ASTM D6331-98(2005)

(Test Method)Standard Test Method for Determination of Mass Concentration of Particulate Matter from Stationary Sources at Low Concentrations (Manual Gravimetric Method)

Standard Test Method for Determination of Mass Concentration of Particulate Matter from Stationary Sources at Low Concentrations (Manual Gravimetric Method)

SIGNIFICANCE AND USE

The measurement of particulate matter and collected residue emission rates is an important test method widely used in the practice of air pollution control. Particulate matter measurements after control devices are necessary to determine total emission rates into the atmosphere.

5.1.1 These measurements, when approved by federal or state agencies, are often required for the purpose of determining compliance with regulations and statutes.

5.1.2 The measurements made before and after control devices are often necessary to demonstrate conformance with contractual performance specifications.

The collected residue obtained with this test method is also important in characterizing stack emissions. However, the utility of these data is limited unless a chemical analysis of the collected residue is performed.

These measurements also can be used to calibrate continuous particulate emission monitoring systems by correlating the output of the monitoring instruments with the data obtained by using this test method.

5.3.1 This test method is useful in such correlation applications when emissions are less than 20 mg/m3.

5.3.2 The correlation test method is most valid when the monitoring instrumentation samples the particulate matter under the same test conditions as this test method.

SCOPE

1.1 This test method covers a method for the measurement of particulate matter (dust) concentration in emission gases in the concentrations below 20 mg/m3 standard conditions, with special emphasis around 5 mg/m3.

1.2 To meet the requirements of this test method, the particulate sample is weighed to a specified level of accuracy. At low dust concentrations, this is achieved by:

1.2.1 Exercising extreme care in weighing,

1.2.2 Extending the sampling time at conventional sampling rates, or

1.2.3 Sampling at higher rates at conventional sampling times (high-volume sampling).

1.3 This test method differs from Test Method D 3685/D 3685M by requiring the mass measurement of filter blanks, specifying weighing procedures, and requiring monitoring of the flue gas flow variability over the testing period. It requires that the particulate matter collected on the sample filter have a mass at least five times a positive mass difference on the filter blank. High volume sampling techniques or an extension of the sampling time may be employed to satisfy this requirement.

1.4 This test method may be used for calibration of automated monitoring systems (AMS). If the emission gas contains unstable, reactive, or semi-volatile substances, the measurement will depend on the filtration temperature, and in-stack methods may be more applicable than out-stack methods for the calibration of automated monitoring systems.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6331 − 98(Reapproved 2005)

Standard Test Method for

Determination of Mass Concentration of Particulate Matter

from Stationary Sources at Low Concentrations (Manual

Gravimetric Method)

This standard is issued under the fixed designation D6331; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

2 bility of regulatory limitations prior to use.

1.1 This test method covers a method for the measurement

of particulate matter (dust) concentration in emission gases in

2. Referenced Documents

the concentrations below 20 mg/m standard conditions, with

2.1 ASTM Standards:

special emphasis around 5 mg/m .

D1193Specification for Reagent Water

1.2 To meet the requirements of this test method, the

D1356Terminology Relating to Sampling and Analysis of

particulate sample is weighed to a specified level of accuracy.

Atmospheres

At low dust concentrations, this is achieved by:

D2986Practice for Evaluation of Air Assay Media by the

1.2.1 Exercising extreme care in weighing,

Monodisperse DOP (Dioctyl Phthalate) Smoke Test

1.2.2 Extendingthesamplingtimeatconventionalsampling

(Withdrawn 2004)

rates, or

D3154Test Method for Average Velocity in a Duct (Pitot

1.2.3 Sampling at higher rates at conventional sampling

Tube Method)

times (high-volume sampling).

D3631Test Methods for Measuring Surface Atmospheric

1.3 This test method differs from Test Method D3685/

Pressure

D3685M by requiring the mass measurement of filter blanks,

D3670Guide for Determination of Precision and Bias of

specifying weighing procedures, and requiring monitoring of

Methods of Committee D22

the flue gas flow variability over the testing period. It requires

D3685/D3685MTestMethodsforSamplingandDetermina-

that the particulate matter collected on the sample filter have a

tion of Particulate Matter in Stack Gases

mass at least five times a positive mass difference on the filter

D3796Practice for Calibration of Type S Pitot Tubes

blank.Highvolumesamplingtechniquesoranextensionofthe

E1Specification for ASTM Liquid-in-Glass Thermometers

sampling time may be employed to satisfy this requirement.

2.2 ISO Standards:

ISO5725Precision of test methods—Determination of re-

1.4 This test method may be used for calibration of auto-

peatability and reproducibility by inter-laboratory tests

matedmonitoringsystems(AMS).Iftheemissiongascontains

ISO9096Stationary source emissions—Determination of

unstable, reactive, or semi-volatile substances, the measure-

concentrationandmassflowrateofparticulatematerialin

ment will depend on the filtration temperature, and in-stack

gas-carrying ducts. Manual gravimetric method

methods may be more applicable than out-stack methods for

ISO10780Stationary source emissions—Measurement of

the calibration of automated monitoring systems.

velocity and volume flow rate of gas stream in ducts

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Fordefinitionsoftermsusedinthistestmethod,referto

Terminology D1356.

This test method is under the jurisdiction of ASTM Committee D22 on Air

Quality and is the direct responsibility of Subcommittee D22.03 on Ambient

Atmospheres and Source Emissions. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2005. Published May 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 1998 as D6331-98. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6331-98R05. the ASTM website.

2 4

ThistestmethodisbasedonISO/CD12141.3,“StationarySourceEmissions— The last approved version of this historical standard is referenced on

Determination of Mass Concentration of Particulate Matter (Dust) at Low www.astm.org.

Concentrations—Manual Gravimetric Method”, available from International Orga- AvailablefromInternationalOrganizationforStandardization,CasaPostals56,

nization for Standardization, Casa Postale 56, CH-1211, Geneva Switzerland. CH-1211, Geneva, Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6331 − 98 (2005)

3.2 Definitions of Terms Specific to This Standard: arepretreatedunderthesameconditions,areused.Thecontrol

3.2.1 filtrationtemperature—thetemperatureofthesampled parts are kept free from dust contamination.

gas immediately downstream of the filter.

4. Summary of Test Method

3.2.2 high volume sampling—sampling at higher rates than

typical in Test Methods D3685/D3685M by using larger

4.1 Asample stream of the gas is extracted for a measured

diameter nozzles and higher flow rates to maintain isokinetic

period of time at a controlled flow rate, and the volume of gas

sampling conditions.

collected is subsequently measured. The particulate matter

3.2.2.1 Discussion—Nozzlesizesaretypically20to50mm,

(dust) entrained in the gas sample is separated by a pre-

with corresponding flow rates from 5 to 50 m /s.

weighed filter, which is then dried and reweighed. Deposits

upstream of the filter in the sampling equipment are also

3.2.3 hydraulic diameter, d

h

recovered and weighed. The increase of mass of the filter and

4 3area of sampling plane

d 5 (1) the deposited mass upstream of the filter plus the deposits

h

perimeter of sampling plane

collected upstream of the filter are attributed to particulate

3.2.4 in-stack filtration—filtrationinthestackorductwhere

mattercollectedfromthesampledgas.Theratioofthemassof

thefilterinitsfilterhousingisplacedimmediatelydownstream the particulate matter collected to the volume of gas collected

of the sampling nozzle and collects particulate matter in the

allows for the calculation of the flue gas particulate concen-

flue gas, under flue gas conditions. tration.

3.2.5 measurement series—successive measurements car-

4.2 Valid measurements can be achieved only when:

ried out at the same sampling plane and at the same process

4.2.1 The gas stream in the duct at the sampling plane has a

conditions.

sufficiently steady and identified velocity, a sufficient tempera-

3.2.6 out-stack filtration—a sampling technique where the

ture and pressure, and a sufficiently homogeneous composi-

filter, in its filter housing, collects particulate matter under

tion;

controlled temperature conditions outside of the stack or duct.

4.2.2 The flow of the gas is parallel to the centerline of the

3.2.7 overall blank—the sample taken in a manner identical duct across the whole sampling plane;

to the flue gas test samples, except that the sampling duration

4.2.3 Sampling is carried out without disturbance of the gas

is shortened to less than 1 min.

stream, using a sharp edged nozzle facing into the stream;

3.2.7.1 Discussion—The overall blank value is expressed in

4.2.4 Isokinetic sampling conditions are maintained

thesameunitsasthemeasurementresult(forexample,mg/m )

throughout the test;

using the average sampling volume of the measurement series.

4.2.5 Samples are taken at a preselected number of stated

The overall blank includes possible deposits on the filter and

positions in the sampling plane to obtain a representative

surfaces upstream of the filter in contact with the sample gas.

sample for a non-uniform distribution of particulate matter in

3.2.8 particulate matter (dust)—solidparticlesofanyshape,

the duct or stack.

structure, or density dispersed in the gas phase at flue gas

4.2.6 The sampling train is designed and operated to avoid

temperature and pressure conditions.

condensation and to be leak free;

3.2.8.1 Discussion—In accordance with the described test

4.2.7 Dust deposits upstream of the filter are recovered or

method, all material that may be collected by filtration under

taken into account, or both; and

specifiedconditionsandthatremainsupstreamofthefilterand

4.2.8 The sampling and weighing procedures are adapted to

on the filter after drying under specified conditions are consid-

the expected dust quantities.

ered to be particulate matter. However, for the purposes of

some regulatory standards, the definition of particulate matter

5. Significance and Use

may extend to condensibles or reacted materials collected

under specified conditions (for example, specified temperature

5.1 The measurement of particulate matter and collected

lower than the flue gas temperature).

residue emission rates is an important test method widely used

3.2.9 sampling line—the line in the sampling plane along in the practice of air pollution control. Particulate matter

which the sampling points are located bounded by the inner measurements after control devices are necessary to determine

duct wall. total emission rates into the atmosphere.

5.1.1 These measurements, when approved by federal or

3.2.10 sampling plane—the plane normal to the centerline

state agencies, are often required for the purpose of determin-

of the duct at the sampling position.

ing compliance with regulations and statutes.

3.2.11 sampling point—the specific position on a sampling

5.1.2 The measurements made before and after control

line at which a sample is extracted.

devices are often necessary to demonstrate conformance with

3.2.12 weighing control procedures—quality control proce-

contractual performance specifications.

duresutilizedfordetecting/correctingapparentmassvariations

due to climatic or environmental changes between pre- and

5.2 The collected residue obtained with this test method is

post-sampling weighing series. also important in characterizing stack emissions. However, the

3.2.12.1 Discussion—Inthisprocedure,controlparts,which utility of these data is limited unless a chemical analysis of the

are identical to those to be weighed for dust measurement and collected residue is performed.

D6331 − 98 (2005)

5.3 These measurements also can be used to calibrate 7.2.2 Measurementsatallthesamplingpointsdefinedin7.3

continuous particulate emission monitoring systems by corre- shall prove that the gas stream at the sampling plane meets the

lating the output of the monitoring instruments with the data following requirements:

obtained by using this test method. 7.2.2.1 The angle of gas flow is less than 15° with regard to

5.3.1 This test method is useful in such correlation applica- theductaxis(methodforestimationisindicatedinAnnexCof

tions when emissions are less than 20 mg/m . ISO10780);

5.3.2 The correlation test method is most valid when the

7.2.2.2 No local negative flow is present;

monitoring instrumentation samples the particulate matter 7.2.2.3 The minimum velocity is measurable by the test

under the same test conditions as this test method.

method used (for example, using Test Method D3154,a

differential pressure larger than 5 Pa); and

6. Interferences

7.2.2.4 Theratioofthehighesttolowestlocalgasvelocities

is less than 3:1.

6.1 Gaseous species present in stack gases that are capable

7.2.3 Iftheaboverequirementscannotbemet,thesampling

of reacting to form particulate matter within the sample train

location will not be in compliance with this test method.

can result in positive interference.

6.1.1 Examples include the potential reaction of sulfur

7.3 Minimum Number and Location of Sampling Points:

dioxide(SO )toaninsolublesulfatecompoundinthemoisture

7.3.1 SeeTest Method D3154, Section 8, Figs. 7 and 8, and

portion of the system (such as with limestone in flue gas

Tables 1 and 2.

following a wet flue gas desulfurization system (FGDS) to

7.4 Access Ports:

form calcium sulfate (CaSO ) or the reaction with ammonia

7.4.1 Provide sampling ports for access to the sampling

gas (NH ) to form ammonium sulfate (NH ) SO and the

3 4 2 4

points selected, in accordance with 7.3 and Test Method

potential reaction of hydrogen fluoride (HF) with glass com-

D3154.

ponents in the sample train with resultant collection of silicon

7.4.2 Ensure that the port dimensions offer ample space for

tetrafluoride (SiF ) in the impingers.

the insertion and removal of the sampling equipment and

6.2 Volatile matter existing in solid or liquid form in the

associated devices.

stack gas may vaporize after collection on the sample train

filtration material due to continued exposure to the hot sample

8. Velocity and Gas Composition Measurement

stream during the sampling period. Such an occurrence would

Apparatus

result in a negative interference. See also Appendix X1.

8.1 See Section 6, Test Method D3154.

7. Requirements for Sampling Plane and Sampling

9. Sampling Apparatus

Points

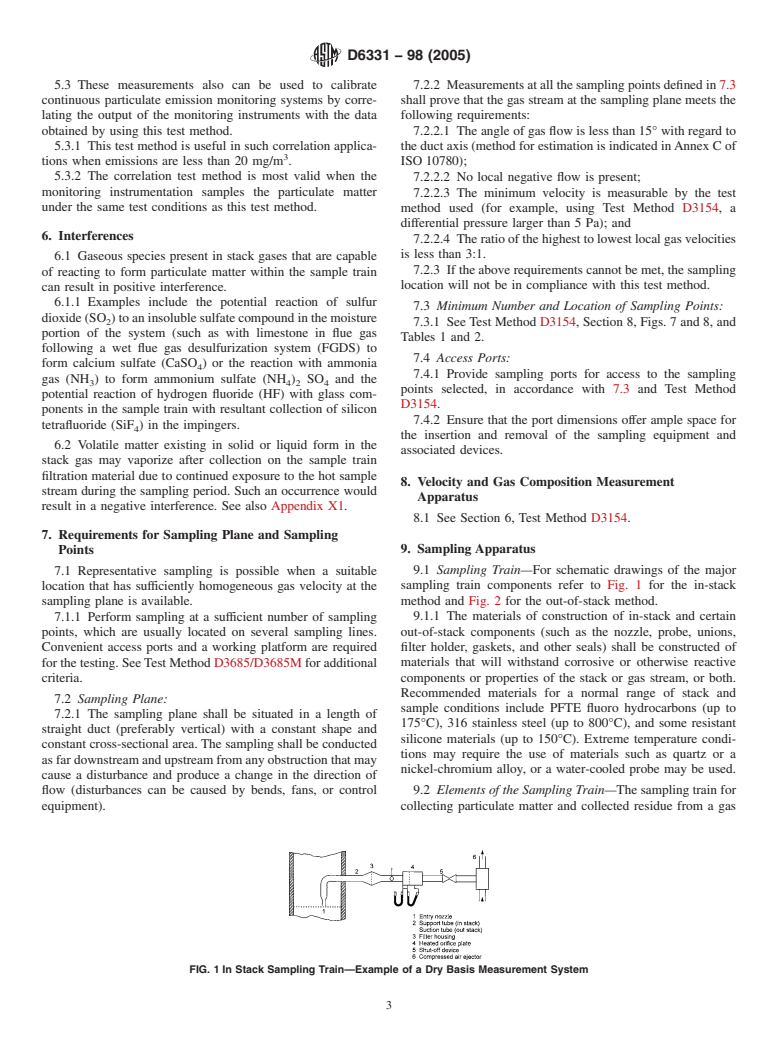

7.1 Representative sampling is possible when a suitable 9.1 Sampling Train—For schematic drawings of the major

sampling train components refer to Fig. 1 for the in-stack

location that has sufficiently homogeneous gas velocity at the

sampling plane is available. method and Fig. 2 for the out-of-stack method.

9.1.1 The materials of construction of in-stack and certain

7.1.1 Perform sampling at a sufficient number of sampling

points, which are usually located on several sampling lines. out-of-stack components (such as the nozzle, probe, unions,

filter holder, gaskets, and other seals) shall be constructed of

Convenient access ports and a working platform are required

forthetesting.SeeTestMethodD3685/D3685Mforadditional materials that will withstand corrosive or otherwise reactive

components or properties of the stack or gas stream, or both.

criteria.

Recommended materials for a normal range of stack and

7.2 Sampling Plane:

sample conditions include PFTE fluoro hydrocarbons (up to

7.2.1 The sampling plane shall be situated in a length of

175°C), 316 stainless steel (up to 800°C), and some resistant

straight duct (preferably vertical) with a constant shape and

silicone materials (up to 150°C). Extreme temperature condi-

constant cross-sectional area.The sampling shall be conducted

tions may require the use of materials such as quartz or a

asfardownstreamandupstreamfromanyobstructionthatmay

nickel-chromium alloy, or a water-cooled probe may be used.

cause a disturbance and produce a change in the direction of

flow (disturbances can be caused by bends, fans, or control 9.2 Elements of the Sampling Train—Thesamplingtrainfor

equipment). collecting particulate matter and collected residue from a gas

FIG. 1 In Stack Sampling Train—Example of a Dry Basis Measurement System

D6331 − 98 (2005)

FIG. 2 Out-Stack S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.