and

manufacturerinthedryorfree-flowingstatewhereasothersare

Multiple Package Lots or Shipments 4to10

supplied moist, it is necessary to employ two different sam-

Practice B—Sampling from Fixed Bed Ion-Exchange

pling devices. Therefore, this practice is divided into Sampling

Equipment Having Unrestricted Head Room 11to15

Practice C—Sampling from Fixed Bed Ion-Exchange

Procedure—Dry or Free-Flowing Material, and Sampling

Equipment Having Restricted Head Room 16to21

Procedure—Moist Material.

1.2 This standard does not purport to address all of the

5.2 Once the sample is obtained, it is necessary to protect

safety concerns, if any, associated with its use. It is the

the ion-exchange materials from changes. Samples should be

responsibility of the user of this standard to establish appro-

placed in sealable, gasproof containers immediately.

priate safety and health practices and determine the applica-

6. Apparatus

bility of regulatory limitations prior to use.

6.1 Sampling Devices, as shown in Fig. 1 and Fig. 2.

2. Referenced Documents

6.2 Sealable, Gasproof Containers, for sample storage.

2.1 ASTM Standards:

6.3 Sample Quartering Materials—A 0.5 by 0.5 m (20 by

D 1129 Terminology Relating to Water

20 in.) sheet of glazed paper, oil cloth, or flexible plastic film.

3. Terminology

7. Kind and Number of Samples

3.1 Definitions—Certain terms in these practices that relate

7.1 For a representative sample from a single package, a

to ion exchange are defined in Terminology D 1129.

minimum of three probes or increments should be taken with

the sampling device.

PRACTICE A—SAMPLING FROM A SINGLE

7.2 For a representative sample from a multiple package lot

PACKAGE AND MULTIPLE PACKAGE LOTS OR

or shipment:

SHIPMENT

7.2.1 If the markings on the package indicate the material to

be sampled is from a single lot (batch or manufacturing run),

4. Summary of Practice

the number of packages selected shall be not less than 10 % of

4.1 A hollow, sample-probe guide that is comprised of

the packages received. When less than 30 packages are

mating threaded sections and that can be extended to any

received, a minimum of three packages shall be chosen at

convenient length by the addition of more sections, is inserted

random for sampling. If a single lot contains more than 30

into an ion-exchange unit.Asampling tube is inserted through

packages and the order of filling is designated on the packages,

the probe guide and is connected to a vacuum source. Ion-

the first, last, and middle packages shall be sampled. If the

exchange material is removed by eduction.Acore sampler also

results of the analysis of these three samples agree within the

may be used.

limits of precision of the test methods used, further samples

from the lot need not be taken. If they are not in agreement,

additional samples may be taken at the option of the parties

These practices are under the jurisdiction of ASTM Committee D19 on Water

concerned.When the entire shipment oran entire lot consists of

and are the direct responsibility of Subcommittee D19.08 on Membranes and Ion

Exchange Materials.

Current edition approved April 15, 1995. Published June 1995. Originally

published as D 2687 – 68 T. Last previous edition D 2687 – 84 (1990). The sampling device described in Fig. 2 is the same as that used in ASTM

These practices were developed from activities withinASTM Committee D-19. Methods C 183, Sampling Hydraulic Cement, Annual Book of ASTM Standards, Vol

Annual Book of ASTM Standards, Vol 11.01. 14.01.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D 2687 – 95 (2001)

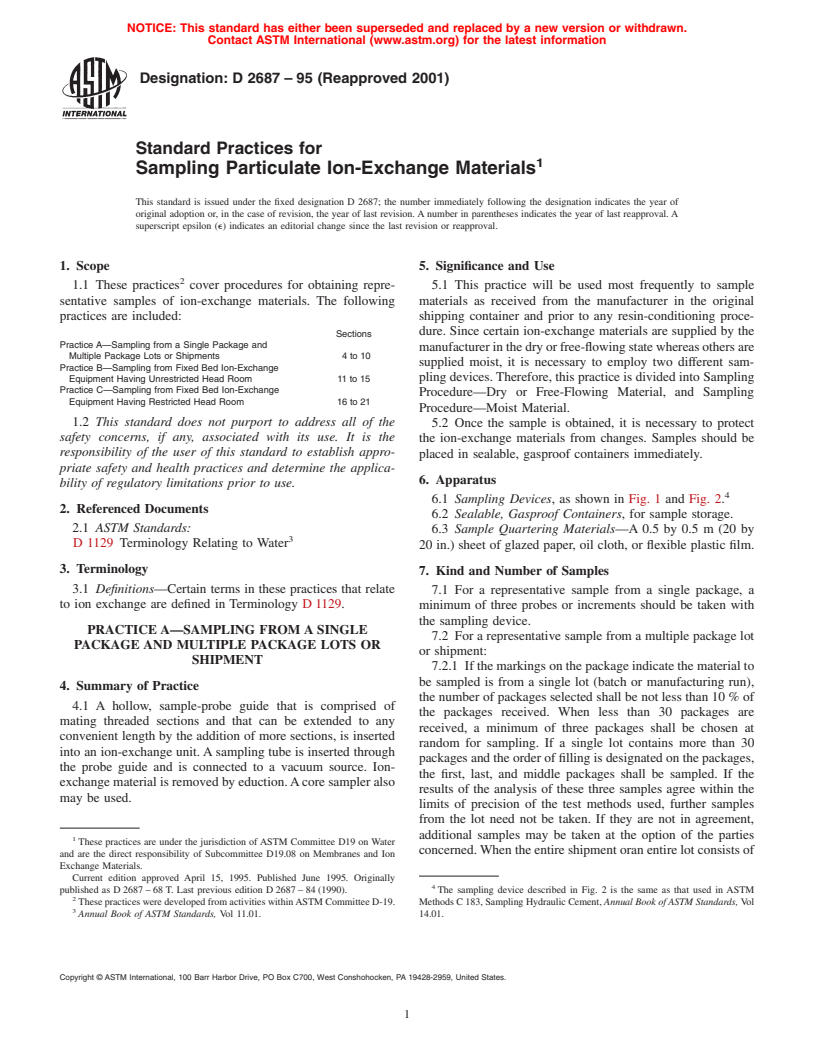

8.1.9 Alternatively, the sampling tube (Fig. 1) may be used

for sampling dry or free-flowing resin. Follow procedure given

in Section 9. Loss of resin from the bottom of the sampler may

occur and cause bias in the sample.

8.2 If the ion-exchange material is dry or free-flowing and

the outer package is a bag:

8.2.1 Transfer the contents of the bag to a drum which has

FIG. 1 51-mm (2-in.) Inside Diameter Plastic Tube with 2.4-mm

a diameter less than its height and will hold the entire contents

( ⁄32-in.) Wall Thickness Ion-Exchanger Sampling Tube

of the bag.

8.2.2 Proceed in accordance with 8.1.

NOTE 3—The sampling device (Fig. 2) can allow resin entering the

upper openings to fall into the bottom portion of the device, thereby

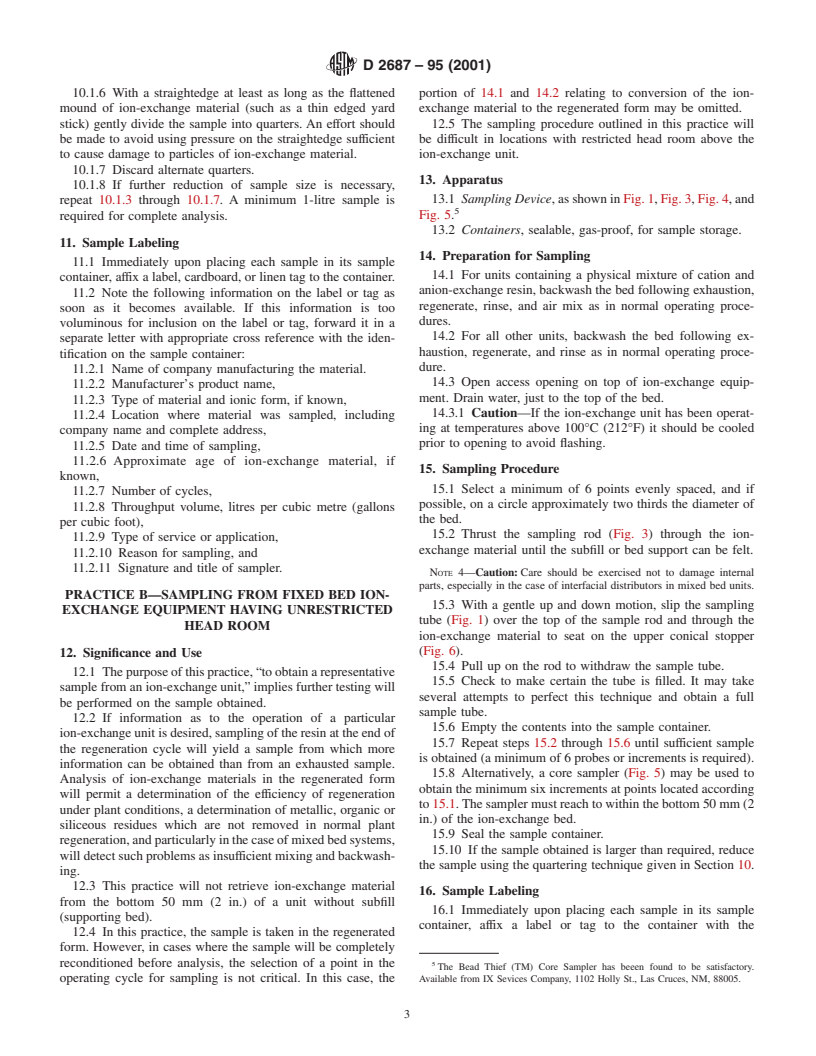

NOTE 1—This device shall be between 1.2 and 1.5 m (4 and 5 ft) long

3 biasing the sample.

and about 35 mm (1 ⁄8 in.) in outside diameter. It shall consist of two

polished brass telescopic tubes with registering slots which are opened or

9. Sampling Procedure—Moist Material

closed by rotation of the inner tube, the outer tube being provided with a

point to facilitate penetration 9.1 If the ion-exchange material is moist and contained in a

FIG. 2 Slotted Tube Sample for Ion-Exchange Resins

drum:

9.1.1 Upend the drum and allow to stand 16 h (overnight) to

redistribute any excess water that may be present.

three packages or less, a sample shall be taken from each

9.1.2 Right drum, rock it slightly from several sides for

package. The number of samples taken with the sampling

uniform packing and open.

device should not be less than three per individual package.

9.1.3 The points chosen for probing on the surface should

7.2.2 If the shipment consists of more than one lot (batch or

lie on a circle approximately two thirds of the diameter of the

manufacturing run) of material, sample each lot separately as

drum.

in 7.2.1. For a representative sample of the entire shipment, the

9.1.4 Rapidly thrust the sampling tube (Fig. 1) to the bottom

numberofpackagessampledperlotshouldbeinthesameratio

of the drum.

as the number of packages of that lot in the entire shipment.

9.1.5 Withdraw the sampling device.

For example, if the shipment consists of 40 drums of lot x and

9.1.6 Empty the contents into the sample container.

60 drums of lot y, sample four drums of lot x and six drums of

9.1.7 Repeat 9.1.4 through 9.1.6 until sufficient sample is

lot y.

obtained.Aminimumofthreeprobesorincrementsisrequired.

If the sample obtained is larger than required, reduce the

8. Sampling Procedure—Dry or Free-Flowing Material

sample using the quartering technique given in 10.1.

8.1 If the ion-exchange material is dry or free-flowing and

9.1.8 Seal the sample container and affix label as outlined in

contained in a drum:

Section 11.

8.1.1 Rock the drum slightly from several sides for uniform

9.2 If the ion-exchange material is moist and the outer

packing and open.

package is a bag:

8.1.2 The points chosen for probing on the surface should

9.2.1 Transfer the contents of the bag to a drum that has a

lie on a circle approximately two thirds the diameter of the

diameter less than its height and will hold the entire contents of

drum and uniformly spaced.

the bag.

8.1.3 Rotatetheinnertubeofthesamplingdevice(Fig.2)to

9.2.2 Proceed in accordance with 9.1.

the closed position, and thrust the sampling device to the

bottom of the drum.

10. Quartering Procedure

8.1.4 Rotate the inner tube to the open position and collect

10.1 Using a sheet of glazed paper, oil cloth, or flexible

the sample by moving the top of the sampling device in a circle

plastic film:

(about75to150mm(3to6in.)indiameter)severaltimeswith

10.1.1 Empty the sample container into the center of the

the open sections forward.

sheet.

8.1.5 Rotate the inner tube to the closed position and

10.1.2 Flatten out the sample gently with the palm of the

remove the sampling device from the drum.

hand until the ion-exchange material is approximately 25 mm

(1 in.) thick.

NOTE 1—The sharp point of the sampling device may pierce the drum

liner. Have the point rounded slightly (by grinding, filing, etc.).

10.1.3 Remix the sample by lifting a corner of the sheet and

NOTE 2—Corrosion may occur after only a few months on this type of

drawingitacross,lowdown,totheoppositecornerinamanner

sampling device and will render it unsuitable for resin sampling.

that the material is made to roll over and over and does not

8.1.6 Empty the contents into the sample container. merely slide along. Continue operation with each corner,

8.1.7 Repeat 8.1.3 through 8.1.6 until sufficient sample is proceeding in a clockwise direction. Repeat this operation

obtained.Aminimumofthreeprobesorincrementsisrequired. three times.

If the sample obtained is larger than required, reduce the 10.1.4 Lift all four corners of the sheet towards the center

sample using the quartering techniques given in 10.1. and holding all four corners together, raise the entire sheet into

8.1.8 Seal the sample container and affix label as outlined in the air to form a pocket for the ion-exchange material.

Section 11. 10.1.5 Repeat 10.1.2.

D 2687 – 95 (2001)

10.1.6 With a straightedge at least as long as the flattened portion of 14.1 and 14.2 relating to conversion of the ion-

mound of ion-exchange material (such as a thin edged yard exchange material to the regenerated form may be omitted.

stick) gently divide the sample into quarters. An effort should 12.5 The sampling procedure outlined in this practice will

be made to avoid using pressure on the straightedge sufficient be difficult in locations with restricted head room above the

to cause damage to particles of ion-exchange material. ion-exchange unit.

10.1.7 Discard alternate quarters.

13. Apparatus

10.1.8 If further reduction of sample size is necessary,

13.1 Sampling Device,asshowninFig.1,Fig.3,Fig.4,and

repeat 10.1.3 through 10.1.7. A minimum 1-litre sample is

required for complete analysis. Fig. 5.

13.2 Containers, sealable, gas-proof, for sample storage.

11. Sample Labeling

14. Preparation for Sampling

11.1 Immediately upon placing each sample in its sample

14.1 For units containing a physical mixture of cation and

container, affix a label, cardboard, or linen tag to the container.

anion-exchange resin, backwash the bed following exhaustion,

11.2 Note the following information on the label or tag as

regenerate, rinse, and air mix as in normal operating proce-

soon as it becomes available. If this information is too

dures.

voluminous for inclusion on the label or tag, forward it in a

14.2 For all other units, backwash the bed following ex-

separate letter with appropriate cross reference with the iden-

haustion, regenerate, and rinse as in normal operating proce-

tification on the sample container:

dure.

11.2.1 Name of company manufacturing the material.

14.3 Open access opening on top of ion-exchange equip-

11.2.2 Manufacturer’s product name,

ment. Drain water, just to the top of the bed.

11.2.3 Type of material and ionic form, if known,

14.3.1 Caution—If the ion-exchange unit has been operat-

11.2.4 Location where material was sampled, including

ing at temperatures above 100°C (212°F) it should be cooled

company name and complete address,

prior to opening to avoid flashing.

11.2.5 Date and time of sampling,

11.2.6 Approximate age of ion-exchange material, if

15. Sampling Procedure

known,

15.1 Select a minimum of 6 points evenly spaced, and if

11.2.7 Number of cycles,

possible, on a circle approximately two thirds the diameter of

11.2.8 Throughput volume, litres per cubic metre (gallons

the bed.

per cubic foot),

15.2 Thrust the sampling rod (Fig. 3) through the ion-

11.2.9 Type of service or application,

exchange material until the subfill or bed support can be felt.

11.2.10 Reason for sampling, and

11.2.11 Signature and title of sampler.

NOTE 4—Caution: Care should be exercised not to damage internal

parts, especially in the case of interfacial distributors in mixed bed units.

PRACTICE B—SAMPLING FROM FIXED BED ION-

15.3 With a gentle up and down motion, slip the sampling

EXCHANGE EQUIPMENT HAVING UNRESTRICTED

tube (Fig. 1) over the top of the sample rod and through the

HEAD ROOM

ion-exchange material to seat on the upper conical stopper

(Fig. 6).

12. Significance and Use

15.4 Pull up on the rod to withdraw the sample tube.

12.1 Thepurposeofthispractice,“toobtainarepresentative

15.5 Check to make certain the tube is filled. It may take

sample from an ion-exchange unit,” implies further testing will

several attempts to perfect this technique and obtain a full

be performed on the sample obtained.

sample tube.

12.2 If information as to the operation of a particular

15.6 Empty the contents into the sample container.

ion-exchangeunitisdesired,samplingoftheresinattheendof

15.7 Repeat steps 15.2 through 15.6 until sufficient sample

the regeneration cycle will yield a sample from which more

is obtained (a minimum of 6 probes or increments is required).

information can be obtained than from an exhausted sample.

15.8 Alternatively, a core sampler (Fig. 5) may be used to

Analysis of ion-exchange materials in the regenerated form

obtain the minimum six increments at points located according

will permit a determination of the efficiency of regeneration

to 15.1.The sampler must reach to within the bottom 50 mm (2

under plant conditions, a determination of metallic, organic or

in.) of the ion-exchange bed.

siliceous residues which are not removed in normal plant

15.9 Seal the sample container.

regeneration,andparticularlyinthecaseofmixedbedsystems,

15.10 If the sample obtained is larger than required, reduce

will detect such problems as insufficient mixing and backwash-

the sample using the quartering technique given in Section 10.

ing.

12.3 This practice will not retrieve ion-exchange material

16. Sample Labeling

from the bottom 50 mm (2 in.) of a unit without subfill

16.1 Immediately upon placing each sample in its sample

(supporting bed).

container, affix a label or tag to the container with the

12.4 In this practice, the sample is taken in the regenerated

form. However, in cases where the sample will be completely

reconditioned before ana

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.