ASTM D1922-09

(Test Method)Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

SIGNIFICANCE AND USE

This test method is of value in ranking relative tearing resistance of various plastic films and thin sheeting of comparable thickness. Experience has shown the test to have its best reliability on relatively less extensible films and sheeting. Variable elongation and oblique tearing effects on the more extensible films preclude its use as a precise production-control tool for these types of plastics. This test method should be used for specification acceptance testing only after it has been demonstrated that the data for the particular material are acceptably reproducible. This test method should be used for service evaluation only after its usefulness for the particular application has been demonstrated with a number of different films.

This test method has been widely used as one index of the tearing resistance of plastic film and thin sheeting used in packaging applications. While it may not always be possible to correlate film tearing data with its other mechanical or toughness properties, the apparatus of this test method provides a controlled means for tearing specimens at straining rates approximating some of those found in actual packaging service.

Due to orientation during their manufacture, plastic films and sheeting frequently show marked anisotropy in their resistance to tearing. This is further complicated by the fact that some films elongate greatly during tearing, even at the relatively rapid rates of loading encountered in this test method. The degree of this elongation is dependent in turn on film orientation and the inherent mechanical properties of the polymer from which it is made. These factors make tear resistance of some films reproducible between sets of specimens to ±5 % of the mean value, while others may show no better reproducibility than ±50 %.

Data obtained by this test method may supplement that from Test Method D 1004, wherein the specimen is strained at a rate of 50 mm (2 in.) per minute. However, specimen geometry and testing...

SCOPE

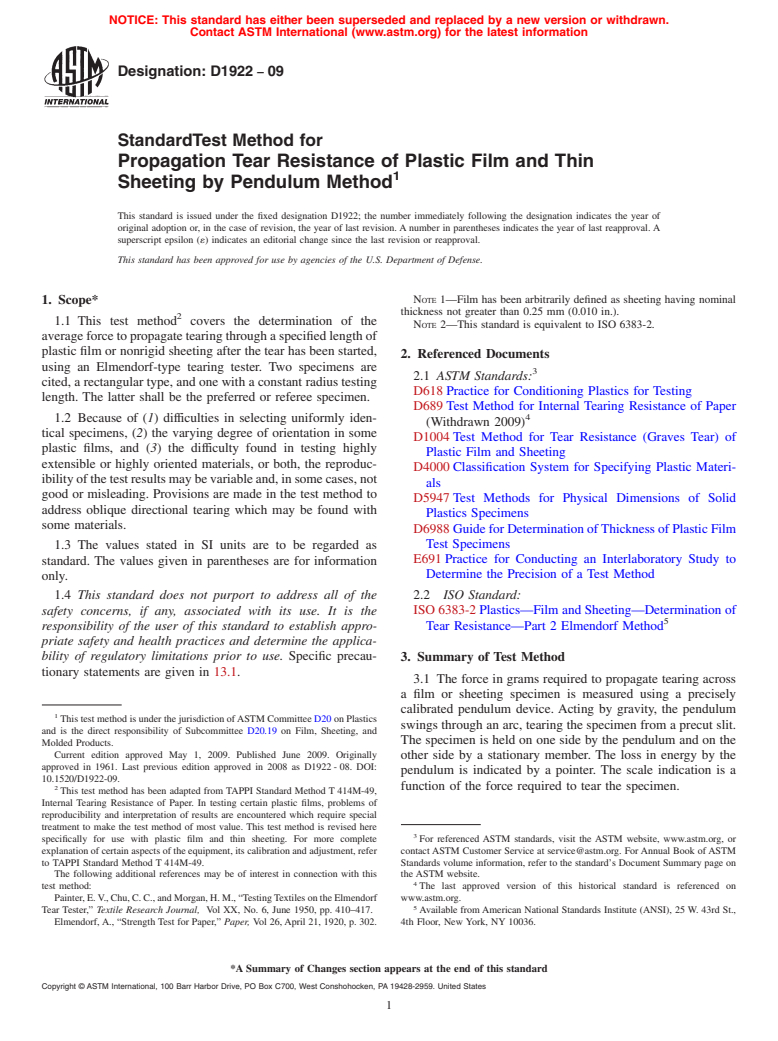

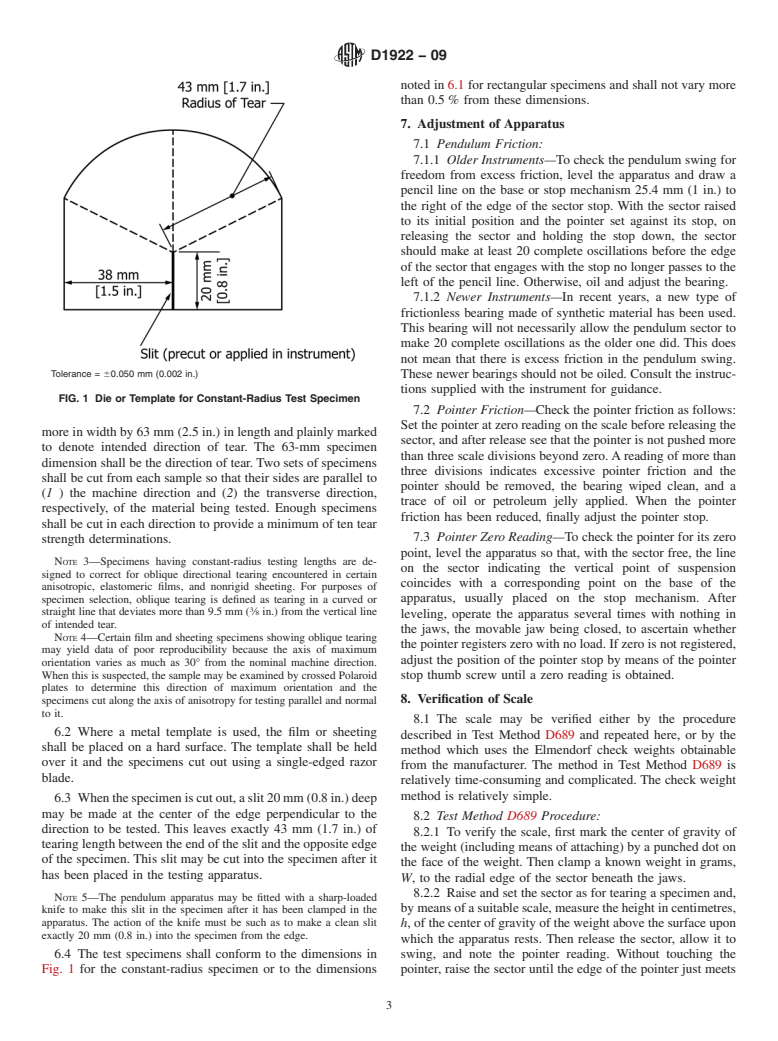

1.1 This test method covers the determination of the average force to propagate tearing through a specified length of plastic film or nonrigid sheeting after the tear has been started, using an Elmendorf-type tearing tester. Two specimens are cited, a rectangular type, and one with a constant radius testing length. The latter shall be the preferred or referee specimen.

1.2 Because of (1) difficulties in selecting uniformly identical specimens, (2) the varying degree of orientation in some plastic films, and (3) the difficulty found in testing highly extensible or highly oriented materials, or both, the reproducibility of the test results may be variable and, in some cases, not good or misleading. Provisions are made in the test method to address oblique directional tearing which may be found with some materials.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 13.1.

Note 1—Film has been arbitrarily defined as sheeting having nominal thickness not greater than 0.25 μm (0.010 in.).

Note 2—This standard and ISO 6383-2 are technically equivalent.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1922 − 09

StandardTest Method for

Propagation Tear Resistance of Plastic Film and Thin

1

Sheeting by Pendulum Method

This standard is issued under the fixed designation D1922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

NOTE 1—Film has been arbitrarily defined as sheeting having nominal

1. Scope*

thickness not greater than 0.25 mm (0.010 in.).

2

1.1 This test method covers the determination of the

NOTE 2—This standard is equivalent to ISO 6383-2.

averageforcetopropagatetearingthroughaspecifiedlengthof

plastic film or nonrigid sheeting after the tear has been started,

2. Referenced Documents

using an Elmendorf-type tearing tester. Two specimens are

3

2.1 ASTM Standards:

cited, a rectangular type, and one with a constant radius testing

D618 Practice for Conditioning Plastics for Testing

length. The latter shall be the preferred or referee specimen.

D689 Test Method for Internal Tearing Resistance of Paper

4

1.2 Because of (1) difficulties in selecting uniformly iden-

(Withdrawn 2009)

tical specimens, (2) the varying degree of orientation in some

D1004 Test Method for Tear Resistance (Graves Tear) of

plastic films, and (3) the difficulty found in testing highly

Plastic Film and Sheeting

extensible or highly oriented materials, or both, the reproduc-

D4000 Classification System for Specifying Plastic Materi-

ibilityofthetestresultsmaybevariableand,insomecases,not

als

good or misleading. Provisions are made in the test method to

D5947 Test Methods for Physical Dimensions of Solid

address oblique directional tearing which may be found with

Plastics Specimens

some materials.

D6988 GuideforDeterminationofThicknessofPlasticFilm

Test Specimens

1.3 The values stated in SI units are to be regarded as

E691 Practice for Conducting an Interlaboratory Study to

standard. The values given in parentheses are for information

Determine the Precision of a Test Method

only.

1.4 This standard does not purport to address all of the 2.2 ISO Standard:

safety concerns, if any, associated with its use. It is the ISO 6383-2 Plastics—Film and Sheeting—Determination of

5

responsibility of the user of this standard to establish appro- Tear Resistance—Part 2 Elmendorf Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

3. Summary of Test Method

tionary statements are given in 13.1.

3.1 The force in grams required to propagate tearing across

a film or sheeting specimen is measured using a precisely

calibrated pendulum device. Acting by gravity, the pendulum

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

swings through an arc, tearing the specimen from a precut slit.

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

The specimen is held on one side by the pendulum and on the

Molded Products.

Current edition approved May 1, 2009. Published June 2009. Originally

other side by a stationary member. The loss in energy by the

approved in 1961. Last previous edition approved in 2008 as D1922 - 08. DOI:

pendulum is indicated by a pointer. The scale indication is a

10.1520/D1922-09.

function of the force required to tear the specimen.

2

This test method has been adapted from TAPPI Standard Method T 414M-49,

Internal Tearing Resistance of Paper. In testing certain plastic films, problems of

reproducibility and interpretation of results are encountered which require special

treatment to make the test method of most value. This test method is revised here

3

specifically for use with plastic film and thin sheeting. For more complete For referenced ASTM standards, visit the ASTM website, www.astm.org, or

explanation of certain aspects of the equipment, its calibration and adjustment, refer contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

to TAPPI Standard Method T 414M-49. Standards volume information, refer to the standard’s Document Summary page on

The following additional references may be of interest in connection with this the ASTM website.

4

test method: The last approved version of this historical standard is referenced on

Painter,E.V.,Chu,C.C.,andMorgan,H.M.,“TestingTextilesontheElmendorf www.astm.org.

5

Tear Tester,” Textile Research Journal, Vol XX, No. 6, June 1950, pp. 410–417. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Elmendorf,A., “Strength Test for Paper,” Paper, Vol 26,April 21, 1920, p. 302. 4th Floor, New York, NY 10036.

*A Summary of Changes

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1922–08 Designation: D 1922 – 09

Standard Test Method for

Propagation Tear Resistance of Plastic Film and Thin

1

Sheeting by Pendulum Method

This standard is issued under the fixed designation D 1922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This test method covers the determination of the average force to propagate tearing through a specified length of plastic

film or nonrigid sheeting after the tear has been started, using an Elmendorf-type tearing tester. Two specimens are cited, a

rectangular type, and one with a constant radius testing length. The latter shall be the preferred or referee specimen.

1.2 Because of (1) difficulties in selecting uniformly identical specimens, (2) the varying degree of orientation in some plastic

films, and ( 3) the difficulty found in testing highly extensible or highly oriented materials, or both, the reproducibility of the test

results may be variable and, in some cases, not good or misleading. Provisions are made in the test method to address oblique

directional tearing which may be found with some materials.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in 13.1.

NOTE1—This standard and ISO 6383-2 1—Film has been arbitrarily defined as sheeting having nominal thickness not greater than 0.25 µm (0.010

in.).

NOTE 2—This standard and ISO 6383-2 are technically equivalent.

2. Referenced Documents

3

2.1 ASTM Standards: D374Test Methods for Thickness of Solid Electrical Insulation

D 618 Practice for Conditioning Plastics for Testing

D 689 Test Method for Internal Tearing Resistance of Paper

D 1004 Test Method for Tear Resistance (Graves Tear) of Plastic Film and Sheeting

D 4000 Classification System for Specifying Plastic Materials

D 5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D 6988 Guide for Determination of Thickness of Plastic Film Test Specimens

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standard:

4

ISO 6383-2 Plastics—Film and Sheeting—Determination of Tear Resistance—Part 2 Elmendorf Method

3. Summary of Test Method

3.1 The force in grams required to propagate tearing across a film or sheeting specimen is measured using a precisely calibrated

pendulum device. Acting by gravity, the pendulum swings through an arc, tearing the specimen from a precut slit. The specimen

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved Nov.May 1, 2008.2009. Published November 2008.June 2009. Originally approved in 1961. Last previous edition approved in 20062008 as

D1922-06a.D 1922 - 08.

2

This test method has been adapted from TAPPI Standard Method T 414M-49, Internal Tearing Resistance of Paper. In testing certain plastic films, problems of

reproducibilityandinterpretationofresultsareencounteredwhichrequirespecialtreatmenttomakethetestmethodofmostvalue.Thistestmethodisrevisedherespecifically

for use with plastic film and thin sheeting. For more complete explanation of certain aspects of the equipment, its calibration and adjustment, refer toTAPPI Standard Method

T 414M-49.

The following additional references may be of interest in connection with this test method:

Painter, E. V., Chu, C. C., and Morgan, H. M., “Testing Textiles on the Elmendorf Tear Tester,” Textile Research Journal, Vol XX, No. 6, June 1950, pp. 410–417.

Elmendorf, A., “Strength Test for Paper,” Paper, Vol 26, April 21, 1920, p. 302.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American National Standards Institute (ANSI),

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.