ASTM D215-91(1996)

(Practice)Standard Practice for the Chemical Analysis of White Linseed Oil Paints

Standard Practice for the Chemical Analysis of White Linseed Oil Paints

SCOPE

1.1 This practice covers the chemical analysis of the usual white linseed oil paints. The methods included are listed in Table 1.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 215 – 91 (Reapproved 1996)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for the

Chemical Analysis of White Linseed Oil Paints

This standard is issued under the fixed designation D 215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

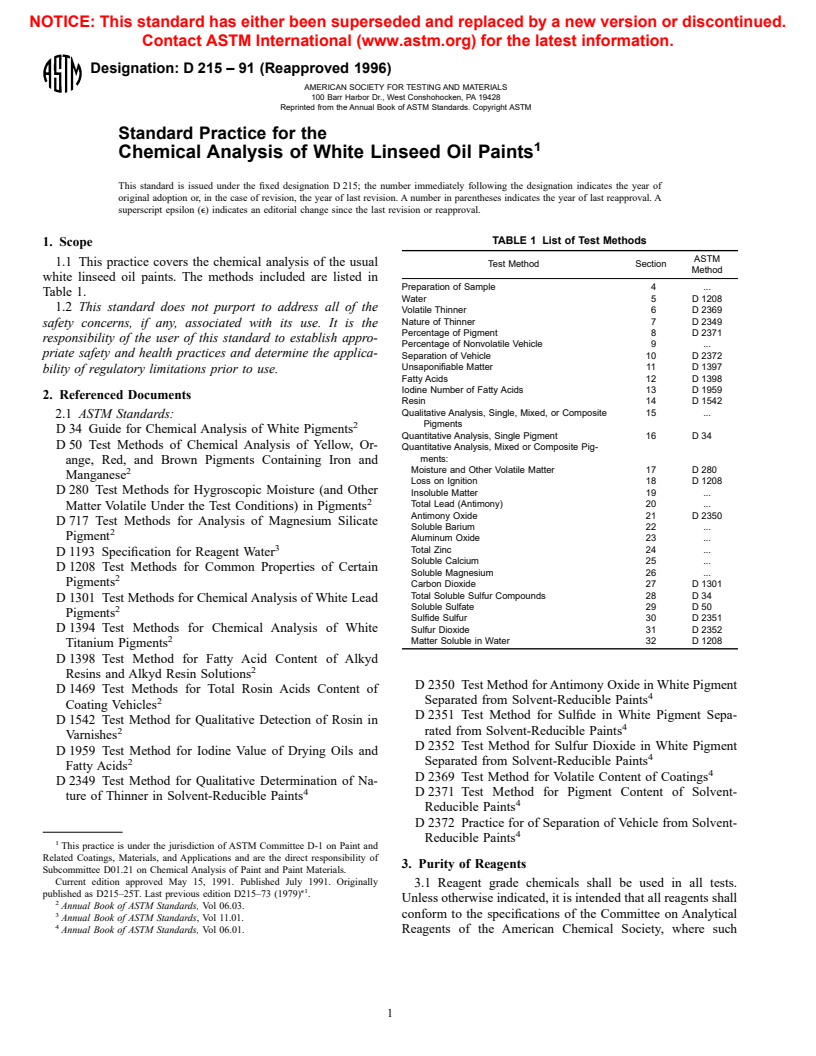

TABLE 1 List of Test Methods

1. Scope

ASTM

1.1 This practice covers the chemical analysis of the usual

Test Method Section

Method

white linseed oil paints. The methods included are listed in

Preparation of Sample 4 .

Table 1.

Water 5 D 1208

1.2 This standard does not purport to address all of the

Volatile Thinner 6 D 2369

Nature of Thinner 7 D 2349

safety concerns, if any, associated with its use. It is the

Percentage of Pigment 8 D 2371

responsibility of the user of this standard to establish appro-

Percentage of Nonvolatile Vehicle 9 .

priate safety and health practices and determine the applica-

Separation of Vehicle 10 D 2372

Unsaponifiable Matter 11 D 1397

bility of regulatory limitations prior to use.

Fatty Acids 12 D 1398

Iodine Number of Fatty Acids 13 D 1959

2. Referenced Documents

Resin 14 D 1542

Qualitative Analysis, Single, Mixed, or Composite 15 .

2.1 ASTM Standards:

Pigments

D 34 Guide for Chemical Analysis of White Pigments

Quantitative Analysis, Single Pigment 16 D 34

D 50 Test Methods of Chemical Analysis of Yellow, Or-

Quantitative Analysis, Mixed or Composite Pig-

ments:

ange, Red, and Brown Pigments Containing Iron and

Moisture and Other Volatile Matter 17 D 280

Manganese

Loss on Ignition 18 D 1208

D 280 Test Methods for Hygroscopic Moisture (and Other

Insoluble Matter 19 .

Total Lead (Antimony) 20 .

Matter Volatile Under the Test Conditions) in Pigments

Antimony Oxide 21 D 2350

D 717 Test Methods for Analysis of Magnesium Silicate

Soluble Barium 22 .

Pigment

Aluminum Oxide 23 .

Total Zinc 24 .

D 1193 Specification for Reagent Water

Soluble Calcium 25 .

D 1208 Test Methods for Common Properties of Certain

Soluble Magnesium 26 .

Pigments

Carbon Dioxide 27 D 1301

Total Soluble Sulfur Compounds 28 D 34

D 1301 Test Methods for Chemical Analysis of White Lead

Soluble Sulfate 29 D 50

Pigments

Sulfide Sulfur 30 D 2351

D 1394 Test Methods for Chemical Analysis of White Sulfur Dioxide 31 D 2352

Matter Soluble in Water 32 D 1208

Titanium Pigments

D 1398 Test Method for Fatty Acid Content of Alkyd

Resins and Alkyd Resin Solutions

D 2350 Test Method for Antimony Oxide in White Pigment

D 1469 Test Methods for Total Rosin Acids Content of

Separated from Solvent-Reducible Paints

Coating Vehicles

D 2351 Test Method for Sulfide in White Pigment Sepa-

D 1542 Test Method for Qualitative Detection of Rosin in

rated from Solvent-Reducible Paints

Varnishes

D 2352 Test Method for Sulfur Dioxide in White Pigment

D 1959 Test Method for Iodine Value of Drying Oils and

Separated from Solvent-Reducible Paints

Fatty Acids

D 2369 Test Method for Volatile Content of Coatings

D 2349 Test Method for Qualitative Determination of Na-

4 D 2371 Test Method for Pigment Content of Solvent-

ture of Thinner in Solvent-Reducible Paints

Reducible Paints

D 2372 Practice for of Separation of Vehicle from Solvent-

Reducible Paints

This practice is under the jurisdiction of ASTM Committee D-1 on Paint and

Related Coatings, Materials, and Applications and are the direct responsibility of

3. Purity of Reagents

Subcommittee D01.21 on Chemical Analysis of Paint and Paint Materials.

Current edition approved May 15, 1991. Published July 1991. Originally

3.1 Reagent grade chemicals shall be used in all tests.

e1

published as D215–25T. Last previous edition D215–73 (1979) .

Unless otherwise indicated, it is intended that all reagents shall

Annual Book of ASTM Standards, Vol 06.03.

conform to the specifications of the Committee on Analytical

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 06.01. Reagents of the American Chemical Society, where such

D 215

specifications are available. Other grades may be used, pro- 7. Volatile Thinner

vided it is first ascertained that the reagent is of sufficiently

7.1 Determine the volatile matter in accordance with Test

high purity to permit its use without lessening the accuracy of

Method D 2369. Calculate the loss in weight as the percentage

the determination.

of water and volatile thinner. Subtract from this the percentage

3.2 Unless otherwise indicated, references to water shall be

of water as determined in accordance with Section 6. Report

understood to mean Type II reagent grade water conforming to

the remainder as percent volatile thinner.

Specification D 1193.

8. Nature of Thinner

4. Hazards

8.1 Determine the nature of the thinner in accordance with

4.1 Ammonium Hydroxide causes severe burns and may be

Method D 2349.

fatal if swallowed. Read the appropriate Material Safety Data

Sheets (MSDS) before using.

9. Percentage of Pigment

4.2 Hydrochloric and Sulfuric Acids cause severe burns and

9.1 Determine the percentage of pigment in accordance with

may be fatal if swallowed. Read the appropriate MSDS before

Test Method D 2371. Preserve the pigment as prepared in a

using.

stoppered bottle for use in Sections 16 and 17.

4.3 Acetic Acid causes severe burns and may be fatal if

swallowed. Read the appropriate MSDS before using.

10. Percentage of Nonvolatile Vehicle

4.4 Nitric Acid causes burns and may be fatal if swallowed.

10.1 Add together the percentages of water, volatile thinner,

Vapor is extremely hazardous and may cause nitrogen oxide

and pigment, and subtract the sum from 100. Report the

poisoning. Read the appropriate MSDS before using.

remainder as nonvolatile vehicle.

4.5 Toluene is flammable. Vapors are harmful. Use with

adequate ventilation. Read the appropriate MSDS before using.

TESTING NONVOLATILE VEHICLE

4.6 Hydrogen Sulfide is both an irritant and an asphyxiant.

Read the appropriate MSDS before using. 11. Separation of Vehicle

4.7 Ammonium Sulfide evolves hydrogen sulfide on contact

11.1 Separate the vehicle from the pigment in accordance

with acid or acid fumes. See 4.6. Read the appropriate MSDS

with Method D 2372. Retain the vehicle so obtained for use in

before using.

the unsaponifiable matter (see 12.1) and fatty acids (see 13.1)

4.8 Barium Chloride—Soluble barium salts are poisonous

determinations.

when taken by mouth. Read the appropriate MSDS before

using. 12. Unsaponifiable Matter

12.1 Determine the unsaponifiable content of the vehicle in

5. Preparation of Sample

accordance with Test Method D 1398.

5.1 On receipt of a sample, make a record of the label noting

especially the brand, the name of the manufacturer, and any

13. Fatty Acids

statement as to the composition of the paint and the net

13.1 Determine the fatty acids in accordance with Method

contents. Weigh the unbroken package, open, note odor and

D 1398.

condition of the contents, pour into a clean container, and mix

thoroughly by pouring from one container to the other, finally

14. Iodine Number of Fatty Acids

leaving the well-mixed sample in the second container which

14.1 Determine the iodine number of fatty acids (see 13.1)

shall be tightly closed. The well-mixed sample shall be used at

in accordance with Test Method D 1959.

once for the analysis. The original can and cover may be

NOTE 1—If appreciable amounts of rosin or of unsaponifiable matter

cleaned with a suitable solvent, wiped dry, and then weighed.

are found to be absent in the vehicle of a paint, the iodine number of the

This weight subtracted from the original weight will give the

fatty acids gives the best indication (though not proof) of the presence of

net weight of the contents. If desired, the specific gravity of the

linseed oil. An iodine number of less than 175 (Wijs) for the fatty acids is

paint may be determined, the weight per gallon calculated, and

an indication that the nonvolatile vehicle was not pure linseed oil.

the volume of paint and the capacity of the container may be

measured. 15. Rosin

15.1 Determine the presence of rosin in the fatty acids (see

ANALYSIS OF PAINT

13.1) in accordance with Test Method D 1542.

15.2 If desired, determine the amount of rosin quantitatively

6. Water

in accordance with Method D 1469.

6.1 Determine water in accordance with Test Methods

D 1208.

ANALYSIS OF PIGMENT

Qualitative Analysis, Total Pigments—Single, Mixed, or

Composite

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

16. Qualitative Analysis

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

16.1 Reagents:

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. 16.1.1 Acetic Acid.(Precaution—See 4.3)

D 215

), CaSO , or other soluble sulfate, the soluble barium will form

16.1.2 Acid Ammonium Acetate Solution—Mix 150 ml of (PbSO

4 4

with the soluble sulfate a precipitate of BaSO which will be determined

acetic acid (8 + 2) 100 ml of water, and 95 ml of NH OH (sp

as “insoluble matter.” If the sample contained strontium sulfate (SrSO )or

gr 0.90).

strontium carbonate (SrCO ), some SrSO may be counted as BaSO ,

3 4 4

16.1.3 Ammonium Hydroxide (sp gr 0.90)—Concentrated

some strontium will count as soluble barium, and some may be counted as

ammonium hydroxide (NH OH). (Precaution—See 4.1)

4 calcium oxide (CaO). Strontium is not separated, as it probably will not be

16.1.4 Ammonium Polysulfide—Pass H S gas into 200 ml of

encountered, or will be present as an impurity in the barium and calcium

compounds.

NH OH (sp gr 0.90) in a bottle immersed in running water or

in iced water until the gas is no longer absorbed; then add 200

16.2.2 Wash the matter insoluble in acid ammonium acetate

mL of NH OH (sp gr 0.90) and dilute with water to 1 litre.

4 solution with another portion of this solution, and finally with

Digest this solution with 25 g of flowers of sulfur for several

hot water. This insoluble matter shall be dried, ignited, and

hours and filter.

tested for siliceous matter, BaSO , and titanium compounds. To

16.1.5 Ammonium Sulfate ((NH ) SO ).

test for the latter, place a small amount of the insoluble matter,

4 2 4

16.1.6 Barium Chloride (BaCl ·2H O). (Precaution—See

or of the original sample (about 0.5 g) in a 250-mL resistant

2 2

4.8)

glass beaker; add 20 mL of concentrated H SO (sp gr 1.84)

2 4

16.1.7 Hydrochloric Acid (1+1)—Mix equal volumes of

and7to8gof(NH ) SO . Mix well, and boil for a few

4 2 4

concentrated hydrochloric acid (HCl, sp gr 1.19)

minutes. A residue denotes the presence of silica or siliceous

(Precaution—See 4.2) and water.

matter. Cool the solution, dilute with 100 mL of water, heat to

16.1.8 Hydrogen Peroxide (H O ), 3%.

boiling, settle, filter, and wash with hot H SO (1 + 19) until

2 2

2 4

16.1.9 Hydrogen Sulfide (H S). (Precaution—See 4.6)

free from titanium. The residue may be tested for lead, barium,

16.1.10 Potassium Dichromate (K Cr O ). and silica.

2 2 7

16.1.11 Potassium Ferrocyanide, Standard Solution— 16.2.3 Add H O to a small portion of the filtrate; a clear

2 2

Dissolve 22 g of pure potassium ferrocyanide (K Fe(CN) · yellow-orange color indicates the presence of titanium. Boil

4 6

3H O) in water and dilute to 1 L. To standardize, transfer about another portion of the filtrate with metallic tin or zinc; a pale

0.2 g (accurately weighed) of pure metallic zinc or freshly blue to violet coloration indicates titanium.

ignited pure zinc oxide to a 400-mL beaker. Dissolve in 10 mL 16.2.4 Treat another portion (about 1 g) of the pigment with

of HCl (sp gr 1.19) and 20 ml of water. Drop in a small piece 20 ml of HCl (1 + 1) and note whether any H S is evolved; boil

of litmus paper, add NH OH until slightly alkaline, add HCl

the solution for about 5 min, add about 25 ml of hot water,

until just acid, and then 3 mL of HCl (sp gr 1.19). Dilute to filter, and wash with hot water. Render a small portion of the

about 250 mL with hot water and heat nearly to boiling. Run in

filtrate alkaline with NH OH, acidify with HCl, and add a little

the K Fe(CN) solution slowly from a buret, while stirring BaCl solution; a white precipitate (BaSO ) indicates the

4 6 2 4

constantly, until a drop tested on a white porcelain plate with a

presence of a soluble sulfate. To another portion of the filtrate

drop of the uranyl indicator shows a brown tinge after standing add a little H SO ; a white precipitate indicates the presence of

2 4

1 min. A blank should be run with the same amounts of lead, soluble barium, or both (some CaSO may also separate).

reagents and water as in the standardization. The amount of Filter, wash to remove free acid, and treat the precipitate with

K Fe(CN) solution required for the blank should be subtracted a few drops of KI solution; the formation of yellow lead iodide

4 6

from the amounts used in standardization and in titration of the (PbI ) indicates the presence of lead. The white precipitate may

sample. The standardization must be made under the same also be treated with H S water; the formation of black lead

conditions of temperature, volume, and acidity as obtained sulfide (PbS) indicates the presence of lead.

when the sample is titrated. 16.2.5 To another portion of the original filtrate (see 16.2.1)

16.1.12 Potassium Iodide (KI). add NH OH until alkaline, render slightly acid with acetic acid,

heat to boiling, and add a little K Cr O solution; a yellow or

16.1.13 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric

2 2 7

acid (H SO ). (Precaution—See 4.2) orange-yellow precipitate indicates the presence of lead,

2 4

soluble barium, or both. To another portion of the original

16.1.14 Sulfuric Acid (1+19)—Carefully mix 1 volume of

concentrated H SO (sp gr 1.84) (Precaution—See 4.2) with filtrate add a few drops of K Fe(CN) solution; a white

4 6

2 4

precipitate with a bluish tinge indicates the presence of zinc.

19 volumes of water.

Pass into the remaining portion of the original filtrate a current

16.2 Procedure:

of H S for 5 to 10 min, add an equal volume of water, and pass

16.2.1 The following qualitative analysis should be made 2

H S into the solution for about 5 min. Filter and wash with H S

and the quantitative scheme modified as required. Add acetic

2 2

water. Digest the precipitate with ammonium polysulfide,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.