ASTM D5968-01

(Test Method)Standard Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 121°C

Standard Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 121°C

SCOPE

1.1 This test method is used to test diesel engine lubricants to determine their tendency to corrode various metals, specifically alloys of lead and copper commonly used in cam followers and bearings. Correlation with field experience has been established.

1.2 The values stated in acceptable SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 5.3.1, 6.6, 6.7, 6.8, 6.9, 6.10, 6.11, 7.1.1, 7.1.2, 7.1.5, and 7.4.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5968 – 01

Standard Test Method for

1

Evaluation of Corrosiveness of Diesel Engine Oil at 121°C

This standard is issued under the fixed designation D 5968; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The method described in this test method is based on the gas turbine lubricant corrosion and

oxidation test described in Federal Test Method Standard 791, Method 5308. Because this test method

relates to corrosion in diesel engines rather than in gas turbines, temperatures, metal coupons, and

certain parts of the test procedure were modified to be more appropriate for heavy duty diesel engines.

The method described in this test method can be used by any properly equipped laboratory, without

2

outside assistance. However, the ASTM Test Monitoring Center (TMC) provides reference oils and

an assessment of the test results obtained on those oils by the laboratory (see Annex A1). By these

means, the laboratory will know whether their use of the test method gives results statistically similar

to those obtained by other laboratories. Furthermore, various agencies require that a laboratory utilize

the TMC services in seeking qualification of oils against specifications. For example, the U.S. Army

imposes such a requirement in connection with several Army engine lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of Information Letters issued by the TMC. In addition,

the TMC may issue supplementary memoranda related to the method (see Annex A1). For other

3

information, refer to the research report on the Cummins Bench Corrosion Test.

1. Scope 1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method is used to test diesel engine lubricants

responsibility of the user of this standard to establish appro-

to determine their tendency to corrode various metals, specifi-

priate safety and health practices and determine the applica-

cally alloys of lead and copper commonly used in cam

bility of regulatory limitations prior to use. Specific hazard

followers and bearings. Correlation with field experience has

4

statements are given in 5.3.1, 6.6, 6.7, 6.8, 6.9, 6.10, 6.11,

been established.

7.1.1, 7.1.2, 7.1.5, and 7.4.1.

1.2 The values stated in acceptable SI units are to be

regarded as the standard.

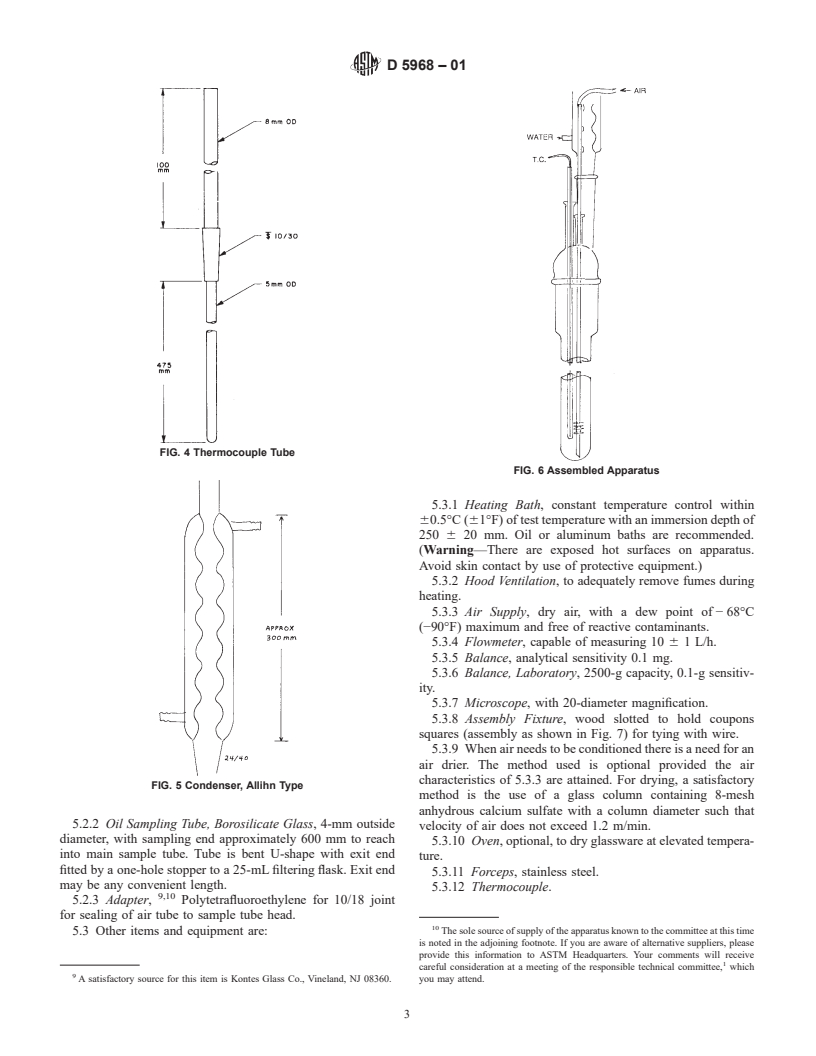

2. Referenced Documents

2.1 ASTM Standards:

D 130 Test Method for Detection of Copper Corrosion from

1 5

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products by the Copper Strip Tarnish Test

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D 4636 Test Method for Corrosiveness and Oxidation Sta-

D02.B0.02 on Heavy Duty Engine Oils.

bility of Hydraulic Oils, Aircraft Turbine Engine Lubri-

Current edition approved Nov. 10, 2001. Published January 2002. Originally

6

cants, and Other Highly Refined Oils

published as D 5968 – 98. Last previous edition D 5968 – 00a.

2

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 15206-4489,

D 5185 Determination of Additive Elements, Wear Metals,

Telephone: (412) 365-1000, Fax: (412) 365-1045 (reference oil test telephone

and Contaminants in Used Lubricating Oils and Determi-

reports), Fax: (412) 365-1047 (other messages), Telephone Oil Assignments: (412)

nation of Selected Elements in Base Oils by Inductively

365-1004.

3

Available from ASTM International Headquarters. Request RR:D02-1322. The Coupled Plasma Atomic Emission Spectrometry (ICP-

6

research report and this test method are supplemented by Information Letters and

AES)

Memoranda issued by the ASTM Test Monitoring Center. This edition incorporates

revisions contained in all information letters through No. 01–1. Users of this test

method shall contact the ASTM Test Monitoring Center to obtain the most recent of

these.

4 5

Wang, J. C., and Cusano, C. M., “Development of A Bench Test to Detect Oils Annual Book of ASTM Standards, Vol 05.01.

6

Corrosive to Engine Components,” SAE Technical Paper No. 940790, 1994. Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5968–01

E 691 Practice for Conducting an Inter-Laboratory Study

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.