ASTM D2243-20

(Test Method)Standard Test Method for Freeze-Thaw Resistance of Water-Borne Coatings

Standard Test Method for Freeze-Thaw Resistance of Water-Borne Coatings

SIGNIFICANCE AND USE

4.1 When water-borne coatings are shipped during cold weather, they may experience cycles of freezing and thawing. Cycles of freezing and thawing cause more damage to water-borne coatings than when the coatings are subjected to steady freezing.

SCOPE

1.1 This test method covers a procedure for evaluating the effect of freeze/thaw cycling on the viscosity and visual film properties of water-borne coatings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2243 − 20

Standard Test Method for

1

Freeze-Thaw Resistance of Water-Borne Coatings

This standard is issued under the fixed designation D2243; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D2805Test Method for Hiding Power of Paints by Reflec-

tometry

1.1 This test method covers a procedure for evaluating the

effect of freeze/thaw cycling on the viscosity and visual film

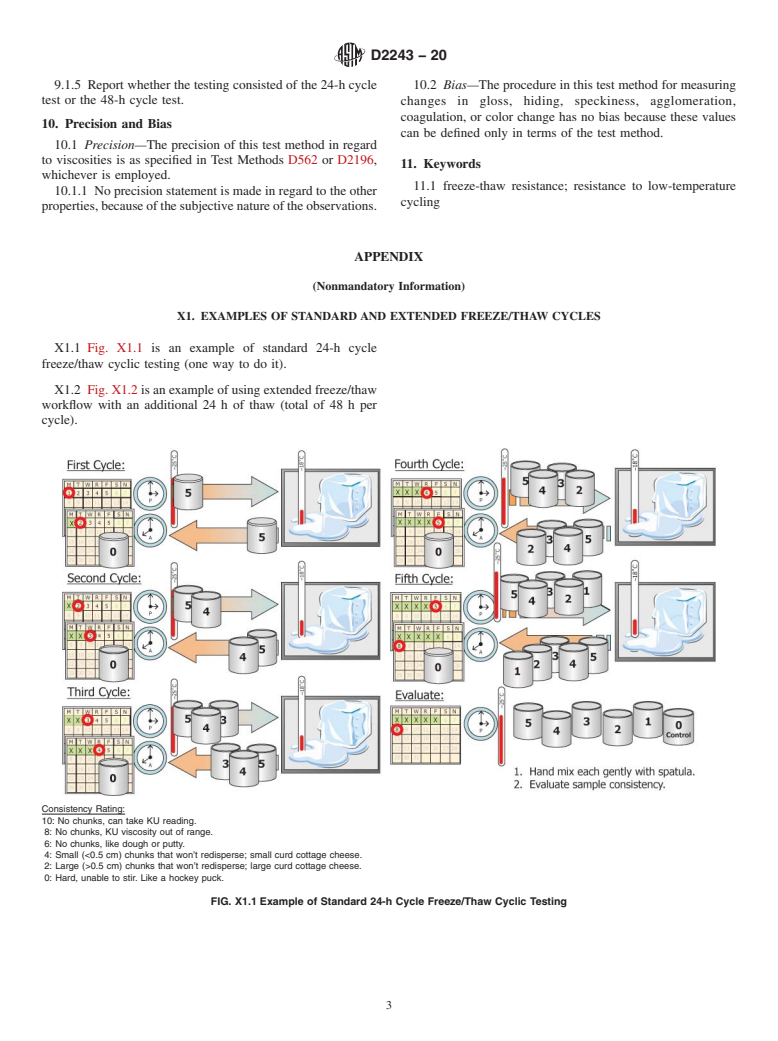

3. Summary of Test Method

properties of water-borne coatings.

3.1 Thewater-bornecoatingisputintoatleasttwopint-size

1.2 The values stated in SI units are to be regarded as the

(500-mL) resin-lined cans. One can is stored at room

standard. The values given in parentheses are for information

temperature, while the other cans are subjected to cycles of

only.

freezing and thawing. After cycling, the paint samples are

1.3 This standard does not purport to address all of the

examined for changes in viscosity and visual film properties.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2 It is critical that the test cans be undisturbed until they

priate safety, health, and environmental practices and deter- reach the number of freeze-thaw cycles at which they are to be

mine the applicability of regulatory limitations prior to use.

tested.This condition simulates actual freeze-thaw behavior of

1.4 This international standard was developed in accor- paints in the field.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. Significance and Use

Development of International Standards, Guides and Recom-

4.1 When water-borne coatings are shipped during cold

mendations issued by the World Trade Organization Technical

weather, they may experience cycles of freezing and thawing.

Barriers to Trade (TBT) Committee.

Cycles of freezing and thawing cause more damage to water-

borne coatings than when the coatings are subjected to steady

2. Referenced Documents

freezing.

2

2.1 ASTM Standards:

D523Test Method for Specular Gloss

5. Apparatus

D562Test Method for Consistency of Paints Measuring

5.1 Test Chamber—A suitable cabinet, room, or enclosure

KrebsUnit(KU)ViscosityUsingaStormer-TypeViscom-

space large enough to contain the specimens to be tested

eter

permittingatleast25mm(1in.)ofairspacebetweenthesides

D714Test Method for Evaluating Degree of Blistering of

of adjacent cans and capable of being maintained continuously

Paints

at a temperature of −18°C (0°F).

D2196Test Methods for Rheological Properties of Non-

Newtonian Materials by Rotational Viscometer

NOTE1—Althoughavariationofthetestchambertemperatureof 62°C

D2244Practice for Calculation of Color Tolerances and

(63.5°F) is allowed, the test chamber temperature should be maintained

Color Differences from Instrumentally Measured Color

as near −18°C (0°F) as practicable and the amount of variation should be

Coordinates recorded and reported.

5.2 Viscometer—A Stormer viscometer with paddle type

rotor as described in Test Method D562 or a Brookfield

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

viscometer as described in Test Methods D2196.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

5.3 Test Charts—Smooth surface paper charts having adja-

Current edition approved Dec. 1, 2020. Published December 2020 Originally

cent black and white areas, and coated with a suitable varnish

approved in 1964. Last previous edition approved in 2014 as D2243–95(2014).

DOI: 10.1520/D2243-20.

or lacquer to render the surface impermeable to paint liquids.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 Paint Brush, 25 mm (1 in.).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.5 Bar Applicator, with a 0.18-mm (7-mil) clearance.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2243 − 20

6. Preparation of Sample and Specimens 8. Examination

6.1 Prepare specimens for testing by filling 500 mL (1-pt)

8.1 After completion of the agreed or s

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2243 − 95 (Reapproved 2014) D2243 − 20

Standard Test Method for

1

Freeze-Thaw Resistance of Water-Borne Coatings

This standard is issued under the fixed designation D2243; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a procedure for evaluating the effect of freeze/thaw cycling on the viscosity and visual film properties

of water-borne coatings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D523 Test Method for Specular Gloss

D562 Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer

D714 Test Method for Evaluating Degree of Blistering of Paints

D2196 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer

D2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

D2805 Test Method for Hiding Power of Paints by Reflectometry

3. Summary of Test Method

3.1 The water-borne coating is put into at least two pint-size (500-mL) resin-lined cans. One can is stored at room temperature,

while the other can iscans are subjected to cycles of freezing and thawing. After cycling, the coating is paint samples are examined

for changes in viscosity and visual film properties.

3.2 It is critical that the test cans be undisturbed until they reach the number of freeze-thaw cycles at which they are to be tested.

This condition simulates actual freeze-thaw behavior of paints in the field.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

Current edition approved Dec. 1, 2014Dec. 1, 2020. Published December 2014December 2020 Originally approved in 1964. Last previous edition approved in 20082014

as D2243 – 95 (2008).(2014). DOI: 10.1520/D2243-95R14.10.1520/D2243-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2243 − 20

4. Significance and Use

4.1 When water-borne coatings are shipped during cold weather, they may experience cycles of freezing and thawing. Cycles of

freezing and thawing cause more damage to water-borne coatings than when the coatings are subjected to steady freezing.

5. Apparatus

5.1 Test Chamber—A suitable cabinet, room, or enclosure space large enough to contain the specimens to be tested permitting at

least 25 mm (1 in.) of air space between the sides of adjacent cans and capable of being maintained continuously at a temperature

of −18°C (0°F).

NOTE 1—Although a variation of the test chamber temperature of 62°C (63.5°F) is allowed, the test chamber temperature should be maintained as near

−18°C (0°F) as practicable and the amount of variation should be recorded and reported.

5.2 Viscometer—A Stormer viscometer with paddle type rotor as described in Test Method D562 or a Brookfield viscometer as

described in Test Methods D2196.

5.3 Test Charts—Smooth surface paper charts having adjacent black and white areas, and coated with a suitable varnish or lacquer

to render the surfa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.