ASTM D1619-16

(Test Method)Standard Test Methods for Carbon Black—Sulfur Content

Standard Test Methods for Carbon Black—Sulfur Content

SIGNIFICANCE AND USE

3.1 The total sulfur content of a carbon black is useful in determining whether a material meets a customer’s specifications, providing data for performing a sulfur material balance around a process for environmental monitoring and reporting, and in calculations for reconstructing a rubber composition from analytical data.

SCOPE

1.1 These test methods cover the determination of the sulfur content of carbon black. The following test methods are included:

Sections

Test Method A

High-Temperature Combustion With In-

frared Absorption Detection Procedures

6 to 13

Test Method B

X-Ray Fluorescence

14 to 19

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1619 − 16

StandardTest Methods for

1

Carbon Black—Sulfur Content

This standard is issued under the fixed designation D1619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope reporting, and in calculations for reconstructing a rubber

composition from analytical data.

1.1 These test methods cover the determination of the sulfur

content of carbon black. The following test methods are

4. Reagents

included:

4.1 Purity of Reagents—Reagent grade chemicals shall be

Sections

Test Method A High-Temperature Combustion With In- 6 to 13 used in all tests. Unless otherwise indicated, it is intended that

frared Absorption Detection Procedures

all reagents shall conform to the specifications of the Commit-

Test Method B X-Ray Fluorescence 14 to 19

tee onAnalytical Reagents of theAmerican Chemical Society,

3

1.2 The values stated in SI units are to be regarded as

where such specifications are available. Other grades may be

standard. No other units of measurement are included in this

used, provided it is first ascertained that the reagent is of

standard.

sufficiently high purity to permit its use without lessening the

1.3 This standard does not purport to address all of the accuracy of the determination.

safety concerns, if any, associated with its use. It is the

5. Sampling

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 Samples of packaged materials shall be taken in accor-

bility of regulatory limitations prior to use.

dance with Practice D1799 or Practice D1900.

2. Referenced Documents

TEST METHOD A HIGH-TEMPERATURE

2

COMBUSTION WITH INFRARED ABSORPTION

2.1 ASTM Standards:

DETECTION PROCEDURES

D1509 Test Methods for Carbon Black—Heating Loss

D1799 Practice for Carbon Black—Sampling Packaged

6. Summary of Test Method

Shipments

D1900 Practice for Carbon Black—Sampling Bulk Ship- 6.1 The specimen is burned in a tube furnace at a minimum

operating temperature of 1350°C in a stream of oxygen to

ments

D4483 Practice for Evaluating Precision for Test Method oxidize the sulfur. Moisture and particulates are removed from

Standards in the Rubber and Carbon Black Manufacturing the gas by traps filled with anhydrous magnesium perchlorate.

Industries The gas stream is passed through a cell in which sulfur dioxide

is measured by an infrared (IR) absorption detector. Sulfur

3. Significance and Use

dioxide absorbs IR energy at a precise wavelength within the

IR spectrum. Energy is absorbed as the gas passes through the

3.1 The total sulfur content of a carbon black is useful in

cell body in which the IR energy is being transmitted. Thus, at

determining whether a material meets a customer’s

the detector, less energy is received. All other IR energy is

specifications, providing data for performing a sulfur material

eliminated from reaching the detector by a precise wavelength

balance around a process for environmental monitoring and

filter. Thus, the absorption of IR energy can be attributed only

to sulfur dioxide whose concentration is proportional to the

1

These test methods are under the jurisdiction of ASTM Committee D24 on

change in energy at the detector. One cell is used as both a

Carbon Black and are the direct responsibility of Subcommittee D24.66 on

Environment, Health, and Safety.

Current edition approved Jan. 1, 2016. Published January 2016. Originally

3

approved in 1958. Last previous edition approved in 2011 as D1619 – 11. DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D1619-16. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

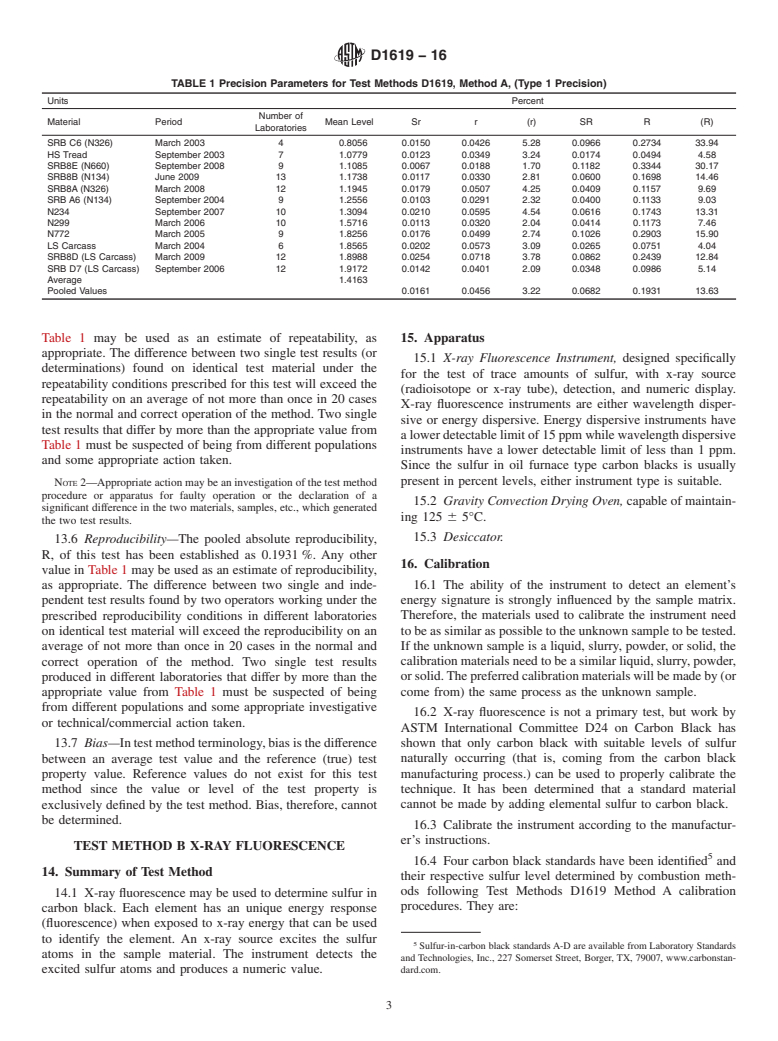

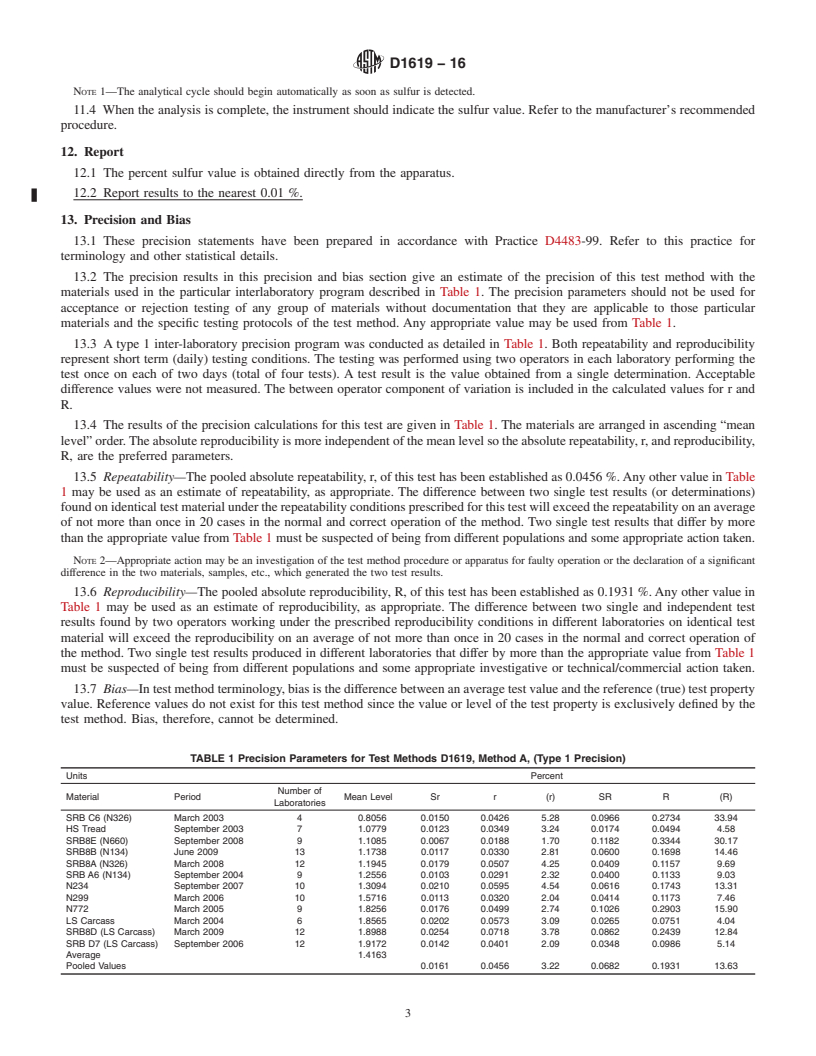

D1619 − 16

reference and a measurement chamber. Total sulfur as sulfur men. If not, refer to the manufacturer’s instructions for

dioxide is detected on a continuous basis. This test method is checking

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1619 − 11 D1619 − 16

Standard Test Methods for

1

Carbon Black—Sulfur Content

This standard is issued under the fixed designation D1619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the determination of the sulfur content of carbon black. The following test methods are included:

Sections

Test Method A High-Temperature Combustion With In- 6 to 13

frared Absorption Detection Procedures

Test Method B X-Ray Fluorescence 14 to 19

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1509 Test Methods for Carbon Black—Heating Loss

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Significance and Use

3.1 The total sulfur content of a carbon black is useful in determining whether a material meets a customer’s specifications,

providing data for performing a sulfur material balance around a process for environmental monitoring and reporting, and in

calculations for reconstructing a rubber composition from analytical data.

4. Reagents

4.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

3

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

5. Sampling

5.1 Samples of packaged materials shall be taken in accordance with Practice D1799 or Practice D1900.

1

These test methods are under the jurisdiction of ASTM Committee D24 on Carbon Black and are the direct responsibility of Subcommittee D24.66 on Environment,

Health, and Safety.

Current edition approved Jan. 1, 2011Jan. 1, 2016. Published June 2011January 2016. Originally approved in 1958. Last previous edition approved in 20102011 as

D1619 – 10.D1619 – 11. DOI: 10.1520/D1619-11.10.1520/D1619-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1619 − 16

TEST METHOD A HIGH-TEMPERATURE COMBUSTION WITH INFRARED ABSORPTION DETECTION

PROCEDURES

6. Summary of Test Method

6.1 The specimen is burned in a tube furnace at a minimum operating temperature of 1350°C in a stream of oxygen to oxidize

the sulfur. Moisture and particulates are removed from the gas by traps filled with anhydrous magnesium perchlorate. The gas

stream is passed through a cell in which sulfur dioxide is measured by an infrared (IR) absorption detector. Sulfur dioxide absorbs

IR energy at a precise wavelength within the IR spectrum. Energy is absorbed as the gas passes through the cell body in which

the IR energy is being transmitted. Thus, at the detector, less energy is received. All other IR energy is eliminated from reaching

the detector by a precise wavelength filter. Thus, the absorption of IR energ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.