ASTM G108-94(1999)

(Test Method)Standard Test Method for Electrochemical Reactivation (EPR) for Detecting Sensitization of AISI Type 304 and 304L Stainless Steels

Standard Test Method for Electrochemical Reactivation (EPR) for Detecting Sensitization of AISI Type 304 and 304L Stainless Steels

SCOPE

1.1 This test method describes a laboratory procedure for conducting an electrochemical reactivation (EPR) test on AISI Type 304 and 304L (UNS No. S30400 and S30403, respectively) stainless steels. This test method can provide a nondestructive means of quantifying the degree of sensitization in these steels (1, 2, 3). This test method has found wide acceptance in studies of the effects of sensitization on intergranular corrosion and intergranular stress corrosion cracking behavior (see Terminology G15). The EPR technique has been successfully used to evaluate other stainless steels and nickel base alloys (4), but the test conditions and evaluation criteria used were modified in each case from those cited in this test method.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 108 – 94 (Reapproved 1999)

Standard Test Method for

Electrochemical Reactivation (EPR) for Detecting

Sensitization of AISI Type 304 and 304L Stainless Steels

This standard is issued under the fixed designation G 108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope rosion Test Specimens

G 3 Practice for Conventions Applicable to Electrochemical

1.1 This test method describes a laboratory procedure for

Measurements in Corrosion Testing

conducting an electrochemical reactivation (EPR) test on AISI

G 5 Reference Test Method for Making Potentiostatic and

Type 304 and 304L (UNS No. S30400 and S30403, respec-

Potentiodynamic Anodic Polarization Measurements

tively) stainless steels. This test method can provide a nonde-

G 15 Terminology Relating to Corrosion and Corrosion

structive means of quantifying the degree of sensitization in

Testing

these steels (1, 2, 3). This test method has found wide

G 28 Test Methods for Detecting Susceptibility to Inter-

acceptance in studies of the effects of sensitization on inter-

granular Attack in Wrought Nickel-Rich, Chromium-

granular corrosion and intergranular stress corrosion cracking

Bearing Alloys

behavior (see Terminology G 15). The EPR technique has been

G 61 Test Method for Conducting Cyclic Potentiodynamic

successfully used to evaluate other stainless steels and nickel

Polarization Measurements for Localized Corrosion Sus-

base alloys (4), but the test conditions and evaluation criteria

ceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

used were modified in each case from those cited in this test

method.

3. Terminology

1.2 The values stated in SI units are to be regarded as the

3.1 Definitions of Terms Specific to This Standard:

standard. The inch-pound units given in parentheses are for

3.1.1 integrated charge (Q)—the charge measured, in cou-

information only.

loumbs, during reactivation as given by the time integral of

1.3 This standard does not purport to address all of the

current density below the reactivation peak of the curve.

safety concerns, if any, associated with its use. It is the

3.1.2 maximum anodic current density (I )—the current

r

responsibility of the user of this standard to establish appro-

density measured at the peak of the anodic curve during

priate safety and health practices and determine the applica-

reactivation.

bility of regulatory limitations prior to use.

3.1.3 normalized charge (P )—the integrated current nor-

a

2. Referenced Documents malized to the specimen size and grain size. P represents the

a

charge (in coulombs/cm ) of the grain-boundary area. The

2.1 ASTM Standards:

method for calculating P is given in 9.2.

A 262 Practices for Detecting Susceptibility to Intergranu- a

3.1.4 reactivation—in the electrochemical reactivation

lar Attack in Austenitic Stainless Steels

4 (EPR) test, the potential sweep from the passivation potential

D 1193 Specification for Reagent Water

returning to the corrosion potential.

E 3 Methods of Preparation of Metallographic Specimens

5 3.1.5 scan rate—the rate at which the electrical potential

E 7 Terminology Relating to Metallography

applied to a specimen in a polarization test is changed.

E 112 Test Methods for Determining Average Grain Size

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

4. Summary of Test Method

4.1 The EPR test is accomplished by a potentiodynamic

sweep from the passive to the active regions of electrochemical

This test method is under the jurisdiction of ASTM Committee G-1 on

potentials in a process referred to as reactivation. The EPR test

Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on

measures the amount of charge associated with the corrosion of

Electrochemical Measurement in Corrosion Testing.

the chromium-depleted regions surrounding chromium carbide

Current edition published Feb. 15, 1994. Approved April 1994. Originally

published as G 108 – 92. Last previous edition G 108 – 92. precipitated particles. Most of these particles in a sensitized

The boldface numbers in parentheses refer to the list of references at the end of

microstructure are located at grain boundaries (see Terminol-

the text.

ogy E 7). Discrete particles located within the grain (referred to

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G 108 – 94 (1999)

as intragranular precipitates) will also contribute to the total of different heats of material that exhibit different Q values

measured charge. Therefore, it is important to examine the solely as a result of differences in grain size.

alloy microstructure following an EPR test, to determine the

5. Significance and Use

relative proportion of corrosion site associated with intergranu-

5.1 This test method describes an EPR test method for

lar versus intragranular precipitates.

quantitatively determining the relative degree of sensitization

4.2 The chromium-depleted zones around carbide precipi-

in AISI Type 304 and 304L stainless steels. The EPR test has

tates in sensitized steels are particularly susceptible to corro-

found wide use as a means to provide a numerical level of

sion in oxidizing acid solutions. Corrosion at chromium-

sensitization in studies of the effects of sensitization on

depleted grain boundary sites causes a rapid rise in the current

intergranular corrosion and intergranular stress corrosion

density when the electrochemical potential is changed from the

cracking behavior. The results of this test method correlate

passive to the active region.

with other test methods (for example, Practice A 262 and Test

4.3 A sensitized steel produces a curve similar to the active

Method G 28) that are commonly used to assess sensitization

portion of the polarization curve during the reactivation from

in stainless steels.

the passive region back to the rest potential (E ) as shown in

corr

5.2 The EPR test can also be used for product acceptance,

Fig. 1. A nonsensitized (solution annealed) steel polarized

under the conditions given in this test method will produce a service evaluation, regulatory statutes, and manufacturing

controls providing that both the supplier and user have agreed

curve with lower current densities than a sensitized steel.

4.4 The EPR test results are readily reproducible, as long as upon appropriate acceptance criteria and a sensitizing treat-

ment. The test is not intended for design purposes since the test

the electrolyte temperature, electrolyte composition, and scan

rate are carefully controlled. The EPR test is significantly conditions accelerate corrosion in a manner that does not

simulate any actual service environment.

affected by the composition, thermomechanical condition and

surface finish of the specimen as well as the presence of 5.3 The EPR test involves the measurement of the amount

of charge resulting from the corrosion of the chromium-

non-metallic inclusions, that result in pitting of the etched

depleted regions surrounding the precipitated chromium car-

microstructure.

bide particles. Most of these particles in a sensitized micro-

NOTE 1—Various cutting and grinding operations can promote sensiti-

structure are located at the grain boundaries. However, discrete

zation of Type 304 (5). Superficial carbide precipitation can occur during

particles located within grains (referred to as intragranular

cutting and grinding or during subsequent low temperature heat treat-

precipitates) will also contribute to the total measured charge.

ments, such as 24 h at 500°C.

(See Fig. 2.) Therefore, it is important to examine the alloy

4.5 The criteria used to distinguish between sensitized and

microstructure following an EPR test to determine the relative

solution annealed samples are the activation charge density, Q

proportion of corrosion sites associated with intergranular

(given by the time integral of current density below the

versus intragranular precipitates. Sites of intergranular attack

reactivation peak of the curve), or the maximum anodic current

will appear similar to grain boundary ditching as defined in

density, I , in the active state. Sensitized steels are easily

r

Practice A of Practices A 262.

activated and show higher Q and I values than solution

r

annealed steels, that are not susceptible to intergranular corro-

6. Apparatus

sion. The value Q is normalized for both specimen size and

6.1 The apparatus necessary for obtaining EPR data consists

grain size. The value normalized in this fashion is called P and

a

of electronic instruments and a test cell. These instruments may

represents the charge (in units of coulombs) per unit grain-

be integrated into one instrument package or may be individual

boundary area. This normalization permits direct comparisons

components. Either form of instrumentation can provide ac-

ceptable data.

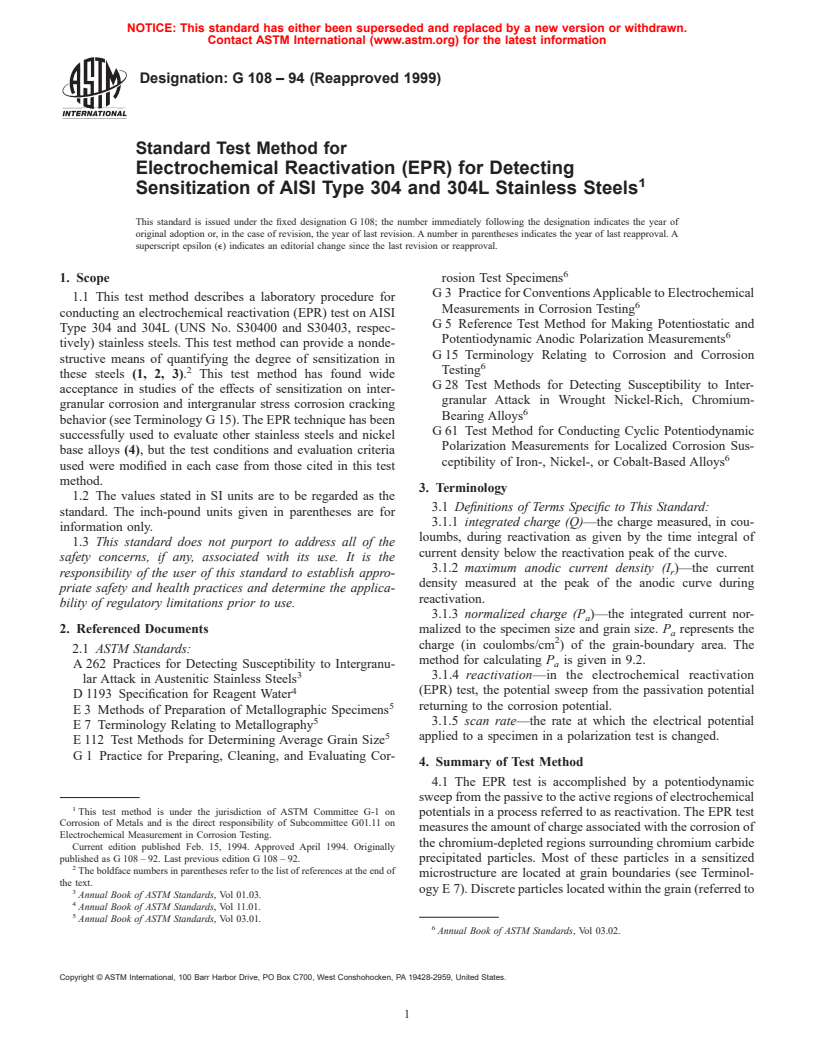

6.2 Typical apparatus, as illustrated in Fig. 3, shall consist of

the following: scanning potentiostat (or potentiostat/voltage

NOTE 1—The calculation of P is based on the assumptions illustrated

a

at left. Mild cases of sensitization usually result in a combination of

intergranular attack and pitting as illustrated at right (7).

FIG. 1 Schematic EPR Curves for Sensitized and Solutionized

AISI Type 304 Stainless Steel FIG. 2 Schematic Microstructures After EPR Testing

G 108 – 94 (1999)

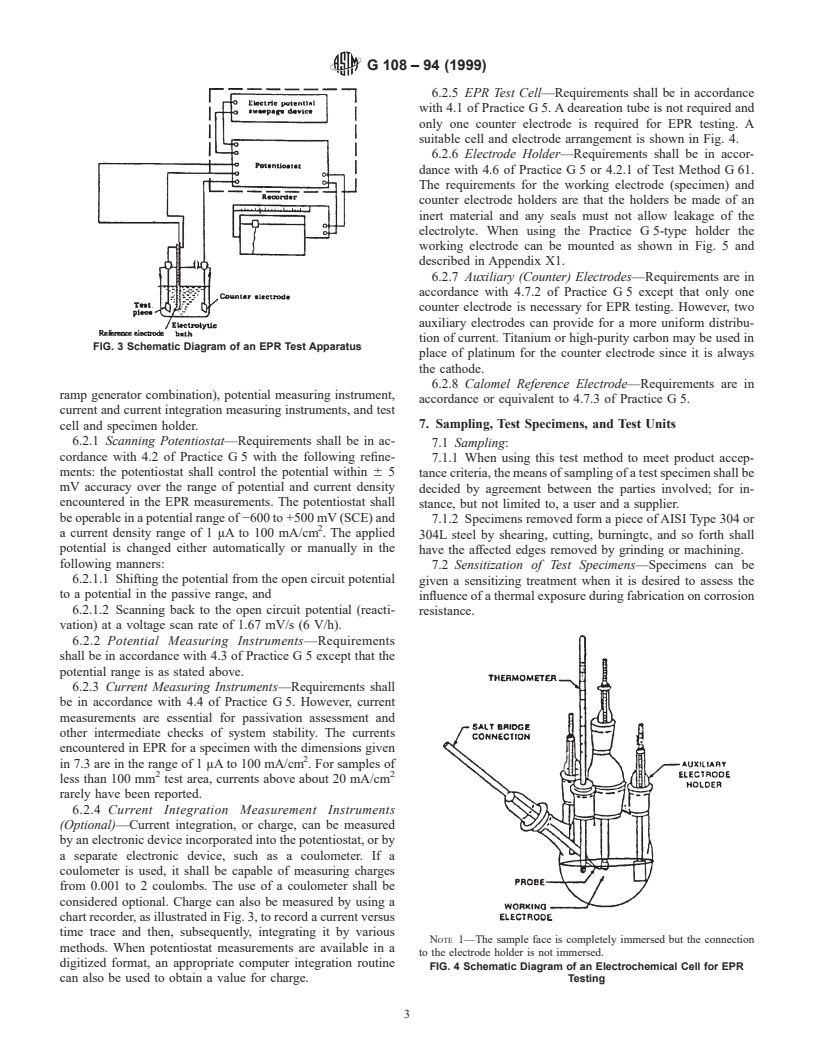

6.2.5 EPR Test Cell—Requirements shall be in accordance

with 4.1 of Practice G 5. A deareation tube is not required and

only one counter electrode is required for EPR testing. A

suitable cell and electrode arrangement is shown in Fig. 4.

6.2.6 Electrode Holder—Requirements shall be in accor-

dance with 4.6 of Practice G 5 or 4.2.1 of Test Method G 61.

The requirements for the working electrode (specimen) and

counter electrode holders are that the holders be made of an

inert material and any seals must not allow leakage of the

electrolyte. When using the Practice G 5-type holder the

working electrode can be mounted as shown in Fig. 5 and

described in Appendix X1.

6.2.7 Auxiliary (Counter) Electrodes—Requirements are in

accordance with 4.7.2 of Practice G 5 except that only one

counter electrode is necessary for EPR testing. However, two

auxiliary electrodes can provide for a more uniform distribu-

tion of current. Titanium or high-purity carbon may be used in

FIG. 3 Schematic Diagram of an EPR Test Apparatus

place of platinum for the counter electrode since it is always

the cathode.

6.2.8 Calomel Reference Electrode—Requirements are in

ramp generator combination), potential measuring instrument,

accordance or equivalent to 4.7.3 of Practice G 5.

current and current integration measuring instruments, and test

7. Sampling, Test Specimens, and Test Units

cell and specimen holder.

6.2.1 Scanning Potentiostat—Requirements shall be in ac-

7.1 Sampling:

cordance with 4.2 of Practice G 5 with the following refine-

7.1.1 When using this test method to meet product accep-

ments: the potentiostat shall control the potential within 6 5

tance criteria, the means of sampling of a test specimen shall be

mV accuracy over the range of potential and current density

decided by agreement between the parties involved; for in-

encountered in the EPR measurements. The potentiostat shall

stance, but not limited to, a user and a supplier.

be operable in a potential range of −600 to +500 mV (SCE) and

7.1.2 Specimens removed form a piece of AISI Type 304 or

a current density range of 1 μA to 100 mA/cm . The applied

304L steel by shearing, cutting, burningtc, and so forth shall

potential is changed either automatically or manually in the

have the affected edges removed by grinding or machining.

following manners:

7.2 Sensitization of Test Specimens—Specimens can be

6.2.1.1 Shifting the potential from the open circuit potential

given a sensitizing treatment when it is desired to assess the

to a potential in the passive range, and

influence of a thermal exposure during fabrication on corrosion

6.2.1.2 Scanning back to the open circuit potential (reacti-

resistance.

vation) at a voltage scan rate of 1.67 mV/s (6 V/h).

6.2.2 Potential Measuring Instruments—Requirements

shall be in accordance with 4.3 of Practice G 5 except that the

potential range is as stated above.

6.2.3 Current Measuring Instruments—Requirements shall

be in accordance with 4.4 of Practice G 5. However, current

measurements are essential for passivation assessment and

other intermediate checks of system stability. The currents

encountered in EPR for a specimen with the dimensions given

in 7.3 are in the range of 1 μA to 100 mA/cm . For samples of

2 2

less than 100 mm test area, currents above about 20 mA/cm

rarely have been reported.

6.2.4 Current Integration Measurement Instruments

(Optional)—Current integration, or charge, can be measured

by an electronic device incorporated into the potentiostat, or by

a separate electronic device, such as a coulometer. If a

coulometer is used, it shall be capable of measuring charges

from 0.001 to 2 coulombs. The use of a coulometer shall be

considered optional. Charge can also be measured by using a

chart recorder, as illustrated in Fig. 3, to record a current versus

time trace and then, subsequently, integrating it by various

NOTE 1—The sample face is completely immersed but the connection

methods. When potentiostat measurements are available in a

to the electrode holder is not immersed.

digitized format, an appropriate computer integration routine

FIG. 4 Schematic Diagram of an Electrochemical Cell for EPR

can also be used to obtain a value for charge. Testing

G 108 – 94 (1999)

machine screw (for example, NC4-40 3 0.3 cm (0.75 in.) long) to the

back surface of the specimen. This assembly is mounted in a suitable

compound that is inert in the EPR electrolyte (see Appendix X1) such that

the front surface upon immersion in the EPR electrolyte is fully in contact

with the electrolyte.

7.3.4 Measure the surface area of the front surface of the test

specimen within 0.1 mm precision and record on the EPR data

record sheet (see Appendix X2).

7.3.5 Specimens can be in any shape that will not be

susceptible to crevice corrosion in the solution. Test surface

2 2

area shall be at least 10 6 0.1 mm (0.016 in. ). It is

occasionally usef

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.